-

Posts

236 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Desertanimal

-

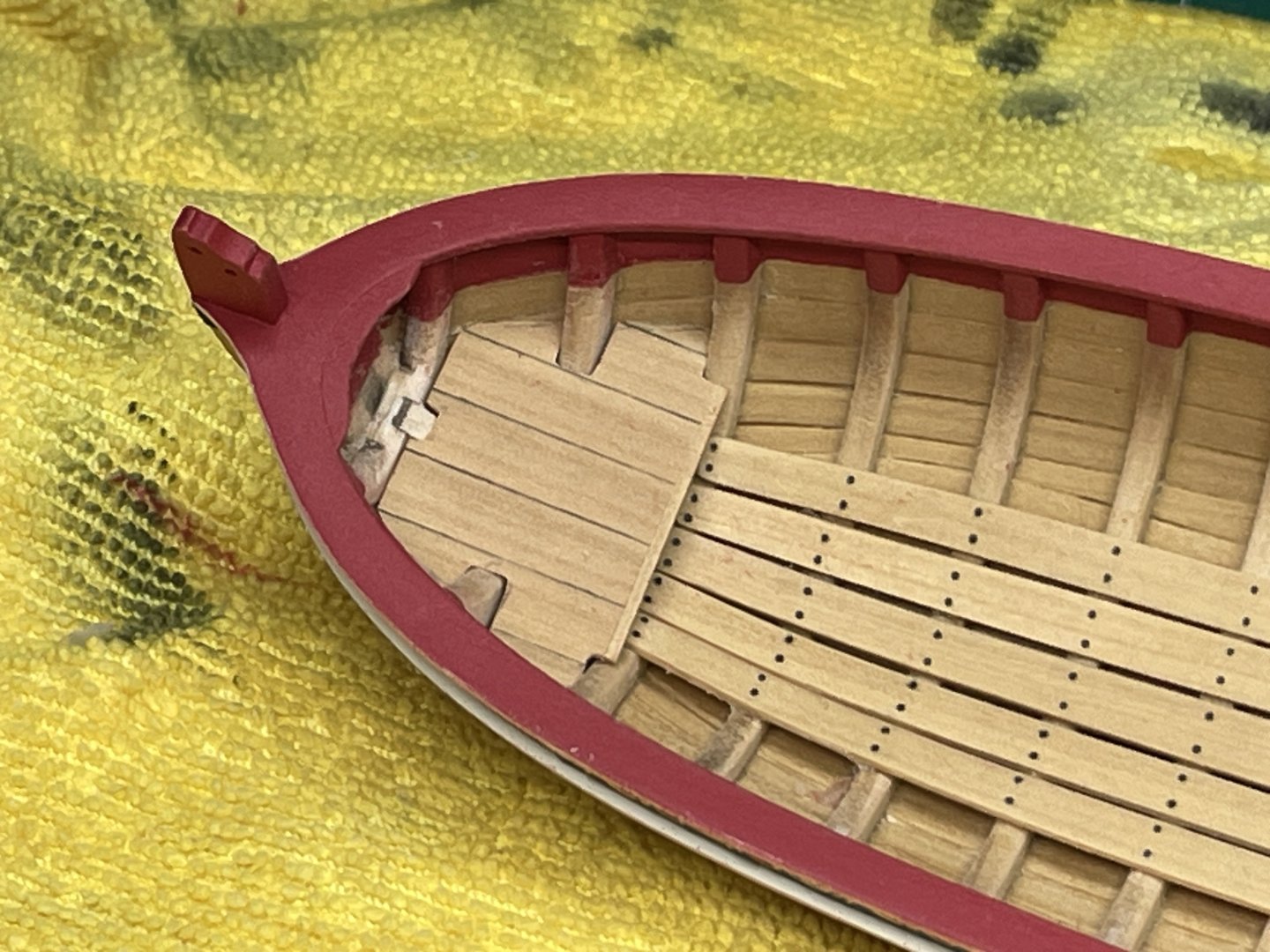

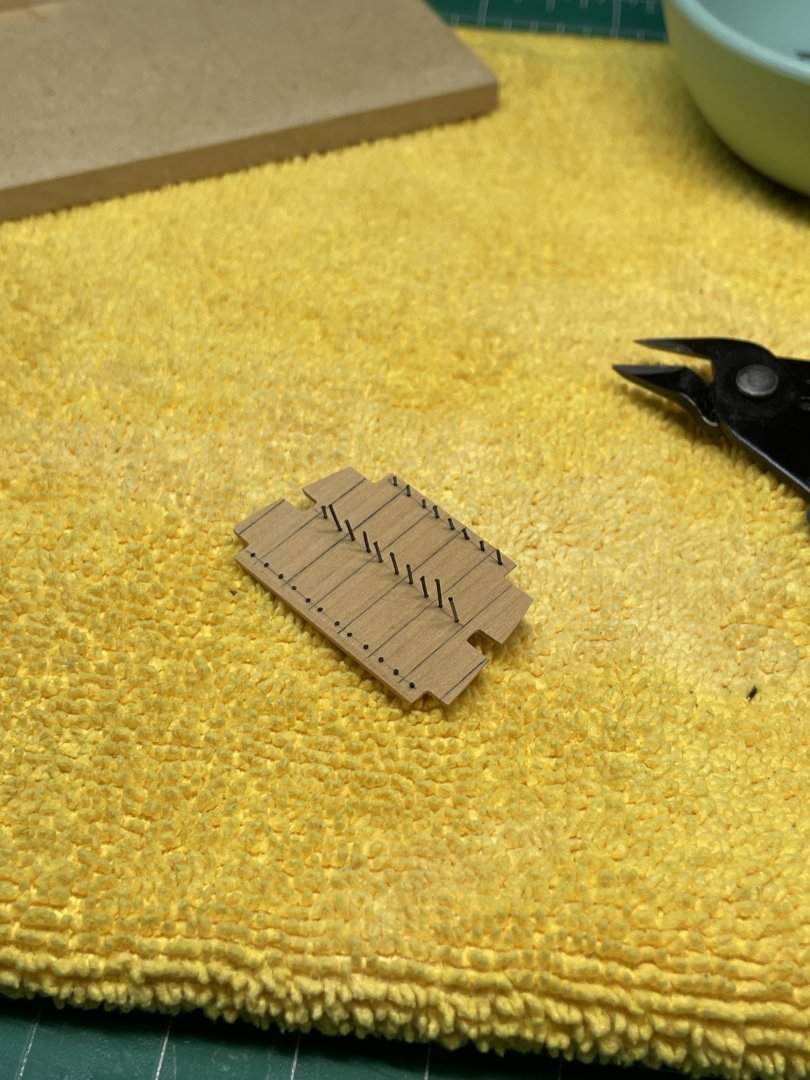

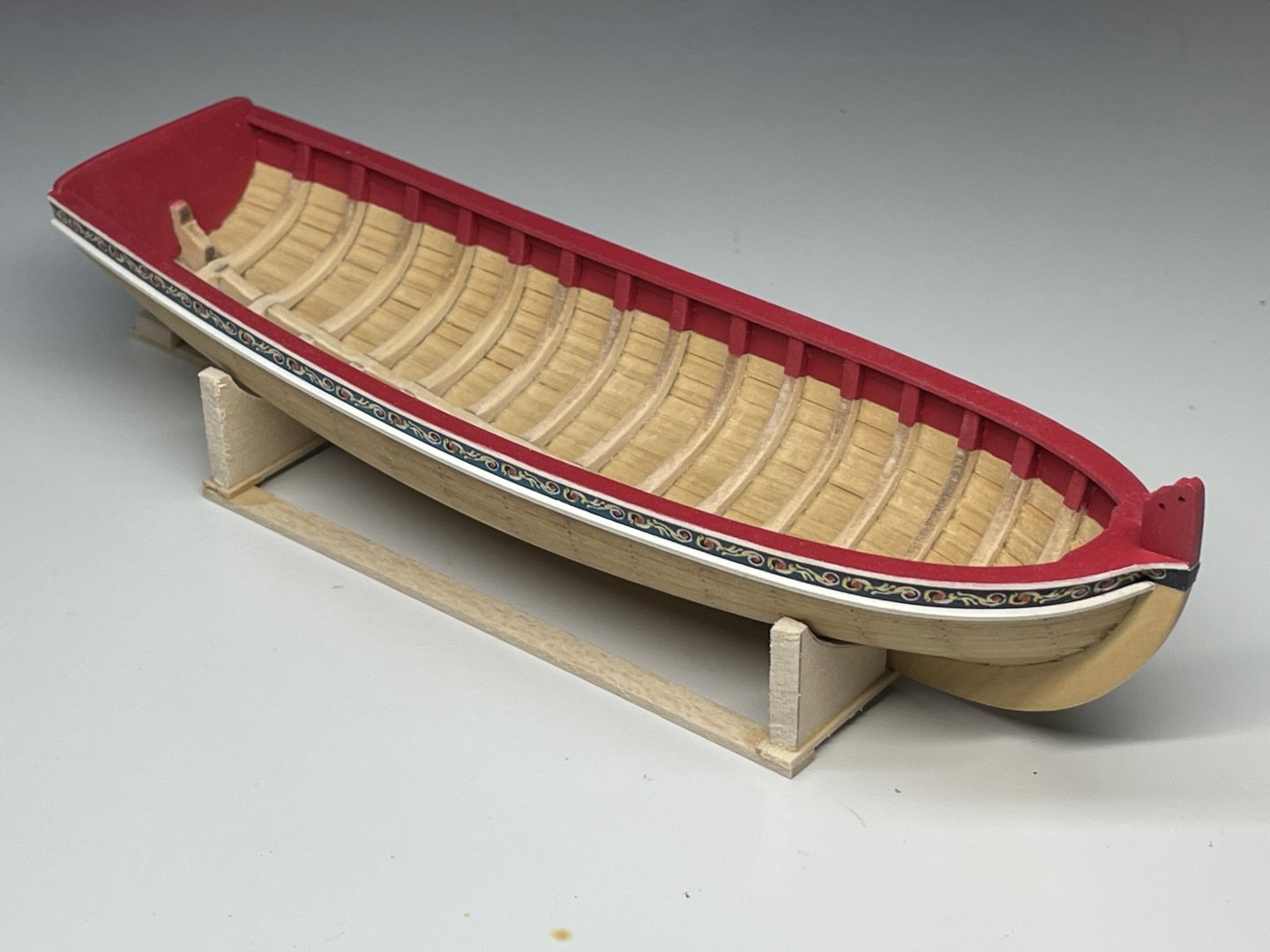

It’s time to install the risers. These were fairly simple however the sides of the frames are not vertical. This comes back to haunt me later. I also forgot to add the nail details until after they were attached so I had to drill them and install the fishing line. I didn’t want to sand the face of the risers because they had been scribed and the edges eased. Sanding the nails flush would remove some of that detail. So I used really short pieces of line and then put a dab of watered down glue on top to hold them in place. Now the locker and seating. The seats really gave me a run for my money. Trying to get all the edge detail to line up was a chore. Also these are all cut from boxwood by hand. I used the template technique again and I think I’ve improved how tight the joints are. The aftmost thwart also needed some custom shaping. Now the one that holds the mast. The ironwork is black paper. Some paper hinges with a piece of wire for locker hinges. Thanks for stopping by!! Chris

- 38 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

Work area pictures only

Desertanimal replied to Johnny Mike's topic in Modeling tools and Workshop Equipment

-

Can’t answer your color questions other than use what looks good to you. Airbrush is a great tool. You will be able to see all your details. Are those other items PE? I have not built Sherbourne. If they are Photo Etched you will probably want to chemically blacken them instead of paint. If you are not familiar there are plenty of posts about doing it. It will give a nice look and be more permanent than paint. Chris

- 61 replies

-

- First build

- Cutter

-

(and 2 more)

Tagged with:

-

USS Constitution by mtbediz - 1:76

Desertanimal replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I didn’t see what size dowel you used. Chris -

