-

Posts

1,915 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by cdrusn89

-

First coat of Badger Windjammer Red applied. I moved the hull into a foam cradle so I could set it on its side. I found painting much easier in that position. Clearly (to me) there will have to a considerable amount of touch-up required once the hull is back in the building cradle. Especially on/around the gun port opening. Another coat tomorrow then....

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

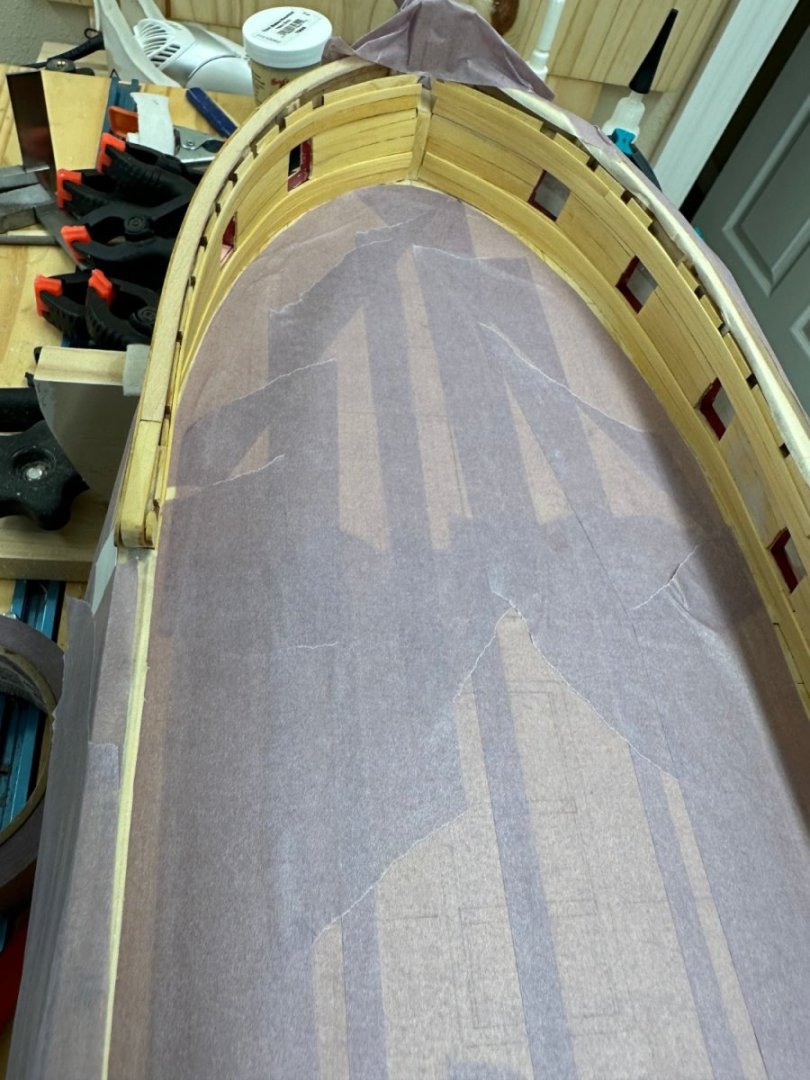

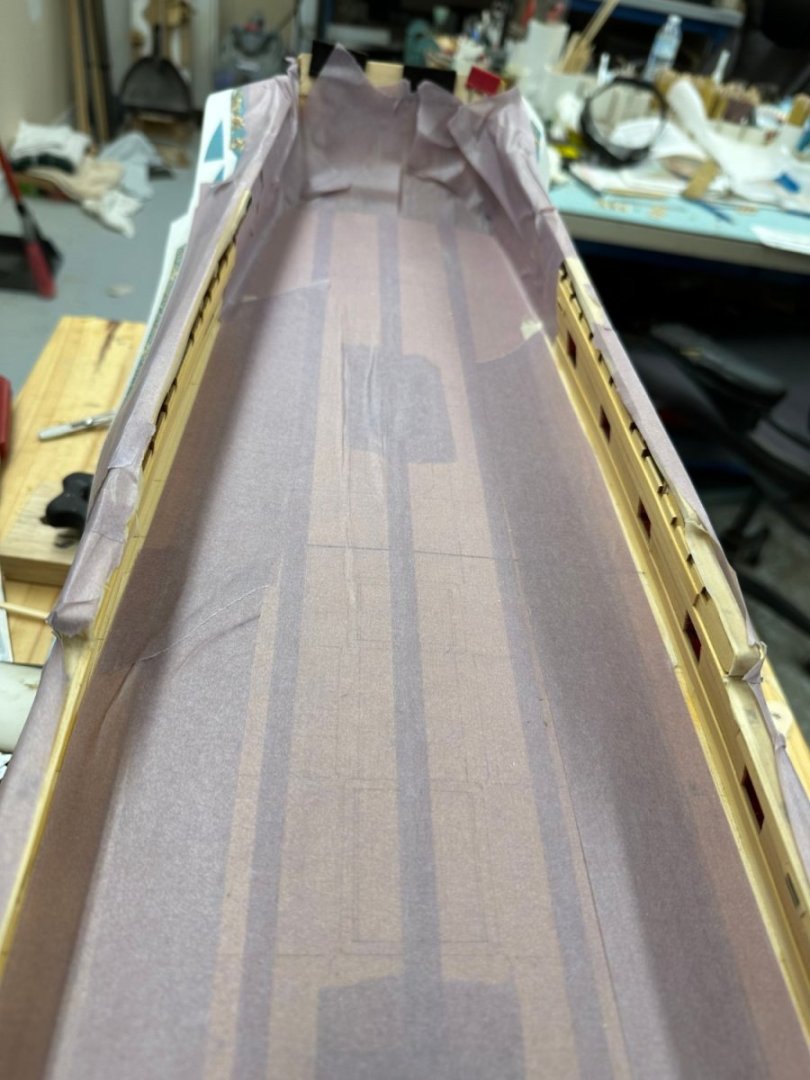

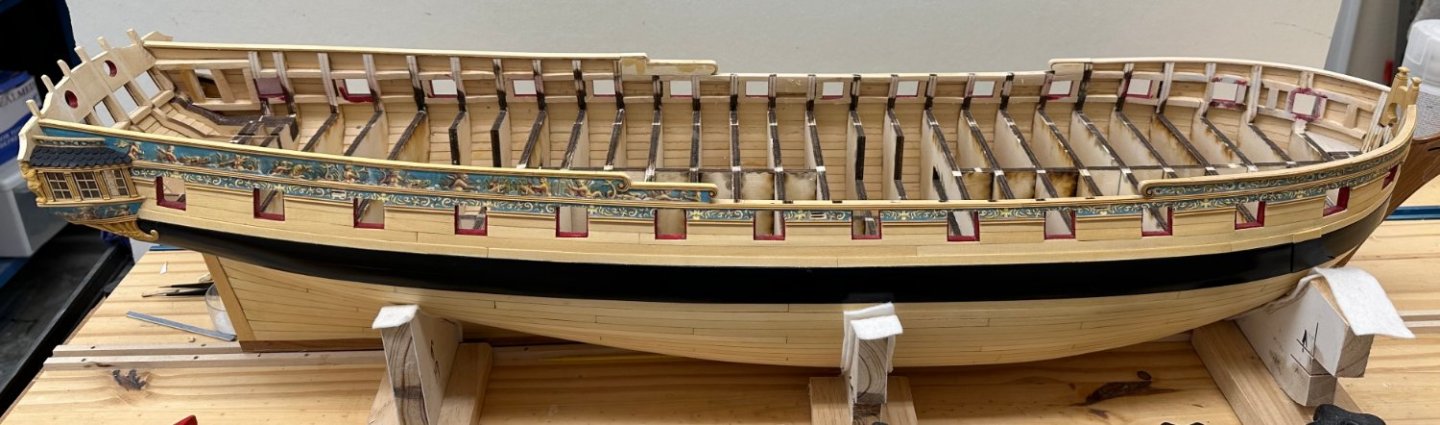

Interior bulwarks planking completed (except for the Great Cabin paneling. I decided that maybe painting first was a better idea. I am sure it will be easier to keep paint off the paneling this way. Bedsides I messed up two of the panels b y not watching what I was doing and the replacements will not be here for a few days soooo....

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks - for the "real" deck I used pieces a bit thicker than the 3/64" so I can use the thickness sander to remove any glue