RMC

Members-

Posts

933 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RMC

-

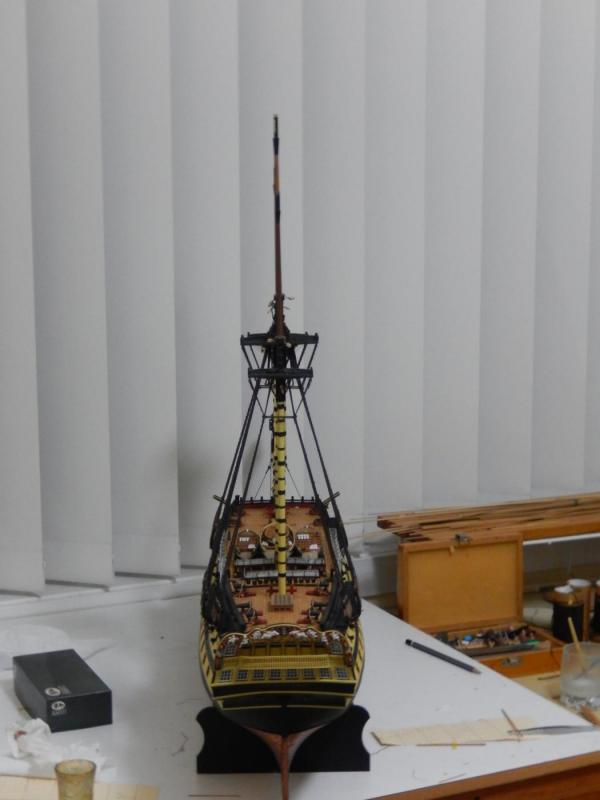

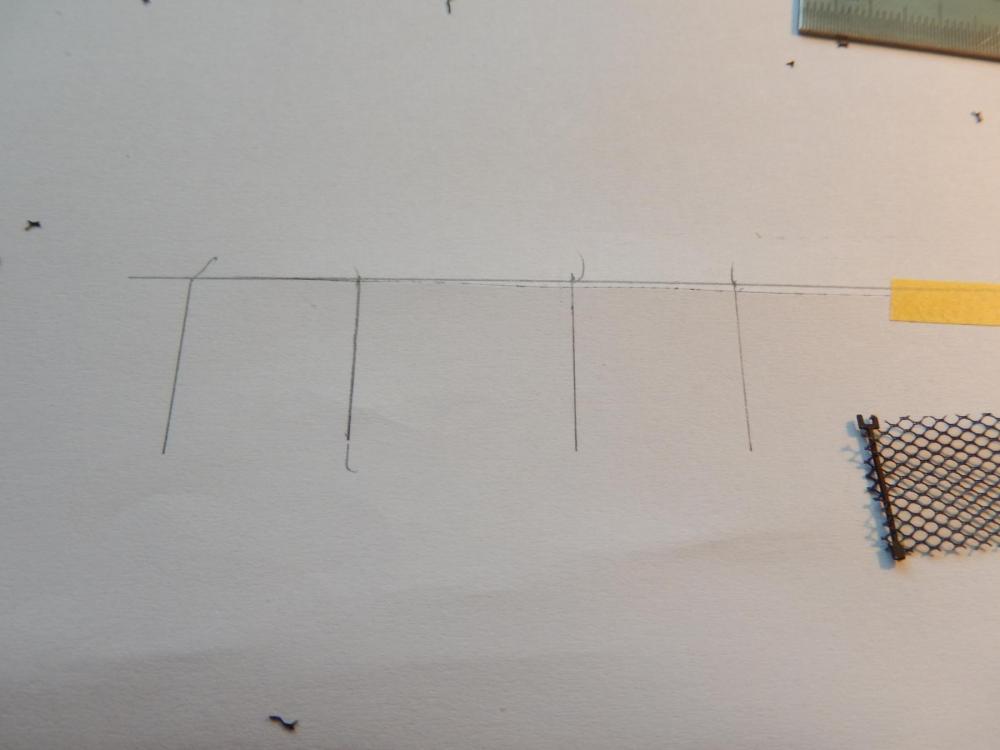

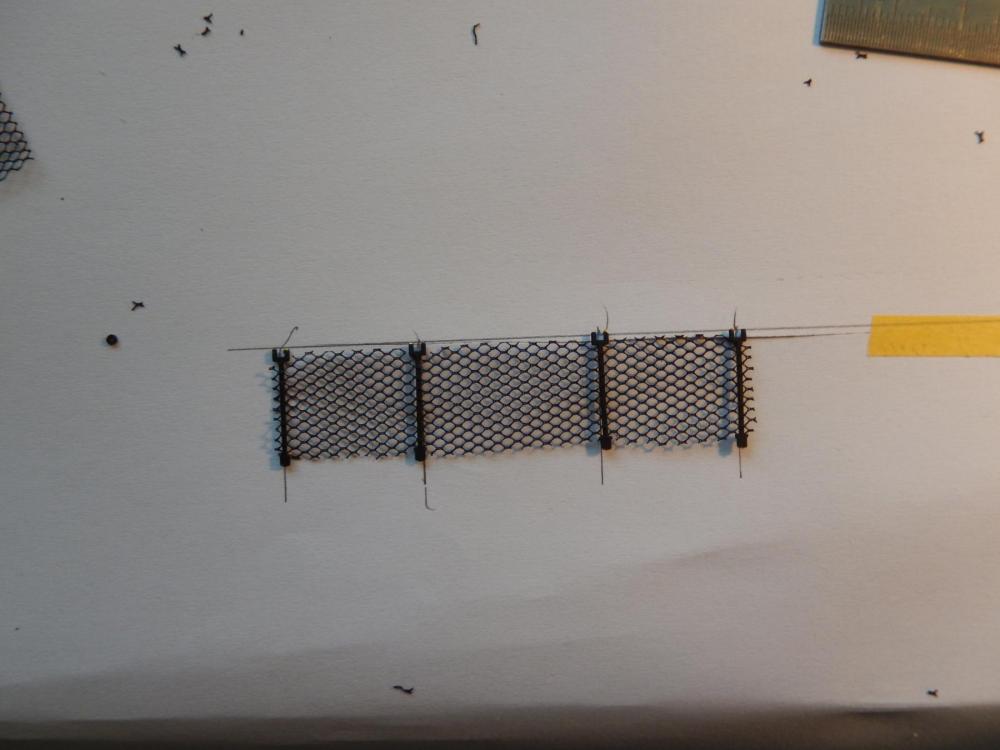

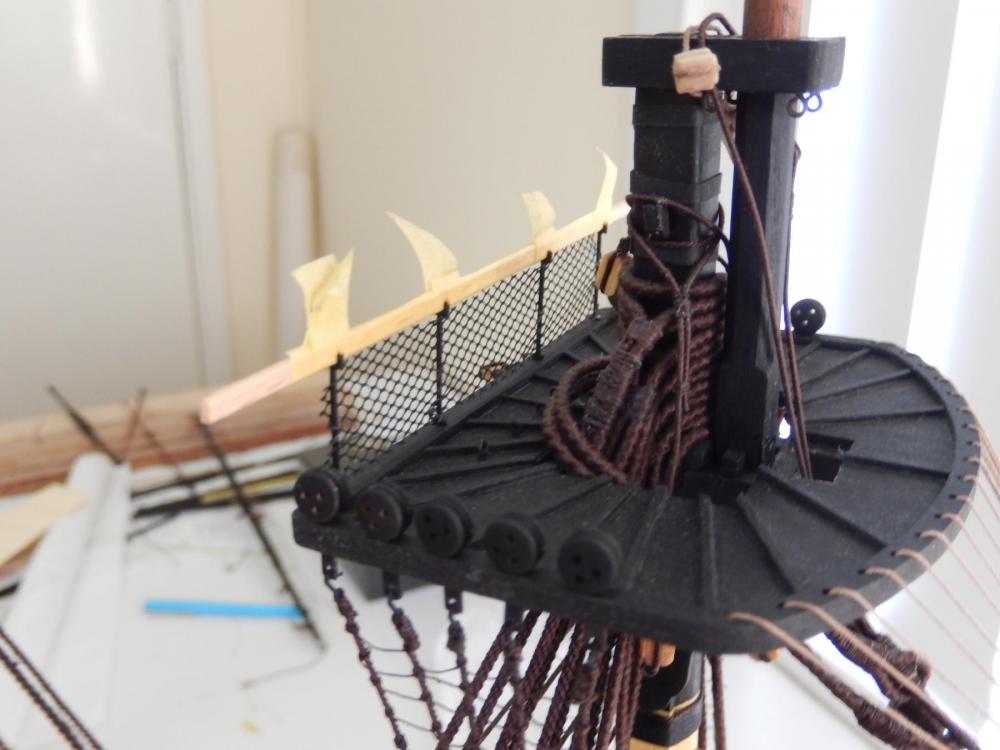

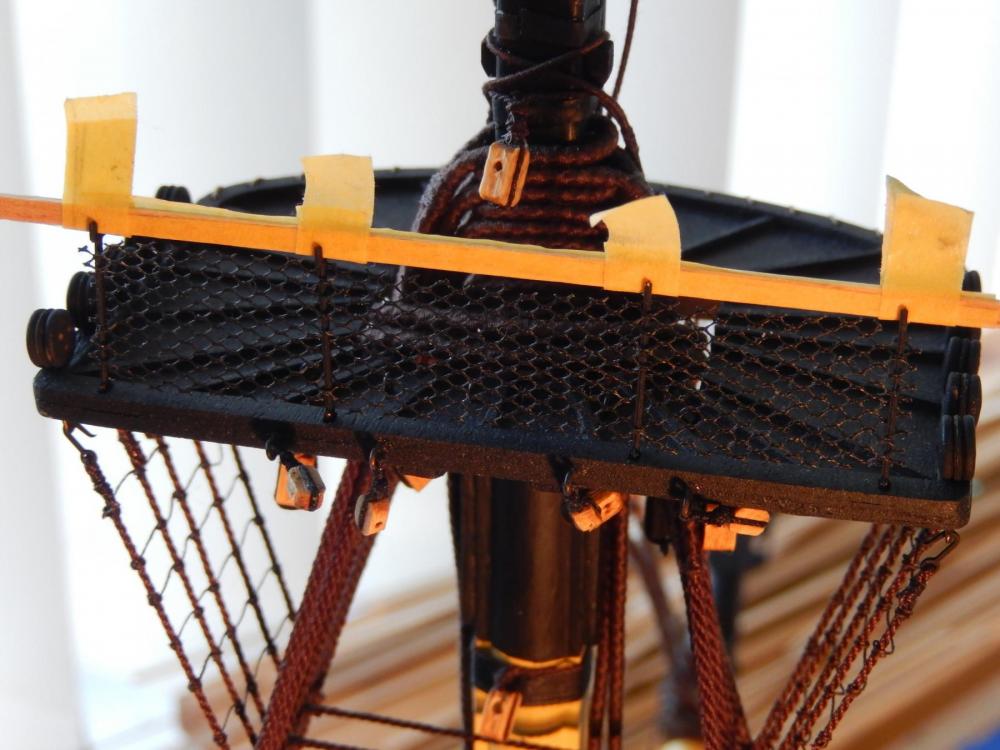

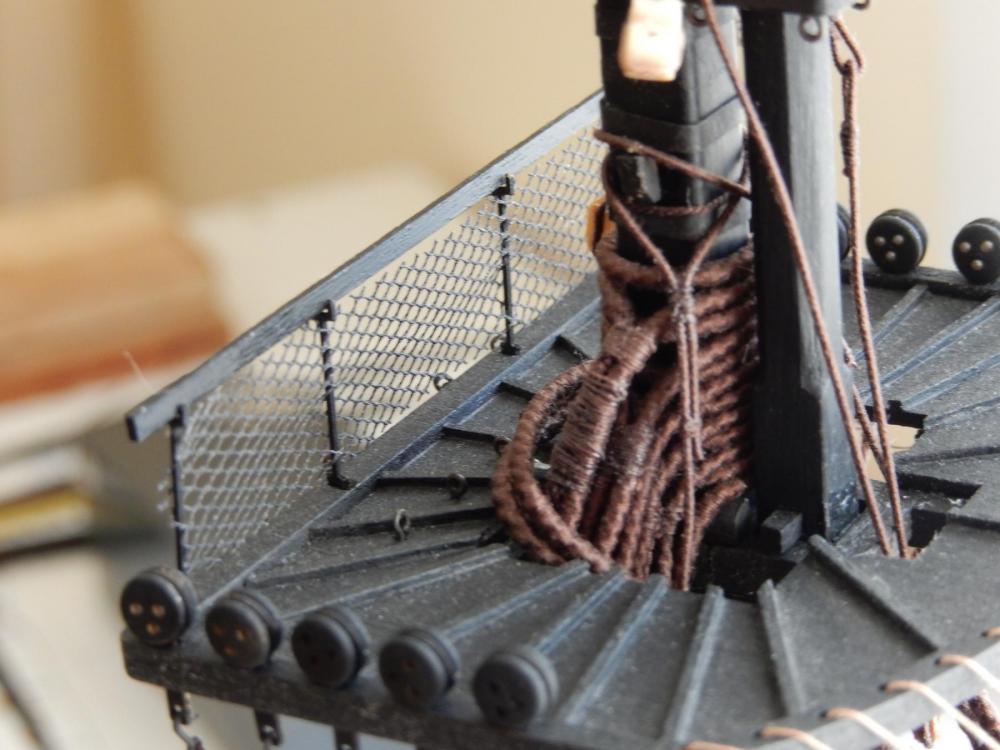

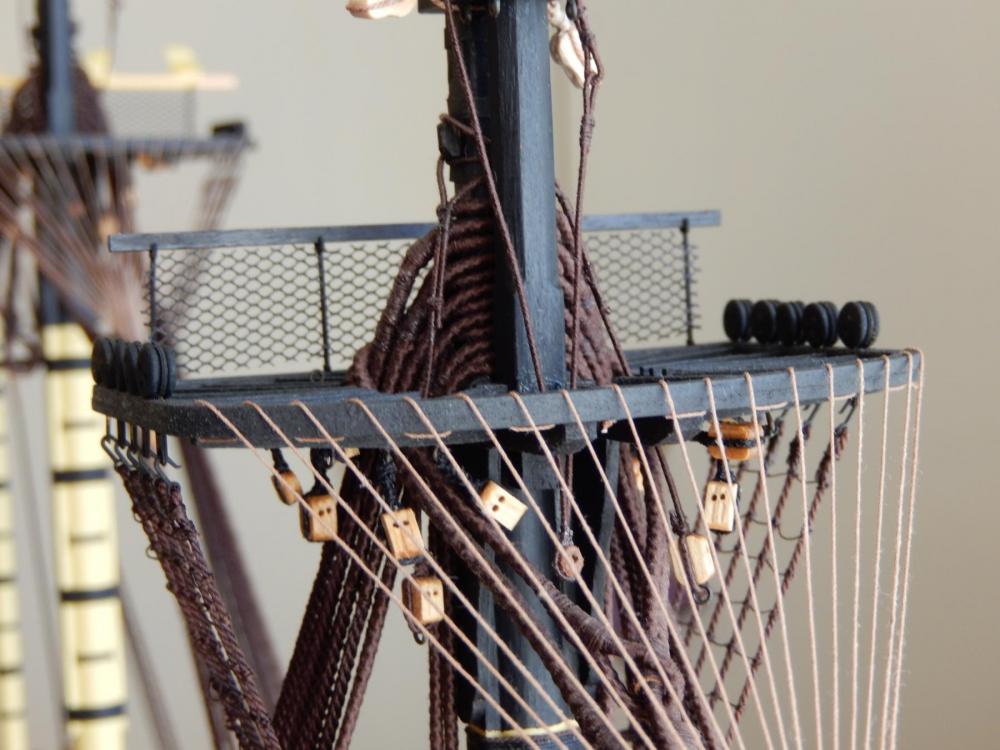

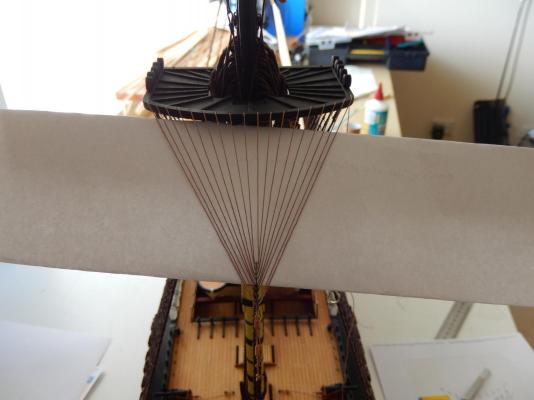

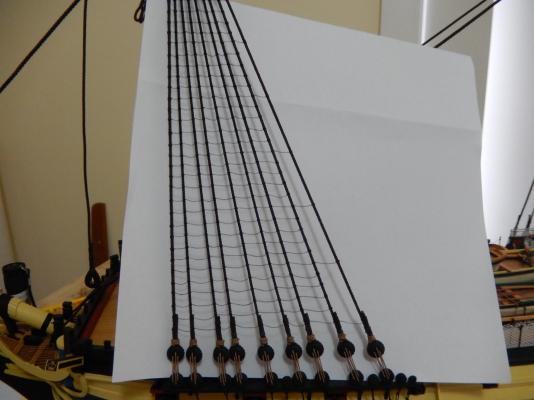

I have made a fair amount of progress oveer the last week or two (the weather has been horrible - winter is finally here). The topmasts have finally been fixed. The hand ropes on the bowsprit have been attached. There was a slight trauma here as I had provided only two eyes for the bow timber heads. It seems I should have provided three - though I haven't found three anywhere on the plans. Despite appearances the ropes are not too taught. I then got a little carried away in fitting netting (the tulle used for the hammock netting was dyed black) to the safety railing on the tops. After all you can't have sailors suing the Admiralyy for failing to provide a safe working environment. It seemed like a good idea at the time. Once I had done one I thought