-

Posts

412 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by olliechristo

-

The drawing is perfect,. That's all I need, totally understand now. Thanks Jeff I'm really enjoying the deck. The plank widths vary considerably so I'm trying to keep same plank to each run, thanks ollie.

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Okay so adding 20 hours to build log... No worries Tom. Glad it shed some light on the Mermaid for you... Jeff, i don't mind at all mate. If i could be of advice to Sailor I would.. Well i have made good progress on planking my deck.. The shift planking is much like some of the mosaic and tiling patterns i have done just different terminology.. I have it well under control, only query is how to calculate when joggling should begin?? I gather it is when the cut at end of plank exceeds a certain length.. ? Regards Ollie..

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Thanks John.that explains a lot, I will Start laying my margin planks.. It would be good to add them but maybes too hard.. They would be rather small I gather, I may just dummy them on the painted side..Regards. Ollie

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Tom, the model itself is 590mm long and 450mm tall.. In real life she was only a small vessel, just 18 metres long, with a beam 5.48 metres wide and measuring 84 gross register tons. Read this pdf if your keen - http://www.anmm.gov.au/webdata/resources/files/Signals86_Mermaid.pdf Sailor1234, Thanks for joining in, She is only two cannons, two culverins, anything but a war ship,, Built for hydrological surveys,, just a bit of self defence I think... Aliluke, thanks for your compliments ans thoughts, I appreciate it.. will do some searches... Thanks all.. Ollie

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Oooh an update, and a Christmas update looking great,, thanks Ron and have great Xmas mate...

-

John, this hobby should have come with warnings.. I can see myself wanting to build the Endeavour from scratch or something else completely outrageous and infinitely time consuming.. SO I have worked out my plank length and they are to be 125mm which equates to 6 metres or about 19.7 feet, The red lines are the 4 Butt pattern im going to be following, the previous were the 3 butt spacing... I have made my margin planks, it took some doing.... I have decided on 4 butt shift pattern as it works better with my margin plank lengths (100mm) so both land on beams which are 25mm apart... I am wondering about scuppers... - should they get cut in before margin plank to avoid damage and how many to put in? Is this first painting of the mermaid showing scuppers? Regards ollie

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Thanks Jeff, It came up really beautiful your Norfolk.. And lots of great pics for me to gather from.. Thanks Brian, I appreciate it, trying to make her a bit unique.. So I realised that joining two planks looked kinda average, and not how it would be done realistically.. so i set about coming up with a solution and i am going to put in the extra effort.. ... I found the closest match of timber i could in the shed, it's a bit darker but i think that will look okay.. I set the table saw (its a rough one) to its minimal cut (about1mm) .. Then i made up a simple jig that anyone could whip up.. Consists of two hardened pieces of metal on a very flat surface, In this case 'stanley' blades, stainless would work good also.. So then file or sand and you cannot go too far beyond your desired thickness you have setup... I have made a couple and they measure 7.5mm wide (thats what the stock was) wide by 0.6mm thickness . the calipers are a bit worn, but i know that so i accommodate for it.. Thanks so much mates..

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Oh no don't be sorry at all. I dont expect anyone to be on here all the time.. Just thought i would have a go.. no glue of course.. Thanks John, you are a godsend, Very thankful as always..

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Ok well i thought i better use some initiative and joined two planks side by side with glue and sanded.. This is all i could think of to do and once caulking is added i don't the eye will really notice it.. Turning some corners today.. Also when I got home early today I was feeling brave and in the mood to cut out my side of hull for the 'revealing' side of the ship.. Regards Ollie

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Just wondering guys... I am going to make a start on the margin plank soon and wondering if it is typical to use the same planks as deck? Jeff'.. I noticed on your Norfolk Sloop you used a thicker and wider margin.... Planks being only 4mm wide it looks tricky to keep the margin at that width and would certainly be a lot easier to start with a wider plank say,, 6-8mm.. Also wondering if it is usual to bend or cut to the curve of bulwarks? Ollie

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

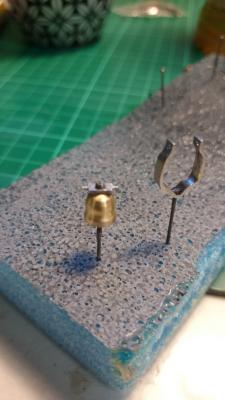

Hi all. Well the first two eyelets were too small, they had 1mm centres, second round was heaps quicker of course.. Pictures show how i made them, i want to have a full circle of metal not a piece of wire joined as i dont have the right soldering gear... these are flattened 2mm brass rod that was supplied for axles, eyelets have 1.5 mm centres now and look right.. primed and let to dry before black.. progress is slow until holidays and then will be patchy but hope to get a couple of solid days in, instead of little bits... Ollie

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

That is interesting tom, I hadnt figured out how to make them yet, but your method of tumbling sounds great.. I have made a homemade tumbler but have been thinking about a loritone 3a or the like.. One of my other hobbies is metal detecting ( i collect hobbies;) Although i search for old coins not in current circulation i happen to find a few modern coins and they are not scoffed at. .. So a tumbler is on my list! It will pay for itself.. Oh and regarding the bits,, Yes i want to order a few more, I like the look of the ones with fatter shank and only short micro bit at end, much less likely to break and flex or wobble. It is silly really to use a long micro bit if not needed. Rarely drilling long holes it would seem.... http://www.ebay.com....=item43bace93e7

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Yeah great if your in oz but, just ordered the micro chuck, 10 piece drill set and micro drill all express posted for $50, not a bad deal a think, thanks for the heads up.