residue. Hopefully I will have the starting point for the Great Cabin deck fully glued up after Super Bowl. Then the real fun starts cutting the "new" strips and gluing them up with the correct "stagger".

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

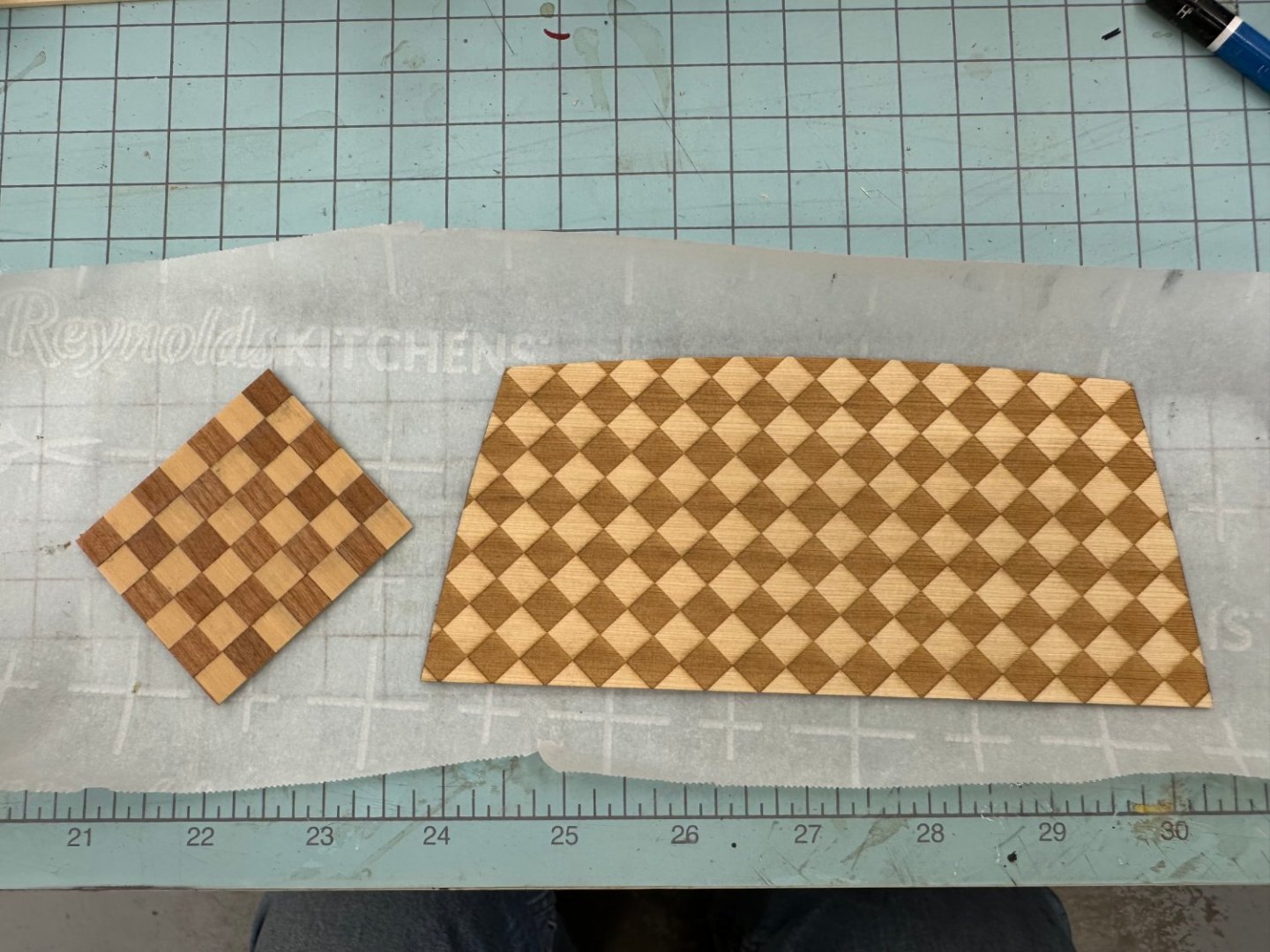

On Confederacy the Great Cabin floor was not provided as a laser cut assembly as it is on Winchelsea. I made the floor on Confederacy using Boxwood and Walnut. As mentioned in the monograph this produced a pretty sharp contract between the blocks. Also, the Walnut (at least the Walnut I had) grain is pretty open and it tended to tear rather than cut cleanly in spite of the very fine toothed saw bland. So for Winnie I thought I would try to make my own floor using Swiss Pear instead of Walnut and Boxwood. I made a small test piece using some "scrap" Swiss Pear that has a very pronounced grain pattern. Hopefully I can find a piece with less prominent grain if I decide to actually make a floor. FYI - the test piece has a coat of WoP while the kit provided floor does not.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

