64Pacific

Members-

Posts

42 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

FriedClams reacted to a post in a topic:

21' Fisherman's Launch by Vaddoc - Scale 1:10 - Plans from Howard Chapelle's "Boatbuilding"

FriedClams reacted to a post in a topic:

21' Fisherman's Launch by Vaddoc - Scale 1:10 - Plans from Howard Chapelle's "Boatbuilding"

-

FriedClams reacted to a post in a topic:

Vigilance of Brixham BM 76 by FlyingFish - 1:32

FriedClams reacted to a post in a topic:

Vigilance of Brixham BM 76 by FlyingFish - 1:32

-

FlyingFish reacted to a post in a topic:

Vigilance of Brixham BM 76 by FlyingFish - 1:32

FlyingFish reacted to a post in a topic:

Vigilance of Brixham BM 76 by FlyingFish - 1:32

-

mtaylor reacted to a post in a topic:

21' Fisherman's Launch by Vaddoc - Scale 1:10 - Plans from Howard Chapelle's "Boatbuilding"

mtaylor reacted to a post in a topic:

21' Fisherman's Launch by Vaddoc - Scale 1:10 - Plans from Howard Chapelle's "Boatbuilding"

-

thibaultron reacted to a post in a topic:

Paddle to the Sea by Jason Builder - Solid Wood - 1941

thibaultron reacted to a post in a topic:

Paddle to the Sea by Jason Builder - Solid Wood - 1941

-

Keith Black reacted to a post in a topic:

Vigilance of Brixham BM 76 by FlyingFish - 1:32

Keith Black reacted to a post in a topic:

Vigilance of Brixham BM 76 by FlyingFish - 1:32

-

This is really neat, being able to follow along with your build and the rebuild of the prototype. Definitely inspiring but my boat building skills are not there yet...

- 88 replies

-

- Vigilance

- Sailing Trawler

-

(and 1 more)

Tagged with:

-

mtaylor reacted to a post in a topic:

Trying to understand white balance

mtaylor reacted to a post in a topic:

Trying to understand white balance

-

Trying to understand white balance

64Pacific replied to Gaetan Bordeleau's topic in Photographing your work. How to do this.

A few years ago I was playing with custom white balance, I wanted to see what would happen if I used some colour that wasn't white.Tthe idea was to drastically see the effect as I wasn't sure what was going on. I had a burgundy box in front of me, I found something with a green or cyan tint to it, the greenish colour was used as the white balance set point, it just happened that the colours were roughly opposite one another on the colour wheel. The camera is now trying to adjust for what it thinks is green light removing the green to get to white. With this custom cyan / green white balance I snapped a photo of the burgundy box. The burgundy sections of the box were nearly converted to grey while the colours with less green stayed a little closer to their actual but were tinted with a green hue. It seemed to me that the colour opposite that of the white balance on the colour wheel was essentially removed from the image. It was a really long time ago that I did this so maybe I will try again and post some tests... -

GrandpaPhil reacted to a post in a topic:

Dom Fernando II e Gloria by muzzleloader - 1:50 - cross-section

GrandpaPhil reacted to a post in a topic:

Dom Fernando II e Gloria by muzzleloader - 1:50 - cross-section

-

mtaylor reacted to a post in a topic:

Dom Fernando II e Gloria by muzzleloader - 1:50 - cross-section

mtaylor reacted to a post in a topic:

Dom Fernando II e Gloria by muzzleloader - 1:50 - cross-section

-

Laptop recommendations?

64Pacific replied to Mike Shea's topic in CAD and 3D Modelling/Drafting Plans with Software

Definitely go with what Ron is saying. For my last build (primarily for Siemens Solid Edge) I bought the fastest (per core) processor that I could afford, substituting quantity of cores for speed. The other consideration is graphics hardware. While there is a hefty price difference you will notice a significant speed and stability increase when using professional grade hardware. Gaming graphics, while powerful have different architecture and 3D CAD software is not optimized for this architecture. All of that said, probably the biggest and most inexpensive upgrade that you can make for a 3D CAD machine is an SSD followed by a lot of fast RAM. -

I think that the timber joints on this model are built to a tighter tolerance than the original ship, spectacular work!

