-

Posts

385 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Pfälzer

-

So, orle, ihr Lieben, jetzt braucht er euren Rat. Ich habe zwei Stunden damit verbracht, meine erste Seilschlaufe zu binden. Die erste, größere, ging gleich wieder auf. Ich fand sie zu groß für den Maßstab 1:90. Also habe ich eine kleinere gemacht. Die mir jetzt fast zu klein vorkommt. Lasst mich bitte wissen, was ihr davon haltet. Liebe Grüße

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

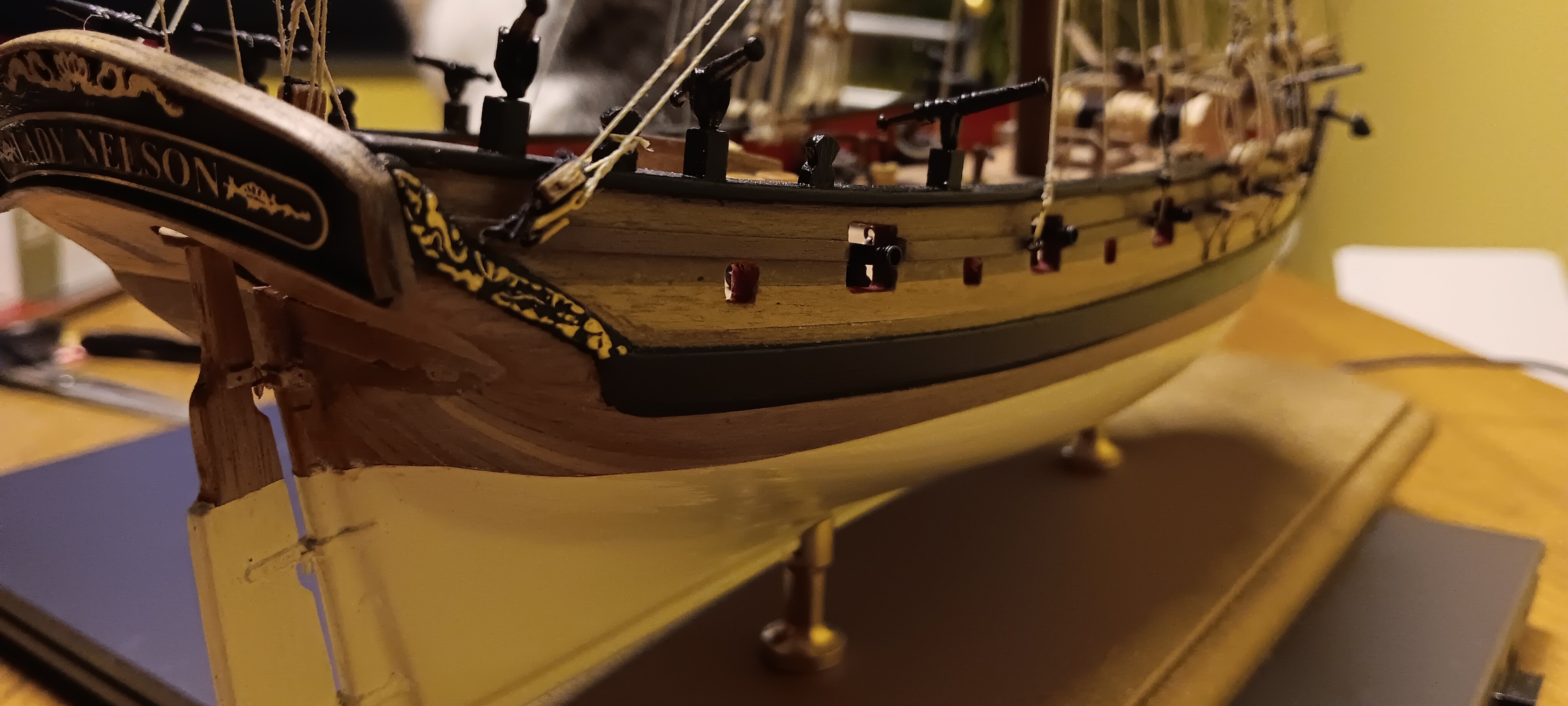

Of course the good lady will be refloated, it's not that dramatic. I've already found a safe place for it in a display case in one of our branches. After painting the frieze details in black, I simply sanded them off with 1000 grit wet sandpaper.

