-

Posts

236 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Desertanimal

-

The first planking is the dressed rehearsal for the second layer of planking. Once you are sufficiently adept at bending the planks fit the fit layer you will just fine tune that fit the second layer. You want the planks to sit in position without having to push or pull the hold them in position. Once the dry fit looks good use a few drops of medium CA glue and you’re off to the races!! I would say to look at several build logs to get what I mean. looking good! Chris

-

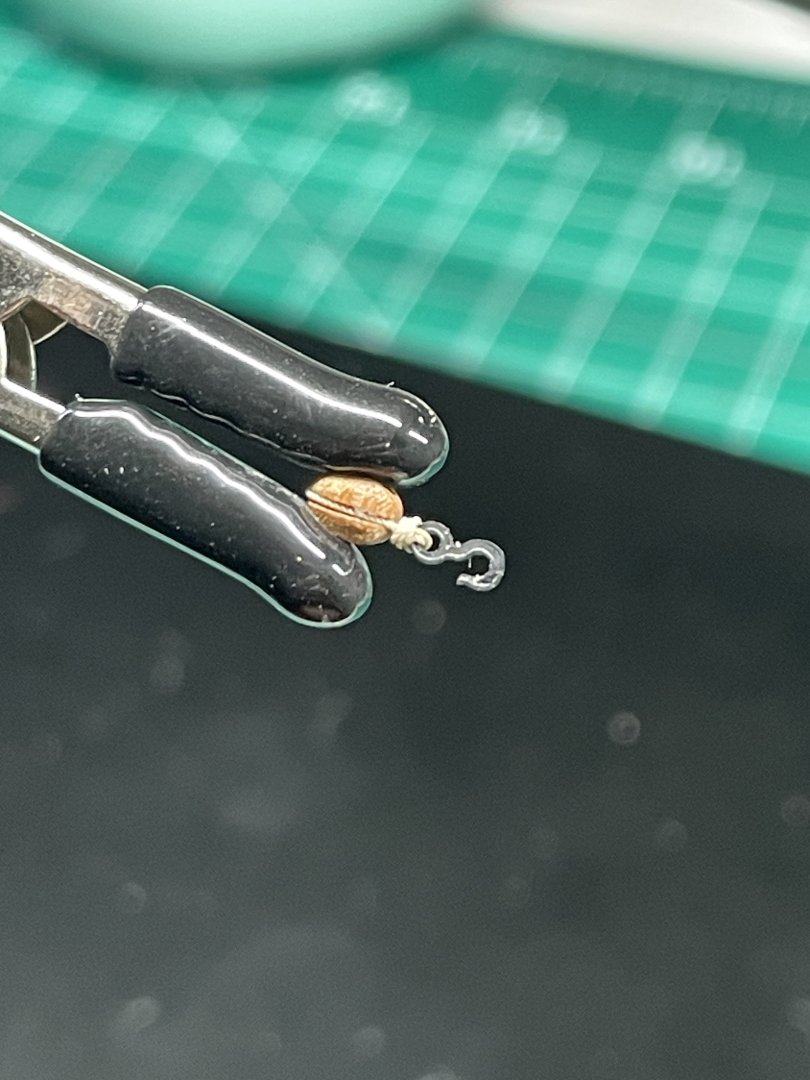

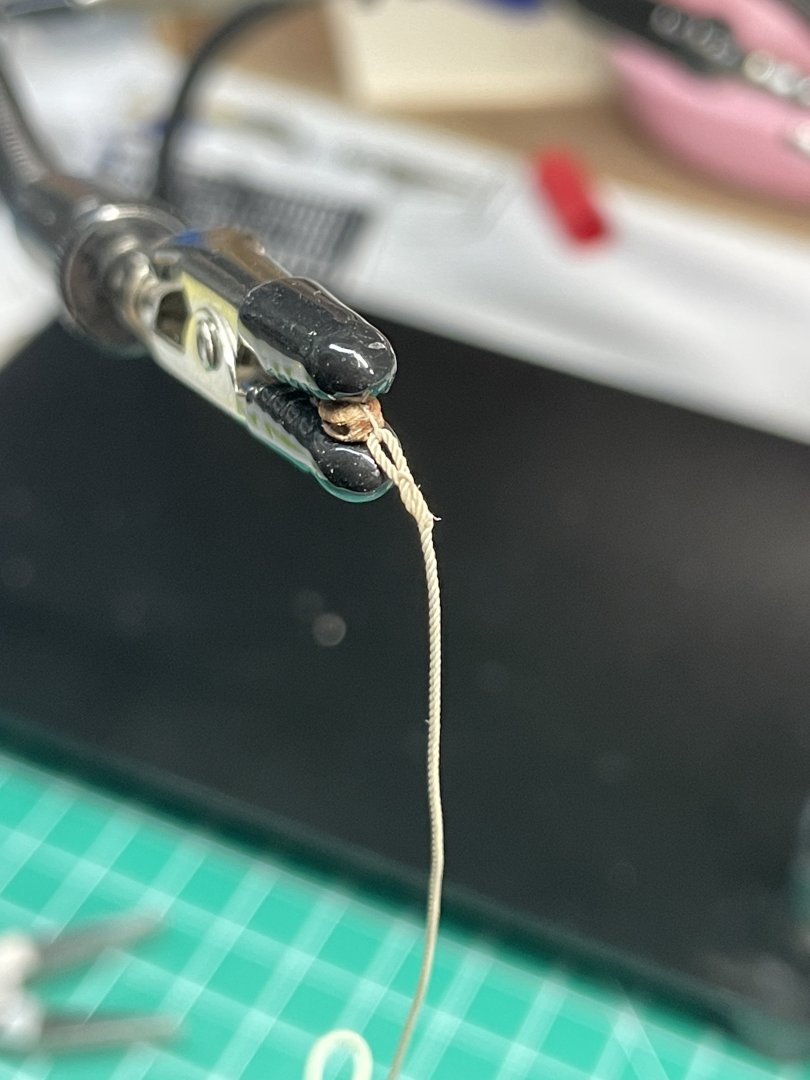

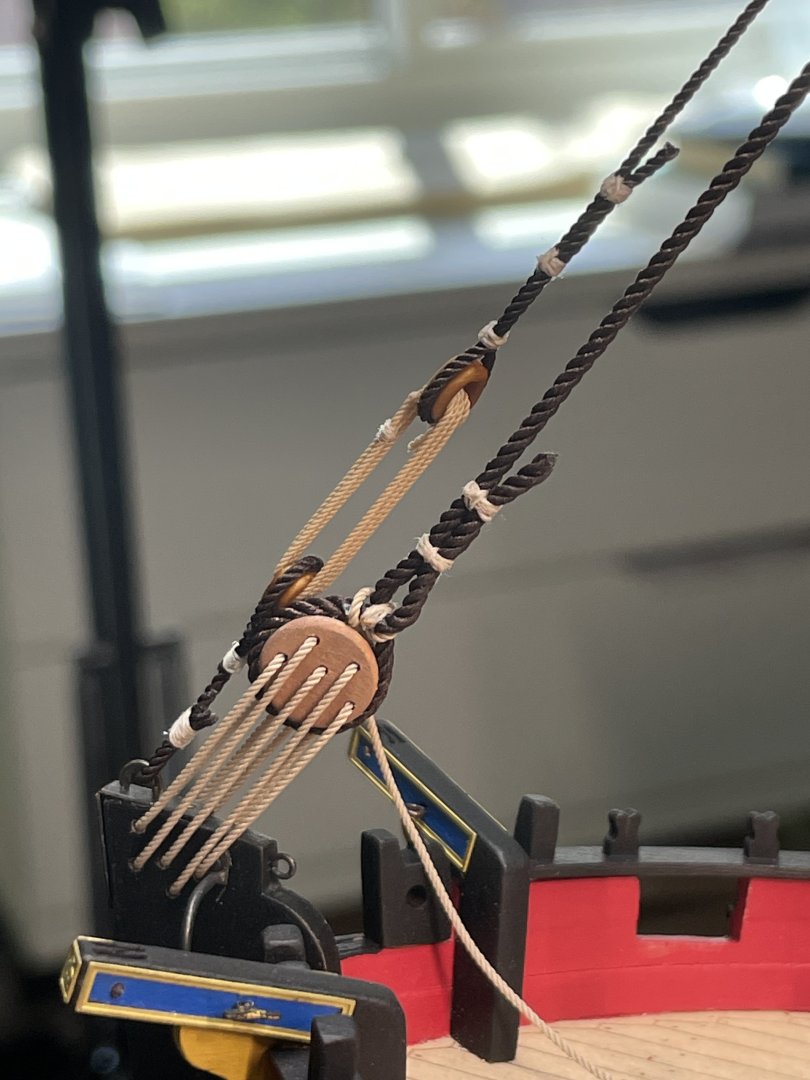

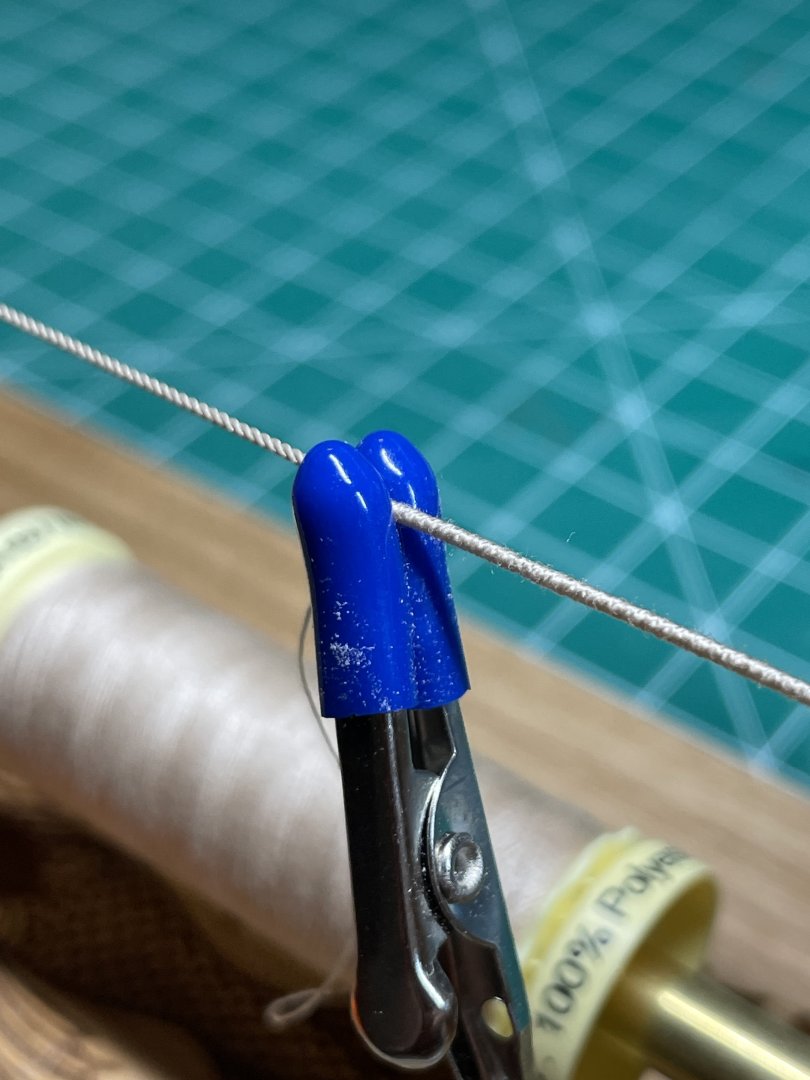

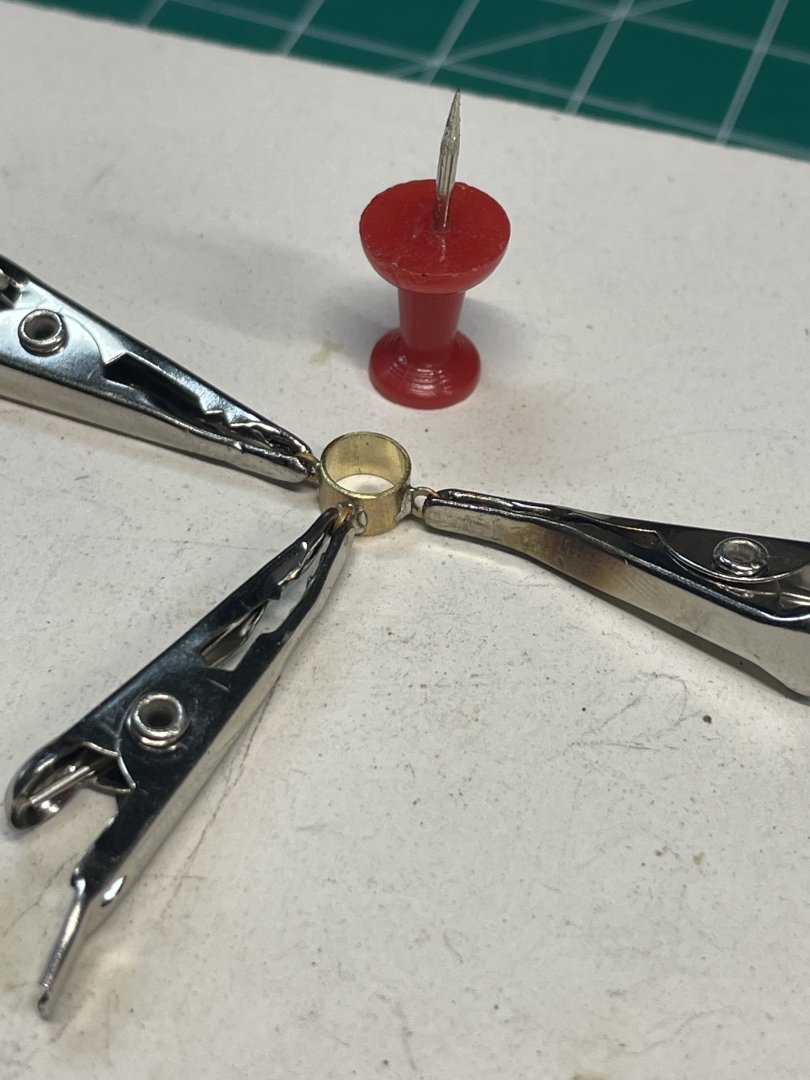

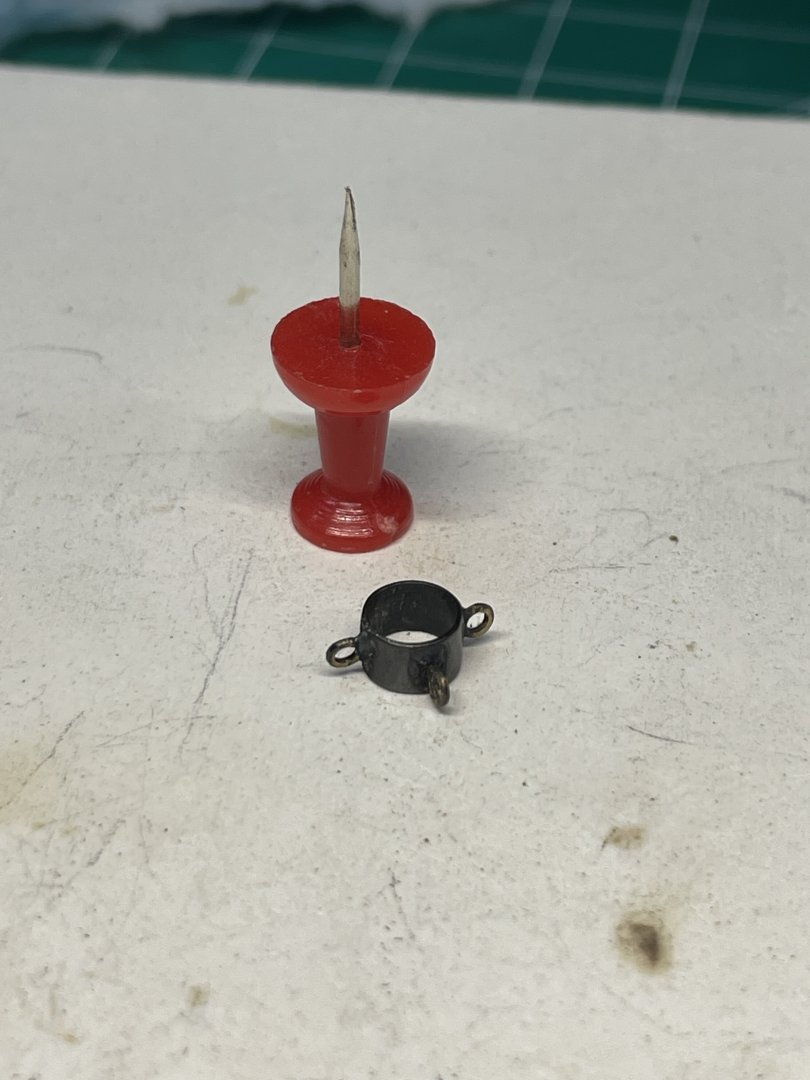

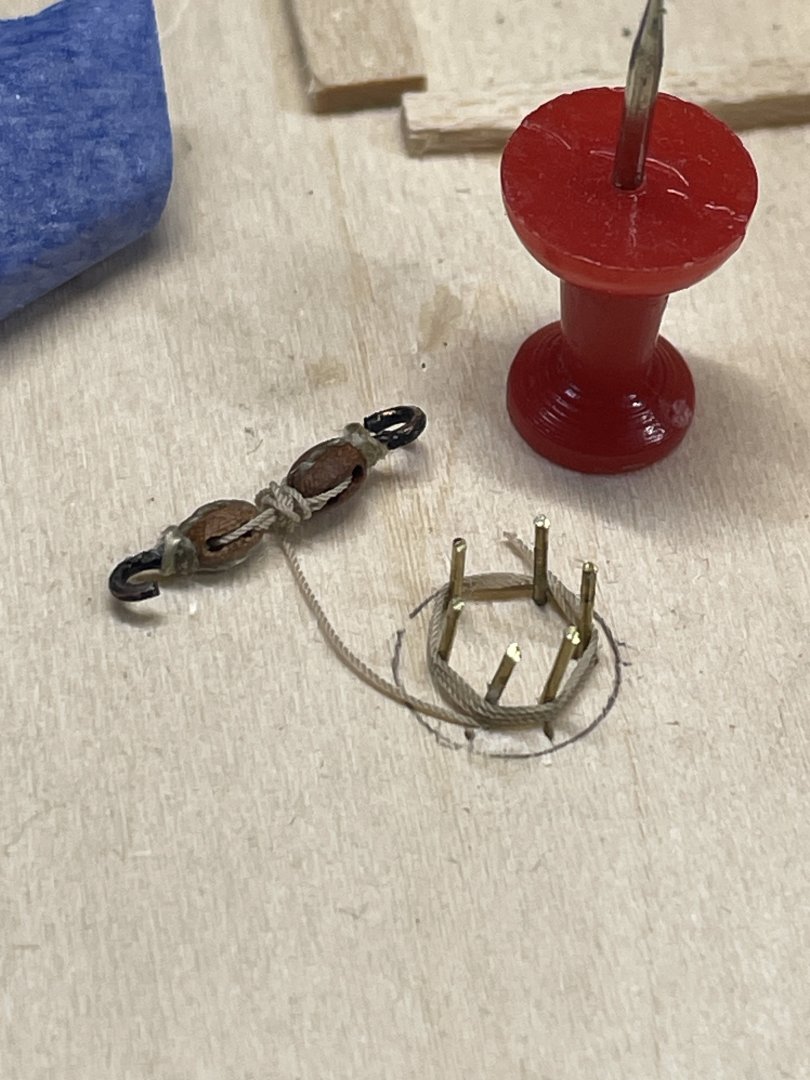

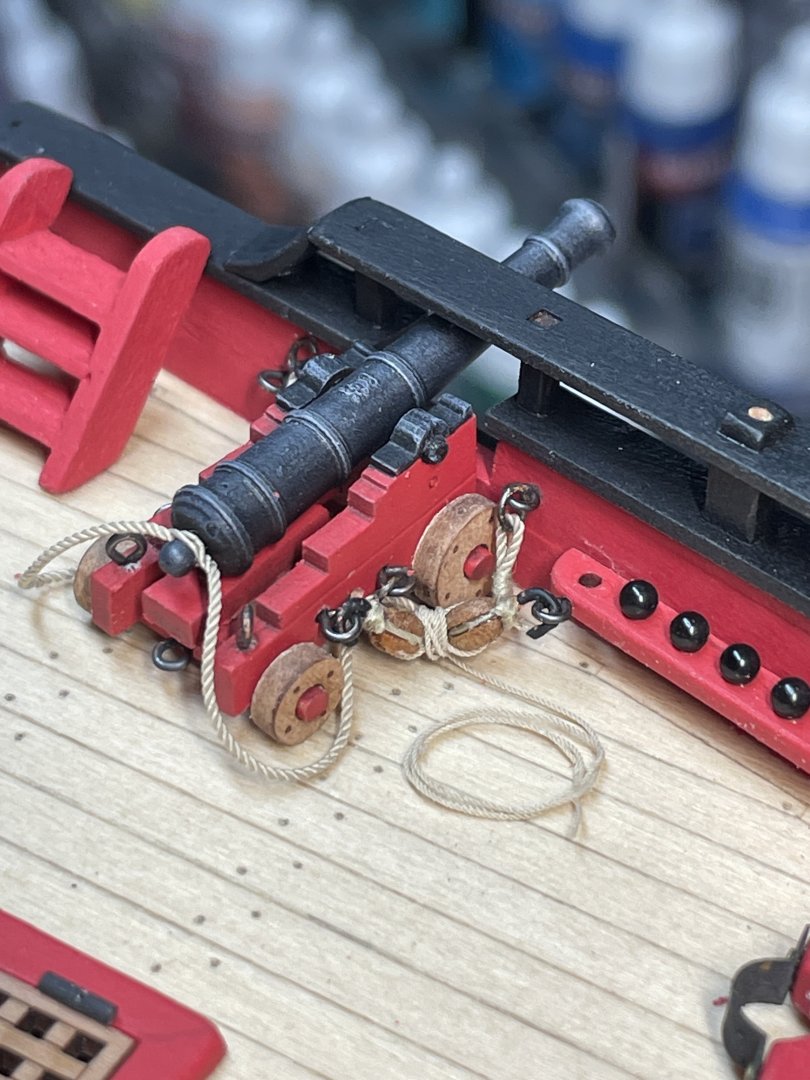

Thanks for the likes! Time to work on the backstays. Seems there are not only many ways to do it, there is no consensus on how it was done on Alert. So again I default to those who have gone before and did them as @Thukydides and @Blue Ensign, I had purchased some violin blocks but they were way too small. So I needed to make my own. I also needed to lash up some blocks with hooks and the circle thing. Is that called a thimble? And here is the result of the backstays. Next I made the mouses for the main stays. I guess I didn’t take a finished photo of them… Here is the tackles up front. I was really itching to play around with the anchor ropes. I got cable laid rope and it looks so cool I just couldn’t resist at least getting an idea of how I wanted it to lay. This isn’t the final position but I was getting ideas. Lashing these together was a chore with so much stuff in the way. Thanks for checking out my build. I appreciate all of you guys! Chris