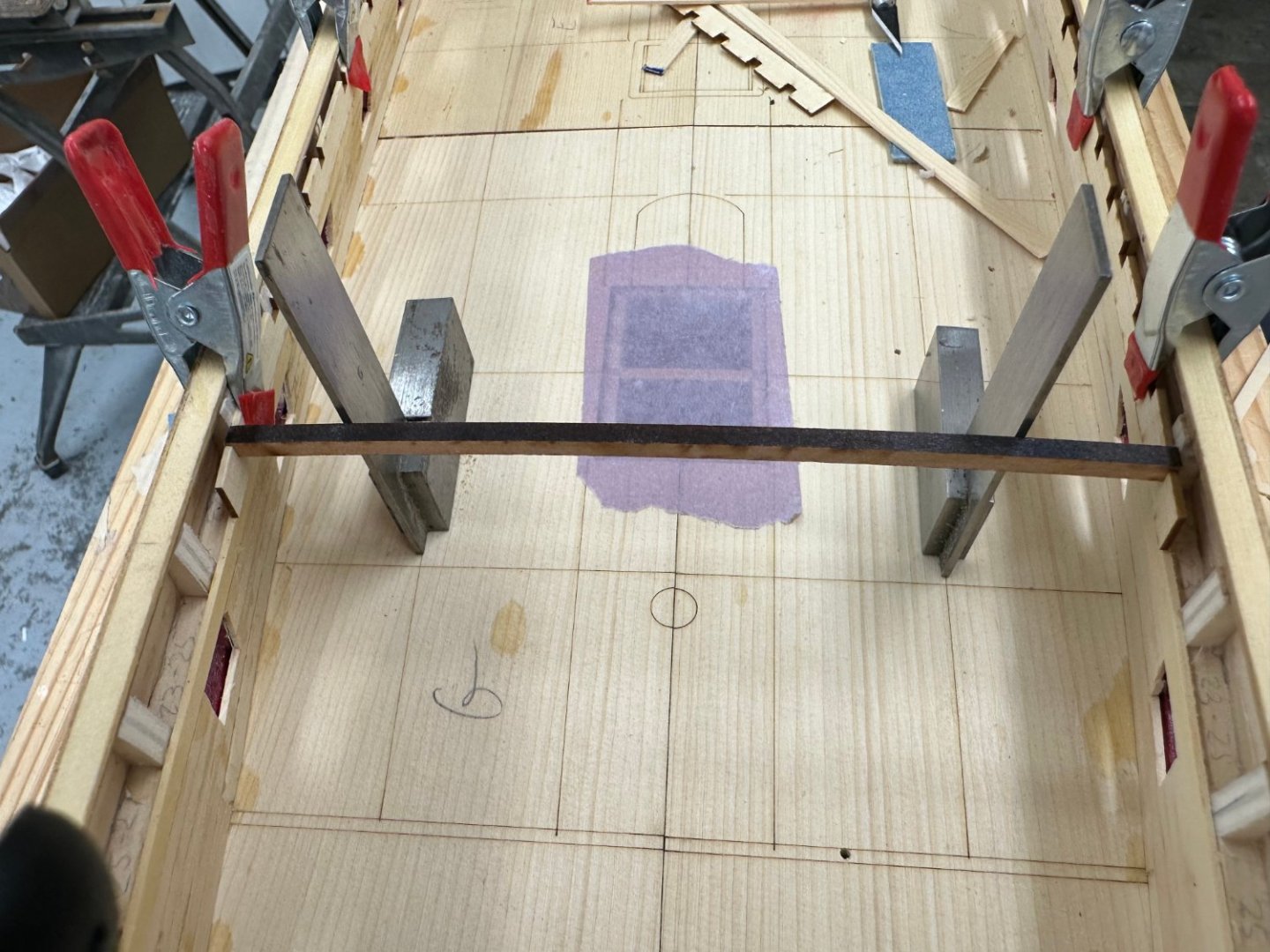

With the forward deck clamps clamped in place I followed a similar process to that used aft to assure myself that the deck beams are going to be perpendicular to the centerline. I used the machinist blocks this time as they stand up much easier than the squares I used aft. The beams loks good so it is time to secure the forward deck clamps.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I installed (clamped) the after portion of the deck clamp on both sides following the instructions and not "tampering with" the junction between the two sections. Here is what it looks like at the stern on each side: Starboard side Port side Looks like they are just short of the transom and, as required, the bottom of the notch is just below top of the stern window opening. I put a 3/64" thick piece of scrap between the transom and the deck clamp on each side to get a better view of how much space between the transom and deck clamp. Here is what that showed: Looks pretty close on each side. I put a deck beam in the aft most slot to see how that would look. I think it is time to glue these deck clamps in place.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I got the first layer of interior planking completed in the quarterdeck area and decided to see how the deck clamps/beams were "shaping up". Assuming I got the false deck pieces installed on the centerline (hopefully I did not screw that up) I thought it might be useful to see how the deck beams would fall. Hopefully perpendicular to the centerline although that might be hard to demonstrate since I have not found a way to get the centerline accurately extended up to the plane where the q-deck beams are. I clamped the deck clamps in place at the hance pieces and tried to line the notches for the last deck beam (on this section of the deck clamp) with a nearby bulkhead extension. Then I got a deck beam (cherry in this case), trimmed it to fit, being careful to take equal (more or less) amounts off each end and fit that into the slot for the after most beam. Then I took two squares, set them on the false deck on the outer most etched lines running fore/aft and looked for how far the squares were from the etched line running athwartships (which is where the forward cabin bulkhead will go). Then I adjusted one of the deck clamps (the starboard one) to get the two squares equidistant from the athwartship line. Here is how that looks: I know they do not look like they are equidistant but I think that is due to the camera's point of view. Looking at it in "real life" they are as close to equidistant as I can get them, even with my "auxiliary eyes" on. I then moved the beam to a forward deck clamp notch that is near the junction between the after two false deck sections. I wanted to check that I had not just picked an auspicious place to run the first check. Here is the picture of the forward "check point". Pretty darn close Since I started with the two deck clamps aligned on one of the bulkhead extensions I wanted to see how much I had moved them "out of alignment" so here are where the two deck clamps are now. This is the port side which was not moved - notch is just aft of the bulkhead extension. This is the starboard side which shows the deck clamp is about 1 mm forward of the aft side of the bulkhead extension. I am going to add the after section of the deck clamps and see how thing look at the stern before taking any drastic action - like gluing the deck clamps in place.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