- 8 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Schlechte Nachrichten, das gute Stück stand die ganze Zeit auf der Fensterbank, zur Freude meiner Nachbarin. Nur unserem Hund war es immer im Weg, wenn es darum ging, Leute durchs Fenster zu zwicken. Tagsüber dachte ich, das sei wohl ein schlechter Platz. Naja, zu lange überlegt, heute hat der Hund es ernst gemeint. Sie sieht zumindest so aus, als hätte sie ein schlechtes Gewissen.

- 8 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

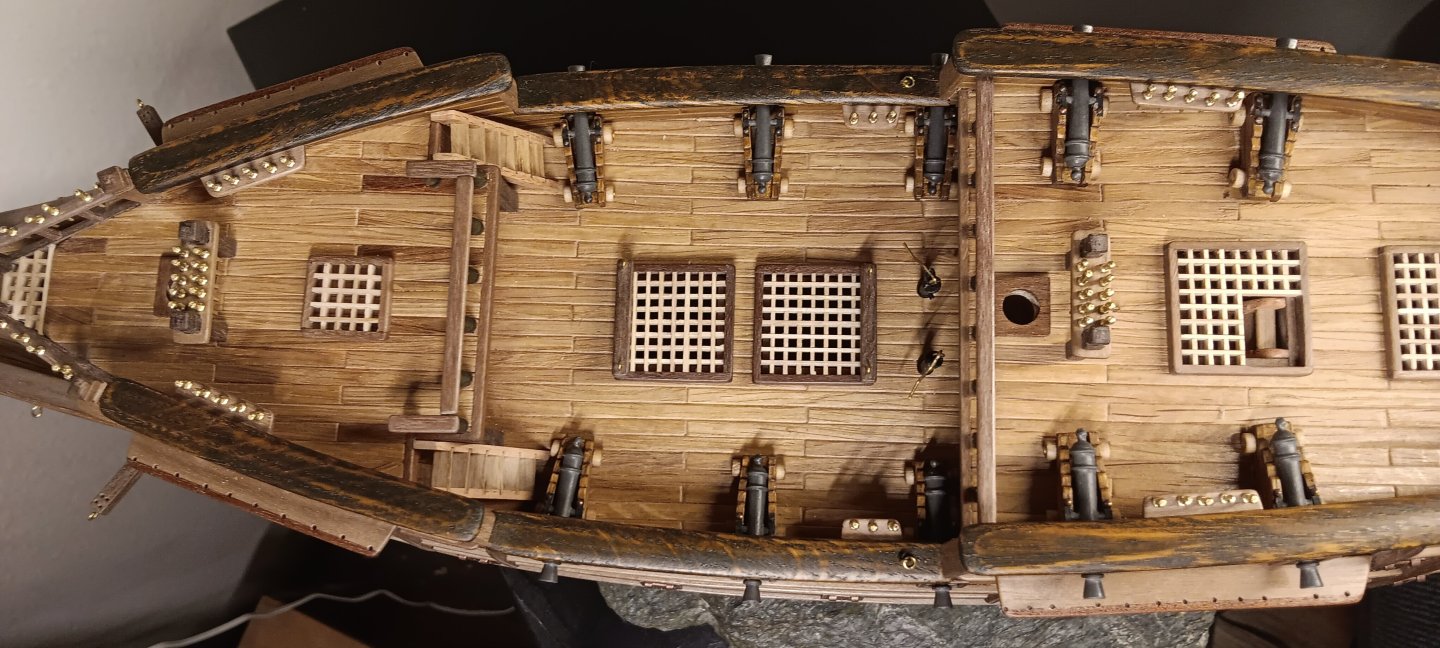

So, ihr Lieben, das Boot ist nun kampf- und wassertauglich. Jetzt gilt es, es segeltauglich zu machen. Auf die Geschütztakelage werde ich wohl verzichten müssen. Als die Schanzen angebracht waren, dachte ich, ich sollte die Löcher für die Ösen bohren, bevor ich den nächsten Schritt machte. Nach dem nächsten Schritt dachte ich, oh, ich sollte die Löcher bohren. Nun, anscheinend habe ich das oft gesagt, denn als ich die Kanonen auftakeln wollte, hörte ich mich denken: ****, da war was mit Löchern. Deshalb machen wir Fehler, damit es beim nächsten Mal nicht wieder passiert. Na dann, ich muss Masten schleifen, tschüss Übersetzt mit DeepL.com (kostenlose Version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

