-

Posts

371 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Pfälzer

-

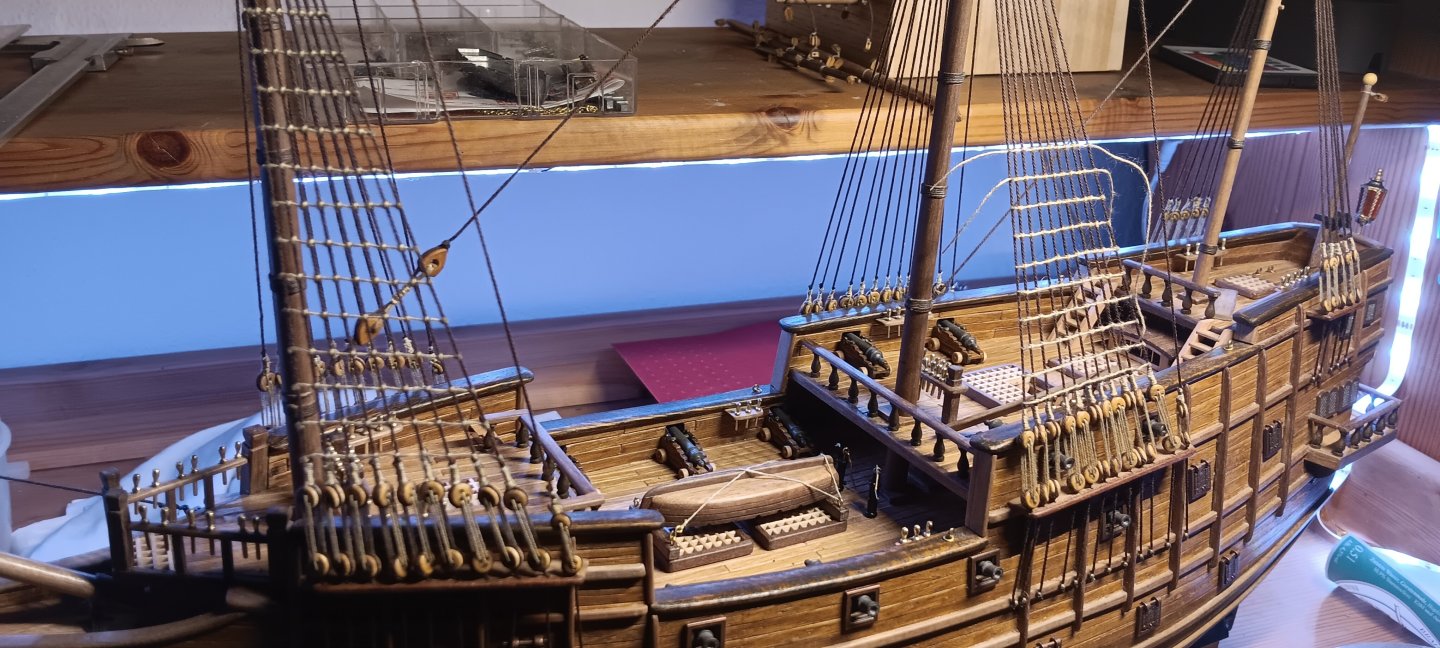

Hello lovelies, I would like to introduce you to my new project. Actually I wanted to continue with lower scales after the San Martin. But then I found this kit on the net and bought it very cheaply. So I bravely embarked on the tall ship adventure. There are only a few finished prototypes of this kit, which makes things even more exciting. I will try to build a model of it from around 1780, even without copper planking. However, I will only make a final decision on this point after the panelling. I like woodwork, so I'm also in good spirits in this respect. As you can see, I also bought some literature to help me. It contains very detailed building plans on a scale of 1:100, which doesn't make much difference. The kit comes with a proof of purchase from 1988, which is confirmed on closer inspection of the contents. I don't have to worry about burnishing the brass. Forty years of storage have left their mark and have already taken care of this issue themselves. Again, nothing is laser-cut, all parts are sawn or milled and of outstanding quality. I quickly had moist eyes when I unpacked the kit. But more on that in the course of the build. I also started building the basic frame straight away, which is hardly worth mentioning. A little sanding here, a little sanding there and everything was just right. Sit back, it's going to be another Translated with DeepL.com (free version) Übersetzt mit DeepL.com (kostenlose Version)