I may as well do the remaining two, but I don't think it was all worth the effort. For those who are also into self-inflicted pain, here is the method I used. A guide was drawn with the verticals spaced by the holes provided on the tops. I used a pair of dividers to obtain the spacing between the holes. A piece of 3x1mm strip was inserted into the notches provided in the posts. The Tamiya tape shown makes the strip a little thicker and enables the strip to stay temporarily fixed in the notches. This is the result for the fore top. Since the photos below, some touching up has been done and it has turned out fairly well.

-

You're rather more ambitious than I am. Sewing is one of the many skills I seem to have missed out on, and at my age I think it's a bit late to start. I am finally in the home stretch in tying the ratlines. It hasn't been the most enjoyable part of the building process.

-

The thought had occurred to me Jose. If have a couple of supports left over I will probably try it when the bow area is finished, but the bow is very crowded as is.

-

Thanks Arthur. I would like to have followed your lead on the metal fittings on the yards, but I am afraid that is well beyond me. I am hoping that with all the other things going on in the rigging, they will not be noticed.

-

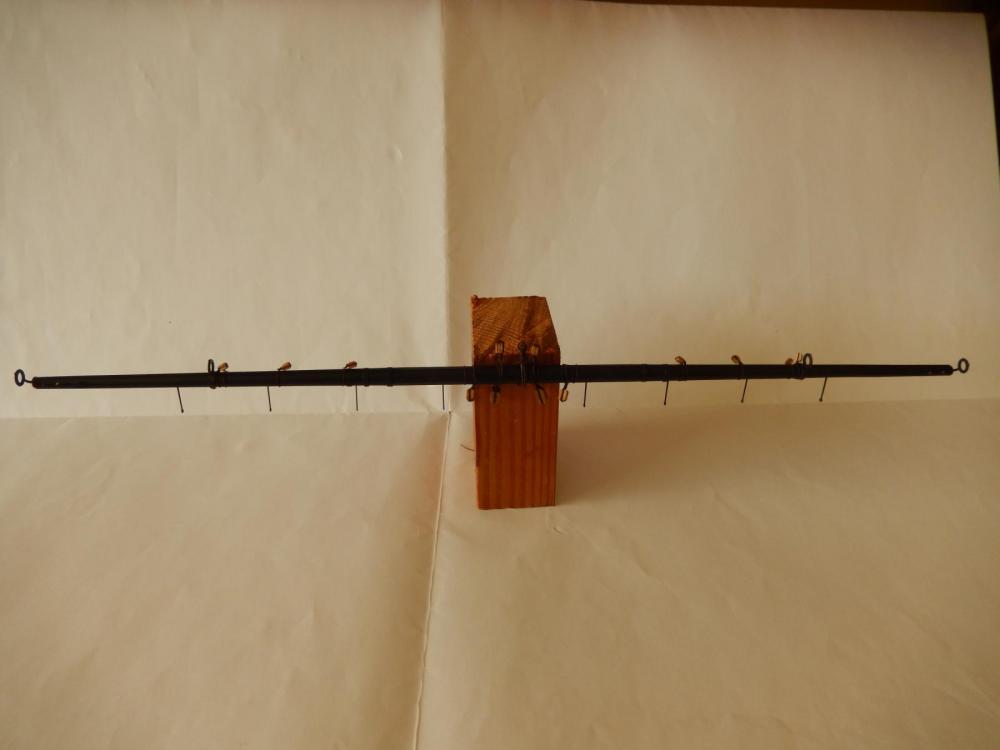

The ship's boats are now finished. I ended up using less than half of the fittings supplied. Even so, the boats are quite cluttered, but I am pleased with the result. I hope less really is more, though I have always had trouble convincing my children of that. As well, I have appropriated (ie, stolen) some ideas from Jose who was kind enough to show me his excellent work on the boats. Unfortunately the photos are not as clear as they should be. I have also been working on the main yard. It has been an exercise in how not to do it. In addition to a couple of silly mistakes, I have made things unnecessarily difficult by doing things in the wrong order. I suggest the following. 1. fit the lower stun sail boom bracket (284) 2. fit the low bracket (inner) (286 NOT 288 as shown incorrectly on the plan) 3. drill holes for, but do not fit the stun sail boom rings (515 and 515a). These may be added last. 4. drill holes to receive foot rope stirrups (524) 5. fit the blocks, leaving sufficient space to tie on the foot ropes. 6. fit the foot rope stirrups and ropes. Here is my rather painful progress.

-

Thanks Brian.I am working concurrently on the ratlines and the blocks on the main yard. I've made a couple of rather silly mistakes on the yard, but should have some photos of a reasonable result towards the end of this week. At least It seems to have turned out quite well, and I've learned a few things in the process. I hope too to have the ship's boats finally finished by then.

-

Arthur: thanks again for all your help. I had already prepared the various blocks off the model as you have suggested. It was the ordering with which I had problems. I shall follow your advice regarding fitting the foot ropes. I have Petersson's book, which, while very useful, is limited. Aside from the book by Lees (I have had difficulty obtaining a copy), is(are) there a book(s) that may help with the terminology? I find at the moment I'm flying in the dark. PS: if you and Jason ever get to Sydney, the drinks are on me.

-

Thanks Jason. Just to confirm - from the cleats: 1. foot ropes. (Horses in the yards?. I thought at first you were having a lend of me ) 2. the sister block marked 'T' 3. The block marked 'O' 4. Lift and sheet blocks marked 'O and V' I think I need a couple of more specialised books on rigging.