- 38 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

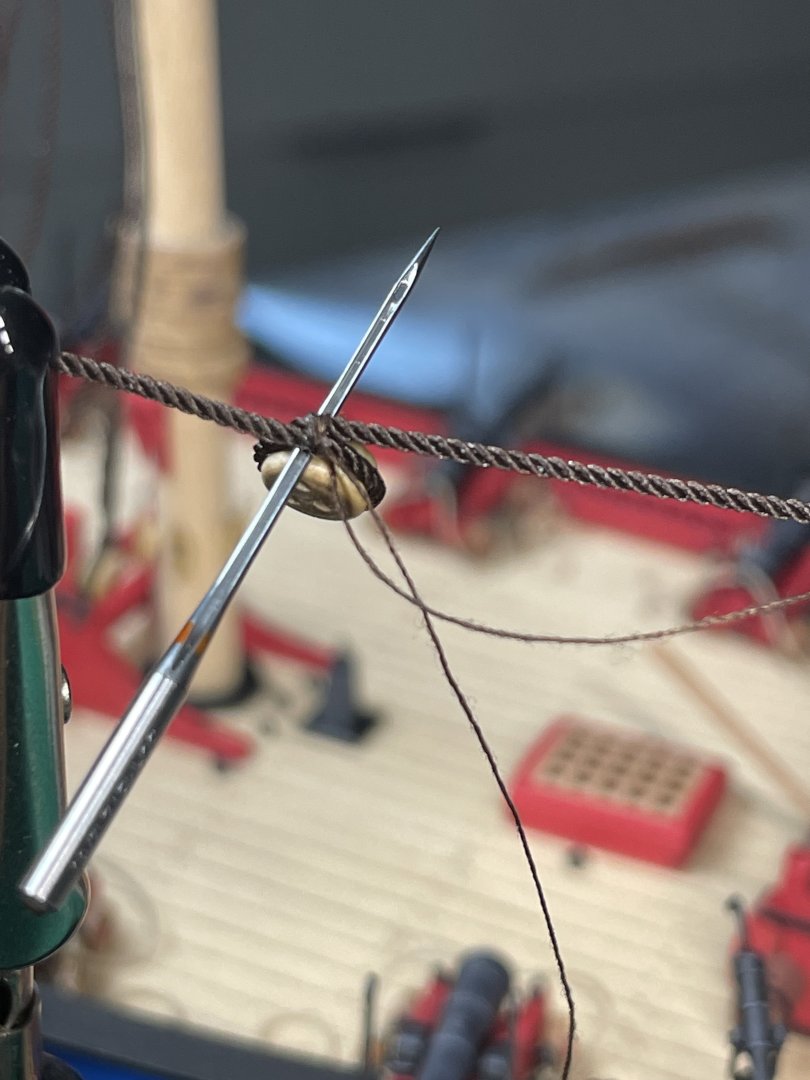

Thanks to everyone still hanging on. Work has been slowly progressing. OK time to work on the shrouds. I used some bent paperclip wire to make a jig to hold the deadeyes at a consistent distance. Then I put a dab of CA at the bottom of the deadeye. Then I used a sewing machine needle to pull the tiny thread under the crossed ropes. I think I did it four times. Finish with a dab of CA then a quick wipe with a finger. Then pull the end up and finish the seizings. Then I tied on some shroud cleats from Syren. Looking at the photos now I’m thinking I should have spent some more time sanding them and giving them a little more roundness to their shape. I must have thought they looked good enough at the time. Then on to the tackles. These were a little fiddly to work through but I think the end result is very rewarding. It adds a great look to the boat. This is my first time doing them. I am pretty happy with how they look. I experimented with a few ways to tie them off. I looked at build logs and the Peterson book Rigging Period Ship Models. I completed one by itself. Once I was satisfied I did the rest all at the same time to keep them looking consistent. A few times it looked like a tangled mess, but it turned out ok. Slow and steady is always the answer for me, although sometime I forget the question… Thanks for checking out my build. I’d love to hear what you think! Next up is the conundrum of the backstays! Chris