-

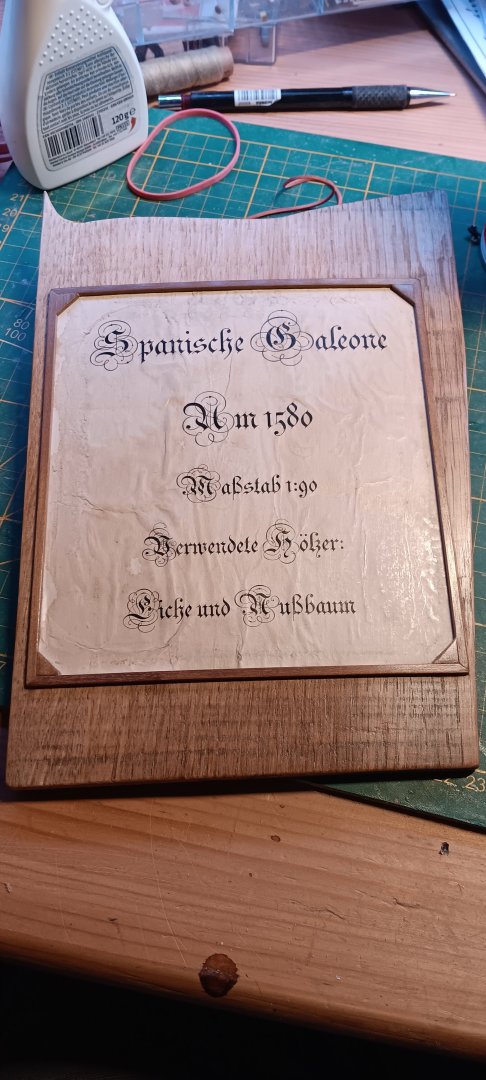

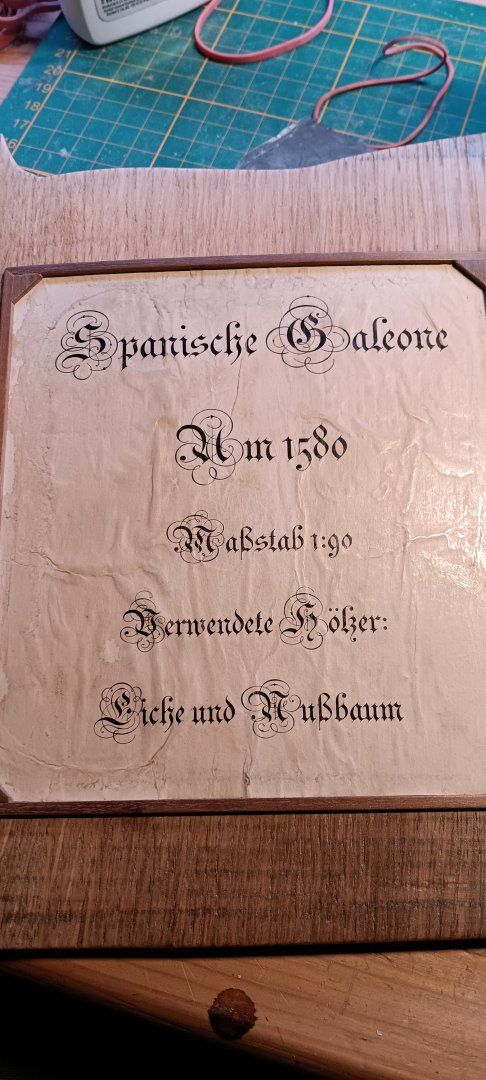

Guten Morgen an diesem schönen Sonntagmorgen, Auf die Segel muss ich noch warten, daher vertreibe ich mir die Zeit mit einer Schautafel. Da ich in einer öffentlichen Einrichtung mit neun Häusern im Umkreis von 30km arbeite, werden meine Schiffe nie alle zu Hause sein. Wir haben einige leere Vitrinen, die ich in Zukunft füllen werde, um meine Kunstwerke der breiten Öffentlichkeit zugänglich zu machen. Viele Grüße aus der Pfalz