-

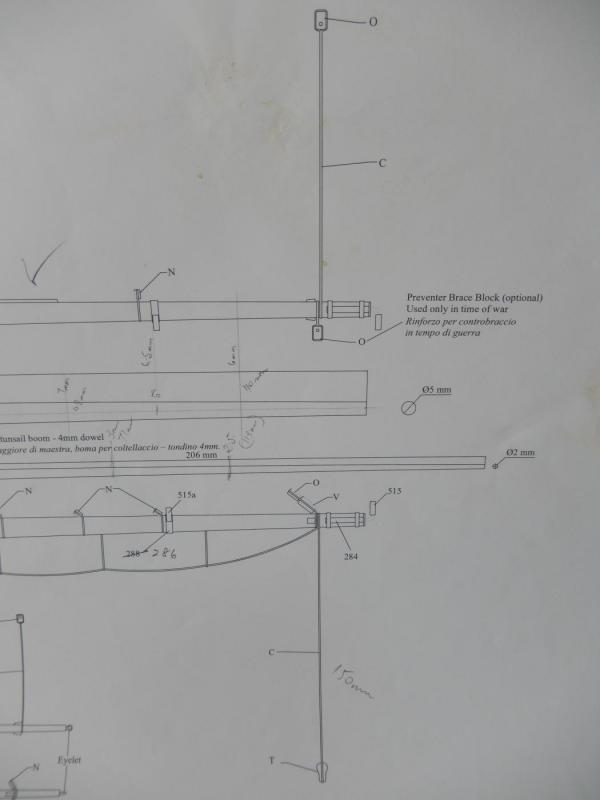

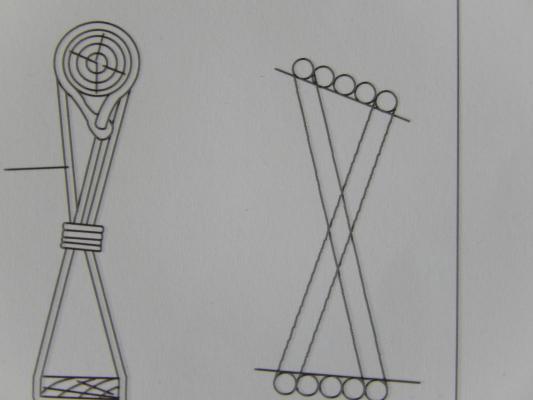

I am having trouble finding the correct ordering in attaching the foot ropes and the various blocks to the yards. Perhaps it may not matter? The following photo shows the relevant part of the main yard. I am not going to attach the Preventer Brace Block ('O') shown. I'm assuming peace for a pleasant change. Aside from that, there are four things to attach to the right of the cleat:(1) from the top diagram the block marked 'O' on the long rope; (2) from the lower diagram the two joined blocks 'O' and 'V' ; (3) the foot ropes;and (4) the sister block 'T' on the long rope. It's quite crowded. Does it matter which order they go? For convenience I would prefer (from the cleat to the end of the yard) (1) the double Block (O, V); (2) the sister block (T): (3) the single bloc(O); and (4) the foot ropes last. Advice/suggestions very welcome.

-

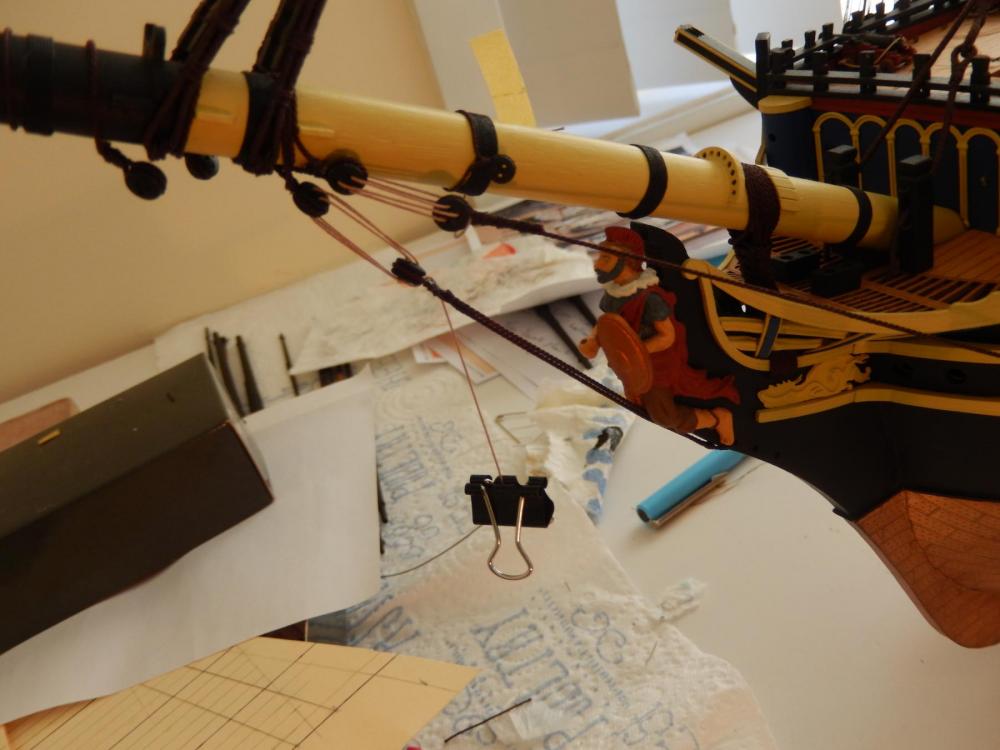

The bobstays are now done. While a little fiddly, they were far easier than I expected. The first photo shows bulldog clips on the lashings to provide some tension. I left them over the weekend, then made any adjustments necessary to make them taught. Tying off the lashings was a bit awkward, but I have found wetting the thread here (and elsewhere) makes it far easier to handle. Here they are, complete. Meanwhile the ratline saga continues while I look for any excuse to avoid them. The port side is now done, those for the main and mizzen masts on the starboard side are yet to do.