- 38 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

CA (cyanoacrylate) "super glue"

Desertanimal replied to Dr PR's topic in Modeling tools and Workshop Equipment

This is exactly what I do. Of course I pretty much have zero humidity in the air. -

That sounds like pretty good news! Good to hear. Sending you lots of good thoughts! Chris

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

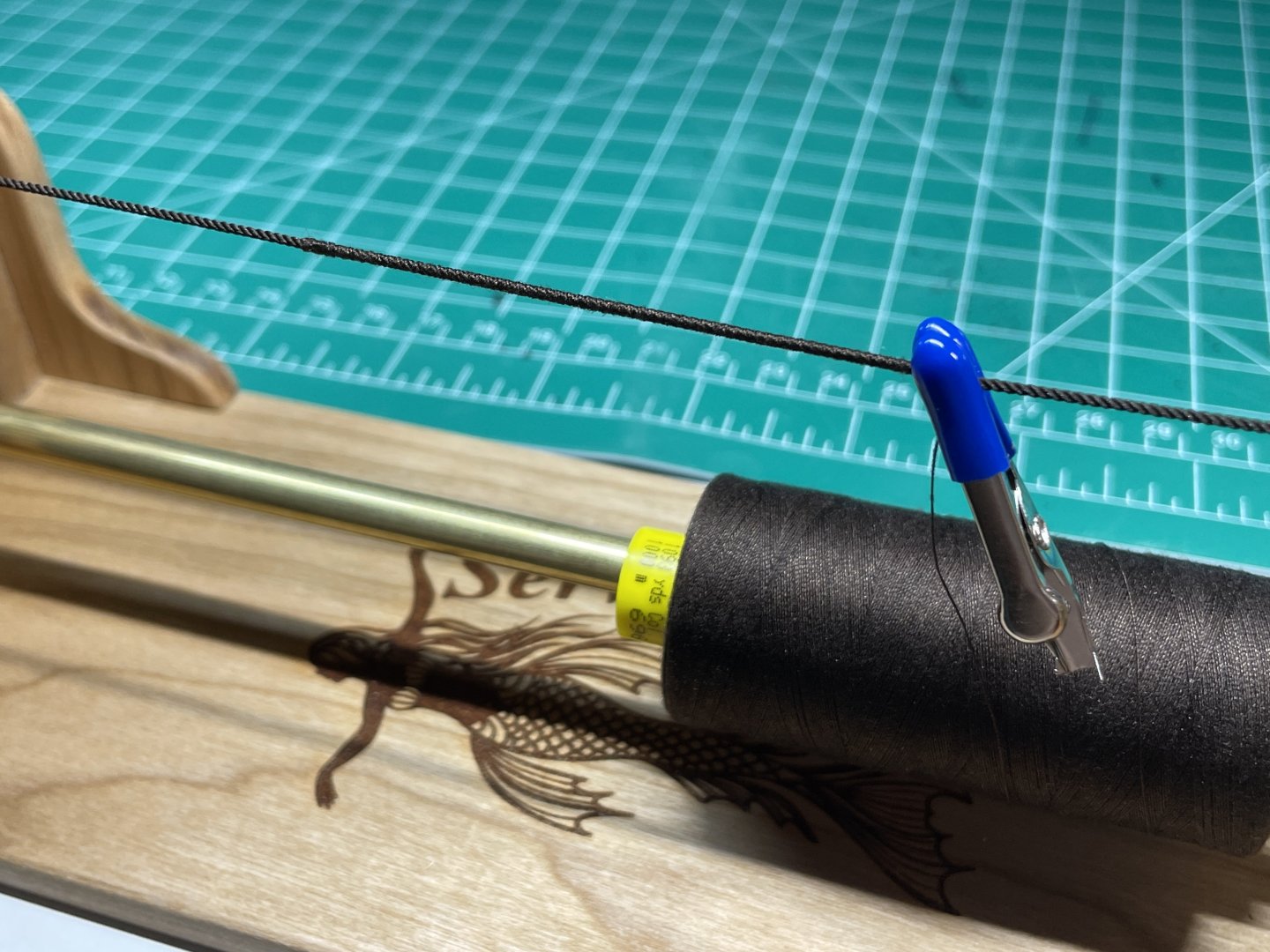

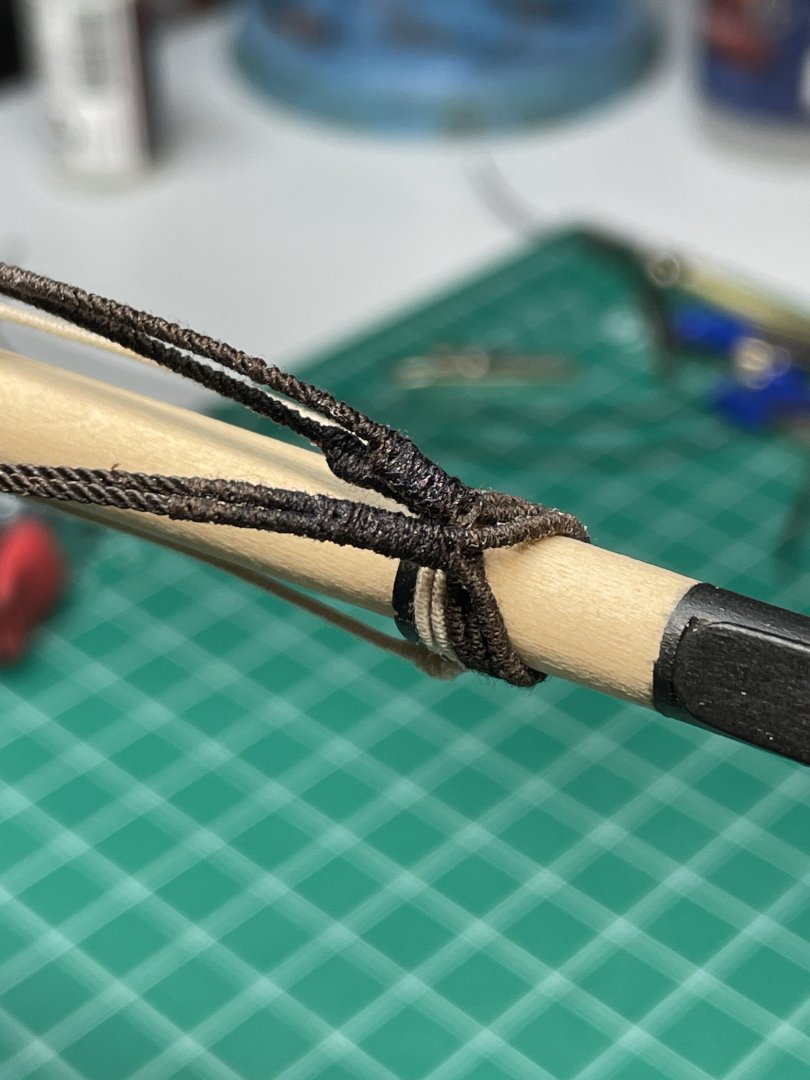

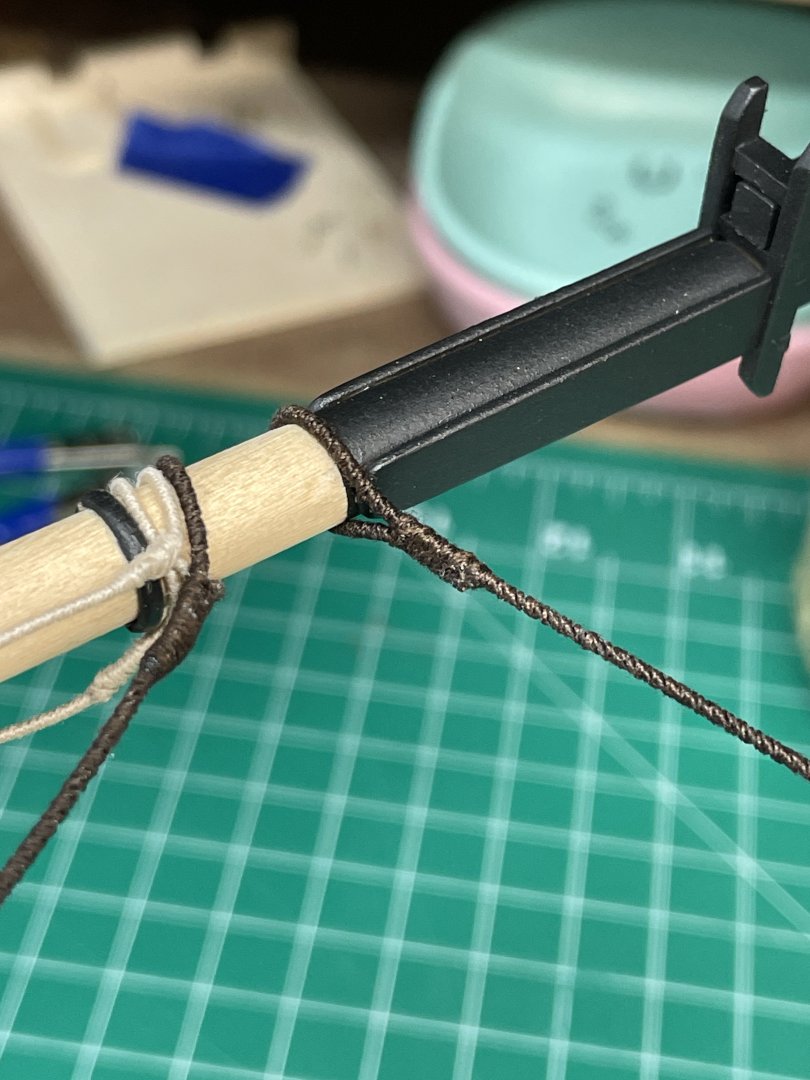

Hi everyone following along! I’m still here. Things got a little side tracked with a big welding project that made a mess of the garage. Well that meant I need to clean up where I’m trying to work. Well, that turned into “this garage really needs a good clean out”. Then I said “hey I have room for a new welder”, then I needed to run a 240v circuit for the new welder…So I’ve been busy. Now that you are caught up on my goings on, let’s get caught up on the build. Its time to work on the shrouds. We are in brand new territory for me with all this rigging. As I’ve stated previously I’m just going to go slow and try to follow some other builds. I believe I pointed this out earlier, but it begs to be said again. Don’t complete the top of the mast before putting the shrouds on. It will make your life much easier. At least this part of it. As my mast was complete I had to serve the shrouds in place. I leaned my vice way over and had the mast mostly horizontal in order to do this. Here are some photos of the serving of the ends of the shrouds. This is how I spliced the ends of the thread in. I would pull the thread through twice. Then a dab of medium ca and a quick rub with my fingers. Here is some of the manual serving done around the mast. A little explanation about the white pendants. They were my practice pieces for both serving the length on the machine and serving around the mast while in place. They are not the best work, and they historically probably wouldn’t have looked like that. But they were my first tries and I want to always know that. So that is why they are there. It was quite interesting to see the progression of the “quality” of the serving after only this many. I would sometimes try something a little different, like change the angle of the needle or such. Some things helped either in quality or being able to do it faster. Others not so much. LOL Finally, here is a glamour shot of her so far. I am quite happy with how she’s looking. She lives in an Ikea cabinet to keep dust at bay, once the bowsprit is on I don’t think she’s going to fit. Thank you all for checking in!