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Thanks so much, they have some great gear

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Thanks all Tom. I had a look at those canons,wow a bit of a contrast to my little babies. Jeff, I want to add as much detail as possible so thanks for asking, I have made some smaller eyelets as I noticed the large shackles are not the only attachments on most canons. I figure the rigging would be the same as other canons of the era? Any advice appreciated. I figure I will need to make 'blocks' to rig these, and I'm thinking I am going to invest some drill bits smaller than 1mm. Ollie

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Whilst im at deck fixtures I felt like getting the cannons built up so i cane check port placements. ,, The kit suplied brass rod for axles but it was a sloppy fit in wheels and i think these small canons may have had timber axles anyhow... i used blackbean and worked it down to 2mm rods... I used bamboo wedges to chock wheels in 1mm holes and they can rotate nicely but not sloppy... I made my own mounts for eyelets also... and a jig to make shackles or clasps to hold canons on mount.. Ready get back to hull work almost,, Ollie

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Hi All, I have finished the windlass except for a few deck 'pins' to hold it on. When scaled up to real size the very top of the bell is just over 1.6 metres tall.. i think its all about right.. Tom i didnt get a chance to read that script on decking, it baffled me at first glance, but maybe you could PM it to me for a look,, about to get ready for planking deck this week.. Thanks

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

I can't thank you guys enough,,, ! Guess what John I got up early and did exactly that,, got some solvent on the bell and cleaned her up and satin clear coated... I had a look at some pictures and I've even impressed myself with this creation.. here she is pretty much done, might blacken up the mounting a little more as have you have suggested TOM.

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Yes and yes. I am a stones throw from Botanical gardens I love those rainbow bee-eaters. We just had that largest flower in the world happen in the gardens again.. If your ever in Cairns again I would be glad to show you some sights.. Most of my family resides down south In Sydney/Bris.. Was great to find i had family "down the road" ... I often visit Sydney.. Regards Ollie

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Thanks Eamonn Tom, that makes sense to me Yes I have been using flat black enamel, and will probably stay with that,. But will do some research anyhow,,Cheers

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Well thanks heaps again guys. I'm getting keen to start that deck planking in the next week.. Not sure of what pattern to do, any ideas are welcome.. Just want to be organised and plan ahead.. SO I put on my metal working costume and set about making the bell, I was keen.. About 4.5 hours and a heap of enjoyment.. After the last adapter adaption going so well I took another football valve and this one was brass, so nice to work with.. The rest kind of explains itself, lots of filing and fiddling.. In the last pic i have tried misting it with black and then satin clear coated, not great, might retry something else... Should I invest in this metal blacken stuff? Can i make my own home concoction perhaps, hmmm I will look into it... Enjoy the pics and thanks for looking. Ollie

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Unfortunately i never met her and I have never been to T.I John, I will have to put it on the list of places to visit.. She was born about 1920 at T.I Hospital. Graduated nursing/midwifery before WW2 at T.i hospital. Went off for first trip off T.i in 1939 by Liner to Singapore, shortly after all civilians evacuated from T.I by U.S forces in 1941, went to Cairns, Husband dies from falling object whilst riding bike in Cairns city street.. She moves to brisbane and is brought back to Cairns when she passed away and buried with her husband just down the road in martyn street. The history of the Island is intriguing..

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

I too am very excited to watch this beauty unfold. My grandmother was born on Thursday Island. looking forward to learning lots from looking at your build.. Thanks John.. Ollie

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Thanks Jeff, great info... The kit says to cut planks at 100mm lengths.. I'm not sure if this appropriate scale or not.. Getting my head around how to do the margin plank.. Should get a few more hours in today.. Ollie

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Thanks so much all of you..!!! You are keeping me very enthusiastic about my build.. I have spent another 3 hours on windlass. It has been a challenge, but all in all, not that hard.. I just need to work out the ratchet and release mechanism now.. I like the one on the 'Harriet' and you may notice that i basically copied my windlass by eye.. I like the little bell on top of the post, i would like to know what it is for and if it was common.. I gather it has something to do with the anchor procedures.. Also any reccomendations on the deck planking would be great... Should this cutter's deck have a margin plank around it? Happy crafting all.

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.