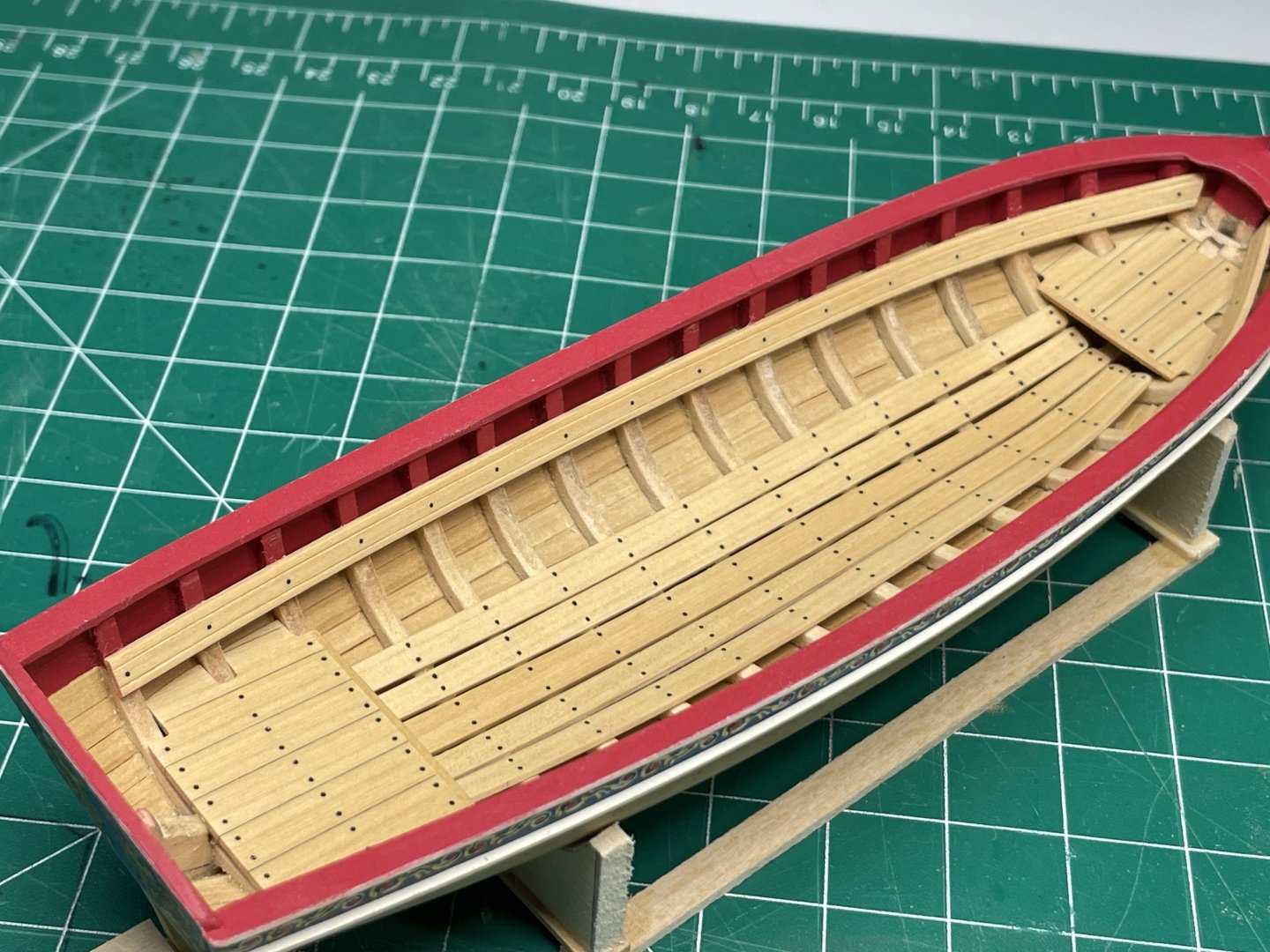

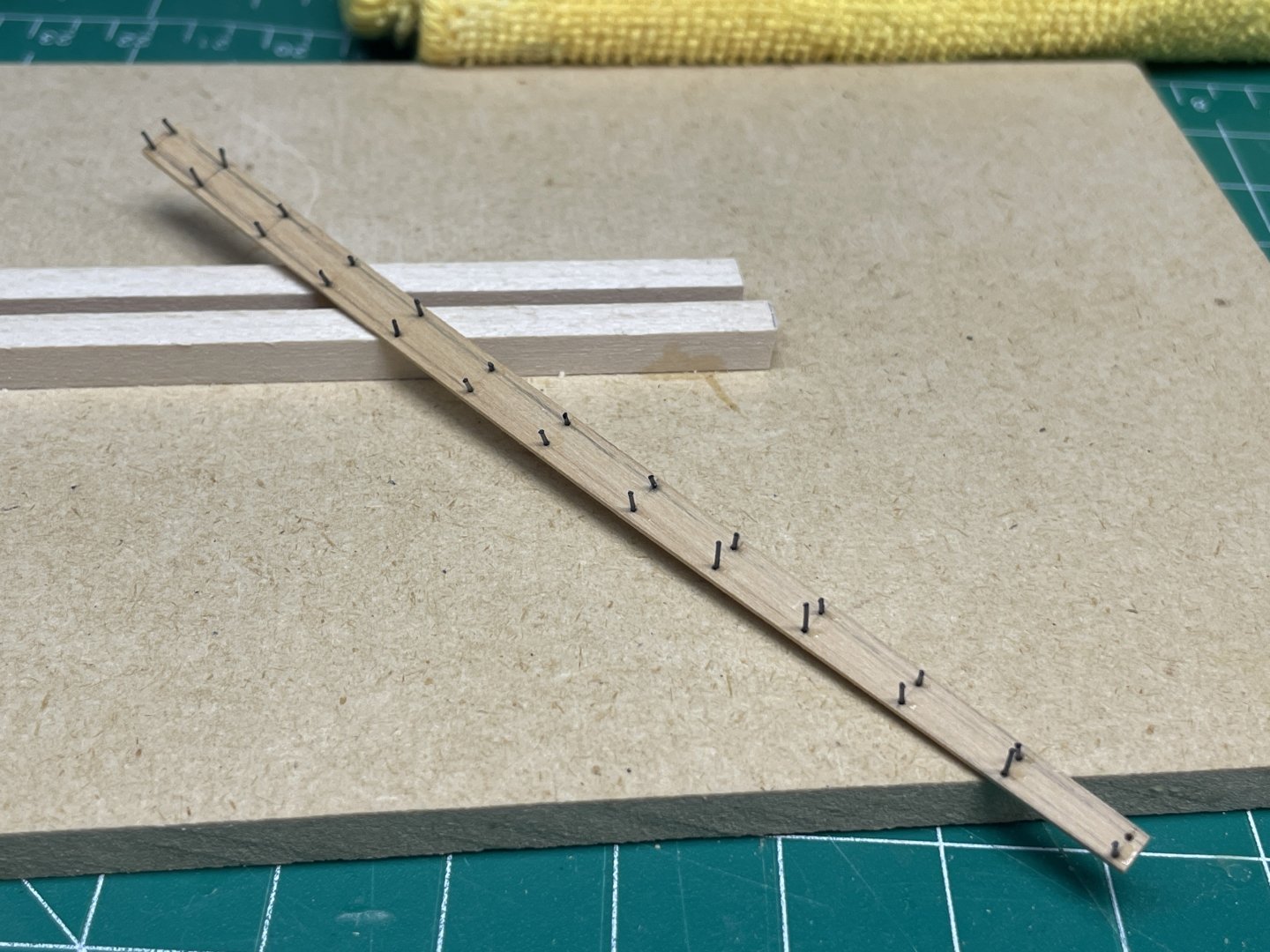

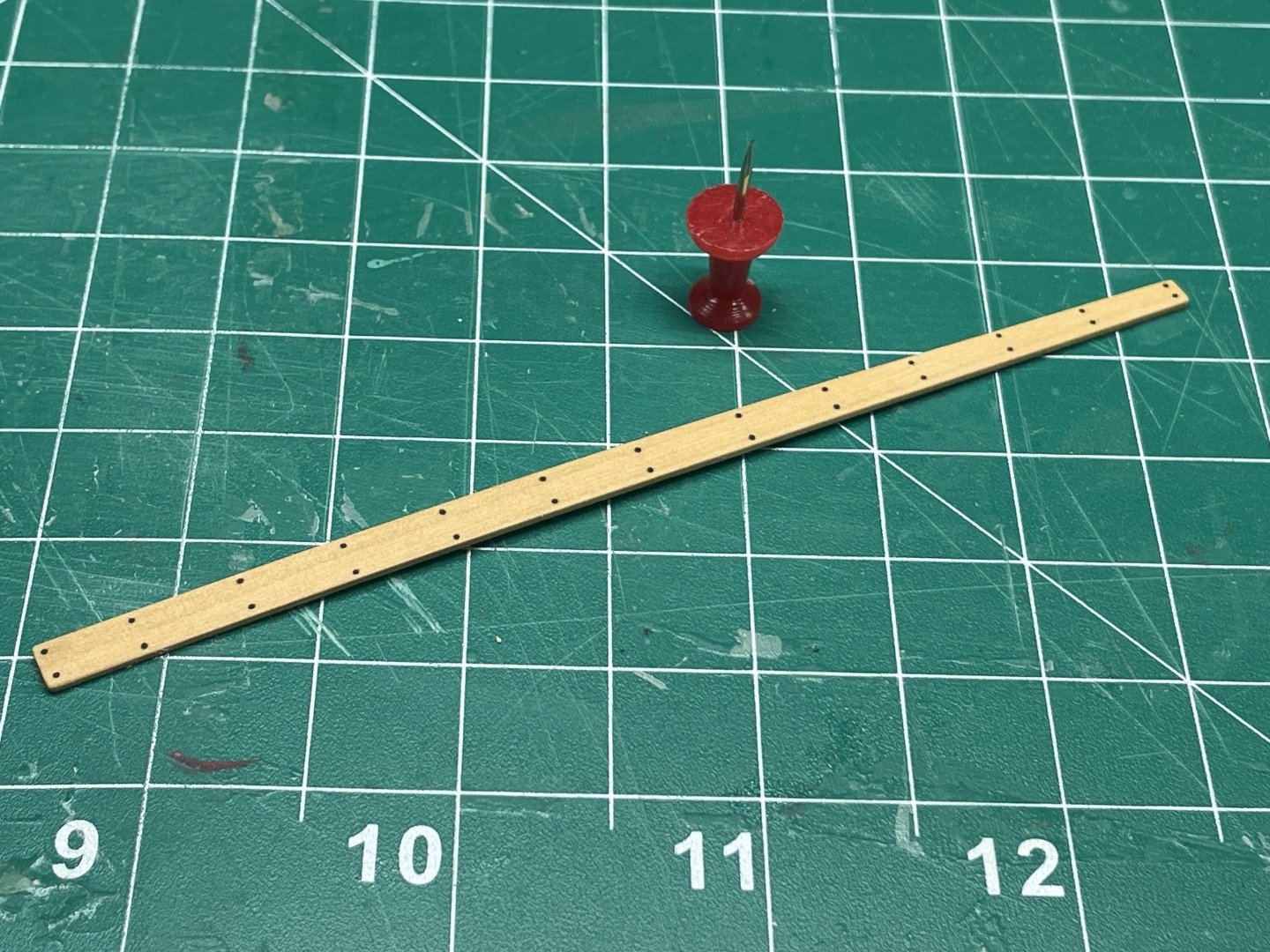

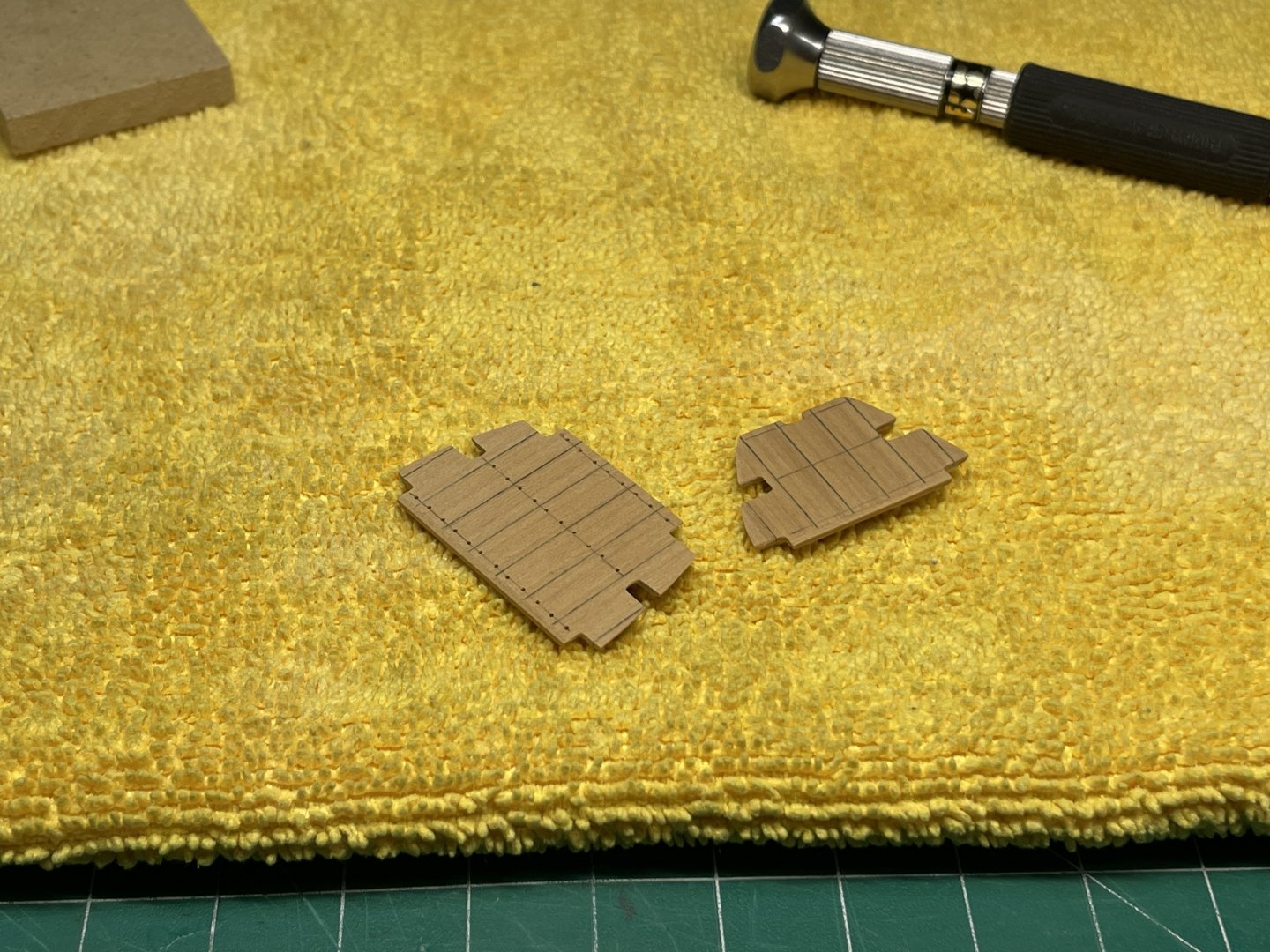

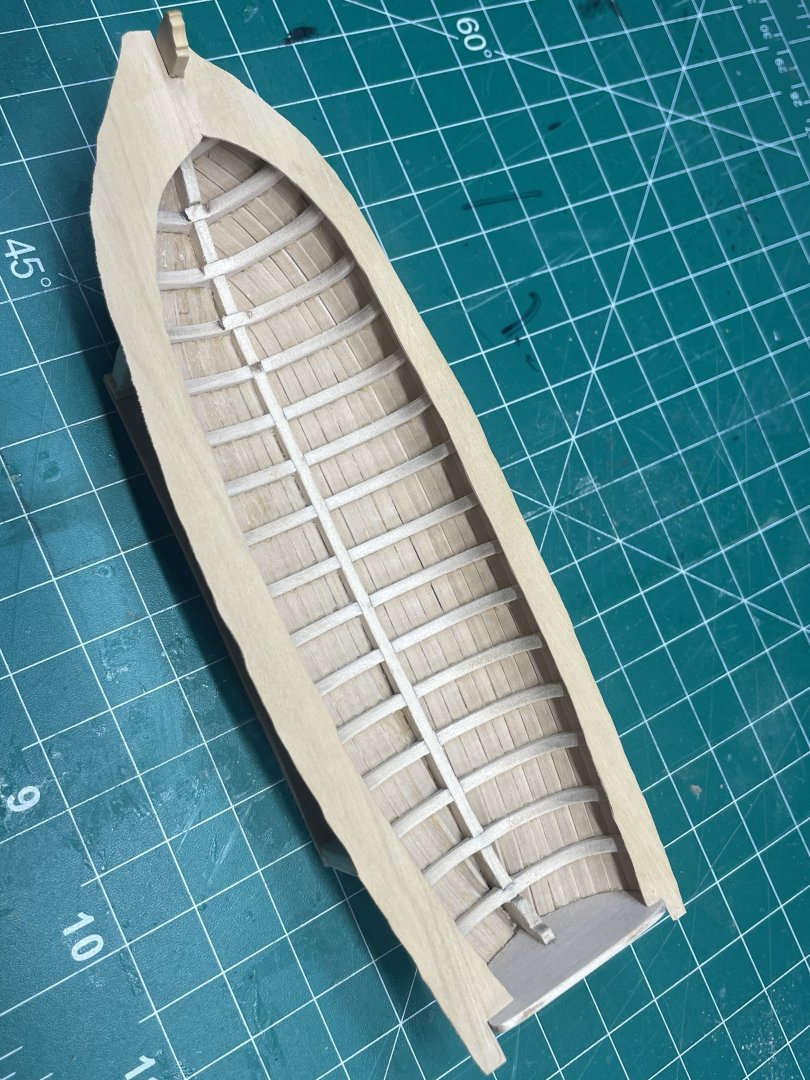

Thank you Chuck. I wanted a quick little project before I started Cheerful. I’m not sure I chose wisely. HAHA. I love the little boat! I’m just really trying to complete her to my highest ability. So that does not equate to quick little project. Time to start on the floorboards. I wanted to play around with black monofilament for bolts or nails and such. I did some shaping of the center board from the plans and also did some test holes for the monofilament I have. I ended up using a #77 drill bit. The line is .40 mm. Then just more of the same for the other boards. I really thought I was doing well and I see the nail lines are not straight. There was a lot of things to keep track of while gluing those in. I’m not going to worry about them and just keep it as a lesson to keep a closer eye on those also. Now on to the little decks. I was not looking forward to these as I have a really hard time visualizing what shape things like this need to be when they have compound curves. Plus its basically impossible to measure in there. I used a trick that I saw in the build log of @BobF. He used little bits of paper and made a template. I tried it and I think it worked out well for me. I transferred it to a single layer of manilla folder then onto the boxwood floors I had made and cut them out. I don’t seem to have any pics of the backs but I did put some 1/32” boards on the back for strength and to help keep them flat. The final fit could be better but I’m good with them. When final dry fitting something like this how do you tell where the part is getting stuck and needs a little more shaping? Here they are installed and a coat of WOP. What do you think of the size of the monofilament? I think it might be a little strong but with all the other stuff going on above them I don’t want them to get lost as they were a lot of work. I’m thinking between the floor boards and the decks I have about 15 hours in them. Thanks for looking!! I appreciate all the comments and likes! Chris

- 38 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

I appreciate that! Thank you. Thank you! Today I’ll be finishing up the floorboards. I think they’re looking good.