- 38 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

You and Maggie are in my thoughts. Best of luck with these issues! Chris

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

Looking for ideas for work area

Desertanimal replied to Desertanimal's topic in Modeling tools and Workshop Equipment

That is an excellent idea that I completely missed out on! The funniest part is I have a desk like that in my office! That will definitely be added to the room. That makes a lot of sense as assembly, light woodworking table. Chris -

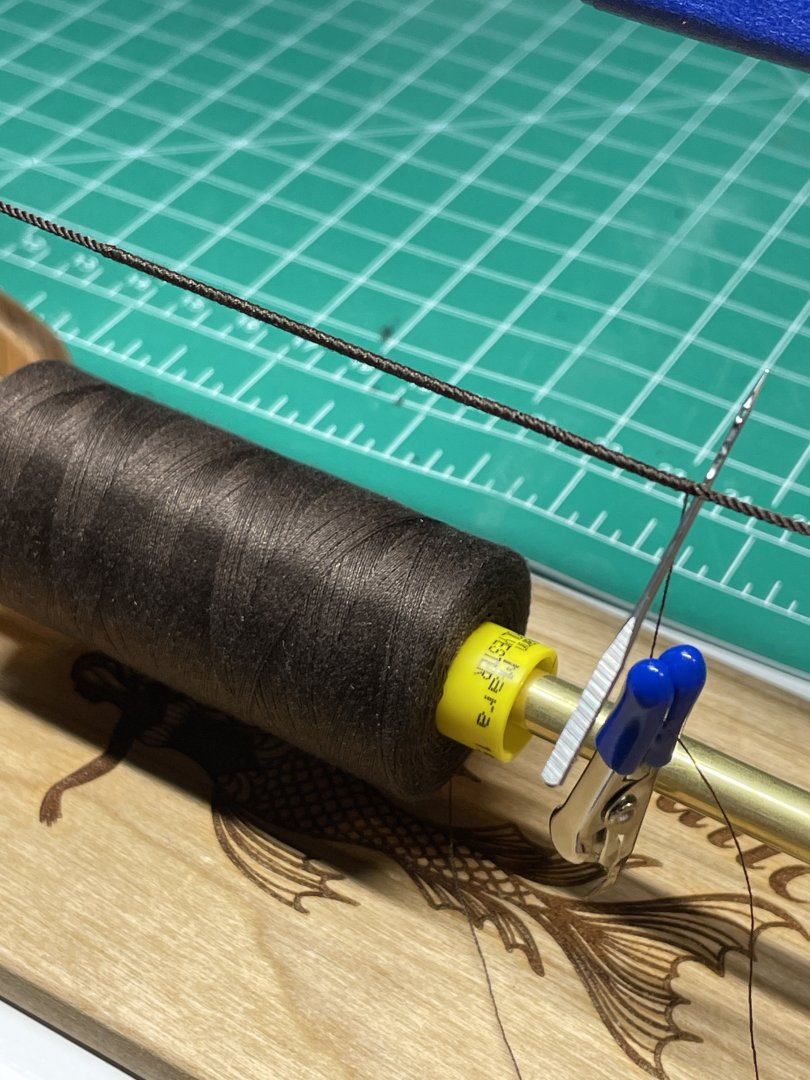

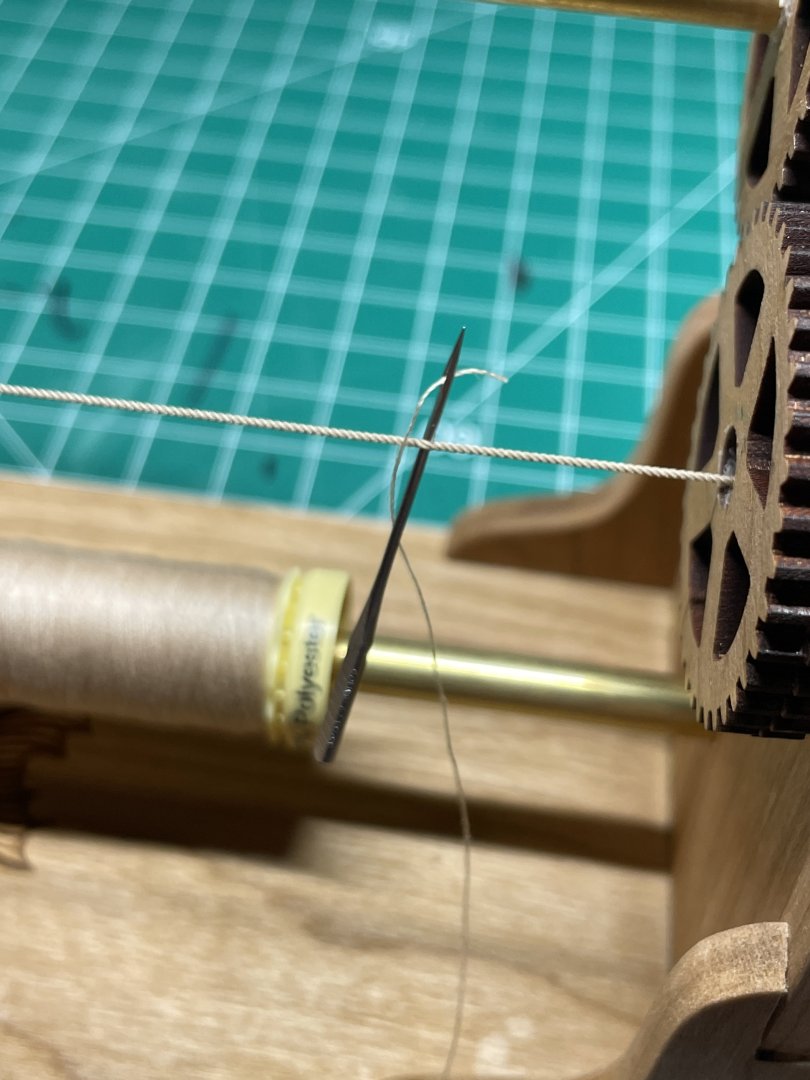

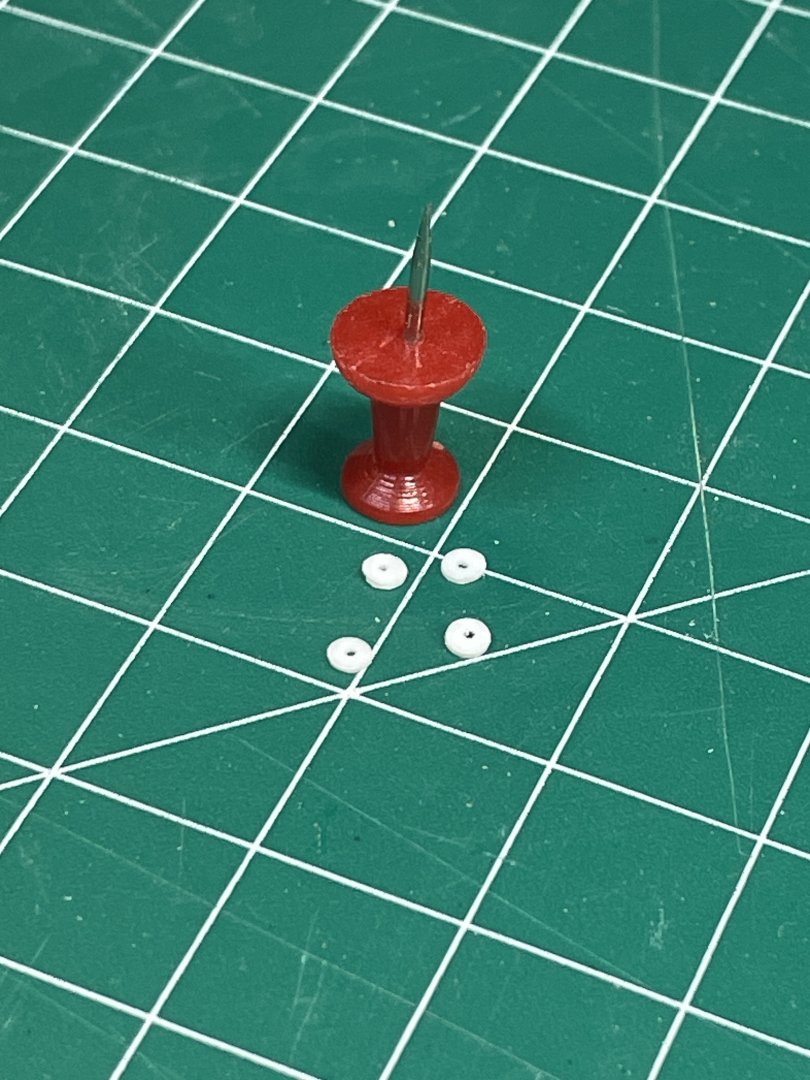

So time to learn to serve! I decided I’d set up the machine and try it. It worked really well, not a surprise. I served up what could be a pendant if it’s usable. After playing around I watched a video and learned I should have done it left to right, while I did it right to left. The mast is together but not secured in the deck. I needed to come up with a plan to serve the shrouds on the ship. I again tried with the same pendant. I looks ok to me. We’ll revisit those later. I next wanted to make a band with the rings on the tip of the bowsprit. I used some brass tubing that happed to be a perfect fit and some photo etch eye bolts. I also made the bracket for the bowsprit from scratch. I can never get over how brutal close up photos are! Now I was faced with a dilemma. I didn’t add any sheeves to the catheads and I am pretty sure I want one of the anchors hanging as in other build logs. So I simply decided to get going on them. Mask the rest of the ship and see what happens. I drilled them and then used a scroll saw blade held in my fingers. I pretty much used that to shape the slots and then used a strip of 220 sandpaper to clean them up. I used some round plastic stock and after drilling I sliced off several discs until I got 4 I could work with. Squared them up but sanding under my fingertip. I inserted them and pinned them in place. Then some Vallejo flat black paint. I am pretty happy how these turned out. I will find out how they work when I get to the anchors. So that’s it for now. A lot more serving in my future! Chris

- 38 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Looking for ideas for work area

Desertanimal replied to Desertanimal's topic in Modeling tools and Workshop Equipment

Those are some great points. Thanks! The room also abuts the garage so I will probably be based on that wall. That will allow me to put dust collection and run air for the airbrush from outside the room. I am really liking the idea you guys have brought up about mobile tables. 👍 Chris -

Looking for ideas for work area

Desertanimal replied to Desertanimal's topic in Modeling tools and Workshop Equipment

Thanks for the ideas! How large are the various tables? -

Looking for ideas for work area

Desertanimal replied to Desertanimal's topic in Modeling tools and Workshop Equipment

Good point! Basically 10 feet by 12 feet. It’s a bedroom in the house so no heavy machines. -

Looking for ideas for work area

Desertanimal posted a topic in Modeling tools and Workshop Equipment

So I’m going to be able to build a personal shipyard from the ground up. So I’d like some opinions on what you would do. Here’s the scenario, East wall has a window two other walls clear. I don’t generally work in the mornings so sun coming in the window isn’t a big concern. However, I’m thinking about backlighting while working on a model being a problem. I’ve got nice windows that are supposed to stop UV and such but who knows. I could also put the worktop on either of the other walls. What do you think? While I have always liked the idea (maybe the look also) of a countertop sort of work top with lower cabinets to either side of me. However lately I’m thinking of a peninsula work area so that I can get around to other sides if needed. Then when sitting at this desktop, that would put tool storage 90 degrees to my right in some sort of cabinets, maybe upper and lower kitchen cabinet style. I don’t know if that is optimal though. I like to have current tools I’m using laid out in front of me. I suppose that doesn’t really prevent that. Just sort of spitballing now, if you couldn’t tell. Lol I’m pretty sure I’d like drawers or doors in the cabinets instead of open shelves. This would be to keep dust off of things. Flooring- Wood, light color, not too much color variation. No seams to swallow tiny parts. Any ideas you’ve got to add? What sort of things do you wish your shipyard had? Thanks for reading if you made it this far! Chris -