-

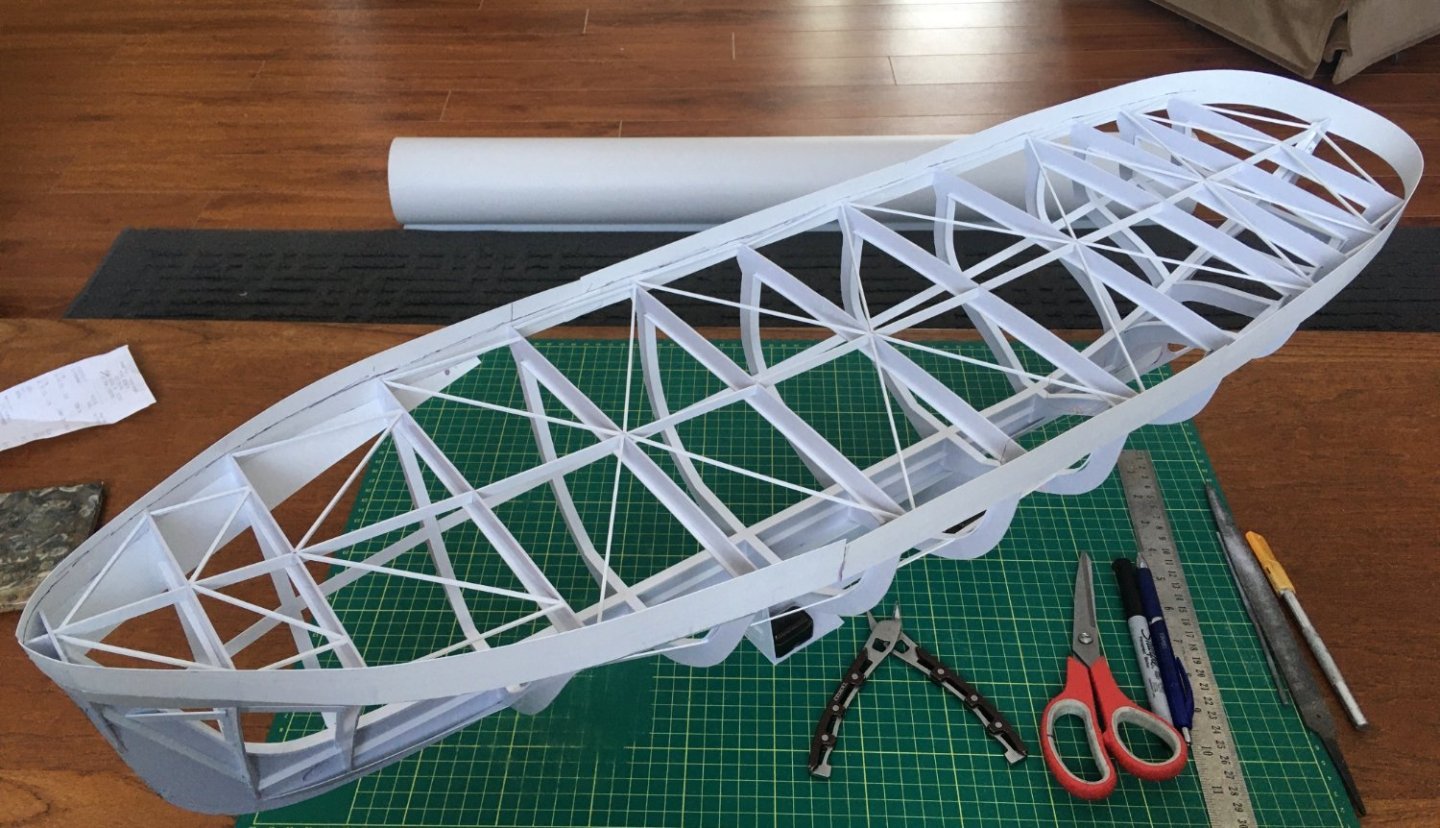

The wife's Cricut was a huge timesaver when laying out the keel and cross sections for my tug build. Definitely not the classic way of doing things but it was hard to argue with the ease and quality of the results. As far as using non-modeling tools for modeling, sewing needles came to the rescue on a scratch built logging truck that I was building years ago (and finished recently). I needed a way to connect the front tires to the front axle while allowing the front tires to steer. I happened to mention this to a seamstress and she suggested cutting down a standard sewing needle. The flare from the cut down eye was enough to hold the needle in a short tube and the cut down end of the needle passed through the tube and nicely into the wheel, the tube was fixed to a pin and linkage to allow the wheels to steer. This was about twenty years ago, I wish that I could find her to say thank you and let her know how it worked out, but I have no way of finding her...