-

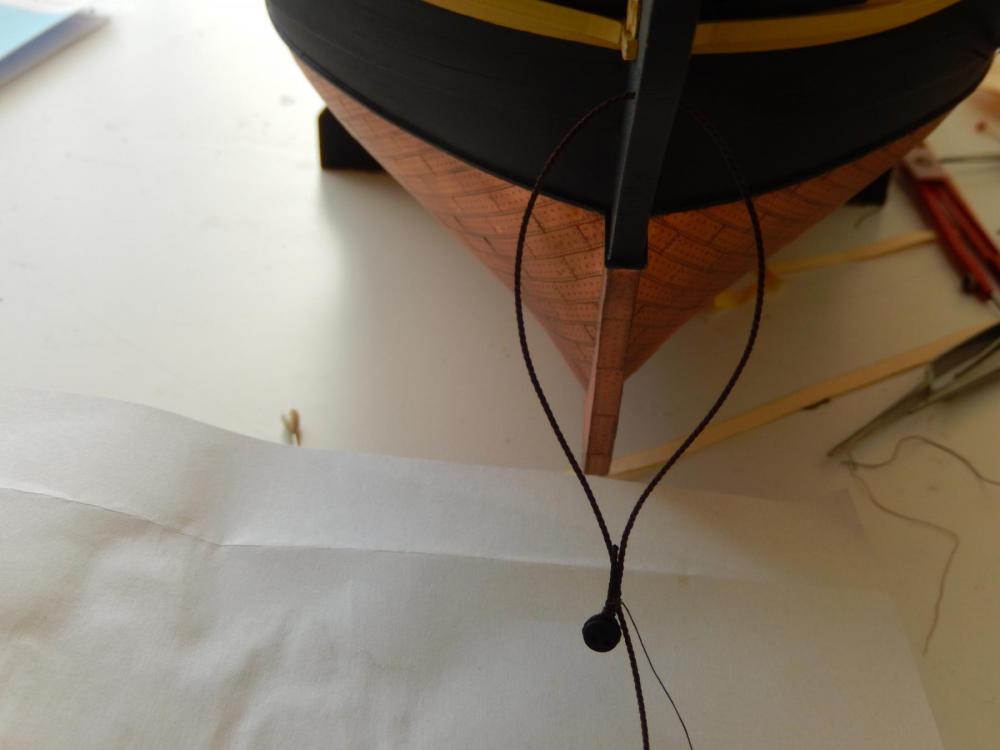

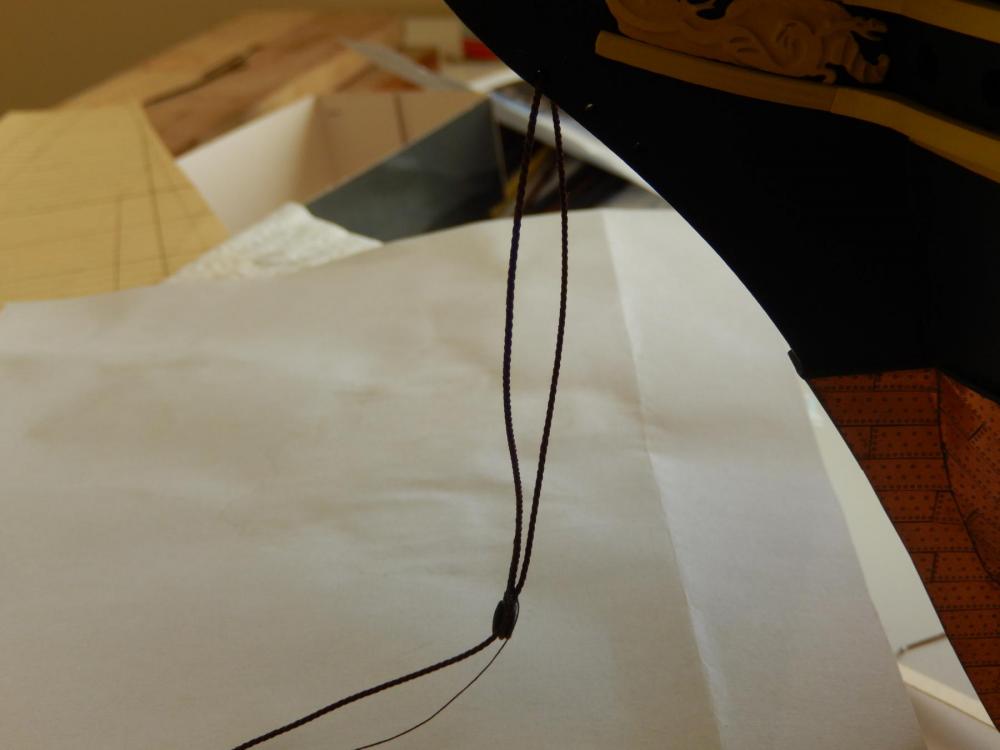

Fixing the bobstays in the same way as the Victory's seems to be a success. It was far easier than I anticipated. I have tried to show the process in the following photos. First, make a loop. The length of thread hanging down shown in the first photo, may be pulled back or forth to adjust the length of the loop. The loop is tied off at the stem. This shows the bobstay fitted (none of the lashing has yet been finally tied off). In the two following photos I have tried to show the doubled ropes in a manner similar to those shown on the Victory. Once the bobstay was fitted, it then occurred to me that with the adjustments that were necessary to make the figurehead fit under the bowsprit, the figurehead may impede the bobstay. Fortunately when I dry-fitted the figurehead there wasn't a problem, though my man looked a little uncomfortable with the rope between his legs.

-

I can't see a join either Arthur. Had I my wits about me I would have taken a closeup of the upper part of the bowsprit. Next time .... I will see if I can reproduce the loop, but I suspect I will eventually make the same executive (and sensible) decision as you have.