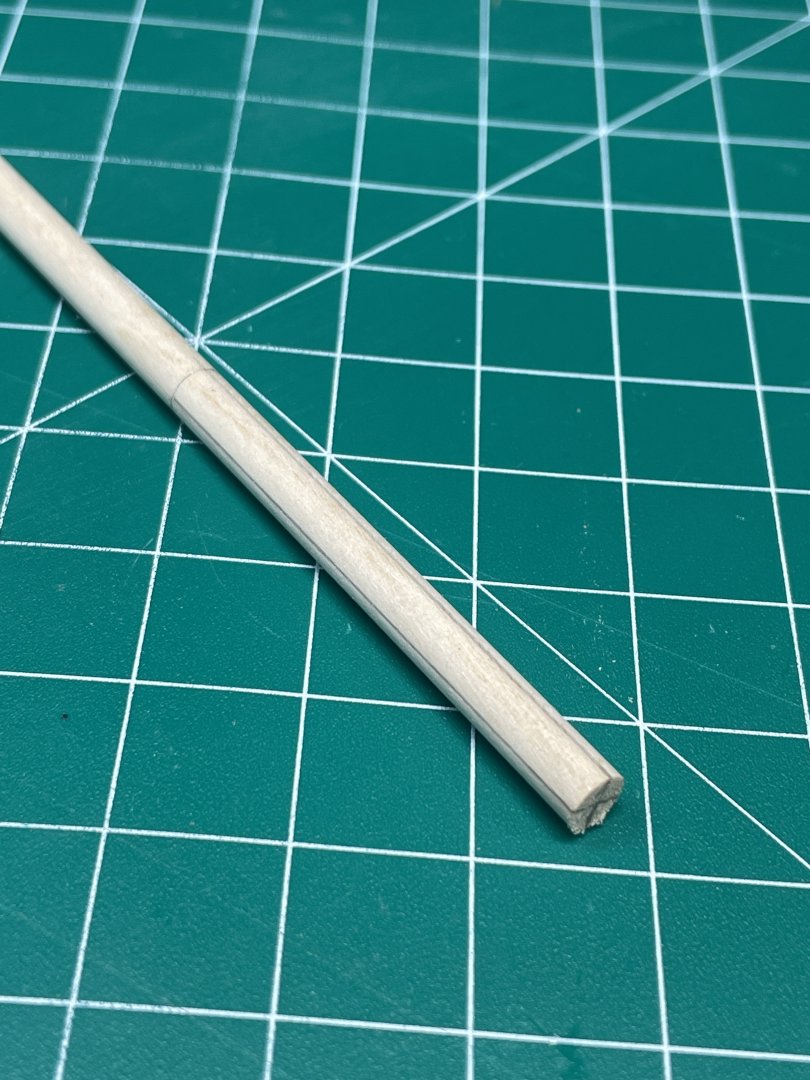

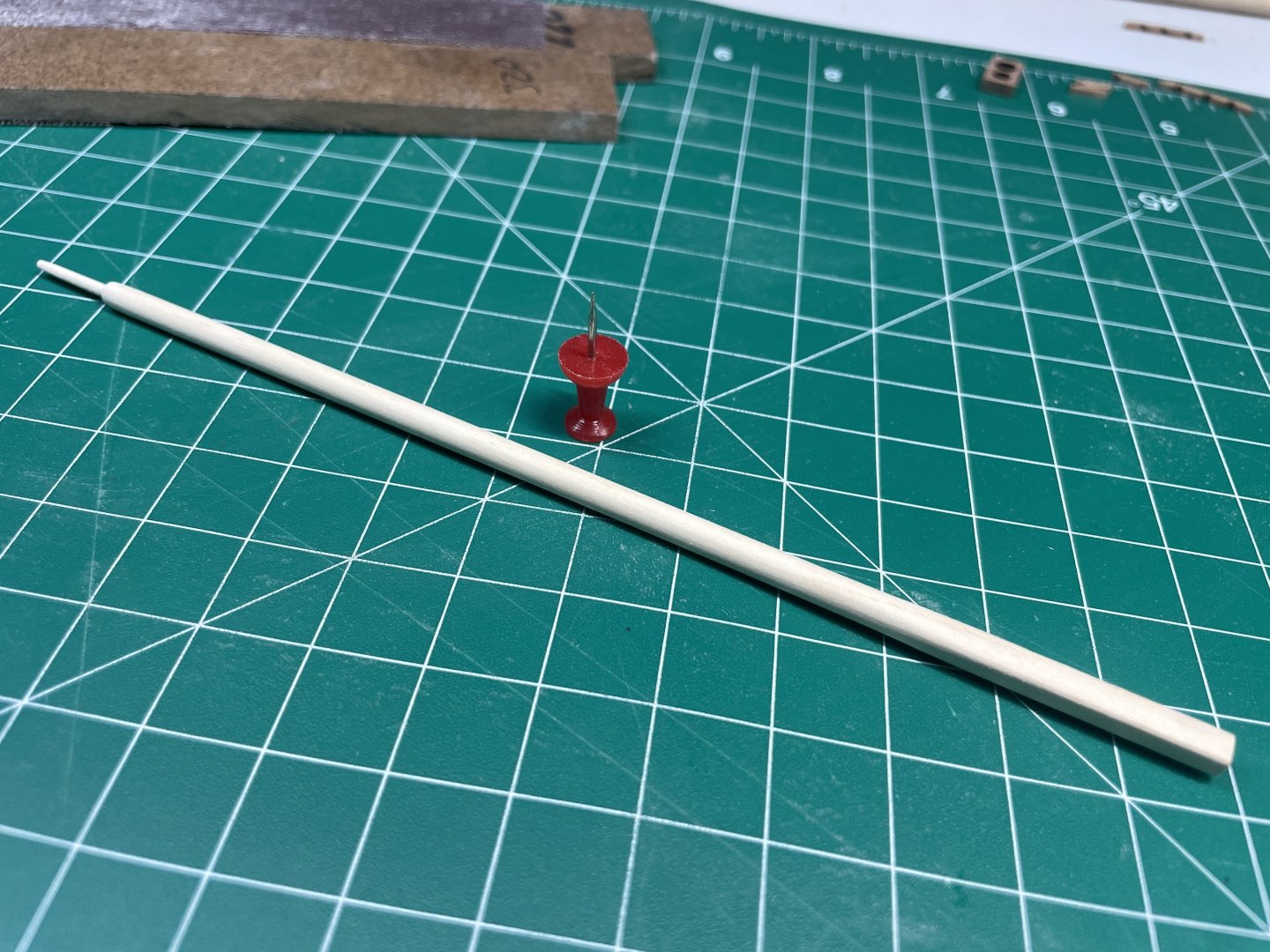

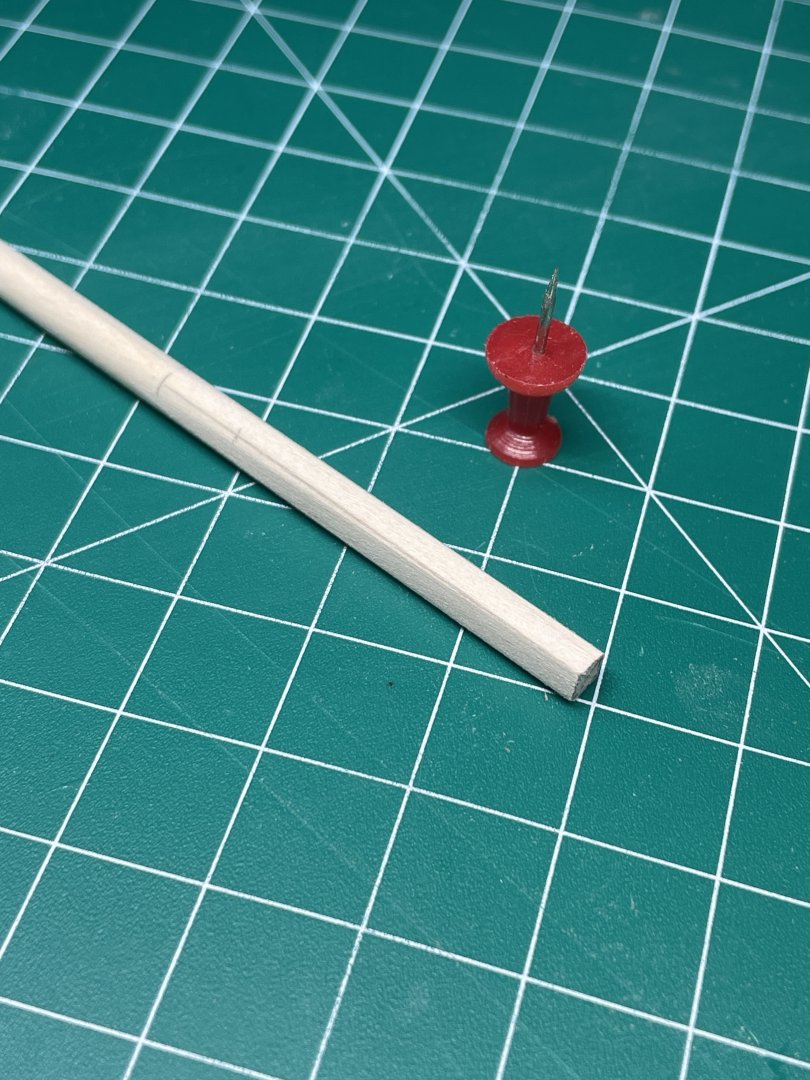

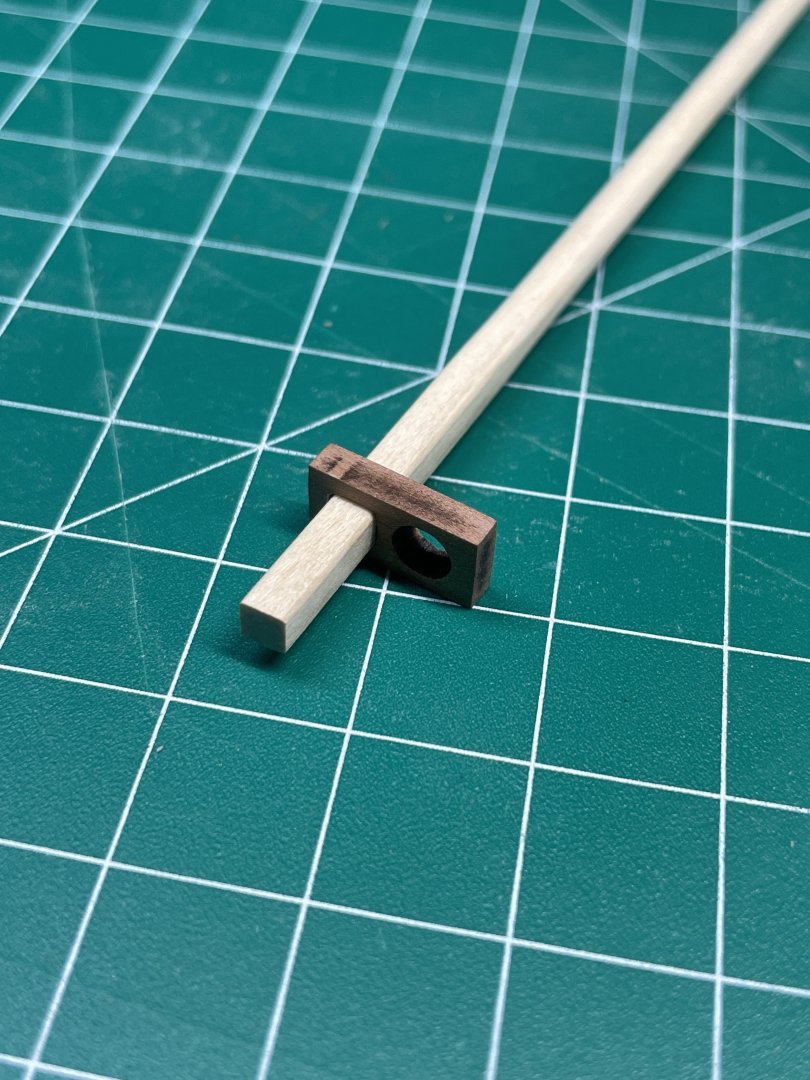

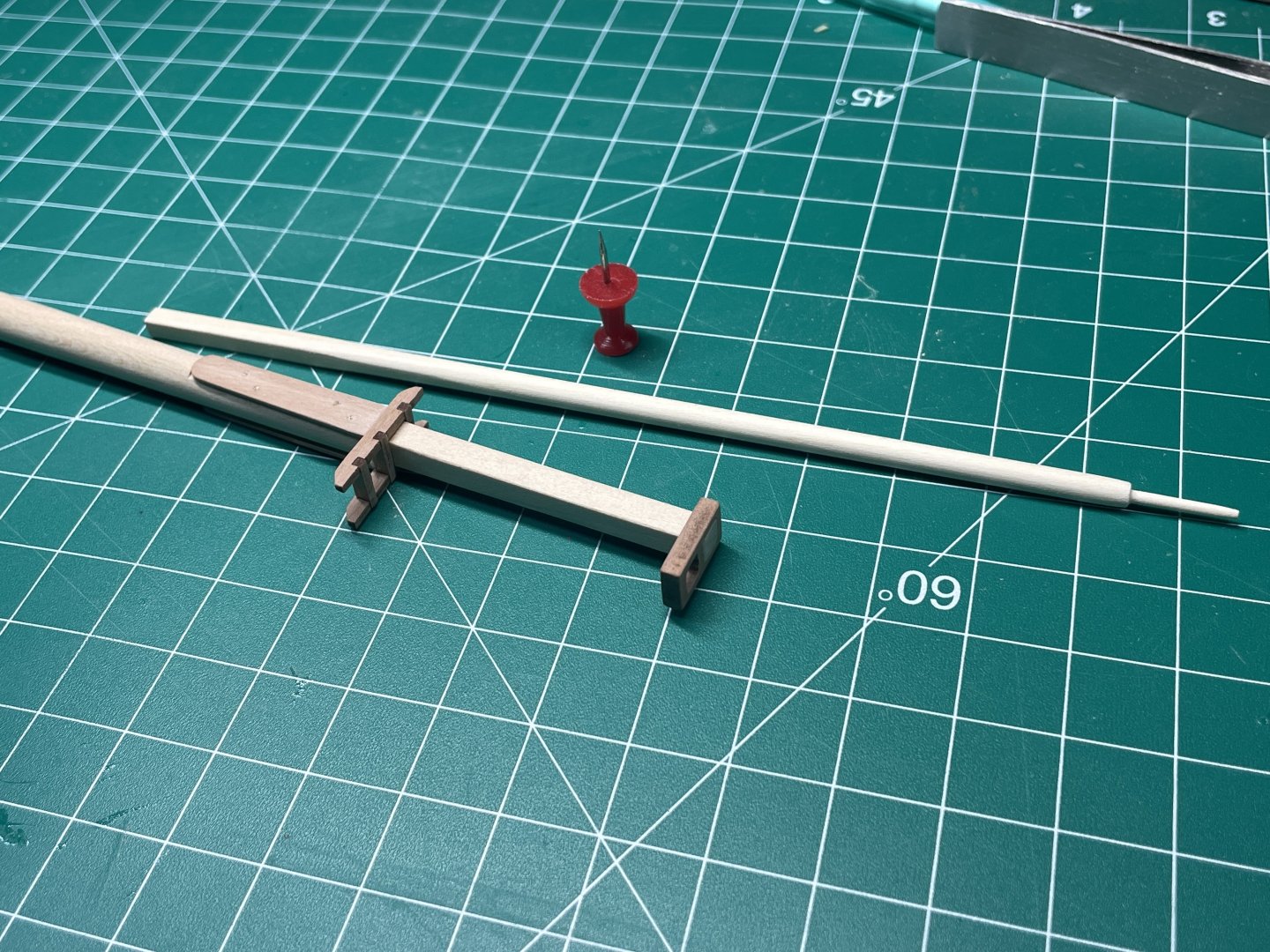

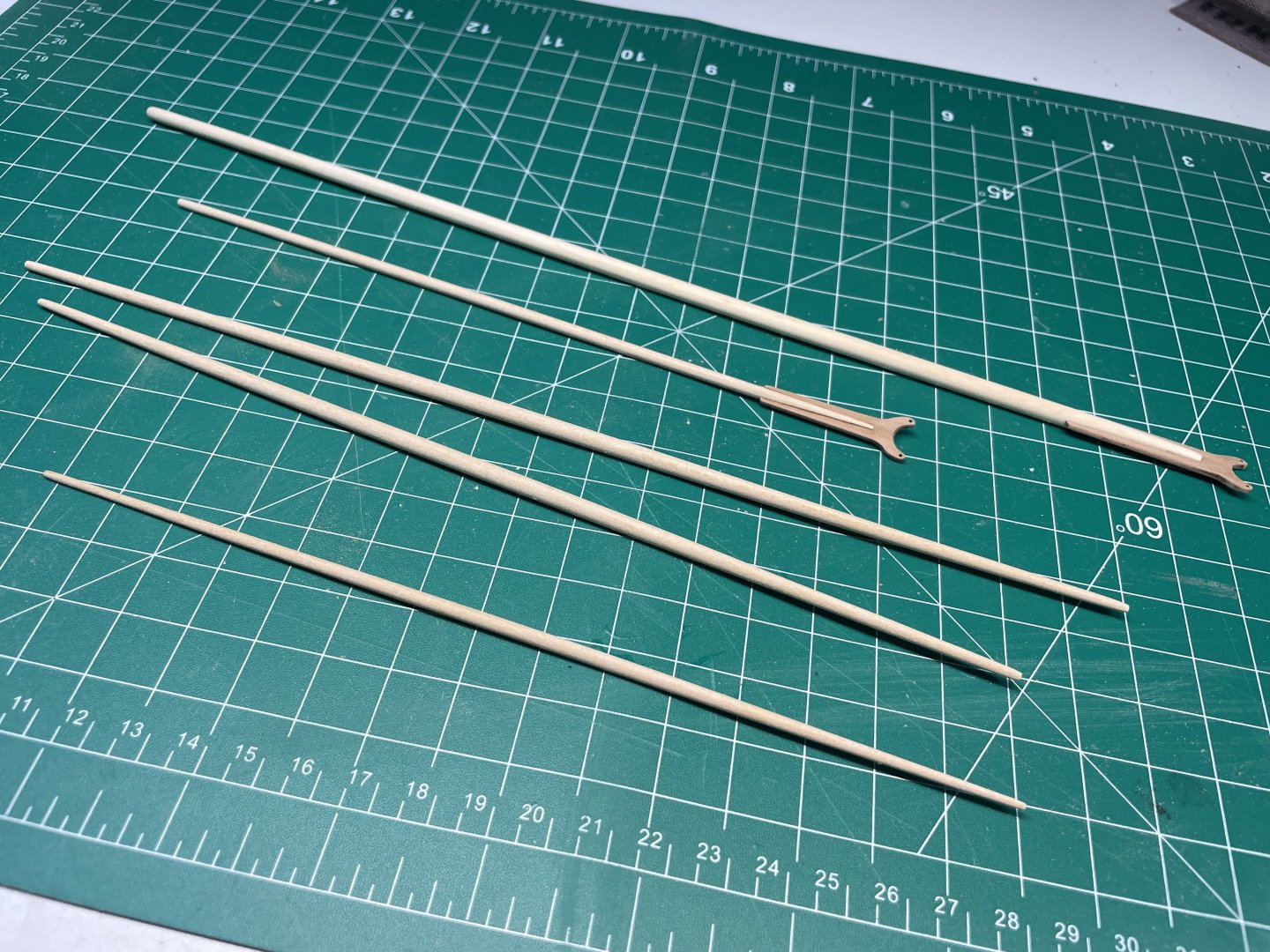

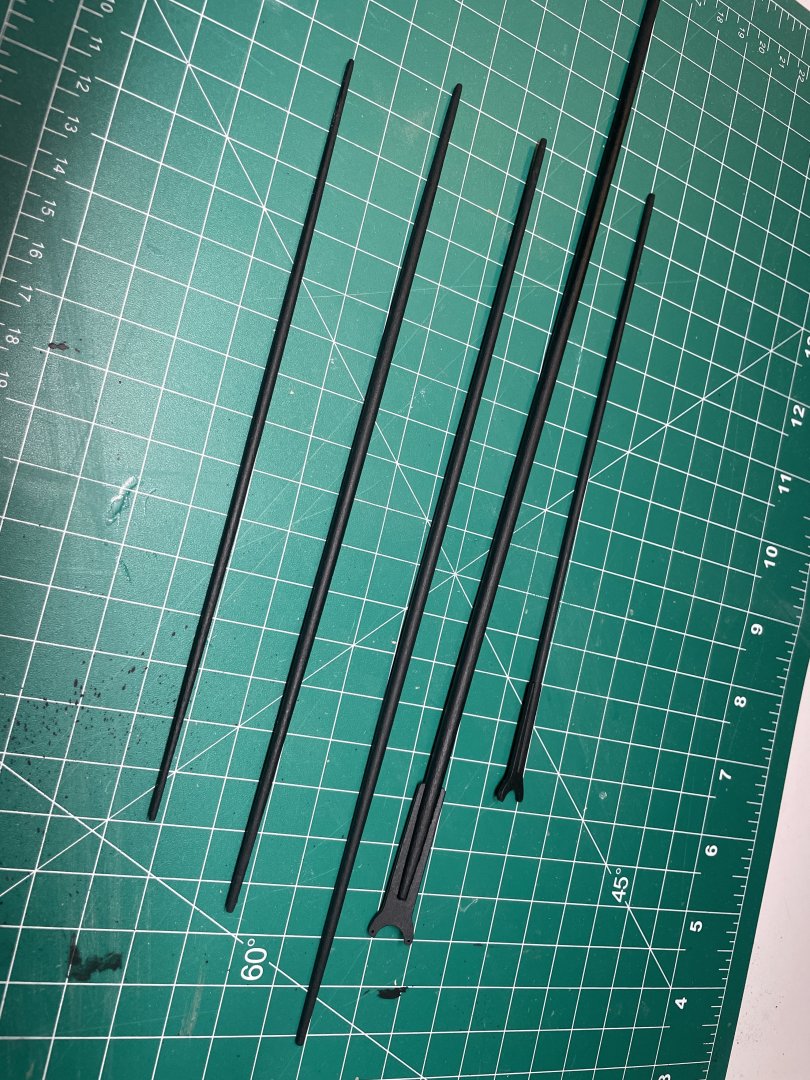

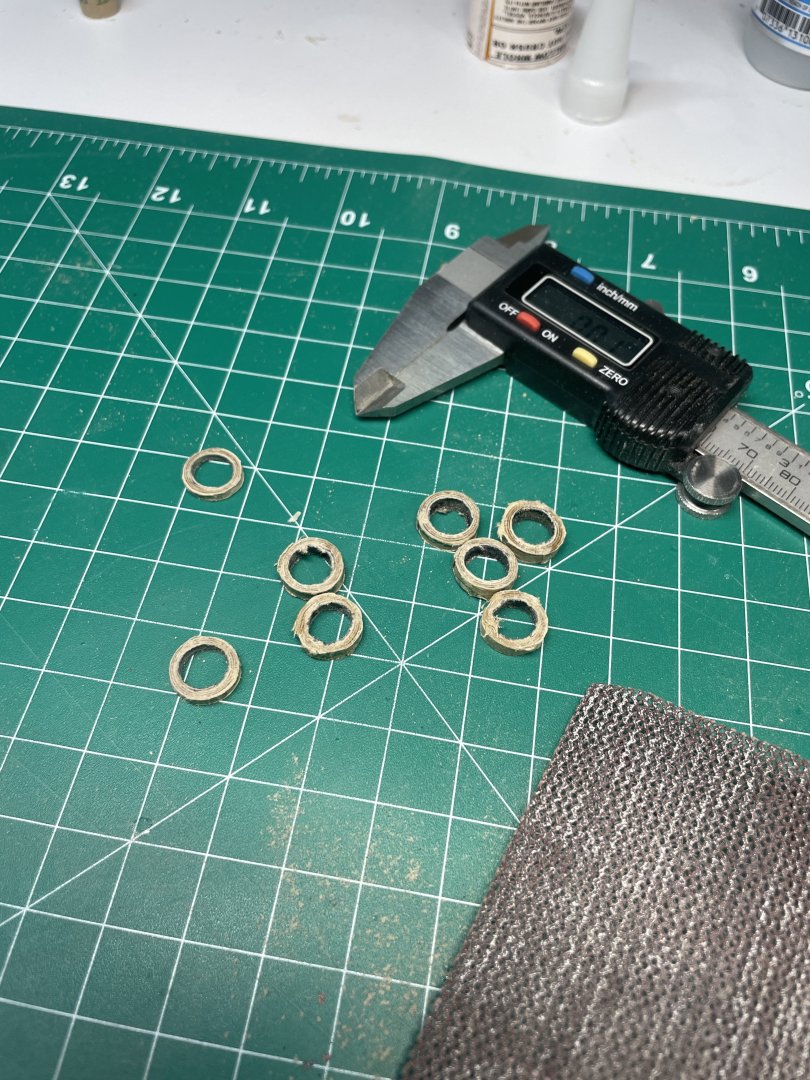

OK it’s time to make some more fiddly things. I made a stove chimney, it turned out shorter than I had wanted but I kept it. I later painted it. Then I started on the topgallant staff. First I marked it off then I just started sanding to the lines. That made it square. In the photos it looks like I turned the step at the top after squaring, but I did that before hand in a drill. And then I painstakingly squared the hole in this piece so it was an excellent fit. (Does anyone see what’s coming?) Then I realized that’s not where it goes…. It looks fine after painting and such. I need to keep closer watch on these things. This is my first ship with a real mast and it has got me scratching my head a lot. I completed the trestle trees and cut out the flat areas for the cheeks and even tree nailed them in with some toothpicks. You can’t really see the treenails after painting, I wish they showed up better. Any tips on that? **Note to future builders. Don’t put this all together until after you have done the shrouds. I shaped all the yards with a variable speed drill and some sandpaper. After marking them out from the plans I would make some notes on various dimensions along the length, then I would roughly followed that. I would grab my calipers and sit on the porch and make sawdust. Thank goodness for Arizona weather. I would start with 100 grit and get the rough taper then 180 would shape it quite closely and 220 to fine tune the taper. I have to say it was pretty simple to get a nice taper on them. Easier than expected so that’s always nice. I thought I had a genius idea for mast rings once while perusing the hardware store. These small rocket engines seemed to have about a 10mm id turns out the end is kind of crushed to the clean part of the tube was too large. I did use the paper and CA and make some rings from that. I sliced some rings off then used rubber cement to glue them to the board and then sanded it face down until they were about 2.5mm thick. I then painted them but later remove it and sanded the outside flatter than I originally had it. These photos show most of the progession. Now a couple of glamor shots of how she was sitting at that point. Now has the swivel guns, stanchions (sp?) and the tiller. The tiller was epoxied and pinned. That is such a long moment arm with so little surface area, I was concerned about that joint ever giving up. Thank you for stopping by. Next up I start some prepping for the rigging. We’re pretty close to real time now as the rigging has really slowed me down. Chris

