-

Posts

354 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Pfälzer

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Don't worry, that's true. I'm currently building the San Martin from Occre, which is the same type of ship. I hadn't paid attention to it and only saw it when the decks were already glued. You just have to lay the deck to see if the offset is correct. The mizzen is attached there with a lateen sail. It is quite possible that this is why it has to be offset from the other masts. Greetings

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

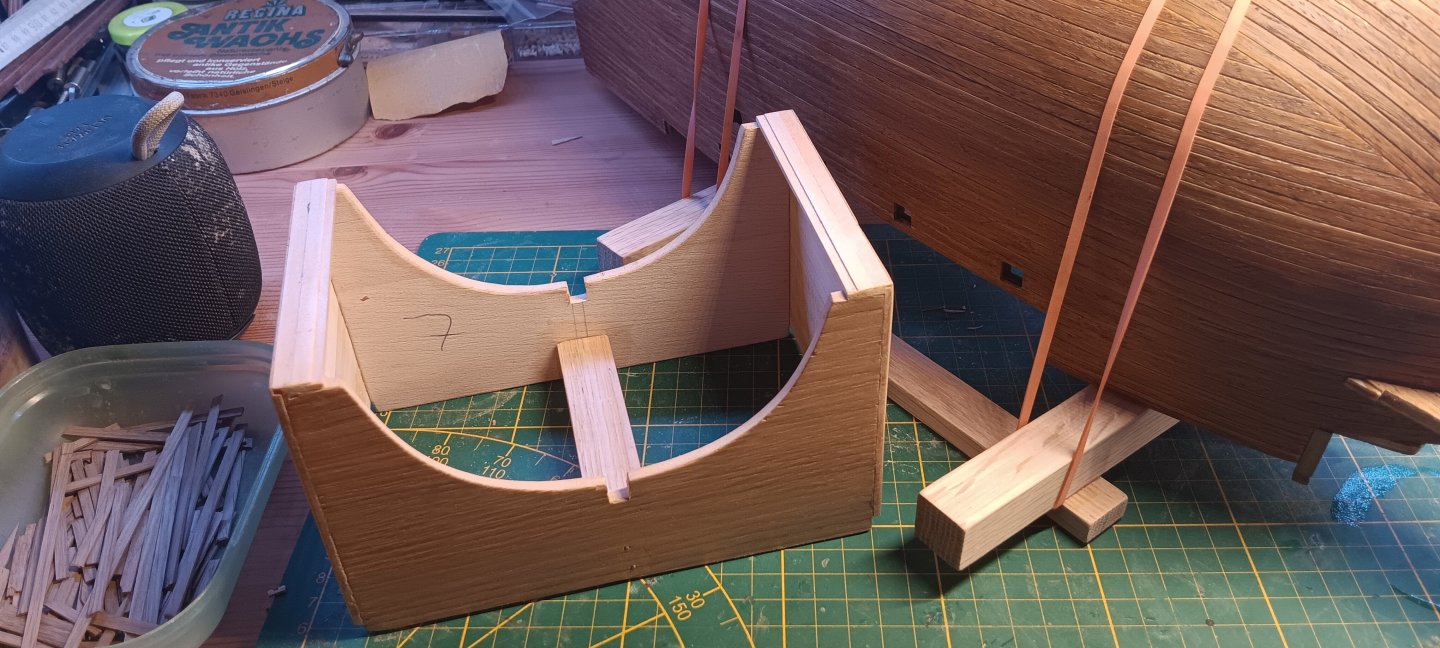

The hull is now planked, sanded with 600-grit paper and the first coat of stain applied. This is now allowed to soak in, then it is sanded again with 1000-grit paper and a second coat of stain is applied. This is because the stain causes the grain of the oak to puff up and the whole hull has just become very rough. I hope that the second sanding and staining will give it a nice vintage look, which will then just need to be waxed and polished. Translated with DeepL.com (free version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Hello lovelies, As you can see, I have decided to continue planking despite the error. Two strips later, frustration set in because the tension wouldn't go away. So I put the stuff in the corner and sulked for two days. Well, in the end everything went well. But I now see the whole thing in a positive light. Because I was able to learn how to get the tension out by rejuvenating a few strips. Above all, to find the point from where and how much to taper. And also good news. I bought a Victory from Corel in the bay for an apple and an egg. Greetings Translated with DeepL.com (free version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