-

The bobstays on the Victory are apparently doubled as the two following photos show. Is this the usual method for 74 gun ships too? Advice is very welcome.

-

I was able to resolve a problem with tying off the bobstays (at least I think that's what they are) to the stem. The plans do not seem to show how it is done. I took a couple of photos of the Victory while in Portsmouth two or three weeks ago which gave me the general idea. Tying off the bowsprit shrouds. I was interested in the revised colour scheme of the Victory - almost a pink - which, based on new research, is evidently the ship's true colour at the time of Trafalgar. Portsmouth is well worth a visit. My only disappointment was the temporary closure of the Mary Rose exhibit for renovation, though there is a small but excellent display of artifacts provided. I was also able to visit the National Maritime Museum in Paris which has a wonderful display of models from the 16th century to the present day. Very highly recommended.

-

Arthur: count it as a very small repayment. Tomasg: I'm not sure I follow what you have in mind, but I'll play around with it. Thanks for taking the time to help. I'm going away on Wednesday for three or four weeks, so things will have to wait.

-

While trying to avoid doing the ratlines for a while, I decided to revisit the ship's boats. Fitting all the oars while trying avoid the appearance of clutter is a bit of a problem. I have experimented by 'fanning' about half of the oars to make space for the anchors and other bits and pieces. It seems to have worked though I have no idea if the result is 'authentic'. Nothing is yet fixed except the crewman. I will certainly use Jdieck's excellent ideas of putting three or four barrels into the boats, and his rope coils tied to the anchors. Incidentally, the smallest boat in my has an enclosed bow, unlike Jdieck's - this gives his boat a little more room to stow things. Even the short oars do not properly fit into mine. This is how I propose to arrange the oars. Suggestions are welcome.

-

The euphroes are on the deadeye and futtock strop set. The other parts on the piece are quite sturdy, and any slight problems with the etching probably wouldn't affect them much. The euphroes are of course very fine, and even a slight problem would affect them significantly. Allowing for scale, your photo shows far more metal around the holes (the last two through which the crows feet thread goes) than do mine.

-

Thanks Arthur. I too had wondered about the etchings. My comments on them were no exaggeration. At the bow end there was only a hairs breadth of brass between the first two holes and the boundary of the euphroes. The merest touch would bend them. At least it has come out alright in the end, though had I not had the copper strip, I don't know what I would have done. I will be going away the week after next to my nephew's wedding (I will finally visit Portsmouth, and also visit the maritime Museum in Paris ) so not much interesting is going to be done for a while. I guess I'll spend whatever time before then on the ratlines .