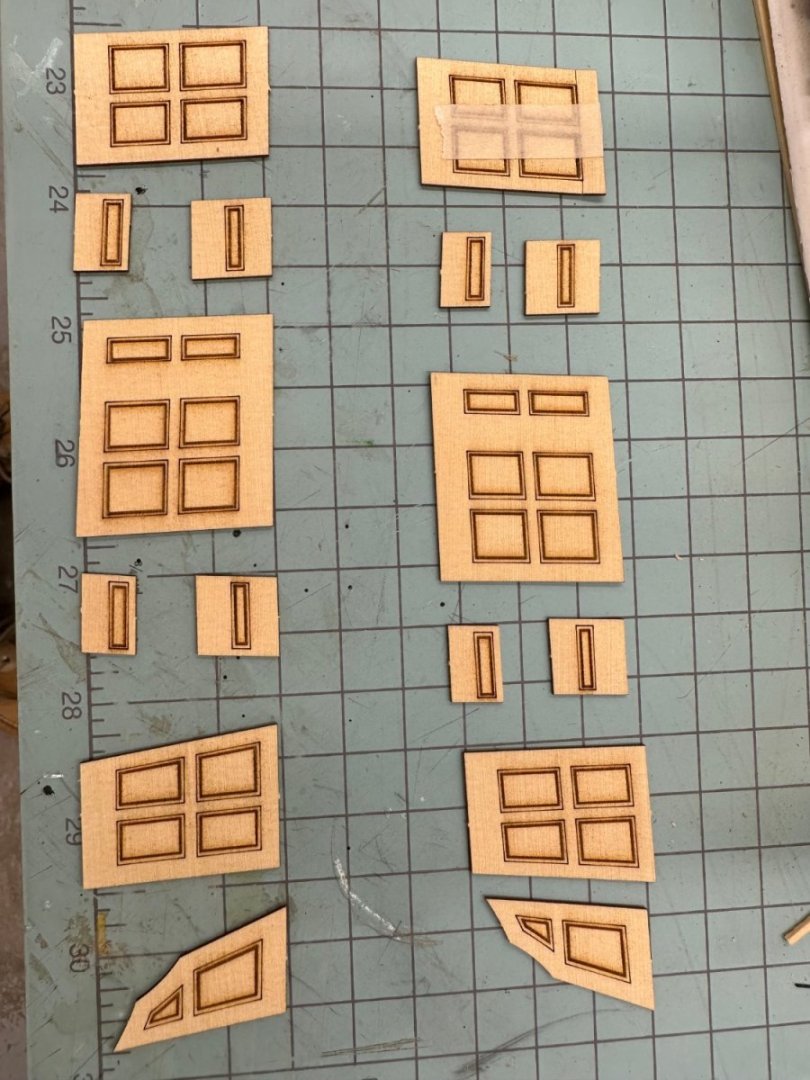

While waiting for glue to dry I inventoried the paneling for the cabins. Good thing as I noticed that the forward panel for the starboard side had both come adrift from the carrier but also broke off the upper most part of the panel. I think it will likely not be noticable but that will be the last panel installed "just in case" a new one is needed. Her are the pieces, starboard side on the right with tape holding the two pieces together. I have since stored them in separate containers so I don't have to divide them up again.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Starboard side interior planking ready for deck clamp installation. Except for the after most piece behind the q-gallery door. Since it is important (according to the instructions) that the bottom of the deck clamp slot at the transom not be above the top of the stern windows I am going to make sure that is the case and then fit whatever piece is necessary to fill in the space between the lower plank and the bottom of the deck clamp.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks. Use it with my complements Edward - better safe than sorry; especially after all the work on the stern. I decided that I am going to put two rows of 1/4" wide planks between each gun port and then put whatever size/configuration is required to get a row that is even across the top of the gun ports. I have plenty of 1/4" planks but am running low on 7/32" and 3/16" for some reason (waste/mistakes perhaps). Here is the q-gallery entrance on the starboard side with 2 rows of 1/4" planking. I am waiting for the rows over the gun ports to establish the width/configuration of what goes above these two. Here are the first five gun ports with two 1/4" planks - take my word for it. Did I mention you can never have too many clamps?