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

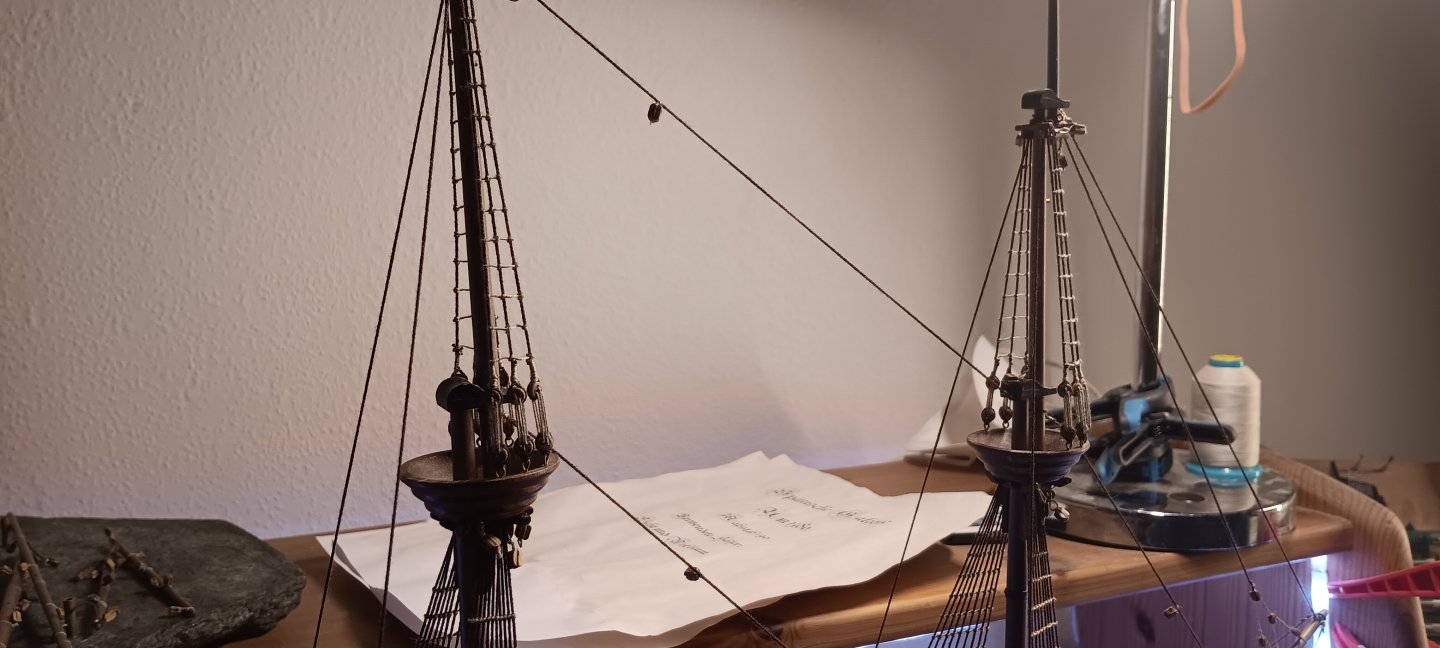

Und wieder einmal heißt es warten. Die Oberwanten sind auch fertig und warten, wie ich, auf die Schneiderin. Komisch, wie man trotz unseres Alters noch ungeduldig werden kann. Schönen Sonntag noch

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Hallo Freunde, die fehlenden Maiden sind endlich eingetroffen, sodass ich endlich mit den Oberwanten weitermachen kann. Durch Zufall bin ich gestern in der Stadt auf die Schneiderin gestoßen. Leider war sie krank und konnte nichts tun, hat aber jetzt mit den Segeln begonnen. Es war schön, sie getroffen zu haben, sodass wir das Design an meine neuesten Ideen anpassen konnten. Ich freue mich schon sehr darauf zu sehen, wie die Segel aussehen werden, wenn sie fertig sind. Passt auf euch auf und bleibt gesund Übersetzt mit DeepL.com (kostenlose Version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Congratulations Bob, your Duchess looks great. Now clean the boatyard and get to work on the next work of art.