- 38 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

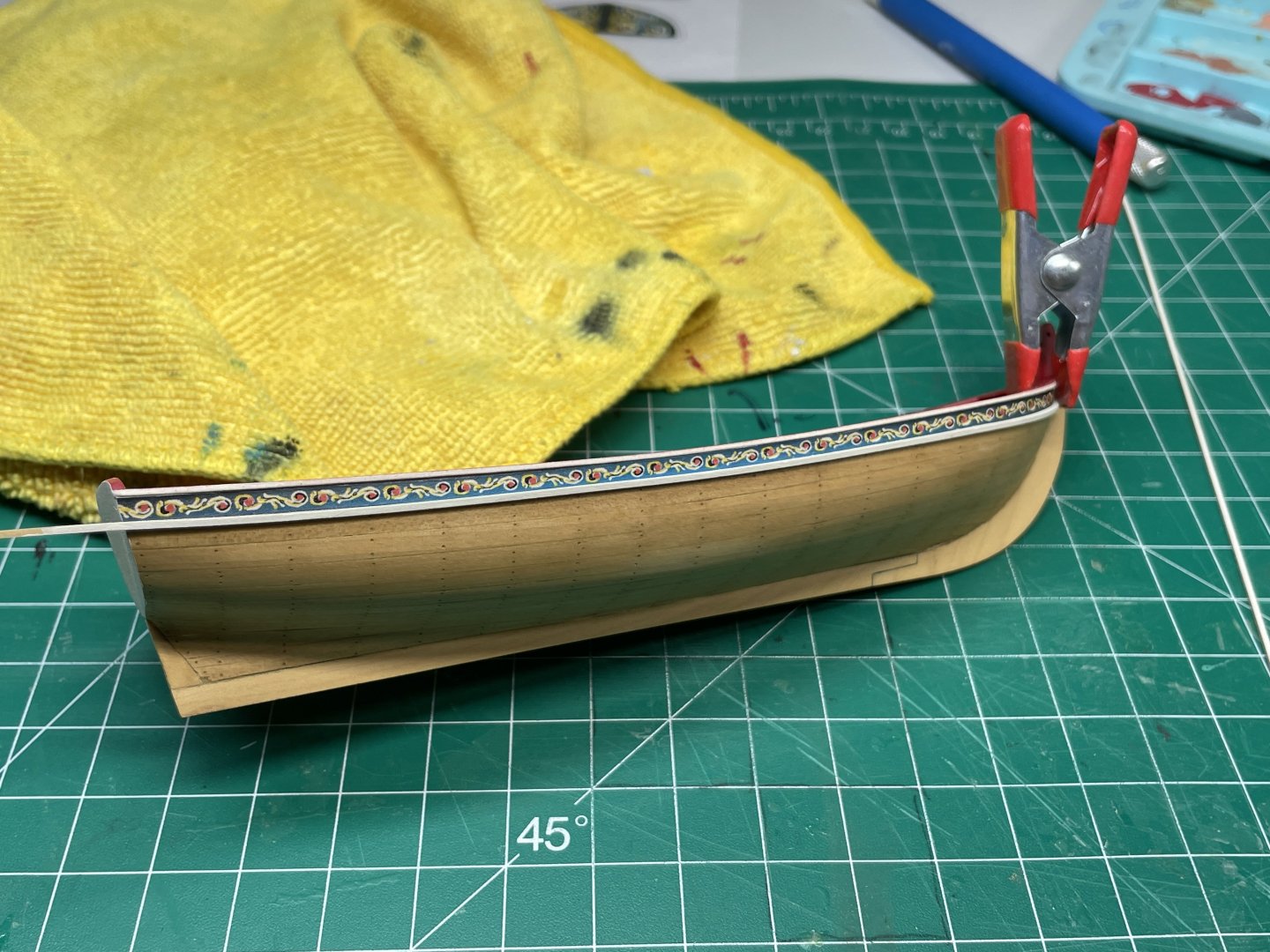

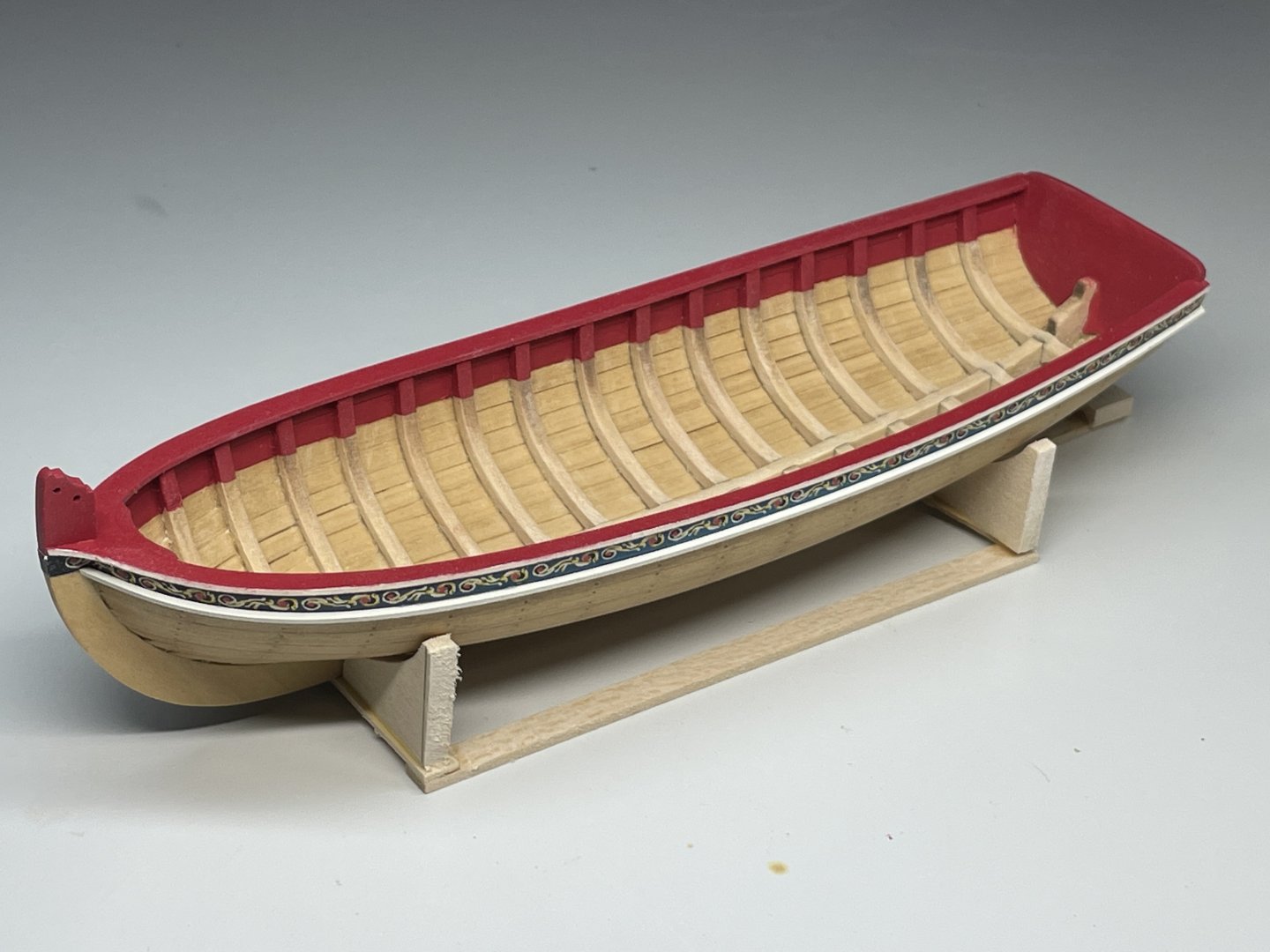

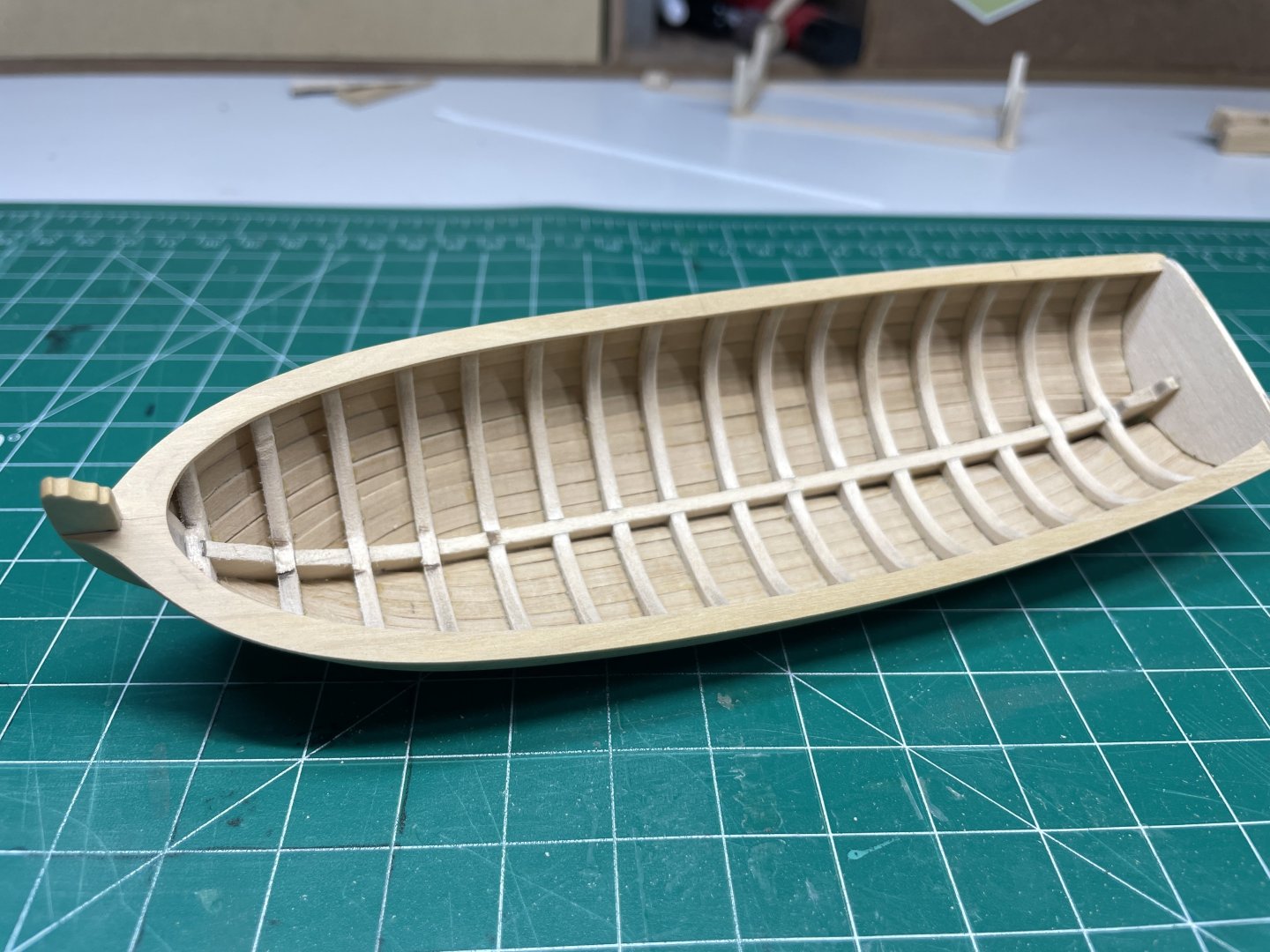

Moving right along this is the final shape of the cap rail. This pic looks like I’ve put a coat of WOP on her also. Now time for the breast hook. I got the basic shape from the plans and also holding a piece of wood up against the location on the boat. Never dawned on me to copy the laser cut part. I never even looked for it. I don’t know if it would have helped or not as the shape probably wouldn’t have match as I’m mounting it flush with the cap rail. Still a little more shaping to do, but it’s mounted. Now time for paint! I enjoy painting, usually. I decided brush was the way to go as I had no interest in masking the inside wales with all those ribs in the way in order to air brush it. I did go back and forth with the edge of the cap being white. I did the red first then the white. Then had to go back and touch up red, then white. I’d say three or four of those cycles and I had it clean. I then used some WOP on it. Later on I was working on it and the poly had not dried and ended up retouching the paint a few more times…. The colors I used are Warpaint- Dragon Red and Brainmatter Beige. I then sprayed the appliqués with mat fixative on both sides and cut one out after it was thoroughly dry. After dry fitting I applied it with some slightly thinned Elmer’s white glue. Repeated that on the other side and then applied the rub rail. I had previously painted it beige on three sides. A little dab of water from my finger and it bend around the tip nicely. I started at the bow and used a dab of medium CA with a little clamp. Once that was secure I continued down the side with titebond. And, as she sits…. Thanks for stopping by!! Chris