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

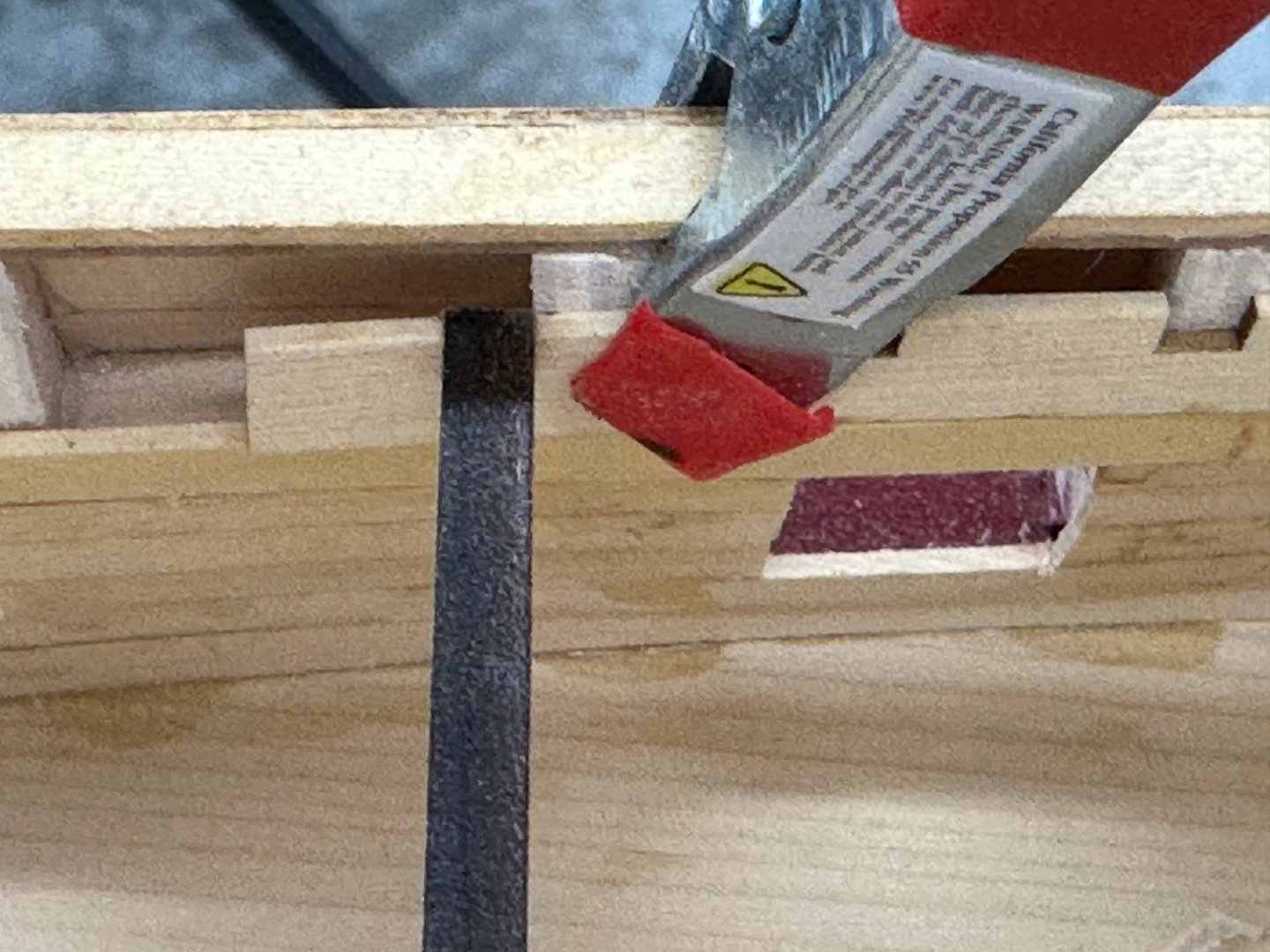

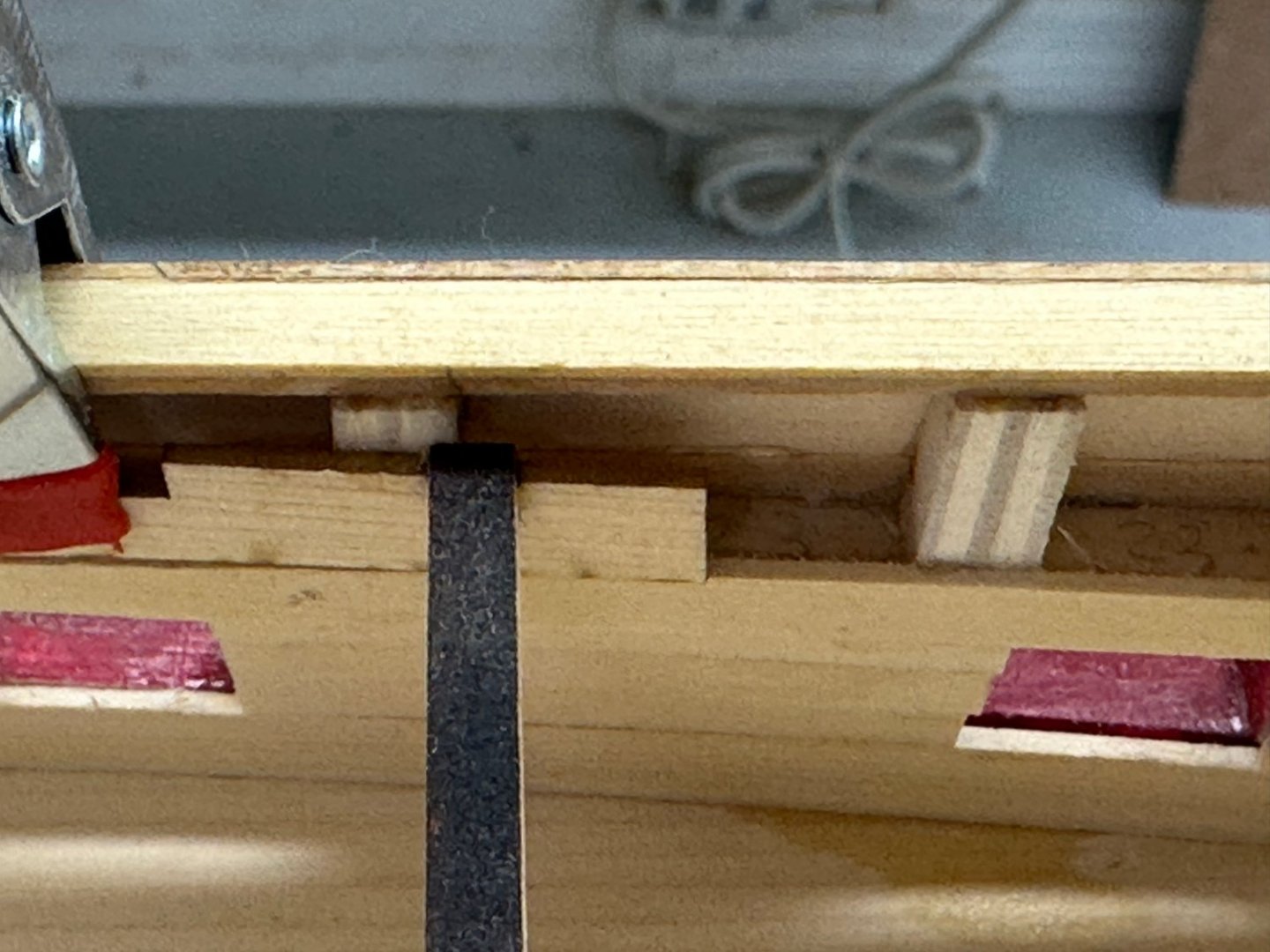

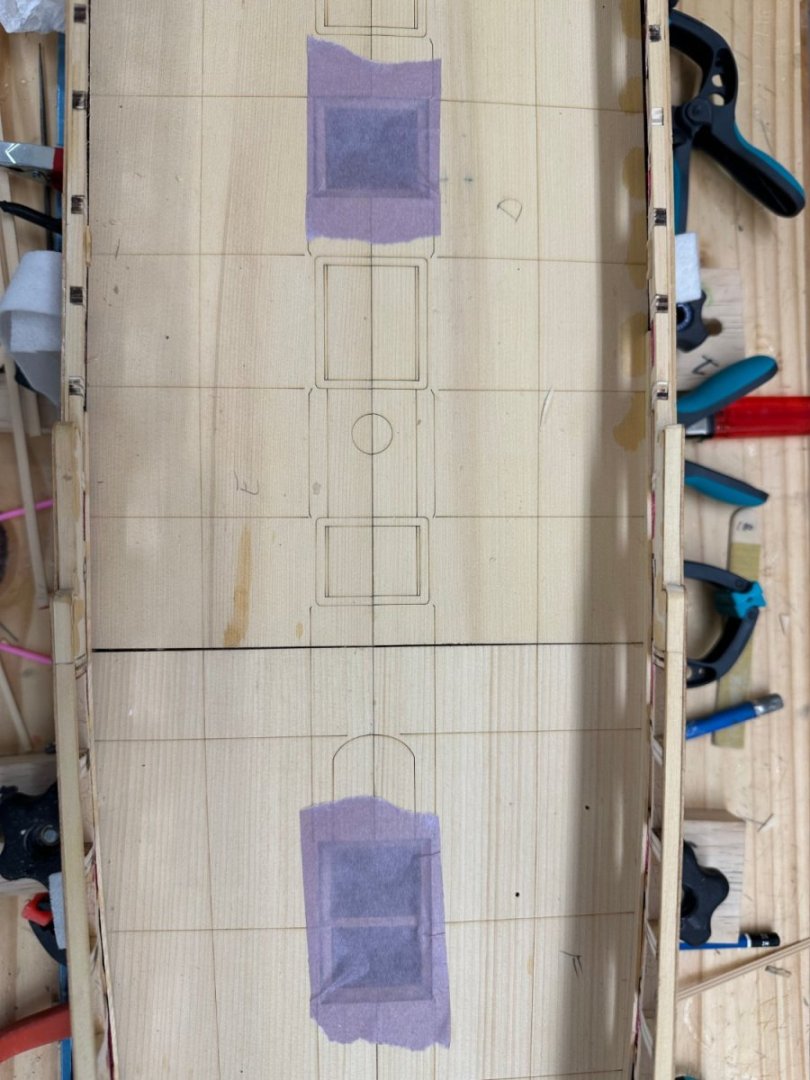

A bit of housekeeping. I learned (the hard way) when building Confederacy that things seem to have a sixth sense when it comes to open hatchways. To keep foreign objects from finding their way into the hatchways I covered them with masking tape. I plan to cut thin basswood sheet to fix inside the coamings until the gratings are available and will keep them fitted to the companionways until the model is essentially finished. Having snagged my sleeve on the stern frame extensions once while working the interior planking behind the q-gallery entrance (no damage thankfully) I decided to add some protection there as well. Two pieces of thin sheet wood held in place with 1.5" binder clips.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The next step is to add the first two rows of bulkhead planking. The upper row should be level with the bottom up the gun ports. The upper piece is 7/32" wide and to lower one is whatever width nit takes to get the upper strake even with the gun port bottom. The instructions note that there may have to be adjustments to keep the upper strake where it needs to be. I decided that maybe it would be easier (on me) to run the upper strake first. adjusting its "run" to stay level with the gun port bottoms. That way I could guarantee the upper strake is level and make whatever adjustments are required to the bottom strake. So here is the aft starboard side with the upper strake glued in place. The piece on deck will be the bottom strake. It is 1/8" wide. Clearly I have less distance between the deck and the gun ports since Chuck's model used a 1/4" wide strake on the bottom. I am not sure what impact this will have going forward. All I can do now is hope the port side is the same. Meanwhile here is the bow, faired with the filler and centerline pieces added. I also added a small piece at the bow to bridge across the gap between the hull and the stem. It cleans up that surface but may interfere with some of the bow work yet to come so I only glued it to the hull to reduce problems if forward portion has to be removed later. It will all be painted black in the end.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