- 38 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

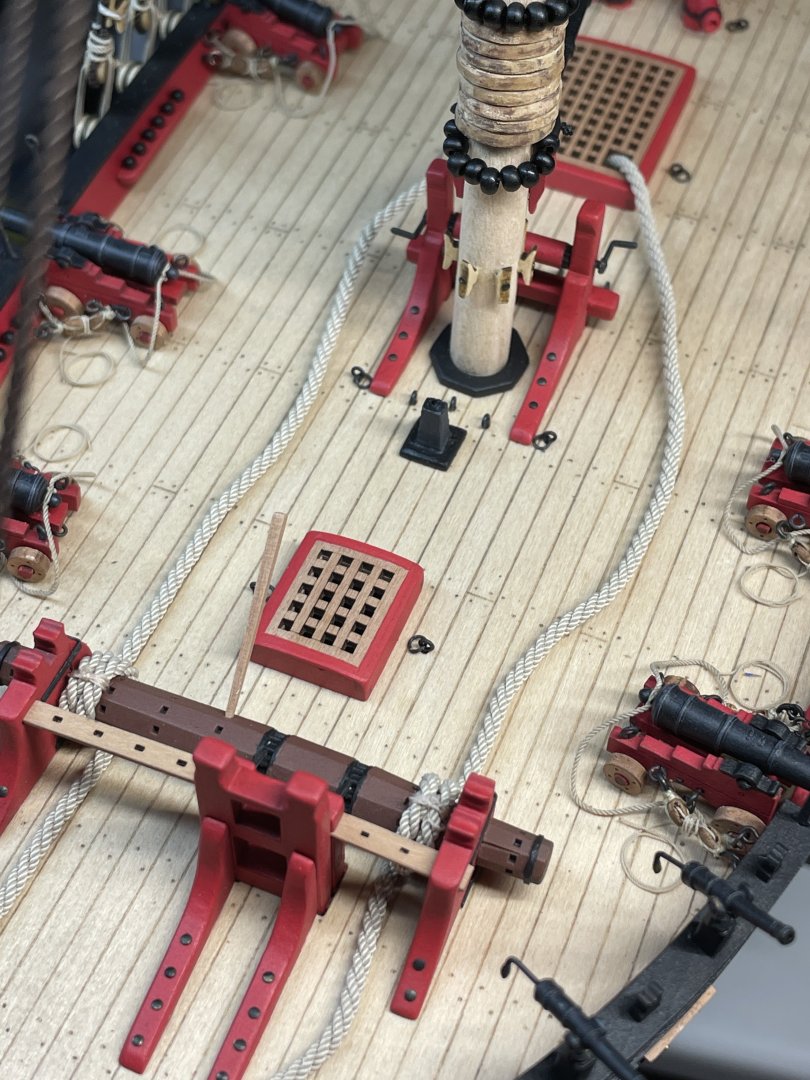

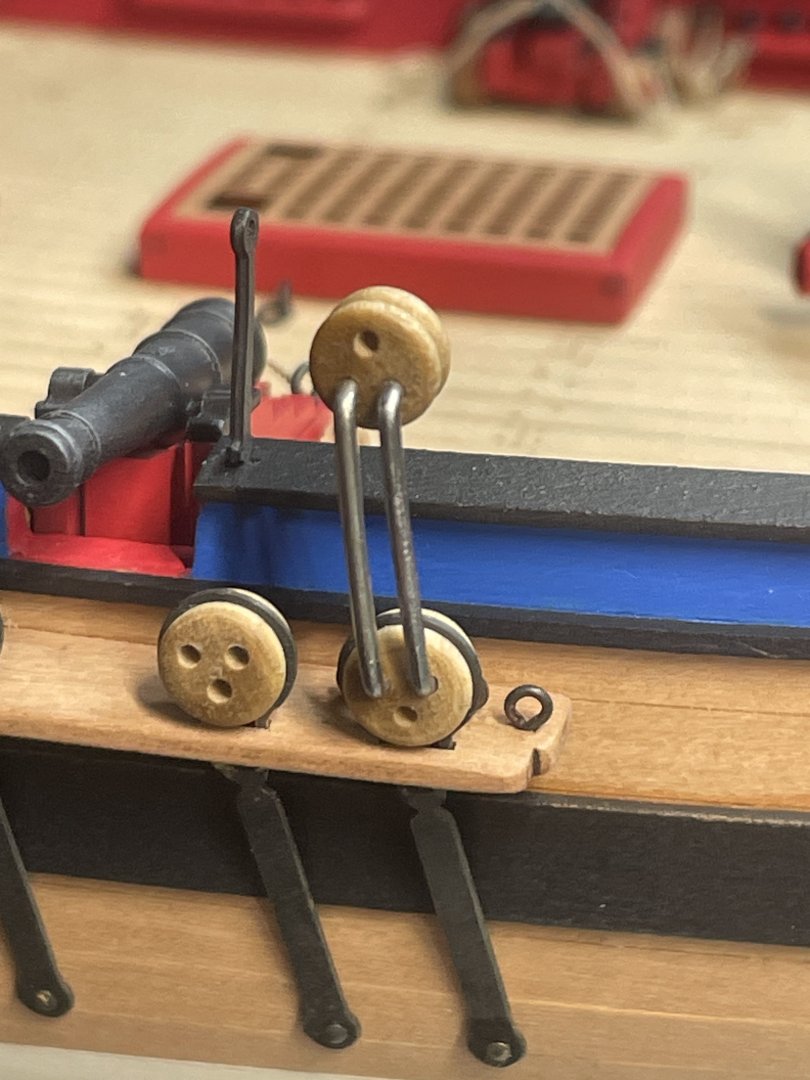

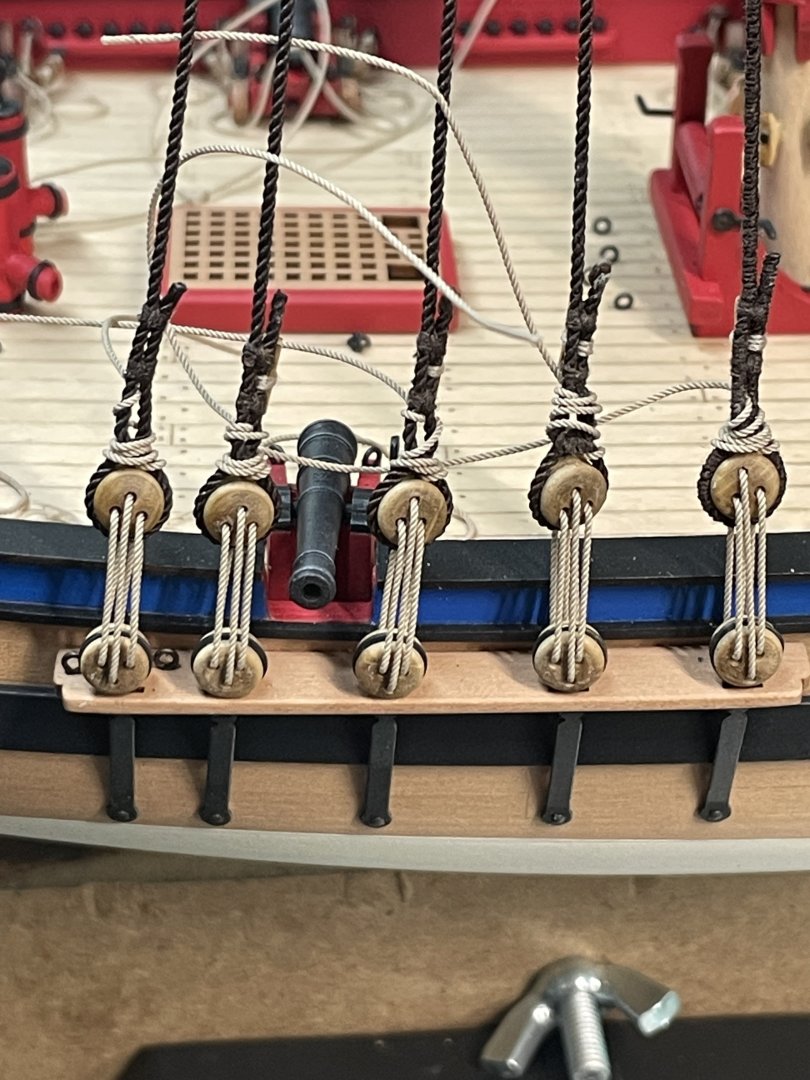

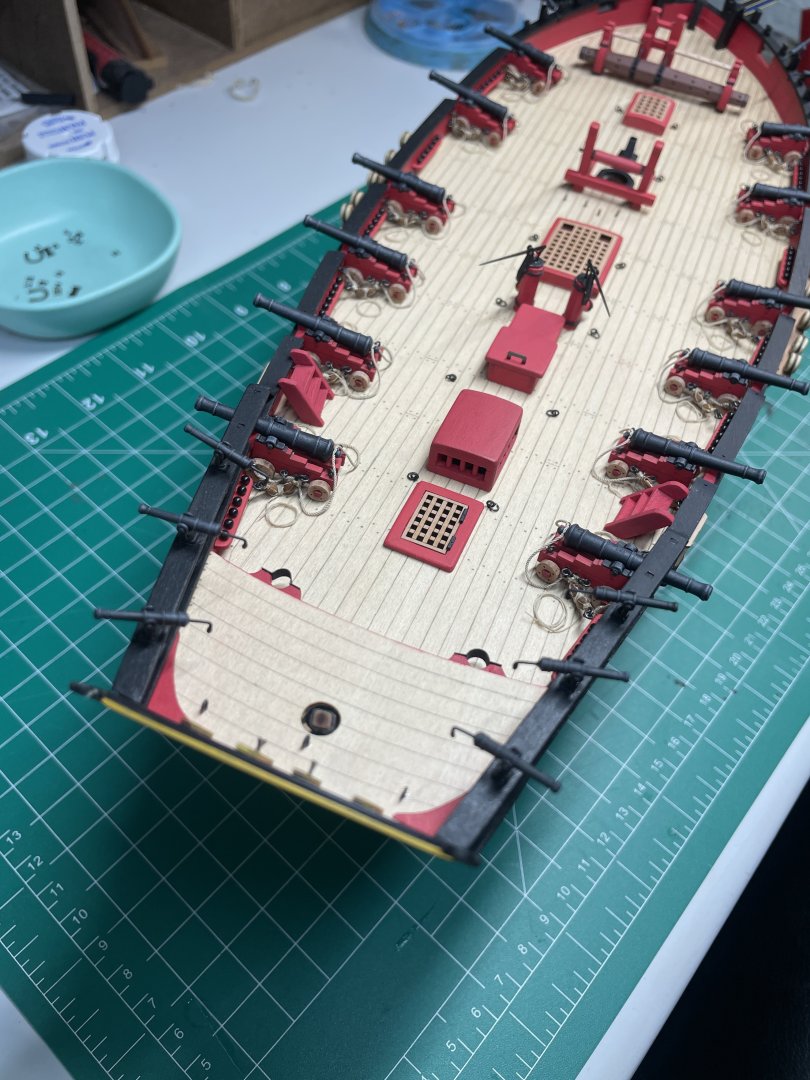

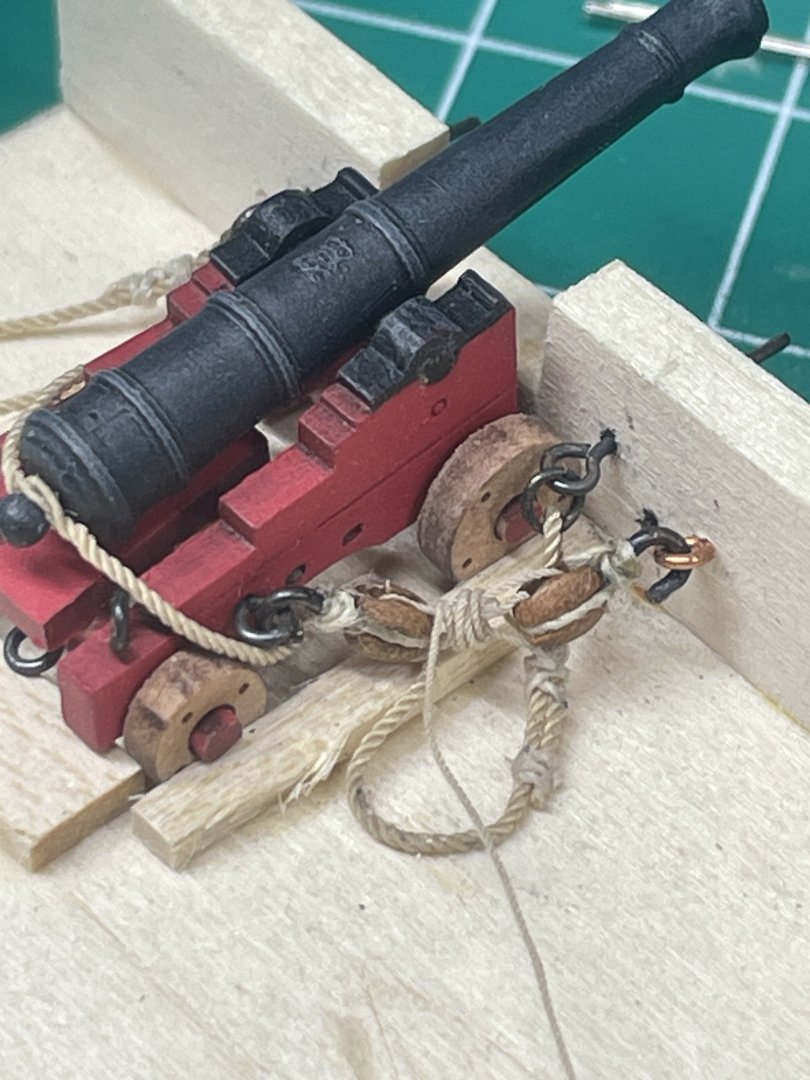

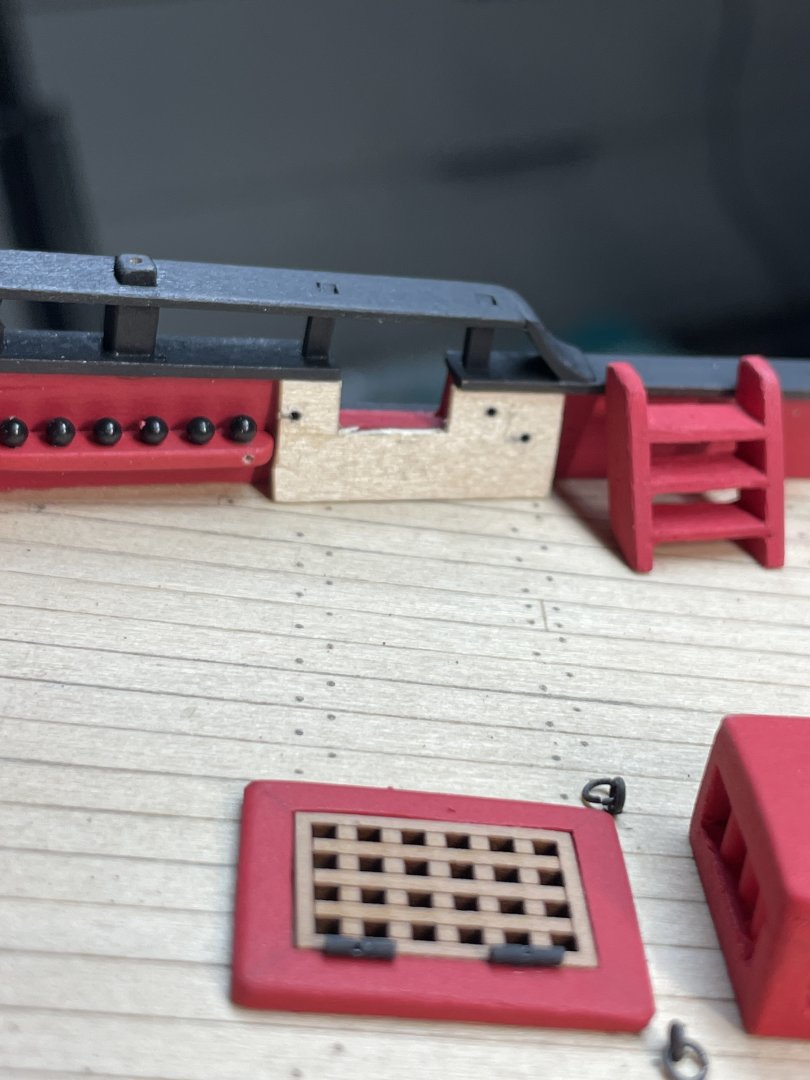

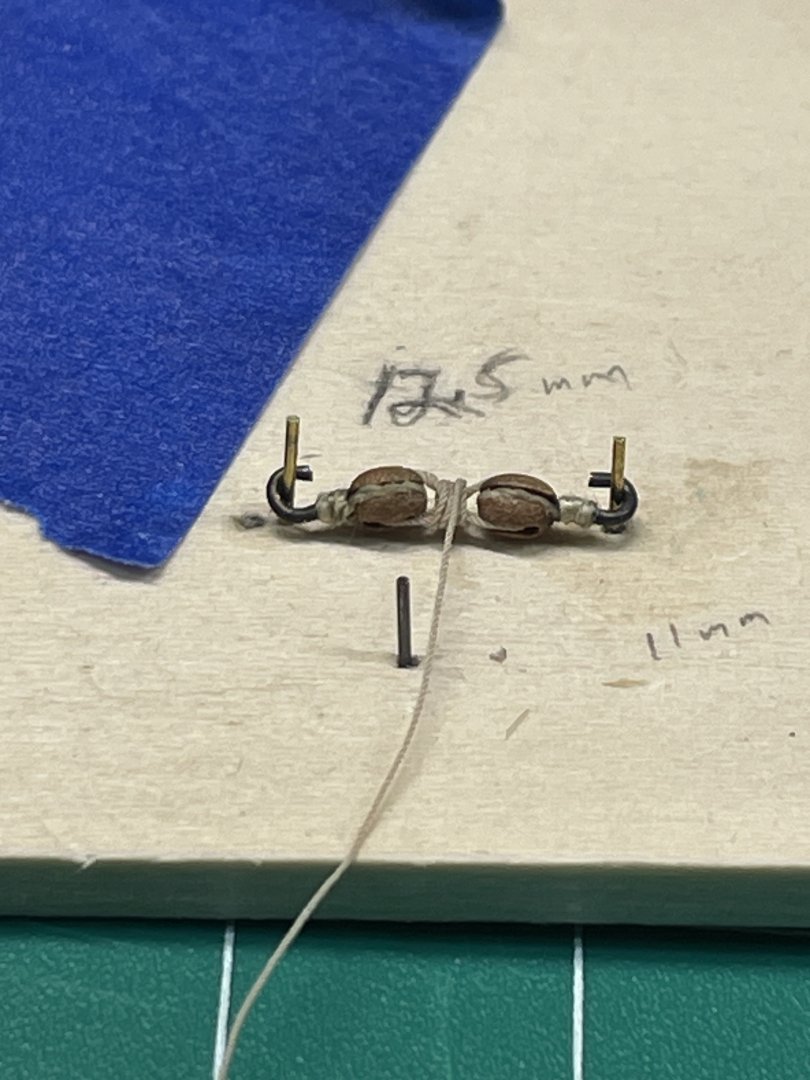

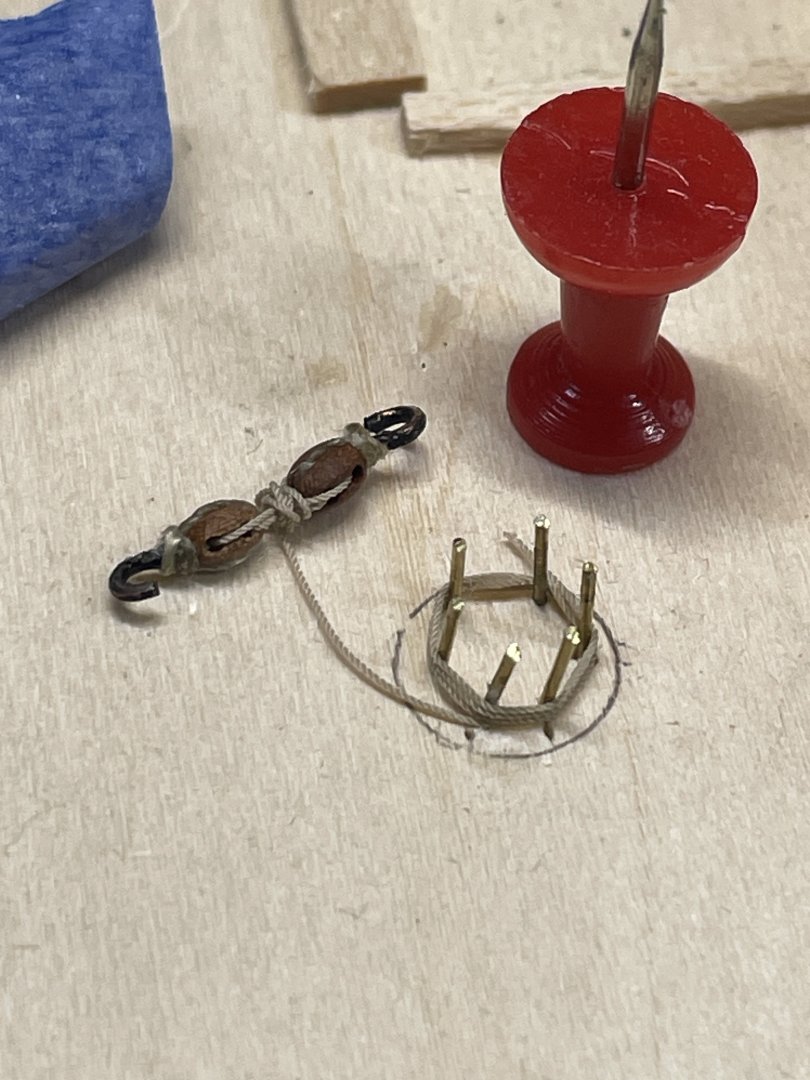

Thank you all for visiting and welcome back! Now it’s time to start the cannon tackles. If I am ever using incorrect terminology on any item. Please kindly correct me. First I rigged up the mock up in order to measure the distance between the hooks. I don’t have all the fancy books that many others have so I just have to use their information. So I weigh the instructions and build logs together, plus what I think looks pleasing. From the mock up I made a marking jig, it is asymmetrical to make way for the racks of cannonballs. I just had to mention terminology so the the name for those would fly out of my head… *Hint drill these holes wayyy before to permanently glue the deck furniture down. Just saying. (Especially the ladders) Drilling the racks is probably way easier before they are installed also….just a thought. I started to rig up the tackles on a jig to hold it still. The shorter one is for the shorter tackles. And the coils. I used watered down matt varnish on the rope after using CA to get it in place. And here we are in place. I used medium CA to hold things down. Later it will get sprayed with Vajello acrylic matt varnish to get rid of any shiny spots. Thanks for looking! In the next post are the boom, gaff and spars. And I scratch build some mast rings! Well, I try…. a few times. Chris

- 38 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Didn’t realize it was so much larger. I’ve seen other build logs and it never clicked that they can get more detail on them. Chris

- 71 replies

-

- grand banks dory

- midwest products

-

(and 2 more)

Tagged with:

-

Thank you Daniel. I appreciate it. Thanks Jacques! I don’t know if you’re planning on rigging the tackles also, but I’ll be posting my process on them today or tmro. Of course it’s pretty much the same as Thukydides and Blue Ensign. Keep at it! Chris

- 38 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.