- 38 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

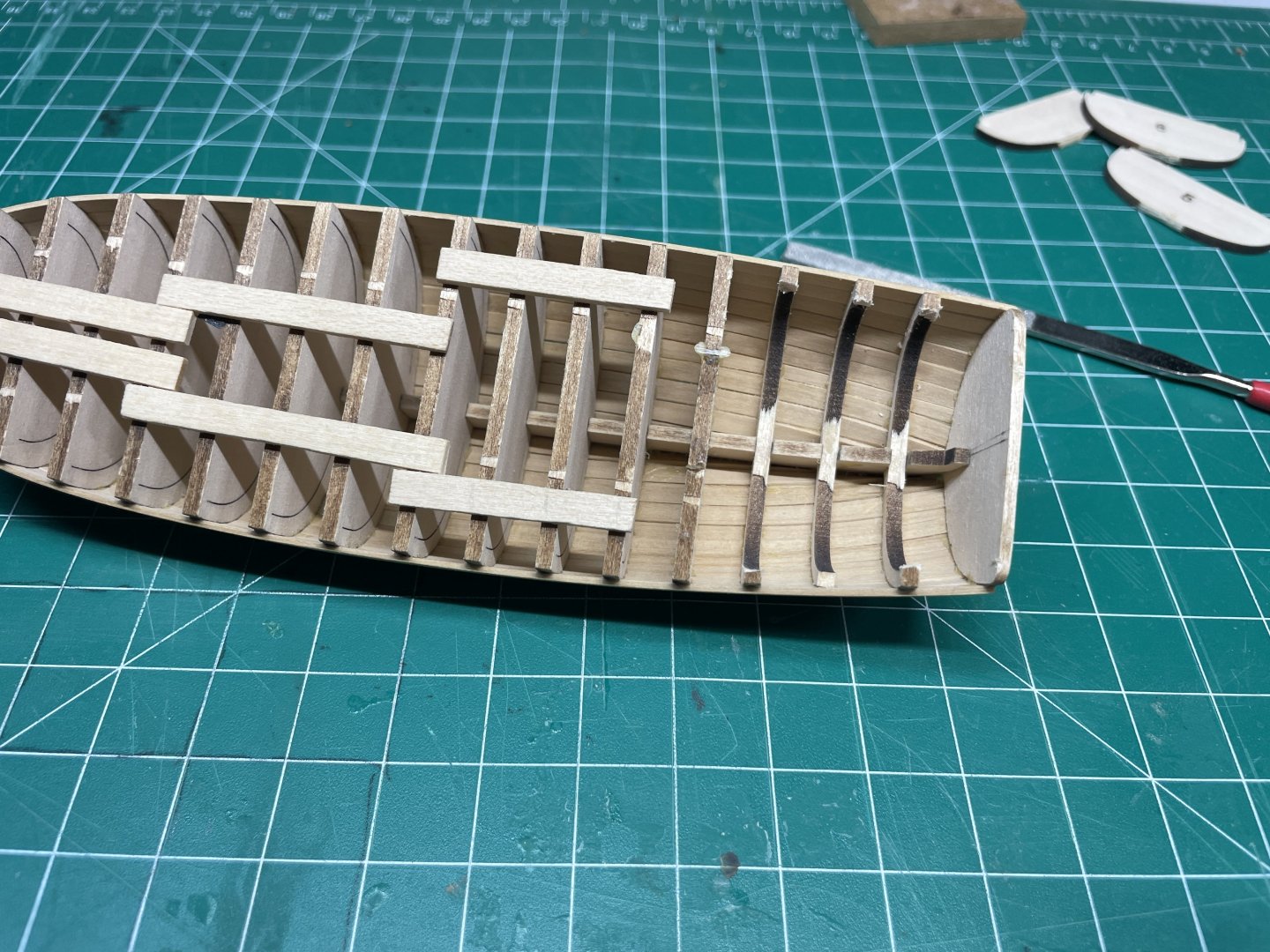

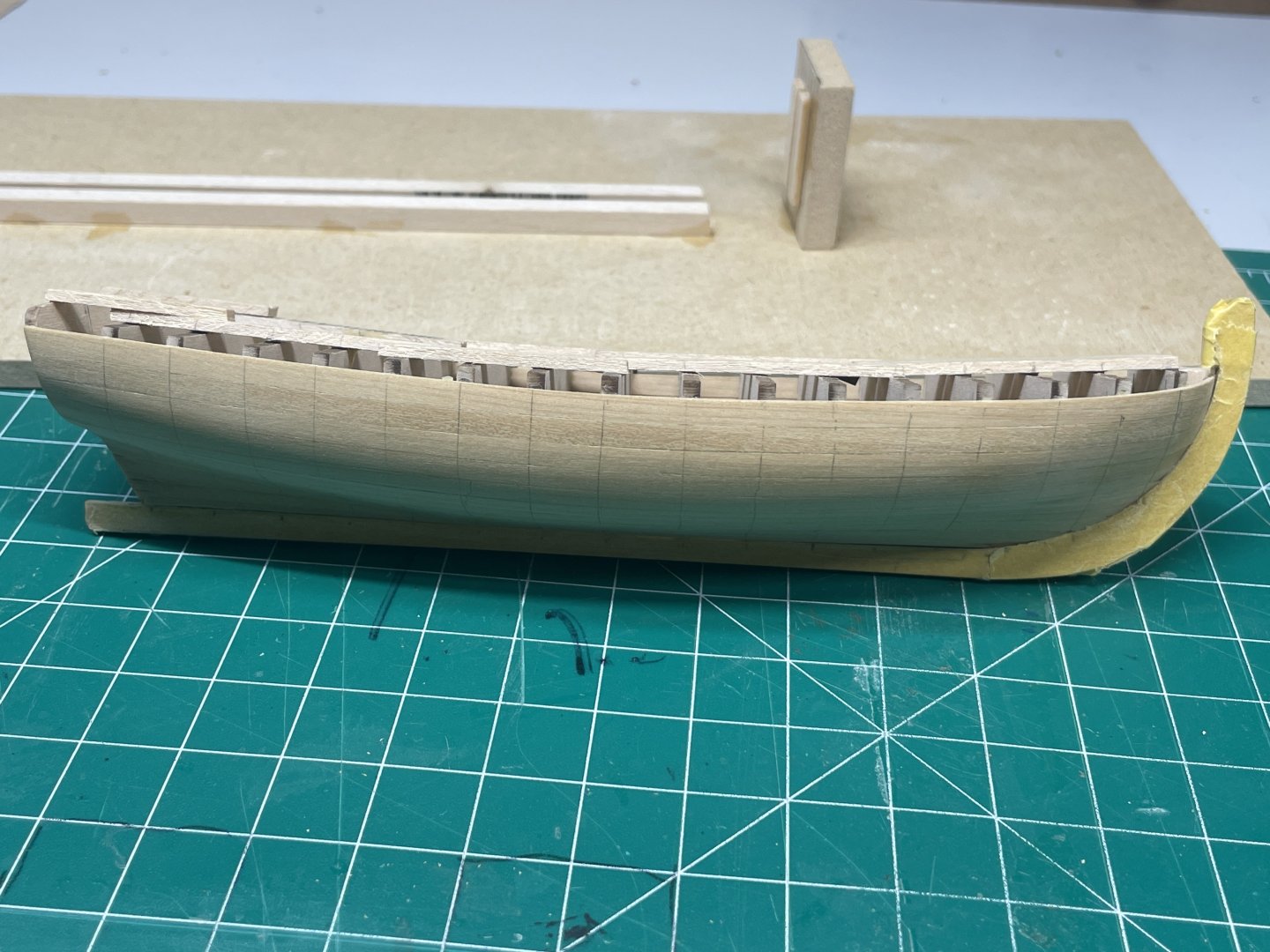

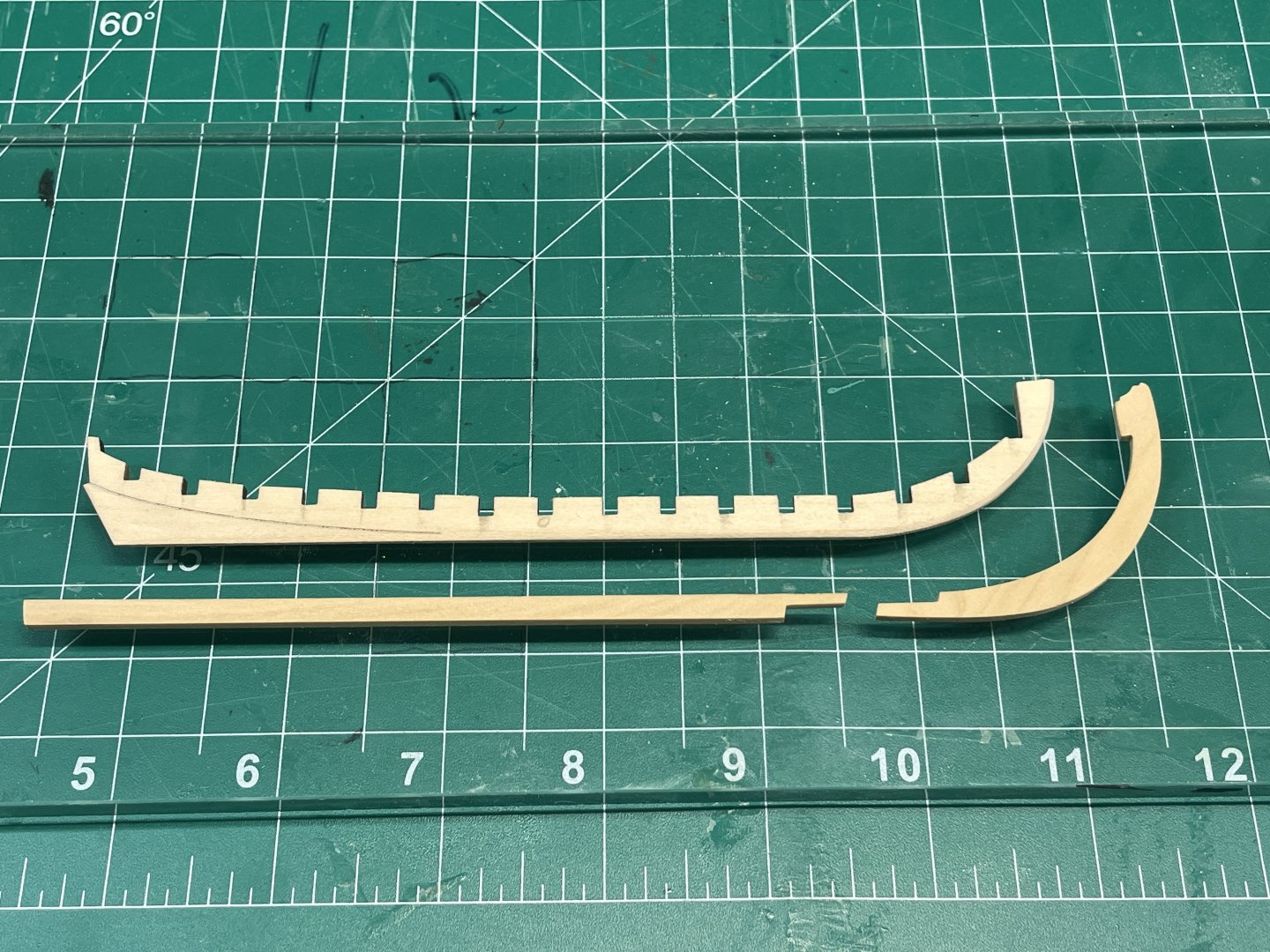

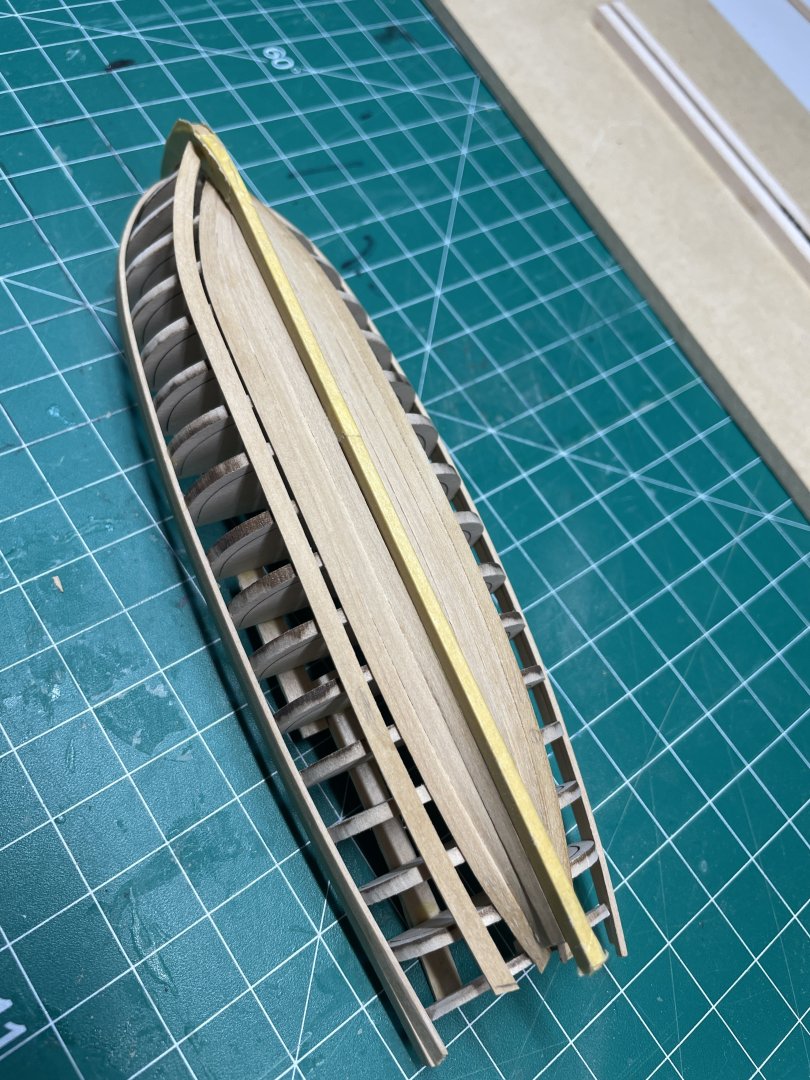

Now it’s time to remove the bulkheads and thin the frames down. I used one of the course files you get in various tool “kits” from model expo. It made quick work of the attachment points without causing any trouble. I did snap off a couple of frame tips that were not attached to the top planks very well. Those were easily glued back on and it’s essentially invisible. I tended to use lesser than more glue because cleanup was hard to get to during planking and it’s not going to be easy cleaning up a lot of excess glue between the frames. Then sanding them down was tedious. I didn’t want to use power like a dremel for fear of taking too much off. So various grits of sandpaper and I went at it. Made a little Thor’s hammer to help. It was OK but wasn’t used everywhere. I saw this on @BobF’s build of this boat. I actually need to give him more credit than just that as I’ve studied his build log immensely. Got them down to where I liked them and then it was time for the cap rail. I held a 1/16 sheet of boxwood against the wale and traced it. Here’s a question for you guys, while I was cutting out the boxwood it seems really brittle has that been other’s experience? Now I was using a bandsaw with a fairly rough cutting blade so it could have been that. Also cutting out small pieces with a sharp exacto will have it split sometimes also. Anyway I cut out the piece way oversized. I cut out the part for the stem and glued it on. I didn't have any curved exacto blades to use for glue cleanup. I ordered some but while waiting continued working on the cap rails. The plan was to NOT glue them on until I cleaned up the inside. Ooops, I missed that memo. So now it’s a little bit harder to get to! HaHaHa. I then sanded them down to a 1/64 overhang. It still looks a little heavy where the breasthook goes, so I’ll probably take that down a little more. Here’s where we stand so far. I’m trying to decide if I can get away without painting the wales since it will be a shame to paint over that woodgrain. Thanks for checking out my build! Chris

- 38 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks Ronald. I really tried to take my time with each plank.