- 207 replies

-

- vanguard models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Staining of hulls.

Pfälzer replied to serpe's topic in Painting, finishing and weathering products and techniques

Ich streiche meine Boote gar nicht. Um die natürliche Farbgebung und Struktur zu erhalten, schleife ich alle Teile mit Schleifpapier 1000 und wachse alles mit Antikwachs. Anschließend wird alles mit den Schminkpinseln meiner Frau aufpoliert. Da ich in Zukunft die Möglichkeit habe reines Bienenwachs bei einem Imker zu kaufen, wird dies im nächsten Projekt getestet. Grüße -

Hello lovelies, I've just been home for a week and my feet don't want to do what they should. It's actually quite nice to be at home with a walking disability, if only I had something to do. I'm still waiting for the sails from the dressmaker and replacement bodices as there aren't enough of them. I actually wanted to install the anchors at the end, but thanks to my current boredom and a bit of impatience, I decided to dedicate myself to the subject today. And as life goes, I have to say it was a good decision. Because I don't think I would have been able to do it as well after the rigging. I'm going back to work next week, screw sore feet, sitting around at home isn't the best thing either. Best regards Translated with DeepL.com (free version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

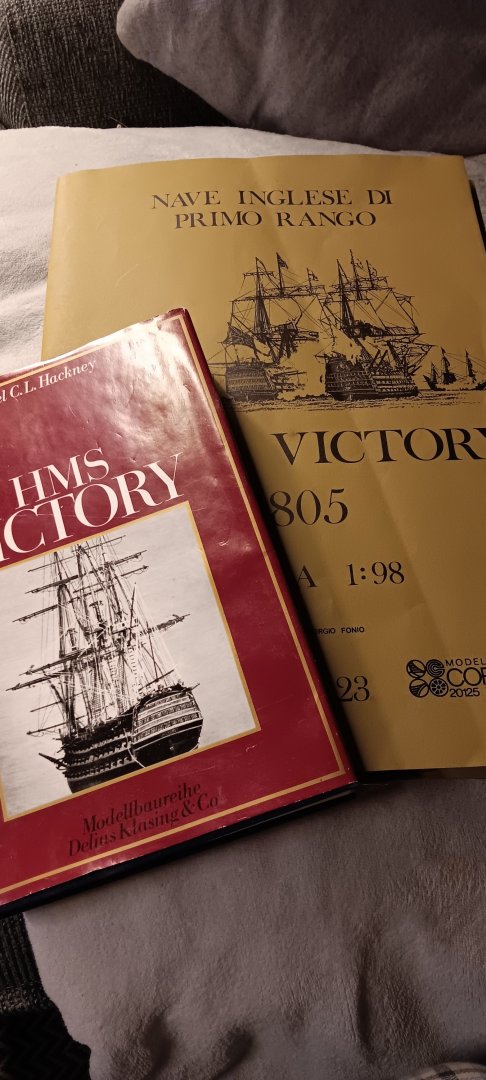

A cheerful hello, I'm glad to read that someone else is building the model at the same time. I also bought a Victory from Corel in the bay. Together with an Endeavour from AL for a mere 100 euros. Should arrive next week, this week I already received some literature to support me. Make a good start, I'll follow up afterwards to see what there is to consider. Good luck