-

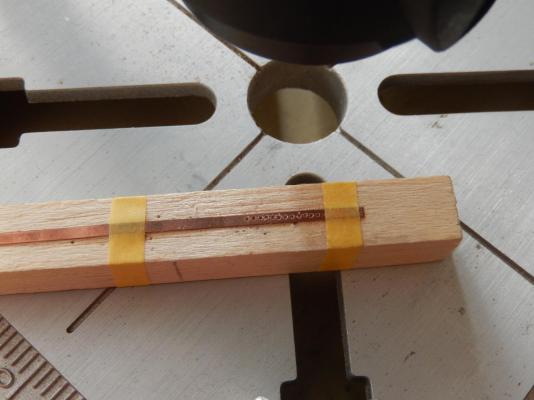

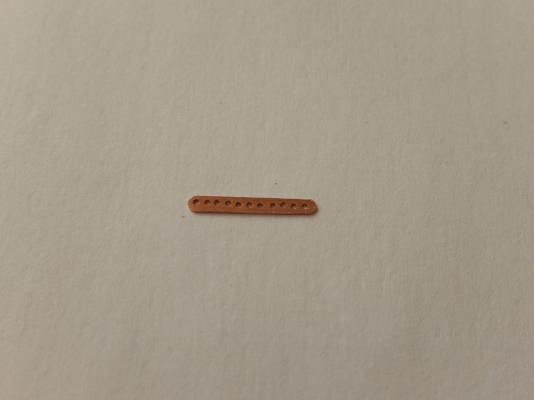

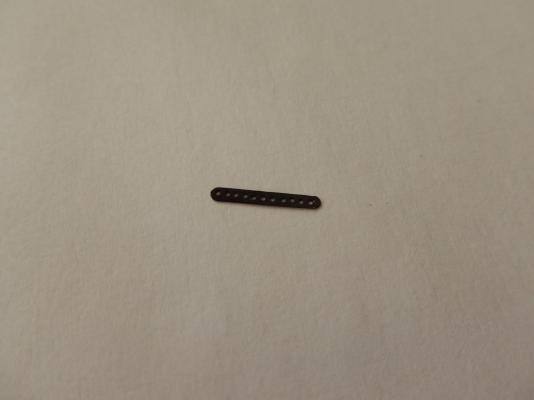

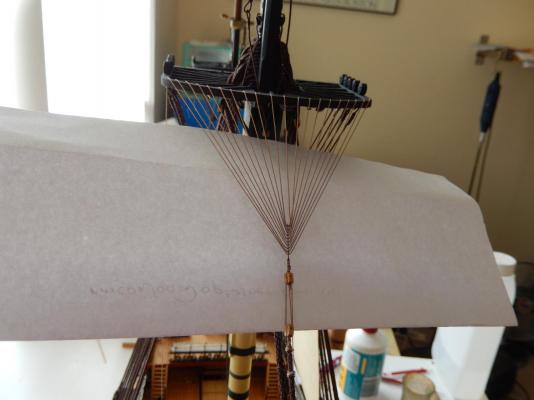

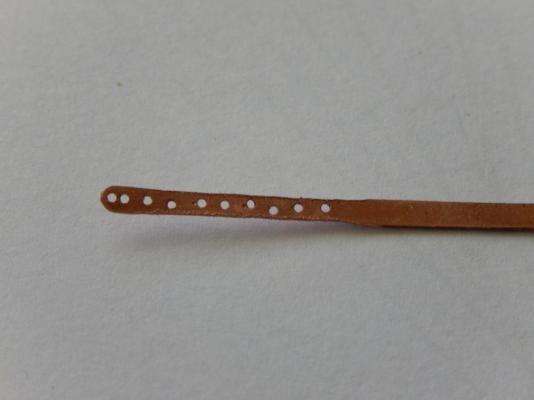

In making up the crows feet for the main stays, the fragility of the euphroes supplied in the kit again became apparent. The first couple of holes towards the bow leave virtually no material around them for support. Touching the euphroe is enough to bend it - bend it a couple of times or so (and it's hard not to) and it will break. Consequently I decided to make replacements for the main and mizzen. This time I used a Dremel drill press to make the holes (something I should have done with the fore stay euphroe). The results are quite good. They are far sturdier than the kit euphroes and very close to their dimensions. If here is a choice between authenticity and practicality, in this case I think the kit got it wrong. Making the euphroe for the main. The resulting crows feet have turned quite well after all the trauma. Here the thread has not yet been made off. I will give it a day or so to settle in before making any necessary adjustments.

-

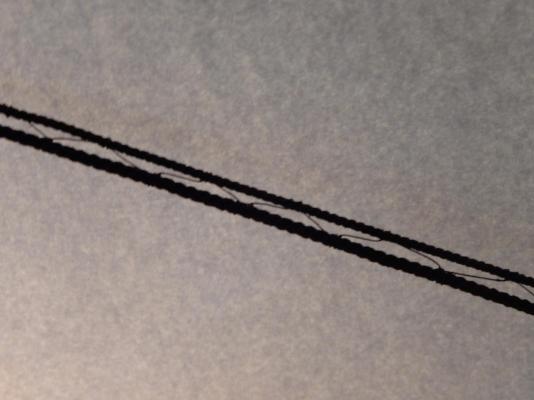

The fore and fore preventer stays are now finished; snaking, and crows feet done. The main and main preventer stays are snaked (?) and the crows feet will be finished over the next couple of days. Here are some photos of progress. Lashing of the fore stay. I don't known if this is correct, but it seemed the most obvious way to do it. The mizzen stay - not a very good photo. Snaking the main and main preventer stays. I have used Arthur's method which was surprisingly easy (I am a highly reluctant knot tier ) and effective (as expected ). It is however quite difficult to see what is going on. Consequently I hung a sheet of paper over a piece of thread tied between the fore and main topmasts to highlight the two stays and show the process more clearly. Snaking the fore stays. This is what it all looked like before the crows feet for the forestays. The crows feet for the fore stays turned out to be a small disaster. One of the holes in the euphoe through which the thread passes was partially blocked. In attempting to unblock it (I used a pin as I don't have a drill bit small enough), I made the hole too large and the euphroe was hanging together by a thread - but not for long . I made an attempt to salvage it (sticking fine electrical wire along top and bottom) which almost worked and possibly would have if the damage had been somewhere other than the second hole. Here is the sad result (I would have painted it, had it worked ...) I then tried some of the same brass from which the euphroe came to make another. The brass proved too hard for the drill bit which kept slipping from the spot. By this time I was not rejoicing. Fortunately I then remembered that I had a little copper strip of a similar thickness and width of the euphroe. Here is the result of a rather fraught process. This is the copper strip in process - the holes are a bit wonkey, and further apart than I wanted. The finished ersatz euphroe - a bit longer than the original. The crows feet after the drama. The new euphroe doesn't appear to be noticeable, though the smaller, original euphroe for the main stays may look a a bit odd. I'll worry about that when I get to it.

-

I just realised that my latest post (today) had gone into a previous edited post - so that it doesn't show up on the table of contents- if anyone is interested.

-

I had trouble in finding how to tie off the lashing to the heart. Petersson was no help and and I couldn't find anything on the net whiich gave me a clue. I settled on putting a loop on one end of the lashing, putting the rest of the thread through to hole in the heart and threading it though the loop. Here is the the loop (before cleaning it up a little). This is a side view showing the loop. I don't know if this is correct, but it works and with so many other pieces of rigging which will eventually be around it, it is unlikely to be noticed - I hope. Again, the only way I could stop the lashings overlapping each other, was to glue them in place one at a time using a small bulldog clip on the end of the thread to supply tension. Finally, finished. Progress on the ratline front. The ratlines for the fore mast are now finished. While I am becoming a little quicker and a little better at it, doing a couple more masts is not an inspiring prospect.

-

The bowsprit is now mounted. I have delayed this as long as possible. It's one more invitation to bump and destroy. I had quite a bit of trouble finding the correct way to gammon the bowsprit. The plan was singularly unhelpful - to me at least. The only thing that seemed clear is that there is a loop formed at the end of the gammoning which goes around the bowspprit and then the rest of the gammoning is wound around it in some mysterious way. I eventually found a reference to the process on this website under masting and rigging. It showed some photos taken from an unnamed book which did prove helpful. If anyone would like a photo of the photo, let me know. Here is the gammoning partially completed, and completed. How the bowprit looks at the moment: I can see a copy of my guide in the background of the following photo. I'm not sure if I have the gammioning right, but it looks OK and it's not going to be changed now.

-

The main and main preventer stays are now attached. Lashing the hearts proved quite awkward. The holes in the hearts provided for the lashing were circular which made it difficult to keep each strand from overlapping previous strands. It would have been far easier to file flat the surface where the lashing was to go. By the time I had figured that out it was a bit late. I solved the problem of the strands wanting to overlap each other by gluing each strand (50:50 PVA) individually - doing one, waiting for the glue to dry, doing another ....... Here is a photo of the lashing for the main stay partially done. The line is held taught by a weight on the end (a pair of spring tweezers). The lashing (almost) complete. The lashing for the preventer stay in progress: and how it all looks at the moment.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.