- 38 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

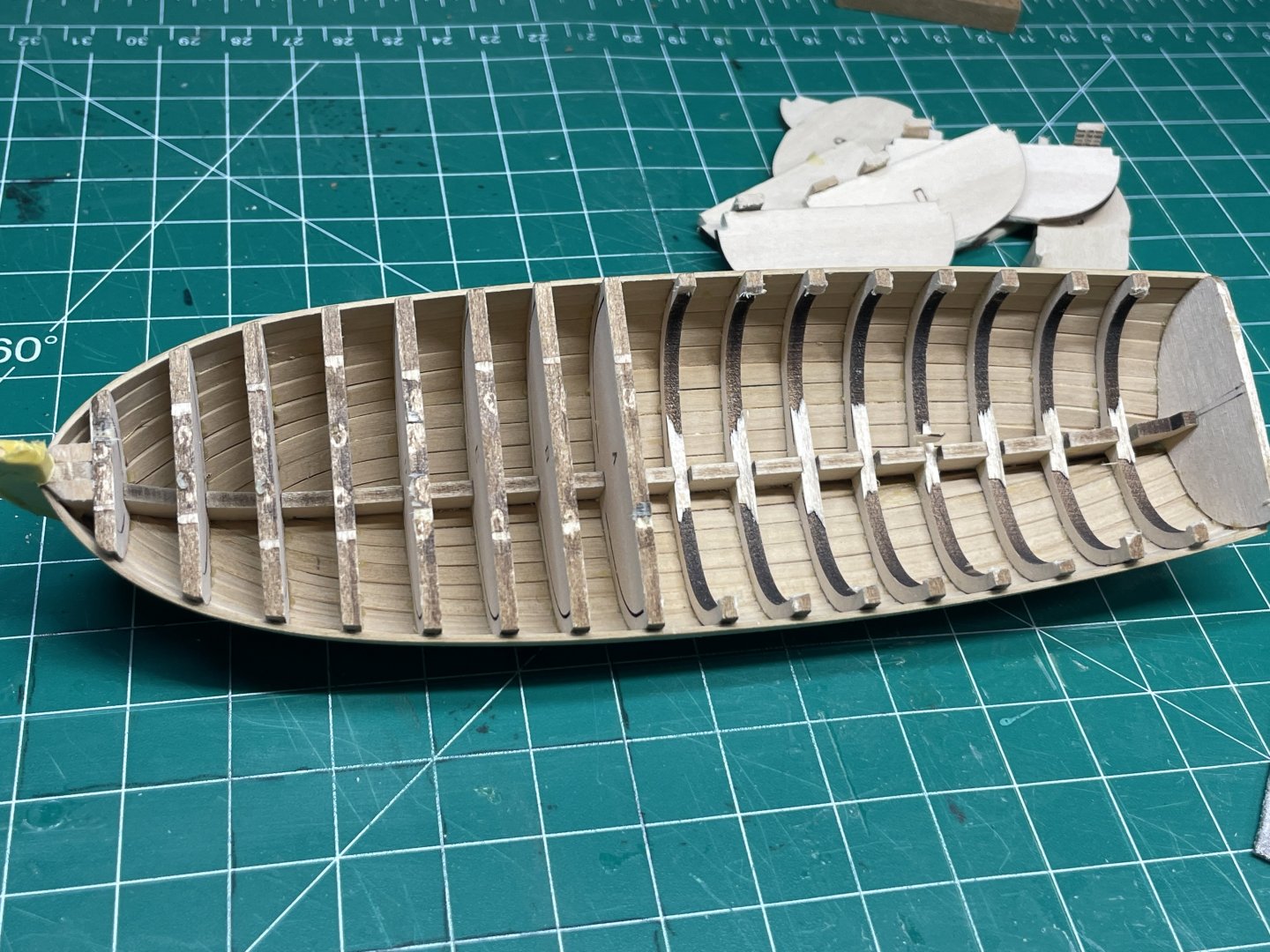

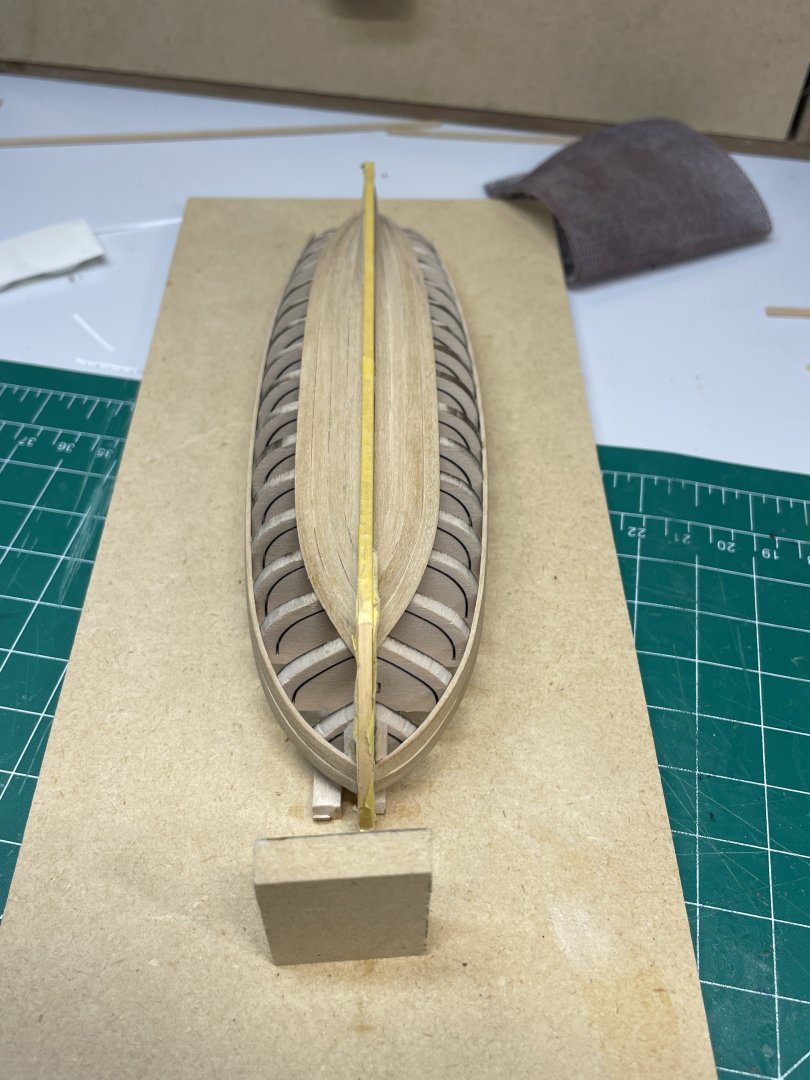

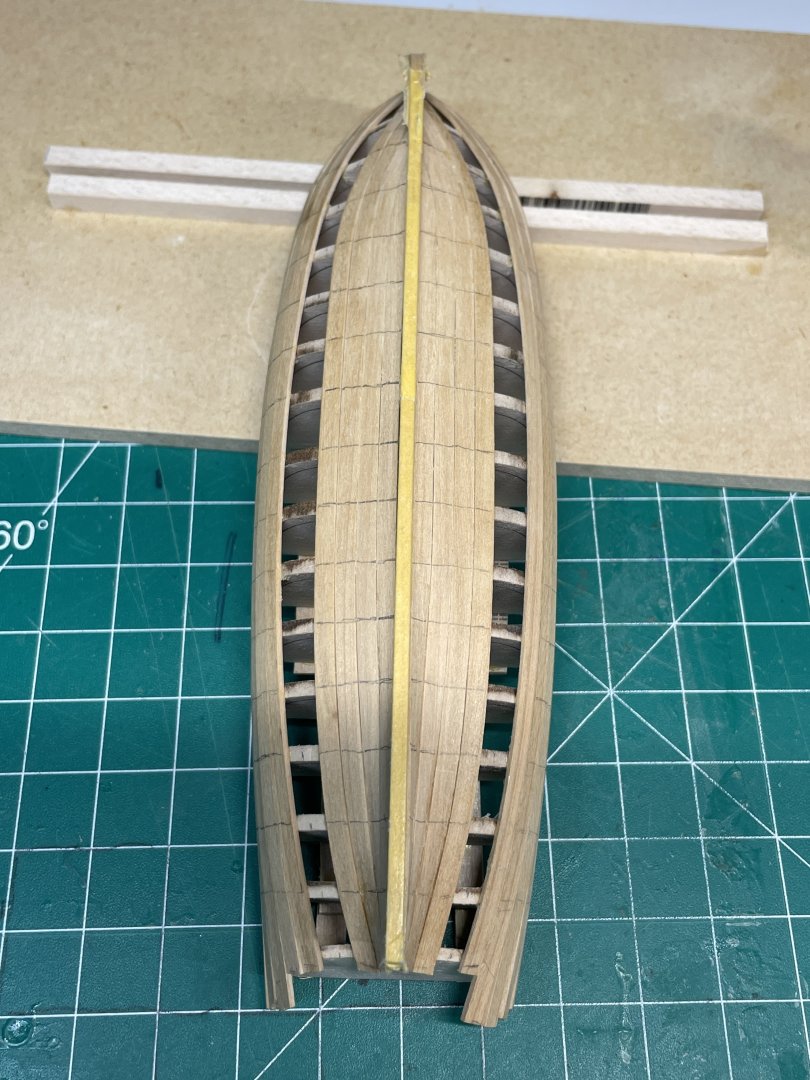

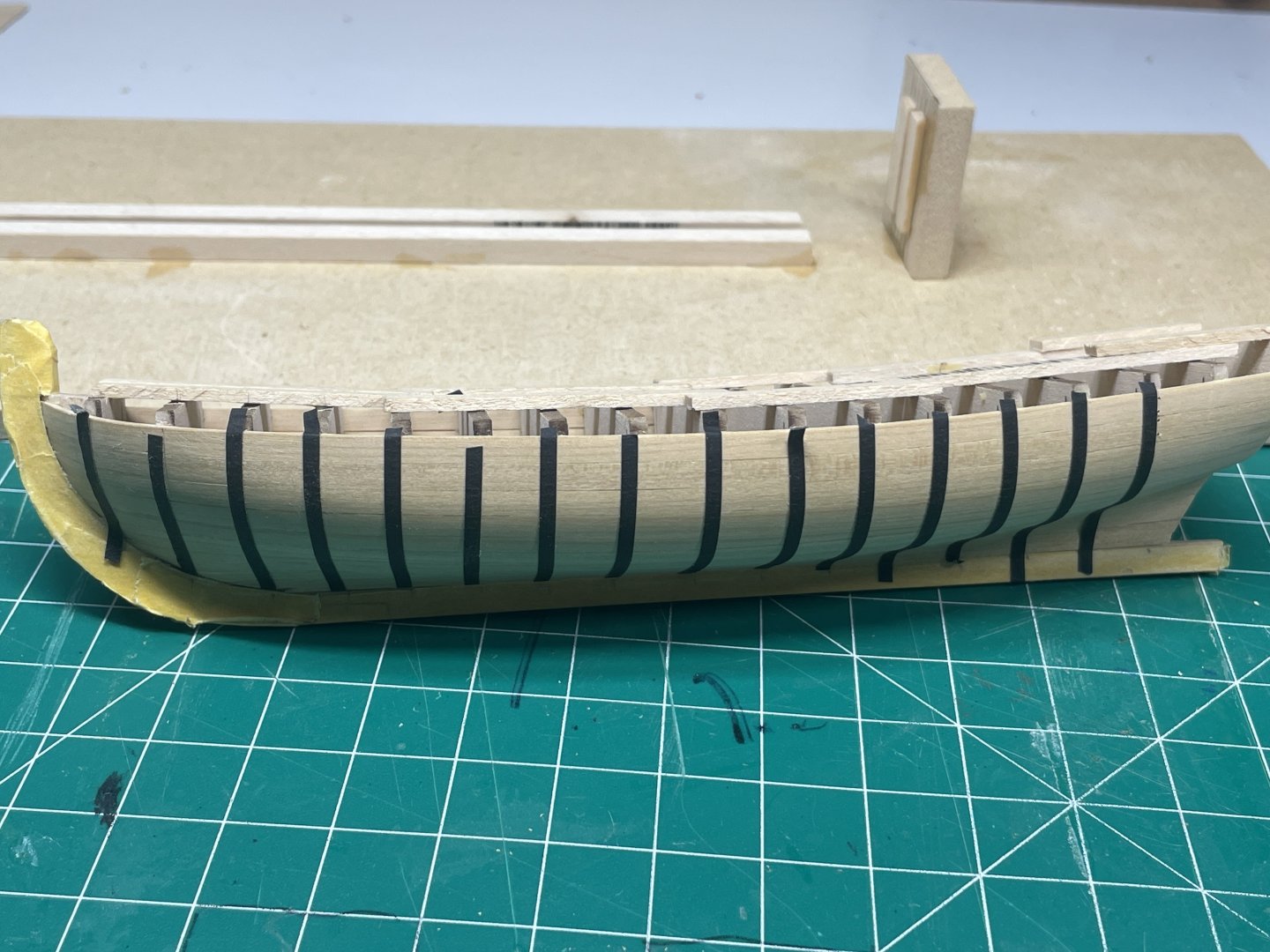

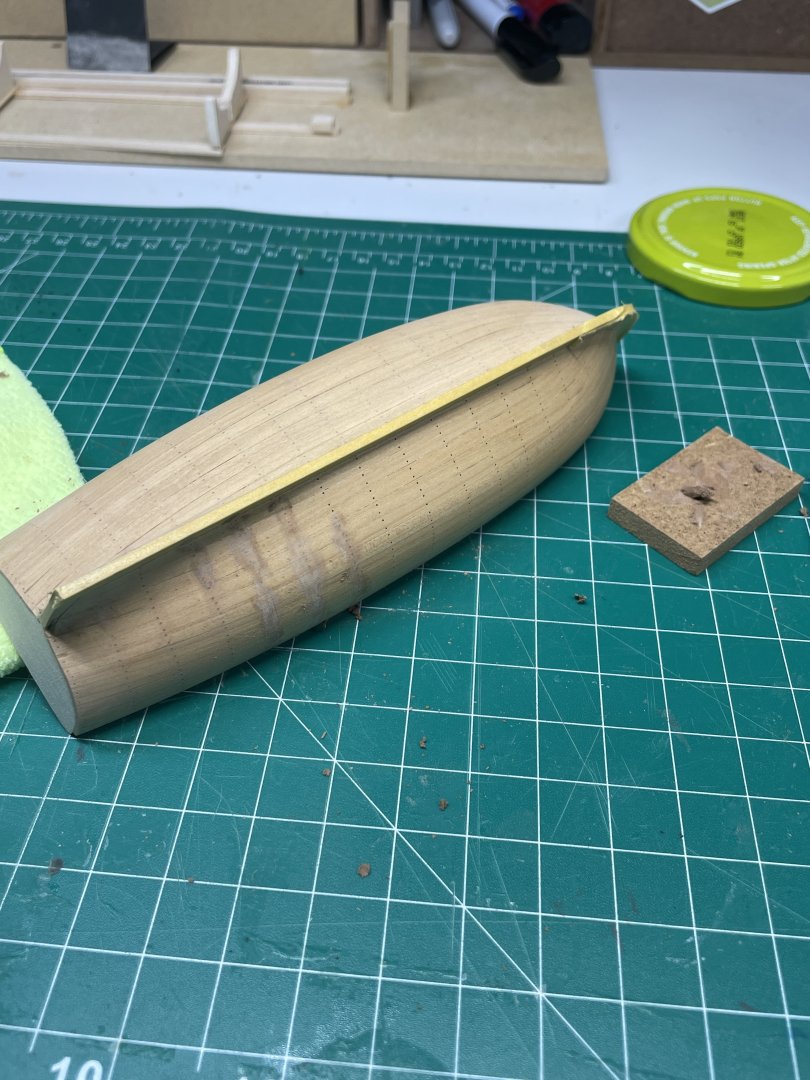

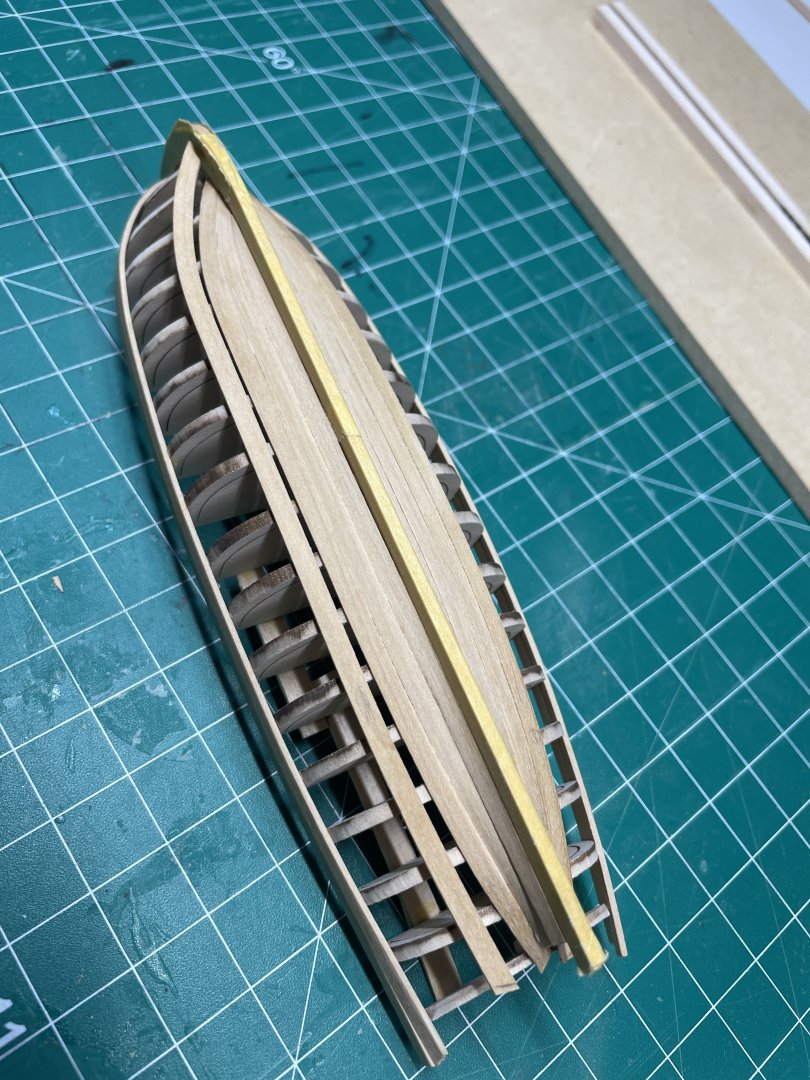

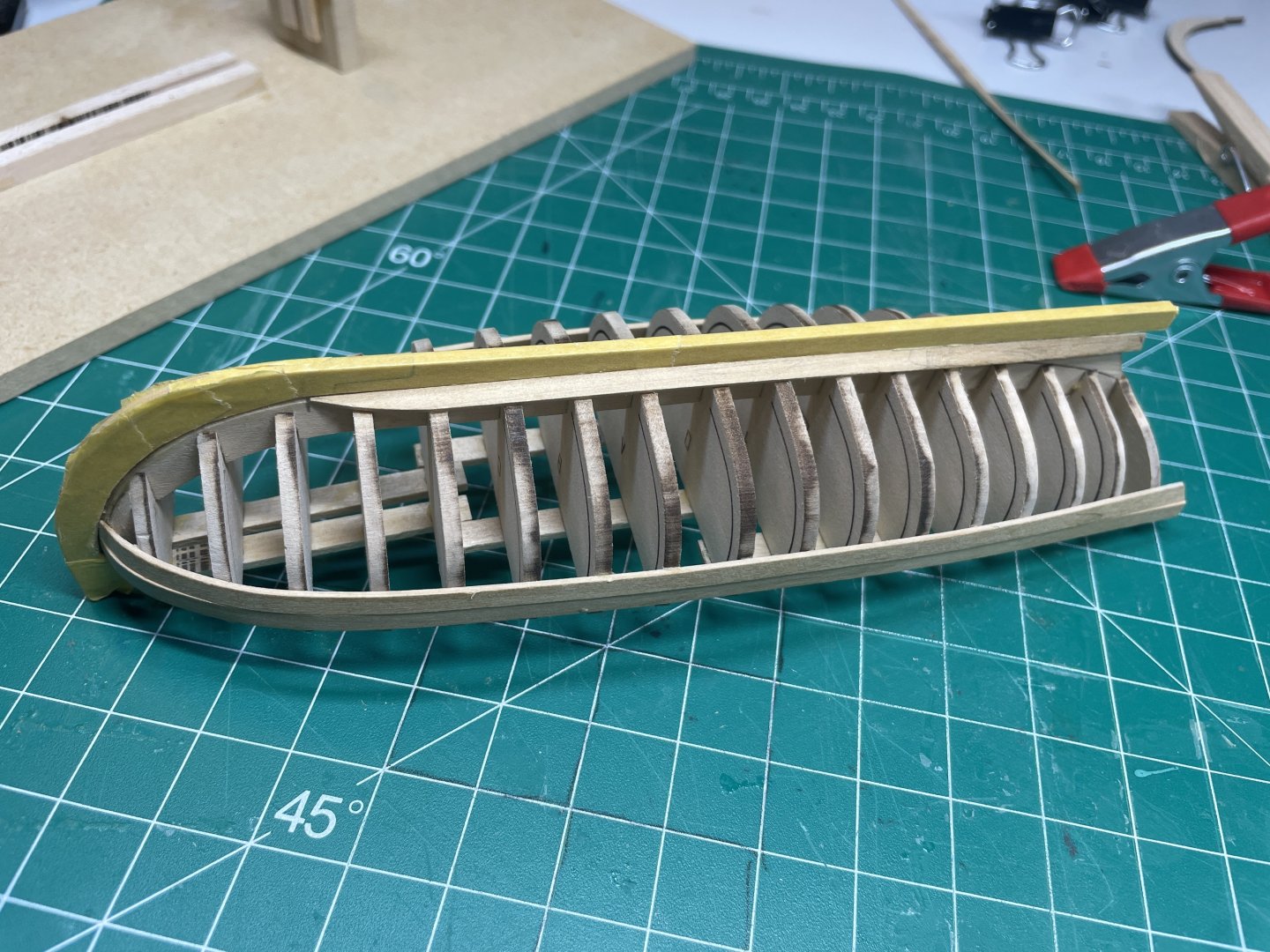

OK so I just made this post like an hour ago, I clicked submit reply and it just went away. So if this ends up posting twice I will delete one. I’m continuing with planking. These are some tight curves since it’s so small. The boxwood seems to want to fight back against bending. Does that match with other’s experience using boxwood? Used some clamps to help keep the seams tight. I used the Scotch tape method to get the shape of the final plank and then shaped it. Here she is pre sanding. Not the prettiest planking but I think my skills are improving. Post sanding. I was able to not have to use any wood filler. I did use a little thinned glue in a few seams while I sanded it smooth. I then used tape to line out the simulated treenails. On the other side I used pencil marks. I’m not sure where the line is between dedication to the craft and insanity. If my rough math is correct I drilled just short of 800 holes. I gave the hull a couple of coats of WOP, this was to try to limit any staining from the wood filler that I plan to use in the holes. I used a lab spatula to push walnut colored wood filler into the holes. I would then use a damp micro fiber cloth to wipe off the excess. One side is WOP’d the other not. I’m really happy with the results. It looks a little shiny because it’s wet. The dots are less pronounced after drying. So in the next steps I will be removing the bulk of the bulkheads. Thanks for stopping in. The likes and comments are always appreciated! Until next time. Chris

- 38 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

Vanguard afficianadios...... Cutter Alert vs Brig Adder

Desertanimal replied to bigcreekdad's topic in Wood ship model kits

I think Hornet pretty much summed it up. I recently finished Alert. Excellent kit like everyone says. Just less rigging with Adder. Among other obvious differences. You can’t really go wrong with either kit. You might get more specific answers if you narrow your question a little. “Compare them” is pretty broad. -