-

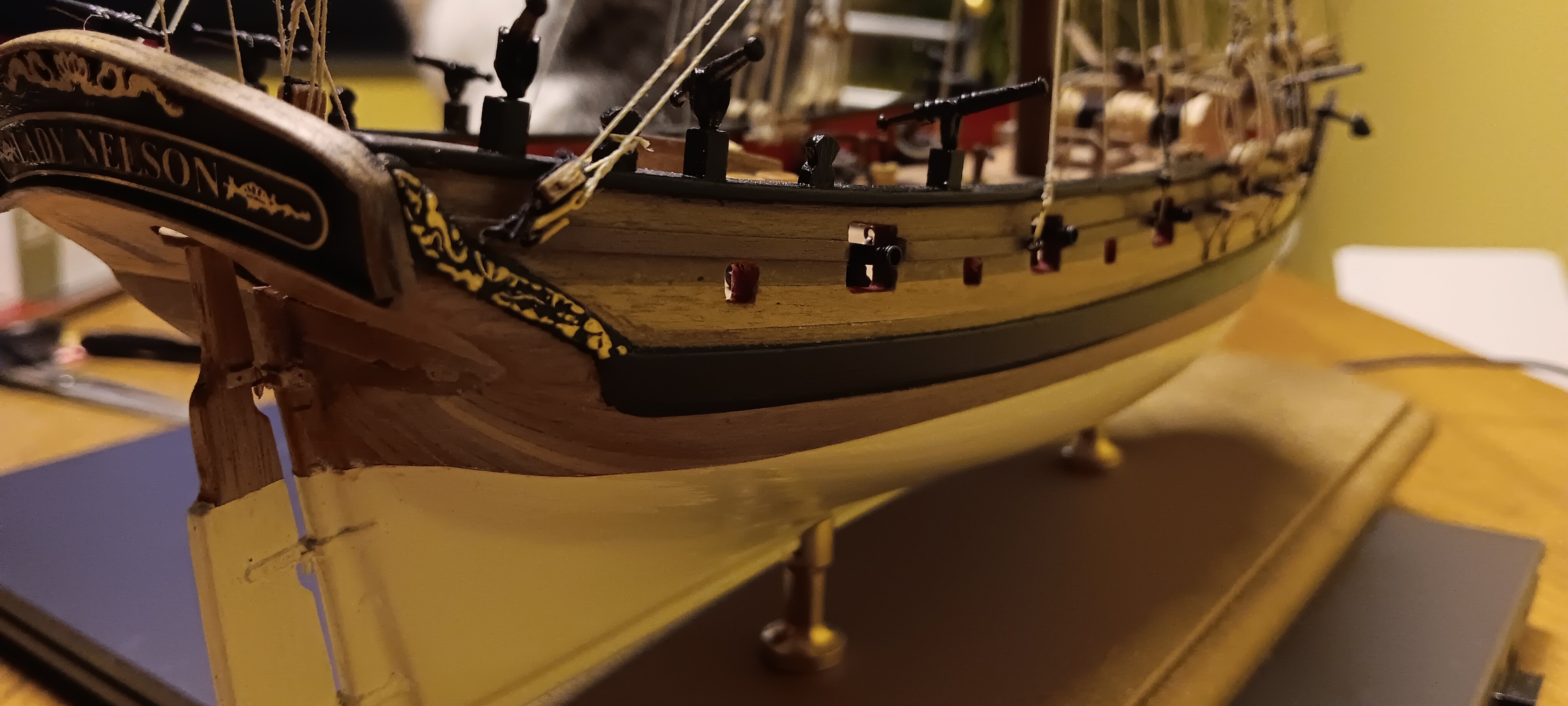

Hallo ihr Lieben, da der Bau der San Martin derzeit ruht und wir auf die Segel warten, habe ich mich an die Reparatur gemacht. Da alle kaputten Teile noch vorhanden waren, ließ sich mit ein paar Handgriffen und ein paar Tropfen Kleber alles reparieren. Grüße