- 31 replies

-

- Paddlewheeler

- Paddleboat

-

(and 6 more)

Tagged with:

-

Very nice work, looking forward to watching this one progress.

- 31 replies

-

- Paddlewheeler

- Paddleboat

-

(and 6 more)

Tagged with:

-

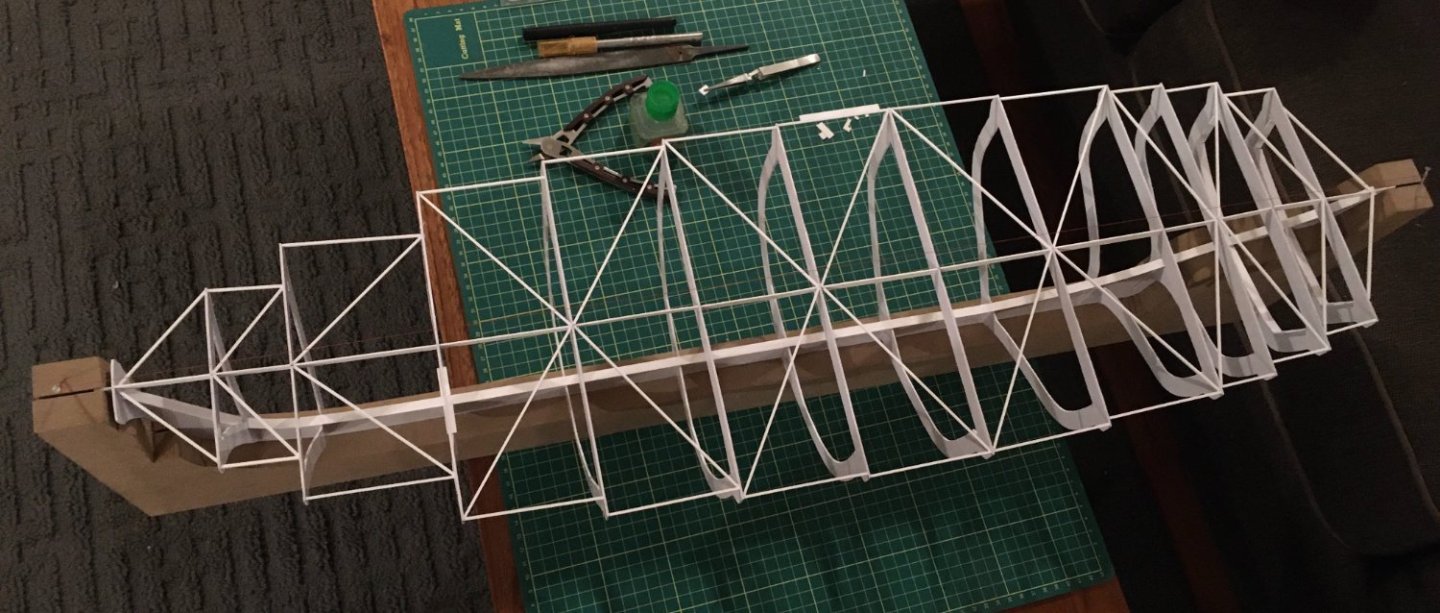

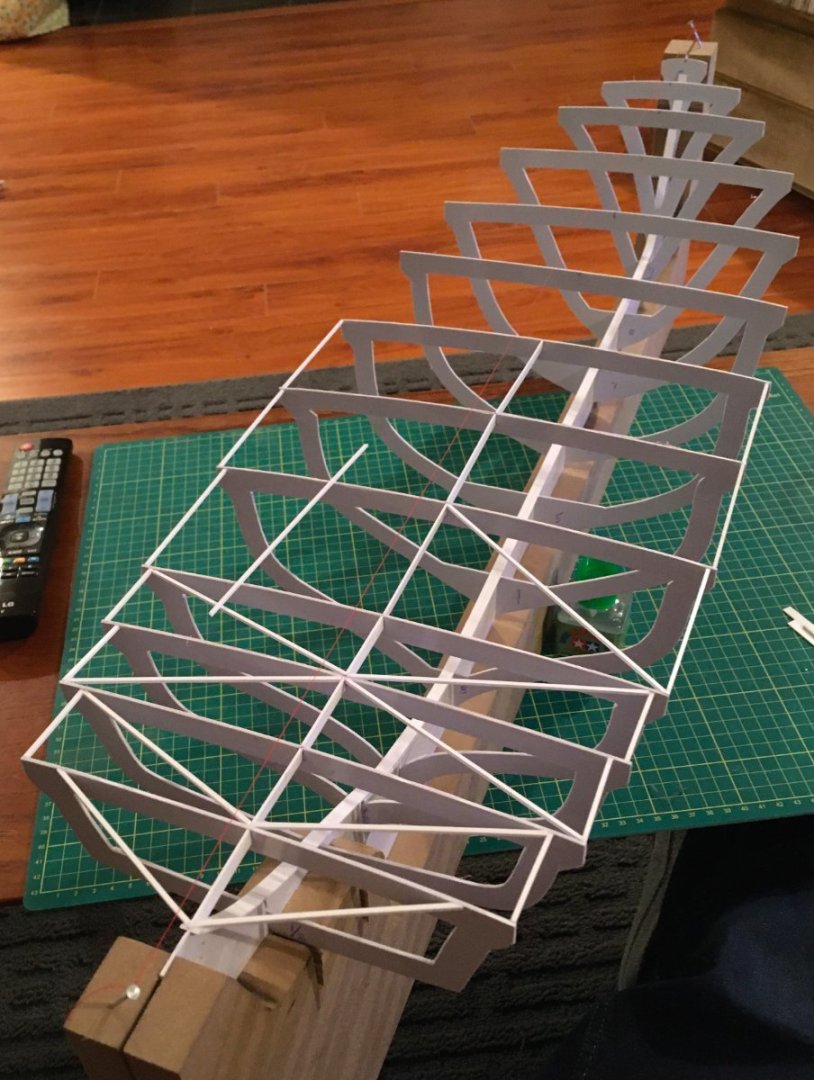

The next step after inserting, but not fixing the ribs to the keel was to start the process of reinforcing the keel. This may have been unnecessary but my thought was rigidity would be an asset, especially when the model was removed from the fixture to begin the process of planking the hull. To do this strips of plastic were added along the length of the keel. Also at this point a stand was built using scraps. Following this and starting at the bow each rib was squared to the keel and to the bench prior to being fixed. Temporary light bracing was then added after carefully measuring to ensure that the ribs remained perpendicular to the keel and parallel to each other. This step took forever, it was measure six times then glue. More bracing on the inside of the ribs and the face of the keel. Some of the planking was being added here. Initially the plan was to roughly skin the model and then apply a second layer. This strategy was soon abandoned in favour of one layer of thicker planking. Once some planking was added at the keel I jumped up to the top of the hull. While I was happy with the shape of this upper planking my process of installing the planking and then trimming to be flush with the deck proved to be too difficult. This was later stripped off.

- 7 replies

-

- Malaspina Straits

- plastic

-

(and 1 more)

Tagged with:

-