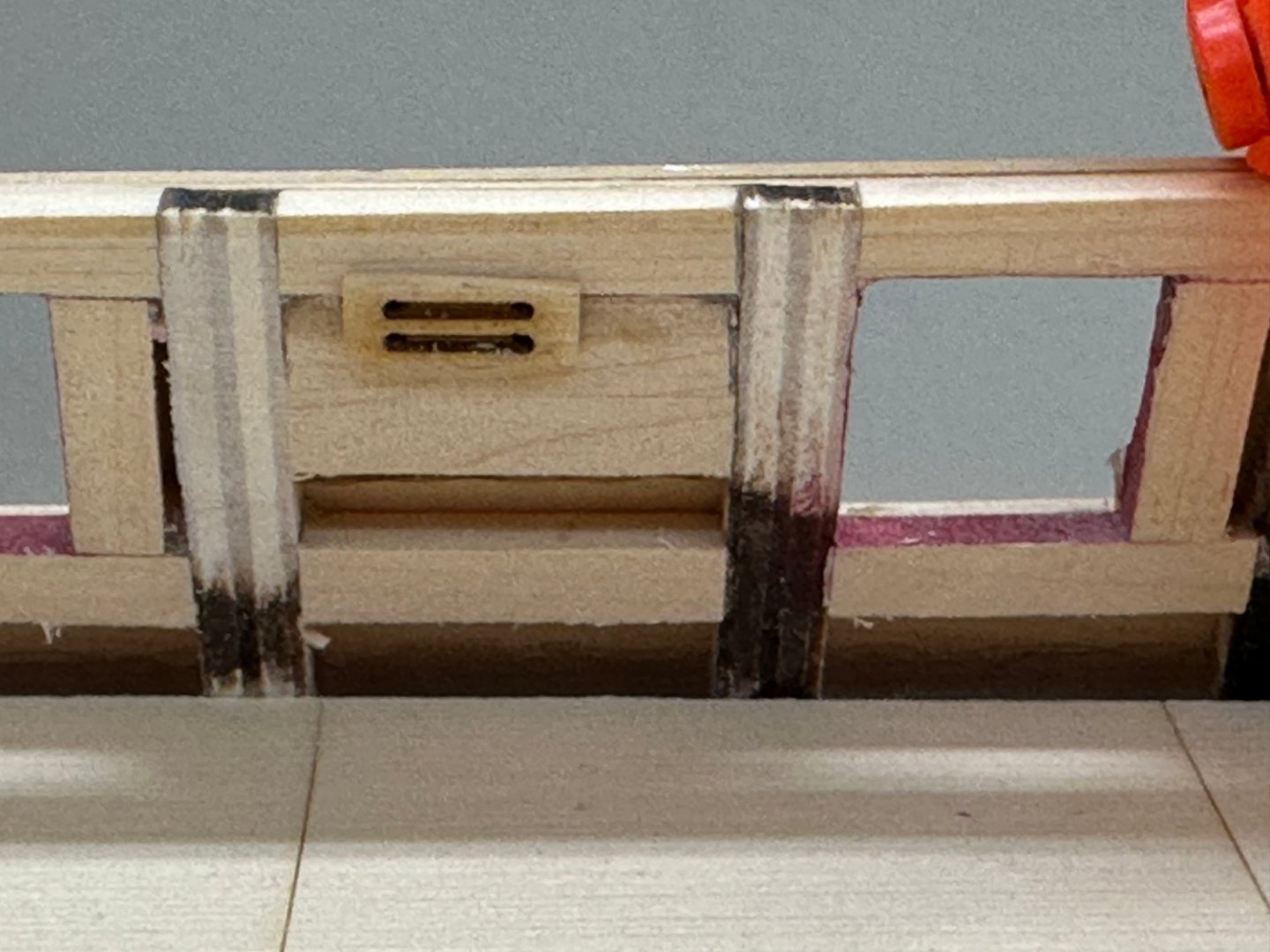

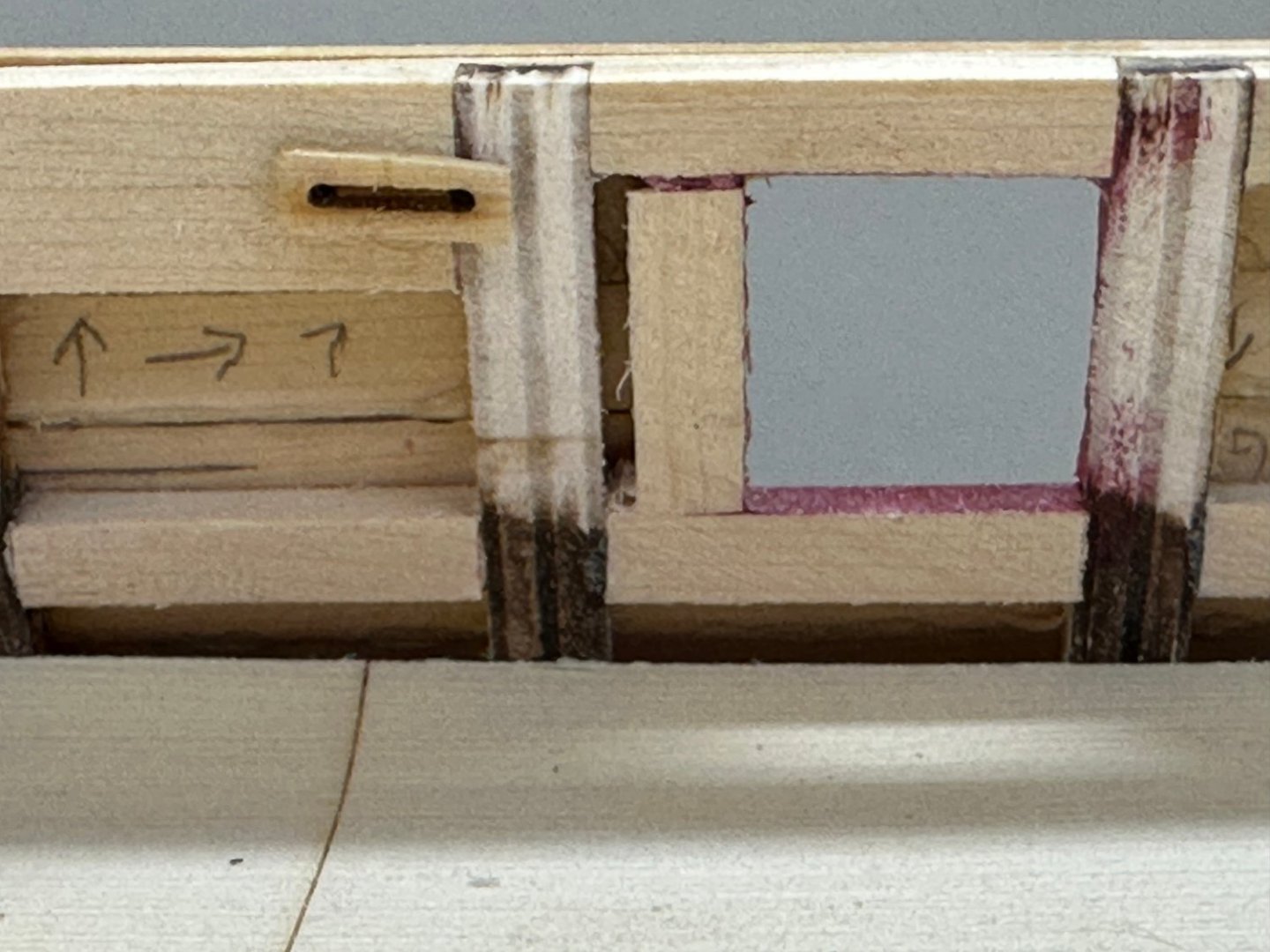

With the false deck in place the next step is to add the fillers on either side of the bow. It appears that I had already considered this area as requiring extra support since I apparently added an intermediate support between bulkhead W and the bow (on each side). I seem to remember having a difficult time keeping everything "together" while framing in the forward gun ports. Anyway, I added the bow filler below the lower sill but had to add the filler in two pieces above the lower sill. Fairing comes next, before adding the strip below the bowsprit hole is added. While waiting for the glue to dry on the fillers I added the inner sheave shells for the forward two sheaves (aft one is to wait until the first layer of bulkhead planking (per instructions).

