Kurt Johnson

Members-

Posts

859 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kurt Johnson

-

I have been waiting for Chis Watton's Revenge since in was just a rumor about 3 years ago. I finally am semi retired so I have the time for her and got together the scratch to order her. So just gotta sit on the front steps waiting for the UPS man. I've been following the Revenge threads here at MSW to help pass the time. What I'm wondering does anyone have any resource suggestions for info about English race built galleons or the Revenge? My searches haven't turned up much. Kurt

-

With micro drill bits that would be used with a pin vise, which are better bits hss or carbon stellfor our purposes? This is for use with wood.

-

Chuck, With regards to strength of things. Do glue or epoxy your gun carriages in place or pin them somehow to the deck? Kurt

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks B.E.!!

-

Does anyone know the area where the cutter HMS Cheerful actualy served? Kurt

-

Matt, I appreciate your imput. I do use a leather stop that I charge with compound. I have seen some fancy sharpening systems out there, but am interestd in traditional ways. I really have always been very interested in hand tools, especially old ones and the proper use of them. My father drummed into me the proper care and way to use a particular tool. I have always been in awe of the apprenticeships that craftsmen underwent to learn their trades in the past. I used to rent a converted skiff house in the Thousand Islands on the St Lawrence River in upstate New York that was built around 1900 for vactation. The beams, etc. all had hand planed beading! The wood work was amazing in what was actually just a boat shed! I really didn't mean brands, but types like paring chisels, etc. I know amazing chisels have been made from old files by some people. That must be work. Kurt

-

I do appreciate sharp tools. I've been woodcarving for over 25 years. Most of my carving tools are Ashley Iles with some Flexcuts thrown in. I was wondering about specific preferences concerning joinery. I actually have a neat little set of Veritas chisels which look promising for modeling.

-

Dave, Read the build from the beginning, lots of good info. Didn't make he Lumberyard connection until then. Kurt

-

Thanks, Very interesting. I going to read the entire build log right now!

-

A question for the people who model those amazing plank on frame models out of box and pear. What type of and brand chisels doe you find work best for creating that fantastc joinery? Kurt

-

Elmer's ProBond

Kurt Johnson replied to Kurt Johnson's topic in Painting, finishing and weathering products and techniques

I didn't do a test on it but I was afraid that was what I would hear. I don't see the praticality of mixing up saw dust. It would onlly stay the right constancy for 2 or 3 holes, and there are a thousand. I know I can always mahe real treenaiils. May be wax will work. -

Is there an American glue that is equvilent to Butapren?

-

Now for something entirely different - card model

Kurt Johnson replied to Kurt Johnson's topic in Card and Paper Models

Thanks!, -

Now for something entirely different - card model

Kurt Johnson replied to Kurt Johnson's topic in Card and Paper Models

Sorry for the way and where I posted this. I guess I wasn't thinking. I downloaded the Digital Navy Oregon, it looked "slightly" simpler ( I'll save the Arizona for a while). I figured if I take my time it might actually get finished. I can just keep remaking parts till they come out right, can't I? I love the pre dreadnought era ships. I live an hour from the Olympia and have climbed all over her. I started reading what I can find on card models. I know I can get support here. So we'll see what happens. Kurt -

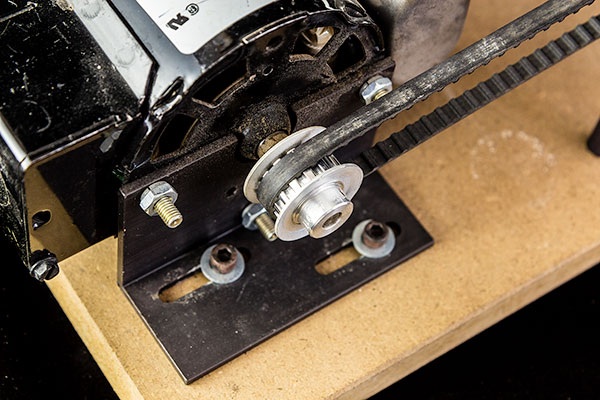

timing belts and pulleys

Kurt Johnson replied to Kurt Johnson's topic in Modeling tools and Workshop Equipment

The manufacturer, Preac, is out of business. I have already up graded the motor to 1/3 hp. I thought it would be an interesting modification while I save up for a Jim saw, which is a ways away. Can't figure out the correct pulley and belt combination. -

I came across this mod for a Preac saw. Toothed pulleys and a timing belt replaced the stock ones. Anyone know where you would get these and what you would properly call them. The existing belt is a 1/4 x 14 inch Truflex and the motor shaft is 0.55 inch in diameter. I'd love to try this out. Kurt

-

Chuck, Would you be able to make a set of the Horseshoes and fish plates, reduced to 3/16. The hinge staps could just go along for the ride. Kurt

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

HMS Alert 1777 by Jaekon Lee - 1/64

Kurt Johnson replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Lee, I continue to marvel at your hull planking! Do you have any pictures of a individual plank being made. Do you use any kind of jig to aide with controlling the change of depth approaching the bow. I've been reading everything I can find on full size lapstrake construction, but at model scale it is intimidating. I have a Veritas miniature block plane and it is a really beautiful tool. Next payday, I'll spring for the shoulder plane. Kurt -

HMS Alert 1777 by Jaekon Lee - 1/64

Kurt Johnson replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Lee, Do you model anything else beside ships? Kurt -

HMS Alert 1777 by Jaekon Lee - 1/64

Kurt Johnson replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Lee, Amazing craftsmanship. Do you have any pictures of other examples of your work? Kurt -

HMS Alert 1777 by Jaekon Lee - 1/64

Kurt Johnson replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Lee, Thanks. That's twice as thick than I thought and obviously doable. I want to try it for the Sherbourne. I was thinking of 1/32 boxwood for planking but that would really be a feat., making a shoulder. I am sure there is someone out there who could, but it ain't me! 1/16 seems reasonable. Once done it could be sanded a little thinner. Now to Lee Valley, I really like those guys. Kurt -

HMS Alert 1777 by Jaekon Lee - 1/64

Kurt Johnson replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Lee, How thick is the planking and how thin is their shoulder? Kurt

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.