San Martin by MikkiC - Dusek - 1:72

Pfälzer replied to MikkiC's topic in - Kit build logs for subjects built from 1501 - 1750

Witch Kind of wood you search. -

Hello lovelies, take a closer look at the photos above. The old scatterbrain made a mistake here. The first strip on the starboard side was easy to lay. With the fourth, I thought it would lay worse than the port side, but didn't think much of it. Then the big surprise after the fifth. I landed on the bow at the point where I had only landed on the port side with seven battens. The first problem was that I needed almost an hour to attach each strip to the hull, so the first four were of course bombproof. The second, more serious problem was that I used waterproof white glue. Soaking and peeling is not an option. In my opinion, sanding the whole thing down and redoing it would be just as counterproductive. So it stays as it is. I'm still a beginner in experimental mode, and no master has yet fallen from the sky. I'll be able to live with it and learn from it. Best regards Translated with DeepL.com (free version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Before more people get it wrong. The slats are currently almost in natural color. The only thing that has darkened them so far is skin grease and sweat from planking. I actually really like this color and would like to keep it that way. But unfortunately all the support boards are still to be added on the outside, and these are made of very dark walnut. So as soon as I've finished the starboard side, I'll stain the whole thing even darker so that the difference in color isn't too pronounced. Greetings Translated with DeepL.com (free version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Sorry Bob, but its still natural Knock, knock

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Thank you very much for your praise. But actually, I don't think it's such a big deal. Somewhere here in the forum someone had a problem with bending Birnbaum. The lovely Chris Watton, whose kit it was, advised him to just lovingly shape the tree with finger warmth. What can I say, it works with oak too, especially if you've grown up among oak trees. I only use good old Ponal (white glue) for this. In contrast to superglue, you can still slip this for some time. Then everything is fixed with self-made wooden clamps every two to five centimeters. Screw clamps are used where this is not enough. The only trick is not to use too much of the glue, spread 3/4 of the strip width with a wet bristle brush. If any glue leaks out after clamping, wipe it away with a mini spatula. Once the glue has hardened, use the same to smooth the edges again and clean them with a brush. Then an hour has passed and it's time for the next one. By the way, I taper from the first point of the fuselage bend by a quarter of the moldings' width towards the bow, and so far I see Translated with DeepL.com (free version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

And another night with little sleep, good morning . As you can see from the pictures above, the experimentation continues. Firstly, I don't really want any chemicals on my boat and secondly, my admiralty is panicking that this build will end just as quickly as the last ones. Which would mean that I would have to spend money on a new kit again. There are no brass etched parts in this kit except for the rudder hinges. Fortunately we are saving everything, so I still have some left over from the Esmeralda to build the gun mounts. So I did a little research and found some ways of aging brass with home remedies. The thing with the zinc and red wine also worked, and it also works with white wine (Kerner Spätlese from the Einselthumer Klosterstück). Here I have now tested the vinegar vaporization variant. To do this, you take an airtight container half filled with vinegar, in this case a good Melfor. Place an elevation in it on which you place the goods to be treated. The resulting vapors will then color the brass within a day as you can see above. A trial with salt and water is currently underway, the results will follow in a few days. Have a nice day Translated with DeepL.com (free version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Hello friends of well-kept wood. Since I'm still in the experimental phase, I'm going about this build a little differently. On the last two ships I installed the keel before the planking. Here I thought I would test the Occre variant. It doesn't work too badly, just installed dry. Let's see, maybe I'll even use the plywood version from the kit instead of an oak replica. Greetings

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.