- 8 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Also, meine Lieben, Das gute Stück ist endlich fertig und die Admiralität hat der Werft die Genehmigung erteilt, es wieder für den eigentlichen Einsatz freizugeben. Das Grundgerüst besteht übrigens aus 20x20mm Eiche, die Innenausstattung aus Eichenholzleisten, die noch aus der Werft stammen, die Dachinnenseite und die Unterseite sind mit Sapelli beplankt, die Dacheindeckung erfolgt mit Bitumenbahnen, um sie wasserdicht zu machen. Sobald die Segel von der Schneiderin zurück sind, geht es mit dem Schiff weiter. Mit freundlichen Grüße Übersetzt mit DeepL.com (kostenlose Version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Hallo ihr Lieben und ein frohes neues Jahr. Hier ist ein Stück, das nur das Leben schreiben kann. Meine Werft wurde gekapert. Ich war etwas verzweifelt wegen des zweiten Segels, also schlug mir die Admiralität vor, eine Schneiderin zu suchen. Mein Einwand, dass das Geld kosten würde, war seltsamerweise irrelevant. Naja, nicht ganz, aber das habe ich erst gemerkt, als es schon zu spät war. Sie hat im Internet ein wunderbares Vogelhäuschen entdeckt, und leider auch meine übrig gebliebene Kiste mit Totholz. Also hat sie beschlossen, eine Bootspause einzulegen, da ich sowieso auf die Schneiderin warten muss. Auch dass die Eichenleisten, die ich brauchte, viel Geld kosten, war egal. Als fürsorglicher Ehemann tut man einfach, was man tun muss, öffnet den Geldbeutel weit, besorgt das Holz, putzt die Werft und legt los. So lebe ich, Marie Übersetzt mit DeepL.com (kostenlose Version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

This is like Dussek build the San Martin. Will be interesst for MikkiC. Thank you