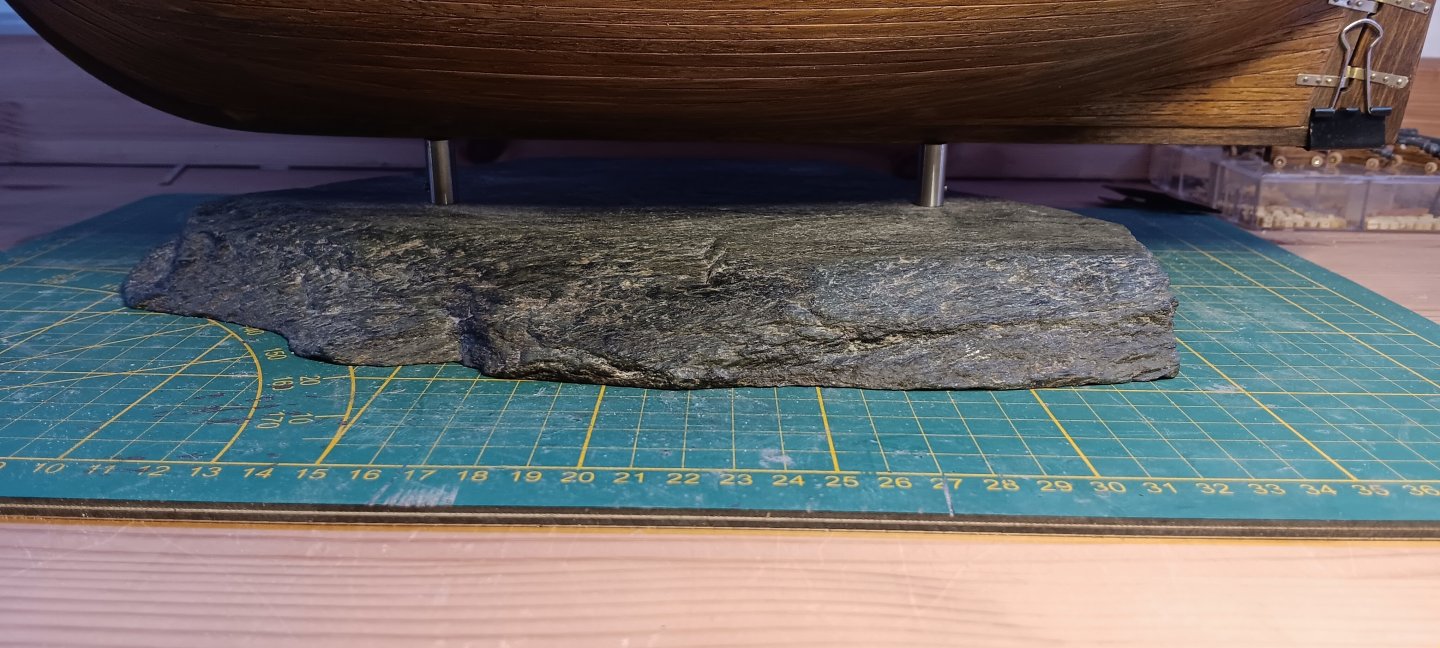

Hello lovelies, I would like to explain the stand in more detail. It's made of soapstone, which I found about thirty years ago at a rubble dump. In our wild years it was used for chopping various powders to party the night away. Then it was used as an ornament on one or two cupboard shelves and now fulfils a very useful purpose. I had to drill two three-millimetre holes and fill them with walnut dowels to install a nameplate holder. Small problem, unfortunately I measured the original pins of the holder and didn't realise that the actual hole in the holder is 4mm. Not dramatic, the ship is not yet fixed, the holder is temporarily lined with adhesive tape. I'll have to look into getting a 4mm brass tube in the next few days, which I can then use to level out the discrepancy. Have a good Sunday Translated with DeepL.com (free version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

Yes, the mounts are too high. But that's because I planked the deck thicker than Occre intended. I think simply wedging underneath would be the wrong way to go. There is still room for manoeuvre at the bulge for the gun, so it will be a smooth mount instead of a curved one. Stupid, because I've already spent days preparing and ageing it. But that's the way it is. I also didn't want my current intestinal upset and have to live with it.🤣 Greetings