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

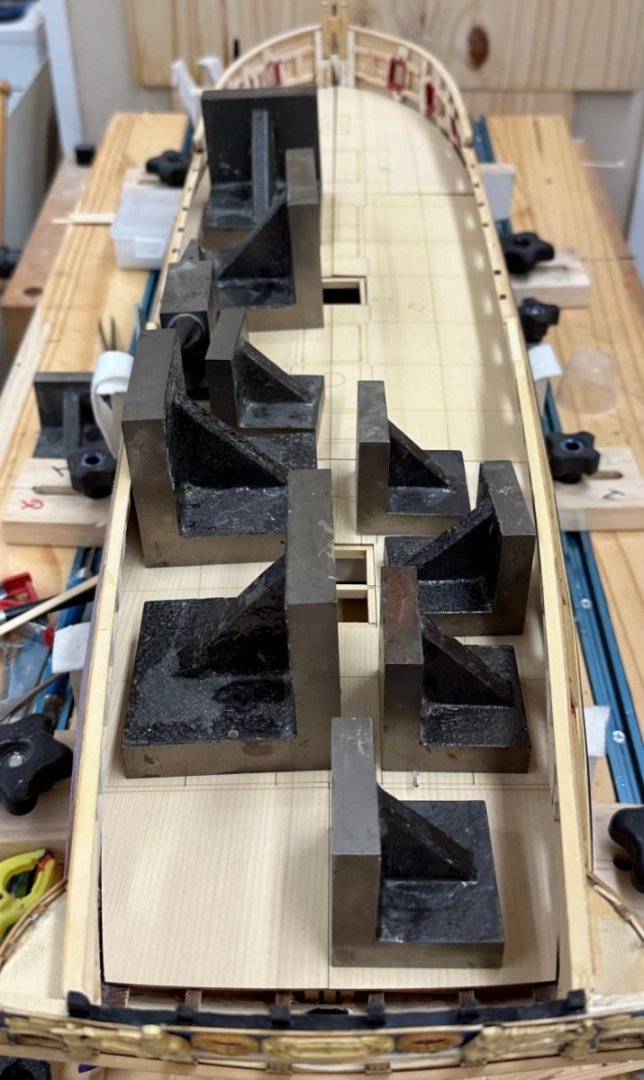

Thanks Frank - I looked at your blog this morning. You have the planking "down". I wish I could do as well. I think I got the carlings for the aft companionway cut so they just "drop" into the mortises - no distortion of the center beam, which would be easy to do - don't ask me how I know, please. With those in place I moved on to adding the false deck. I had to take a bit off the outer edge of all of the false deck pieces but got them all dry fitted and lined up before I when to the glue (neutral pH PVA). I found a use for the machinists angles that I have accumulated over the years. Are excellent weights to keep the false deck pressed down on the underlying structure. I had enough to do three sections at a time. When the aft deck was dry (overnight) I couldn't resist placing one of the guns and a 1/48th figure that I got through the NRG Store "on deck".

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

With the stern completed (finally!!) focus shifts to the interior. First step is to plank the two interior platforms below the gun deck. In the forward platform I must have gotten the centerline plank a bit off to one side because when I got to the outboard edges I had to use a 3/16" wide plank on one side and a 7/32" on the other.Not that anyone is going to see much of the platforms anyway but... So here is the forward platform with the supports glued in and the decking sanded and tack ragged but not yet WoPed. Before I glued the supports in I checked to make sure they were square with the bulkheads - no issues. So I planked the aft platform and was adding the supports. When I checked for square I found a slight slant with the aft end being inboard slightly. I clamped a square to bulkhead 21 and am in the process of gluing in the starboard support member perpendicular to bulkhead 21. I am tempted to use some thin CA to secure the support as it has taken me more than a few tries at getting the support square and level with the four bulkheads it touches. A problem for this weekend since no football.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks for the tip on the sanding sealer. Not sure I am at a point where I can use it now but when I get to the figurehead I will definitely give it a try. Anyway, I managed to get all the stern decoration installed and an additional coat of flat finish applied. I did not use the kit provided "columns". But I did use the residual pieces from the kit provided upper molding (laser cut) to fill in above and below the "columns" which I made from boxwood using the same molding cutter I used for the middle side molding although I used it at its full 3mm width instead of the 2.4mm width used on the sides. Unless I have missed something (highly likely) this concludes the stern decorations. I still have to add the window frames but am not going to add them until I actually have to - I fear they are too fragile and I am too clumsy to avoid damage until there is no way to avoid it.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Adding the ornamentation to the stern. Got the port side "finished" (touch up needed). I am not sure why the "wreaths" have a different "color" than the rest of the ornaments. They are supposedly all CDC machined boxwood but... For what it is worth the figures aft of the q-gallery windows are also the same color as the wreaths. Everything is going to get another coat of matte finish once the touch-up is done but I may have to live with the color difference. At least it is consistent on each side - so far. I would echo the monographs caution about the figures being delicate. I broke the leg off the figure while filing the grove in the bottom to allow them to extend over the cove. Not the best job "fixing" it but it is hopefully not too noticeable without the close up photo.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I decided to fit the rudder now that I have it "complete". I still need to touch up some of the black on the pintles and gudgeons but hopefully that will not mess things up too much. With the hull back upright I dry fit the cove and the items above it. I had to take a bit off the edges of the center molding in order for it fit between the wreaths. I will add the stern windows after I get all the decorations on the stern completed to avoid the possibility of poking one out or otherwise damaging them during the decoration installation.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Working on the rudder mounting - I took Chuck's advice in the monograph and only put pins in the lowest and next to the uppermost hinge points. The very top one is almost inside the opening so that one would be hard to maneuver. So here are the two hinges with their supports attached to the hull. I will add the interior hinges (no pins) after I get the corresponding hinges on the other side in place. I used 24 gauge wire in the holes at the ends of each piece and fishing line elsewhere. A drop of thin CA on each wire/line was all I used to secure the pieces to the hull. Hopefully no one is going to try and "swing the rudder".

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

While waiting for things to dry, or to take a break from whatever is bedeviling me at the moment I took a crack at the cove molding. I tried for the "concave look" as described in the monograph but am not sure I was successful. I used the same red color (Badger Windjammer Red) as I used on the gun carriages and will use on the interior bulwarks so it does not look quite like the monograph. One word for those who may come later to Winnie - the transom and thus the cove molding is curved in the fore/aft dimension. Make sure the molding inside the cove is well secured before trying to attach it to the transom. Luckily I discovered this "issue"during a dry fit and was able to correct it on the workbench. Would have been a bit more of a challenge if the cove was glued to the transom and interior molding popped off.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Chuck and Glenn - yes; I did not notice the lower counter molding until you mentioned it. Has been added using the same molding as below the friezes on the sides. And since I have the hull upside down decided now would be a good time to drill out the hole for the rudder. But, I need to assemble the rudder to make sure I make the hole big enough. So, since I have the chapter 5 wood package I got out the rudder and the accessories (pintles and gudgeons) and put the rudder together. Here is the rudder and the hole. I decided to only make the hole as large as necessary. I will touch up the edges of the hole and frieze before turning the hull over again. I will not actually install the rudder now, just get everything ready so it will just "slip in" when I get to chapter five.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Somehow I must have missed the directions to add the friezes to the transom area so I took the time now to invert the hull and add them as well as the molding that outlines the upper and lower counter. I also painted the upper transom area the cerulean blue using the Window Newton watercolor paint. As suggested I used the blue plus a drop of white. I think it is pretty close to the blue in the friezes but could probably have used another drop of white. I have a few more touch-ups to do on the port side and then it is more transom detailing including adding the stern "decorations".

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Starboard side - I put one coat of Wipe-on-Poly over the entire side (above the wales; wales have 4 coats already). I am finding it hard to get started on the port side as it seems the gremlins have made off with some of the parts (q-gallery uprights for instance). Perhaps a pause to clean up and put things back where they belong is in order.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Starboard side from stern to waist is "finished". I looked all over the plans and could not find a description of the molding that I am supposed to scrape so I "faked it". The middle one is "two grooves (aka three humps)" and the lower is one groove - just so they are different. Working the forward portion now - may get it finished tomorrow so I can switch to the port side. Need to mill more molding too. And there are 22 more cannon to mount on the carriages.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.0ea7cc025c9c6c804078de7c0a20626d.jpeg)

.thumb.jpeg.a739a40c433b8189e4a89a877d25dfa7.jpeg)