Keeping the water out is probably one of my biggest concerns, visions of the tug sinking have definitely crossed my mind! With a combination of fibreglass resin and body filler I should have a good chance of keeping it out of Davey Jones' Locker! Initially there was no plan to install the prop. shaft, or any of the RC gear for that matter. Once the shaft arrived a jig was designed and 3D printed. This jig, complete with an appropriately sized hole was slipped over the keel, the hole was sized to accept a drill bit. Nervously but without hesitation a 3/8" diameter hole was bored into the keel and through the ribs. Following a bit of minor filling the stuffing box was inserted and fixed with JB Weld, this epoxy was used as it is what was handy in the shop. I believe that in my nervous state no photos were snapped of the jig on the model or in use, I will however post a few screen shots of it in the slicer.

- 7 replies

-

- Malaspina Straits

- plastic

-

(and 1 more)

Tagged with:

-

Welcome, and that is a great looking model! The HMS Prince looks like an intimidating ship, both to have seen on the seas all those years ago and to model, wow.

-

Thanks Guy. Now that the weather is turning I am getting really excited to get the hull done and into the pond for a test, a few weeks and it should be ice free. Hopefully at that time the hull will be done. Maybe tonight I will find some time to update the thread with some shots of the next steps... That is a great looking tug that you served on, very classic lines. I am sure that you have some interesting stories of life aboard.

- 7 replies

-

- Malaspina Straits

- plastic

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.310f97bdf7b8240283f31cf065a02893.jpg)