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

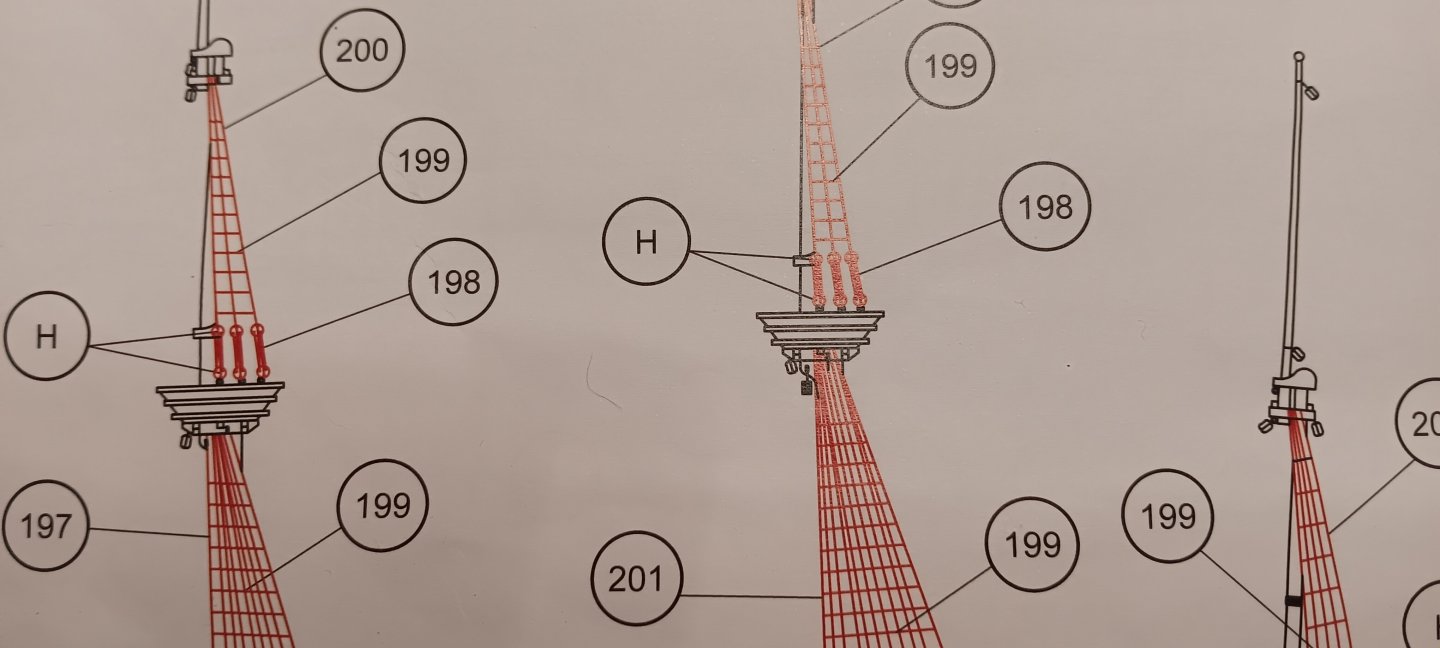

Hallo ihr Lieben, der Ärger ist verflogen, die dicke Luft verschwunden. Also machte ich mich an die Arbeit an den Wanten, nachdem ich eine Lösung für mein Problem gefunden hatte. Am Großmast konnte ich Platz gewinnen, strukturell nicht korrekt, aber optisch akzeptabel, ich mag einfache Lösungen. Am Fockmast gelang es mir, indem ich begann, den Mast von hinten abzuspannen. Leider führte dies dazu, dass die Spannung nach vorne hin zunahm, was zu dem kleinen Schönheitsfehler führte, den man sehen kann. Aber nur am letzten Maiden, also nicht dramatisch. Die Maiden habe ich auch mit Eiche gebeizt, da sie für das Gesamtbild zu hell waren. Am Besanmast werde ich in den nächsten Tagen arbeiten und dann Leinen weben. Schöne Tage euch allen Übersetzt mit DeepL.com (kostenlose Version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Good morning everyone, This Spanish construction miracle is starting to get on my nerves. When I attach all the shrouds to the lower mast, they overlap halfway through. So I used the topmast, only to realise that there will be problems with the yard. If you look at the rigging plan, that's exactly how it should be. The most annoying thing is that Occre is a big sponsor here, but they don't seem to care about the results of their buildings as much as a sack of rice falling over in China. I praise Chris Watton, who gets in touch immediately when a user has a problem with his designs to point out solutions. Dear friends of Occre, that's what you call customer service. And that's how you please your customers and keep them, just by the way. For me personally, this will be my last kit from your company. I'm afraid you won't care, but you shouldn't underestimate the effect of a bad review like mine. Farewell, I'm off to continue my troubles. Translated with DeepL.com (free version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Hallo ihr Lieben, die Merkwürdigkeiten der Takelage werden langsam lustig. Die letzten beiden Tage habe ich mit den Wanten am Großmast angefangen. Schön, wie ich irgendwo gelesen habe, Steuerbord vorne rechts. Mit einer Schlaufe um den Großmast. Mittlerweile bin ich in der Mitte angekommen und habe festgestellt, dass im Krähennest nie genug Platz für alle Leinen sein wird. Außerdem überlappen sie sich schon fast auf halber Höhe. Also habe ich mir den Bauplan angeschaut. Ich kann mich irren, aber mir scheint, dass der Konstrukteur die Seile nur zwischen den Bäumen platzieren will. Ich werde in den sauren Apfel beißen und nochmal von vorne anfangen, inklusive der Stenge. Dem lieben Kirill werden die Haare zu Berge stehen, wenn er das sieht. Grüße Übersetzt mit DeepL.com (kostenlose Version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