Beautiful build BE! Your work is exemplary and your logs are a joy to watch. Not to mention the wealth of information they contain. I really like the display you chose. Chris

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

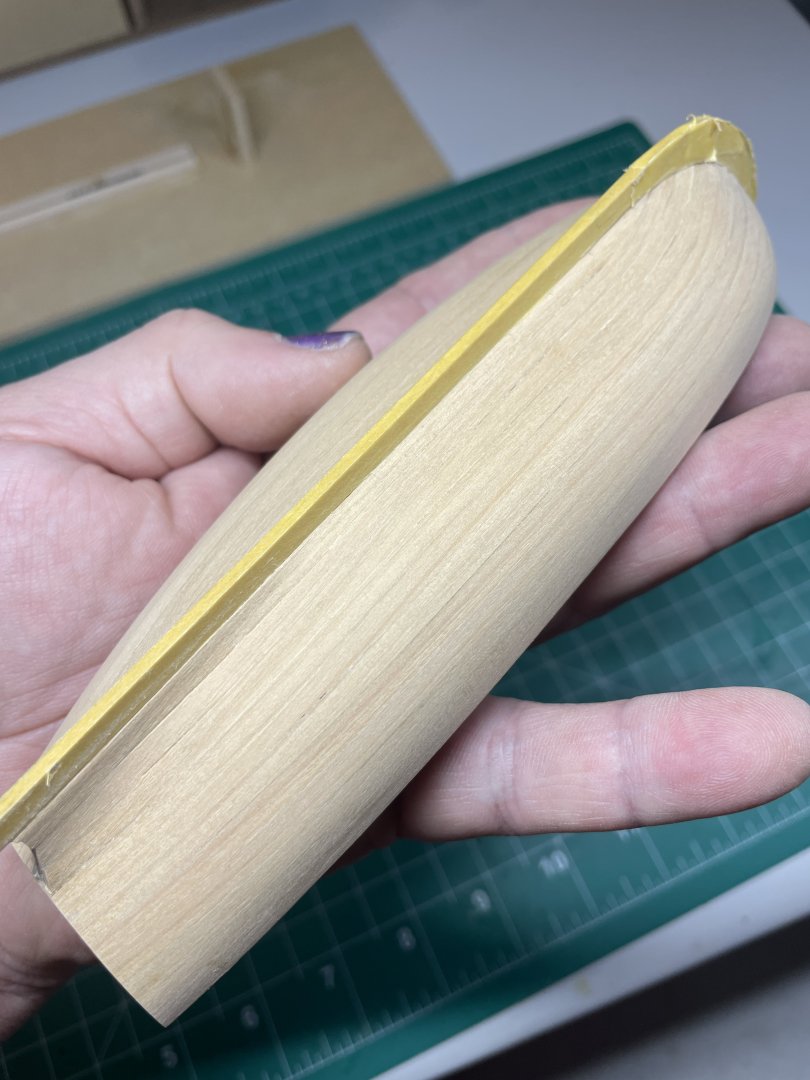

First off PVA won’t cause trouble on the second layer. Planking is for sure a big stumbling block for many. Including me. You ask how to cut the planks, that’s the easy part. Use a steel ruler and put it on top of TWO planks laid side by side. One you will trim the other is just to hold up the left edge of the ruler, assuming right handed. That keeps the ruler level. Then it’s bend and fit, trial and error. Are you edge bending? That’s the key for many. Once you have that figured out it will help a lot. A combination of edge bending and curving the plank will usually get it to sit quite flat. You hear a lot about clamping the planks in place. You should not need a lot of clamping pressure to hold them. They should sit flat so a little finger pressure is all it takes to get the glue to hold then start on the next plank. Usually the matching plank on the other side, so your a step ahead. You’ve already made one just like. Except opposite bend direction. In this picture you see the plank edge bent to match the curve. Next I’ll curve it along the length and it should lay very nice. That plank is boxwood. I use water and a small quilting iron. No boiling, no ammonia, or any other silly stuff you’ll hear. I’m far from an expert with this but I do think I’ve improved my skills over my earlier boats. This boat will not be painted so I’m trying very hard not to use any filler. Hope this helps a little and makes sense. Chris

-

Congrats on completing her. It was a while in the making but she turned out great! Chris

- 177 replies

-

- Sherbourne

- vanguard models

-

(and 3 more)

Tagged with:

-

No they are extras. There are two of each cut out for you. Small pieces can be fragile so they gave you extra. Chris

- 28 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 2 more)

Tagged with:

-

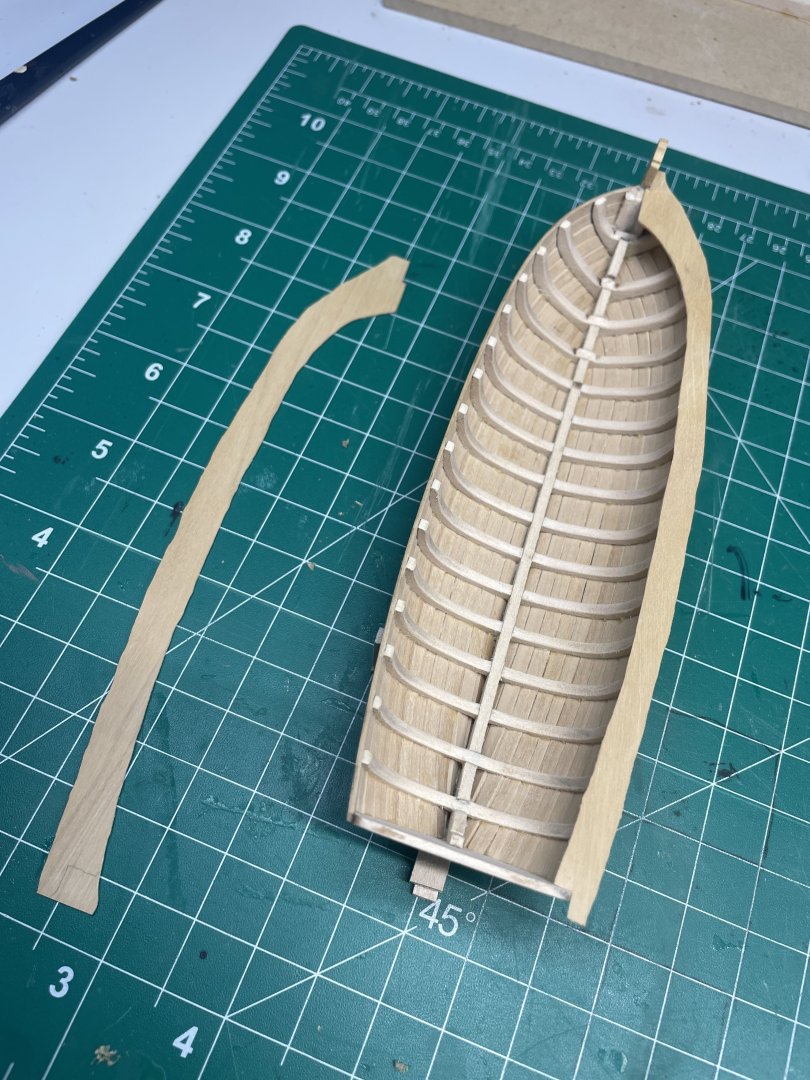

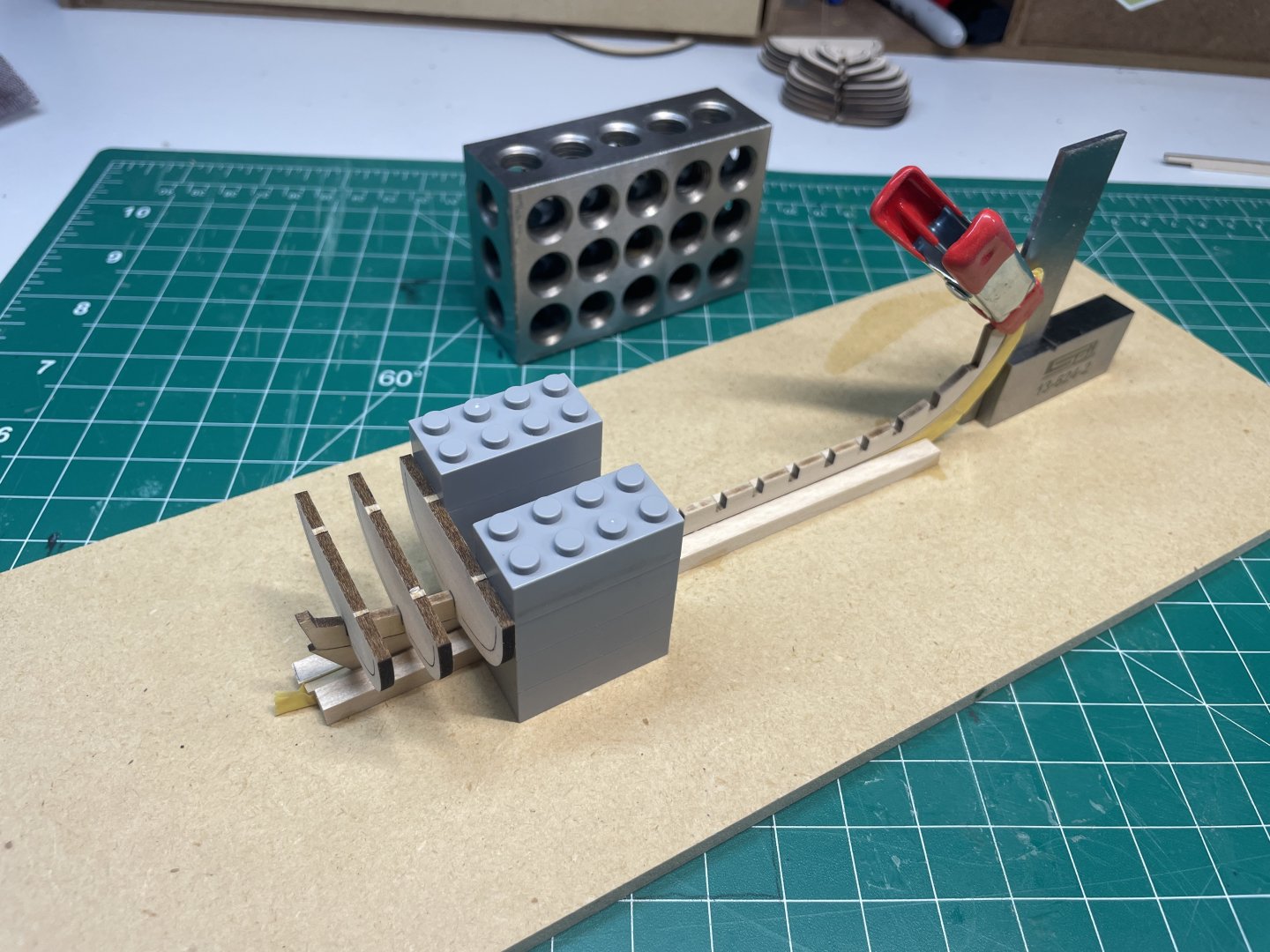

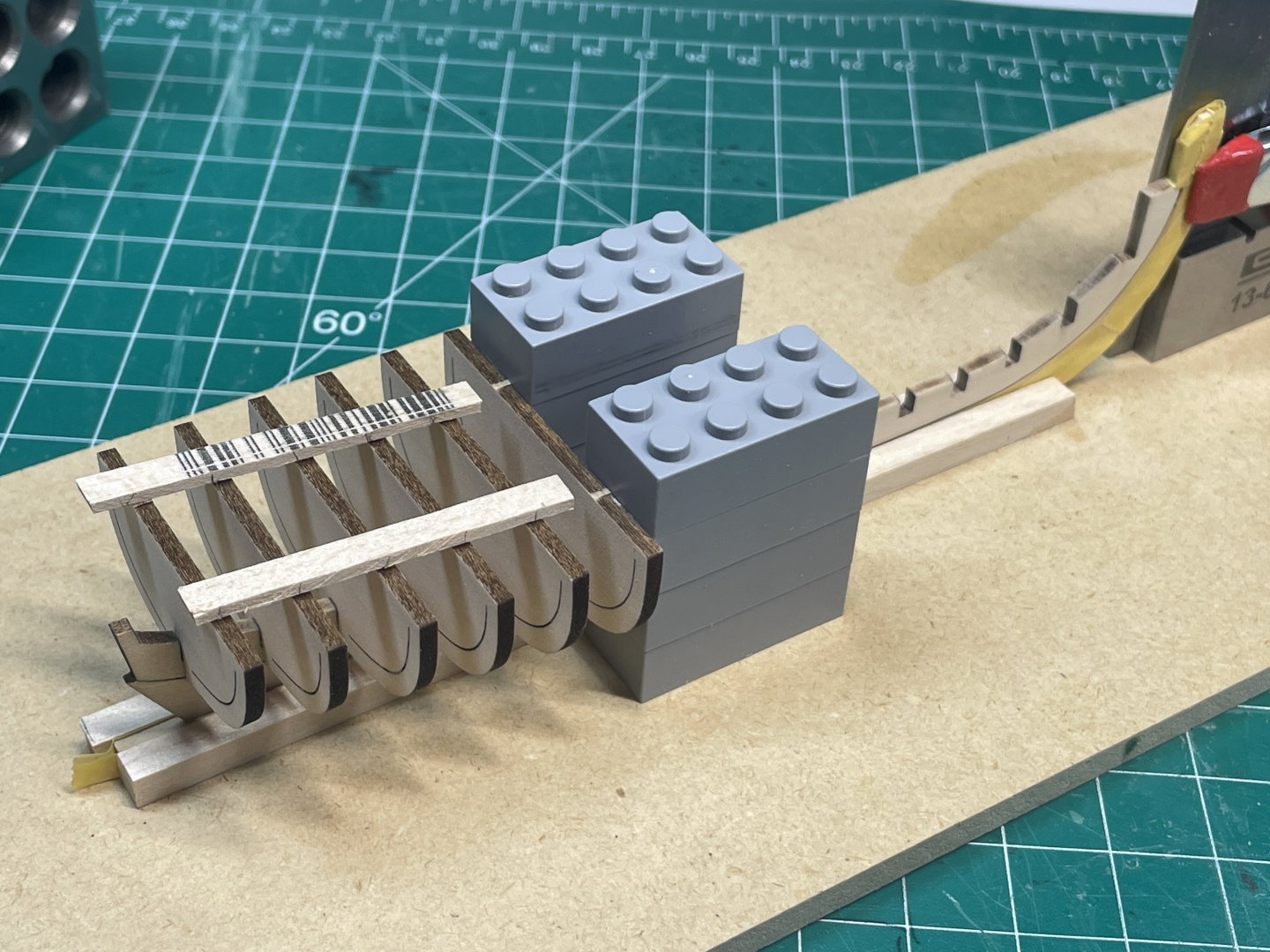

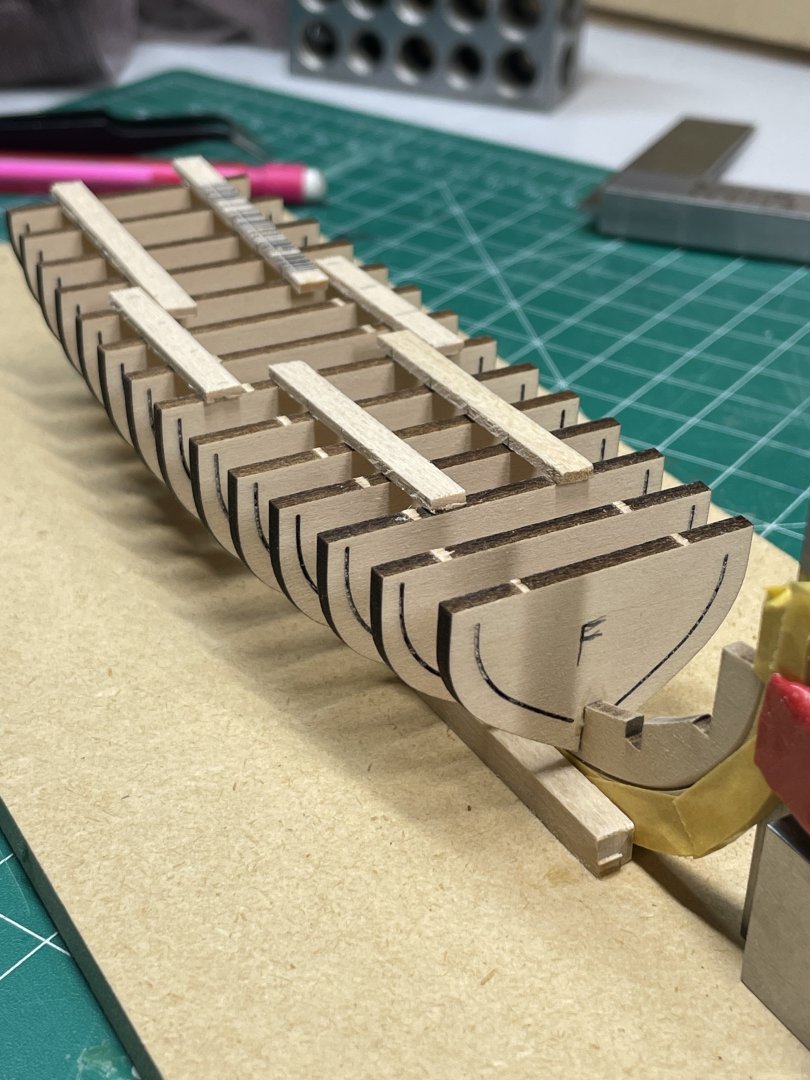

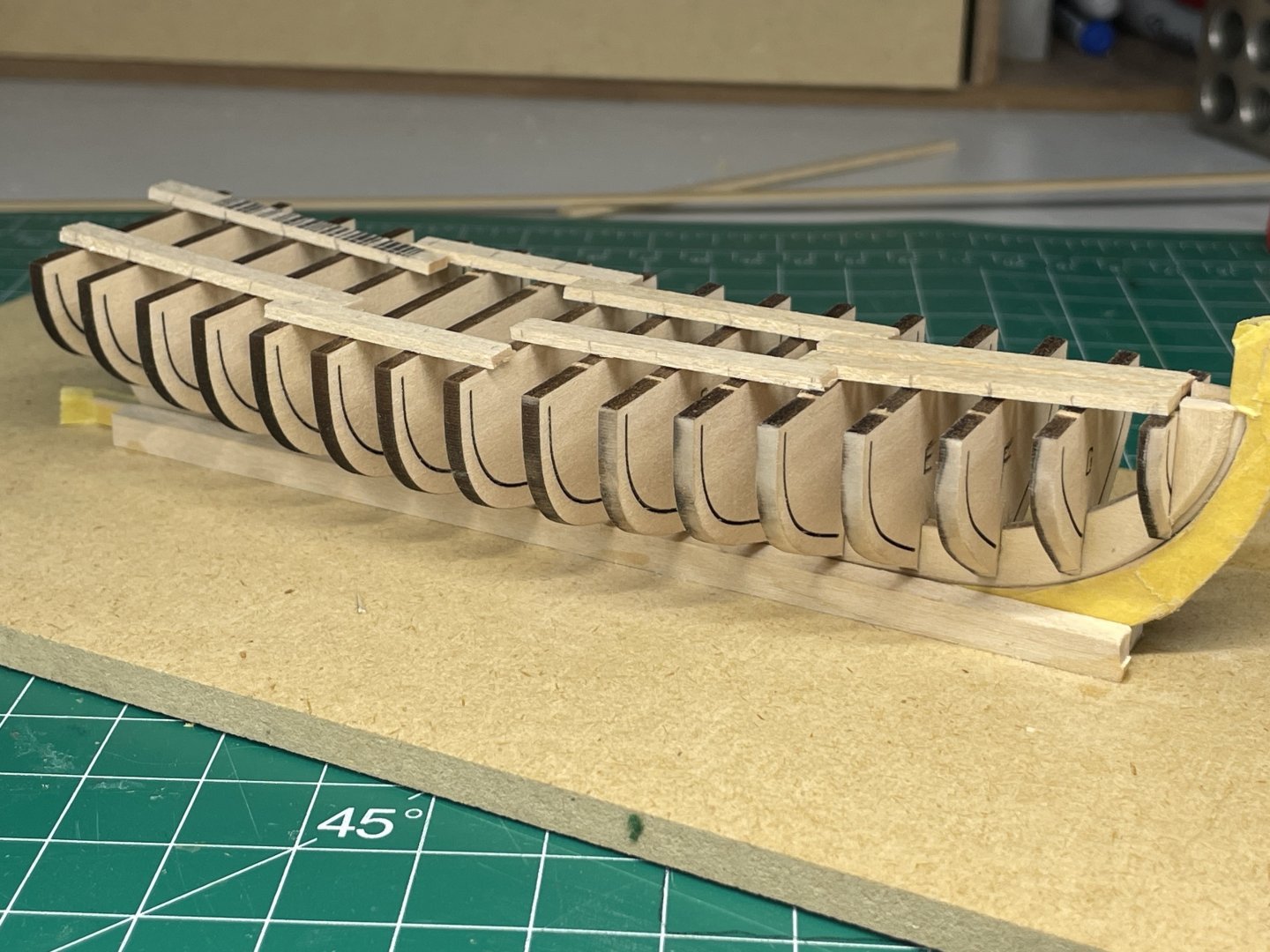

So after Alert my plan was to start Cheerful. I had begun getting all the stuff together and actually purchased Chuck’s last laser cut starter pack. 👍 Then I saw an email with the Longboat on sale. I thought a smaller project might be a good chance to improve my skills. I started looking at some build logs and also decided to replace the basswood with boxwood. I contacted Joe at Modeler’s Sawmill and he set me up with the requisite pieces. I had already purchased all the Alaskan yellow cedar for Alert from him and I highly recommend his services. Since this is an older kit it’s pretty much been done before which is good for me but I can’t say it’s going to be a particularly interesting build log for the reader. Here’s hoping someone enjoys watching. Here we go with the photos… Marking out the keel and stem on a piece of boxwood. I then cut them out with a hand scroll saw. I cut the scarph joint and I’m preparing to glue it to the false keel after sanding the bevel. I’m doing it on a piece of glass. Little MDF building board I put together to keep it square. Using Lego blocks, I saw it on here and decided to try it out. I glued support pieces as I went along to keep it square. I glued them to the waste part of the bulkhead. Starting the fairing process. This always causes a lot of stress on me. I’m always worried I’ll take off the wrong amount. I put two planks at the top as the instructions stated, then went to the garboard strake. This is another place where I’m just never sure I’ve got the shape correct. I’ve got the keel and stem taped to protect them. Here’s a shot showing the size. Planking this little boat is not easy. This is an example of the edge bending needed up at the bow. I had some difficulty getting the twist at the stern but I’m thinking it will be OK. Thinking of previous builds basswood might bend easier, but maybe not as smoothly as boxwood…? Or maybe my technique has improved making the bends smoother. Hahaha I’ll leave it here. Hope you enjoyed the pictures. Chris

- 38 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

I think planking the hull is a real stumbling block for many new builders. You will improve with practice. Do as much research as you can looking at other logs to get a handle on the planking, as well as the tutorials Thuky has directed you to. It’s an important part of the build. Looking good! Keep it up! Chris

- 20 replies

-

- Sherbourne

- Vanguard Models

-

(and 1 more)

Tagged with:

-

She is a lovely boat Jacques! Very well done. I enjoyed following along, your work is always a joy to watch. Chris

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

The NRG office is back open

Desertanimal replied to ferretmary1's topic in NAUTICAL RESEARCH GUILD - News & Information

Welcome back Mary! You take your time, nothing is more important than recovery for the long term. The phone messages will be there when you get to them! Chris -

Amazing work. I never tire of your photos. Chris

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.