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

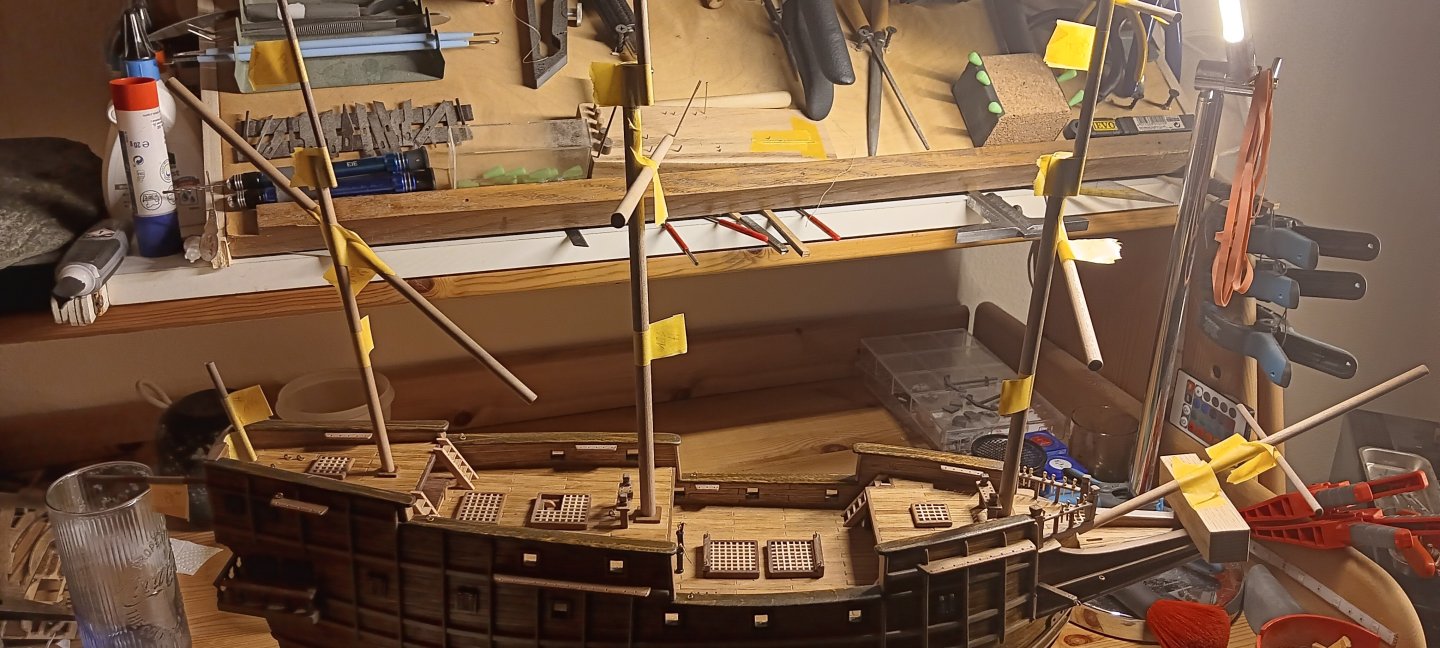

Hello everyone, a short summary. There was a small problem. When I was assembling the skeleton, I forgot to sand a bevel for the transom at the stern, which I first noticed when planking the deck. As a result, the transom moved about 2mm aft, I didn't think much of it and compensated with a cross moulding. This came back to haunt me when attaching the mouldings to the hull. There's a gun port in my way where the pütting comes from the main mast. As I had started to fit the mouldings aft, I realised this too late to change it, it would cause irrevocable visual damage to the hull by mortising the mouldings. So I didn't make the mouldings up to the counter in that area. I will hardly notice it, as the shrouds run along there. When I wanted to continue on the starboard side, I realised that I didn't have any more material. I hadn't really checked this beforehand as I still had two mouldings left over from the Esmeralda. Due to the thicker deck planking, I had to use them for the deck framing of the gratings. Now I still have exactly the amount I need, but not in one piece and in three different colours. So I decided not to order more from Occre, but to order 10 metres of it, which is always good if you have enough. At the same time, I also ordered the pole dowels in walnut, as the shipping costs have to be worth it.Daher habe ich begonnen Geschützpforten und Fenster zu installieren bis das Material eintrifft. Grüße an alle Translated with DeepL.com (free version)

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

-

- 210 replies

-

- San Martin

- OcCre

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.