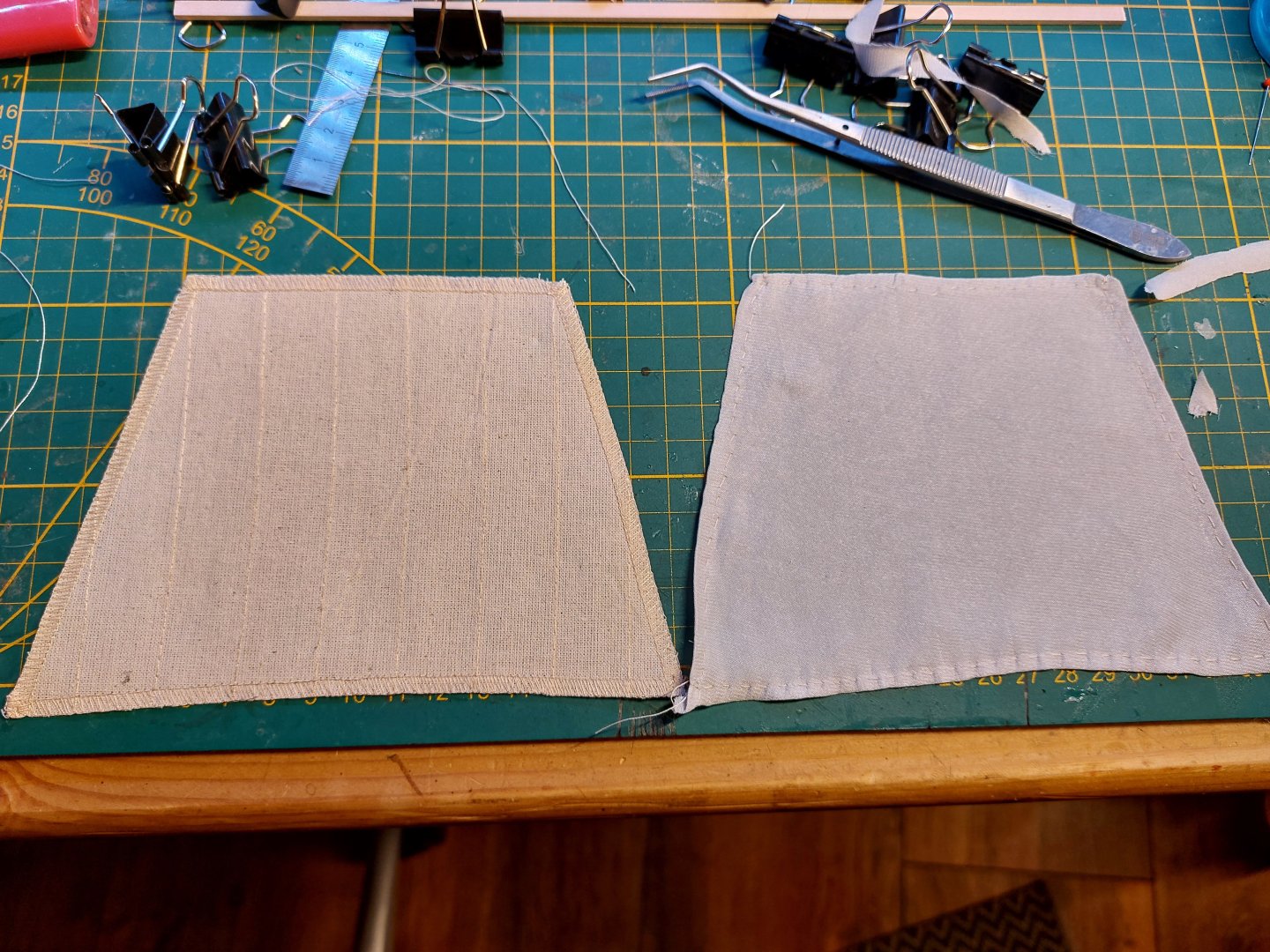

Hi Knock Knock, yes, this build will be the first time I have used sails. I have secured a fine silk fabric for it by reaching into my daughter's wardrobe. Let's see if I succeed. Greetings my dear

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Hello Kirill, I've taken the trouble to look into the matter again for you. On all the videos available on YT, the stays are tensioned in the same way. After inspecting my own construction, I have a hunch that there is a reason for this. Apparently the correct rigging collides with the present construction. I fear that the assembly of the yards would then be difficult. Nevertheless, thanks for the suggestion, it will be incorporated into the construction of the Victory. Greetings

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.