RMC

Members-

Posts

933 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RMC

-

The stays for the fore and main topmasts are fitted. The main topmast stay provided a particular problem. The thread specified is 1.3mm. The Syren thread I am using is 1.37mm. Not much difference really. In fact it turned out that there wasn't much practical difference as the 1.3mm thread would not have fitted through the hole provided in the block in any event. This necessitated enlarging the hole in the block to 1.5mm. Now this was a very fraught process as there is very little access indeed, and the probability of damage is high. I then put a little CA on the end of the thread to stiffen it making it easier to thread through the hole. This of course caused the thread to swell slightly so the it would not fit through the 1.5mm hole. Having said 'goodness gracious me' (or words to that effect), I cut off the CA and put dilute PVA on the end of the thread. This time there was no swelling, but the Syren thread showed a delightful tendency to unravel when I attempted to thread it through the hole despite the PVA. You may gather that this was not one of my best afternoons. Finally after a number of unsuccessful tries (each time losing a bit of thread so that the thread was close to being too short) - success. There is a lesson in all of this - make sure your thread fits BEFORE fitting. This is the culprit. This how things stand at the moment. I have hung bulldog clips to the ends of each stay to keep the lines taught. I'll leave them like that until I return in 2 or 3 weeks.

-

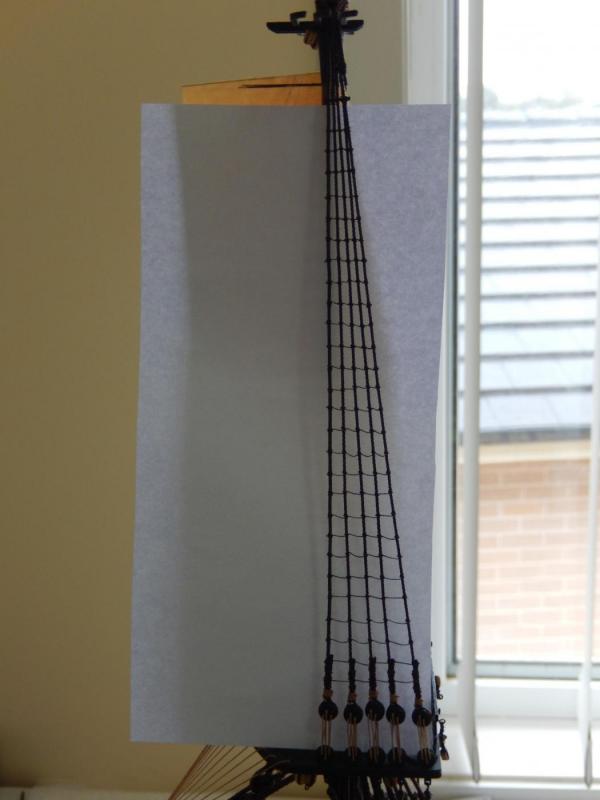

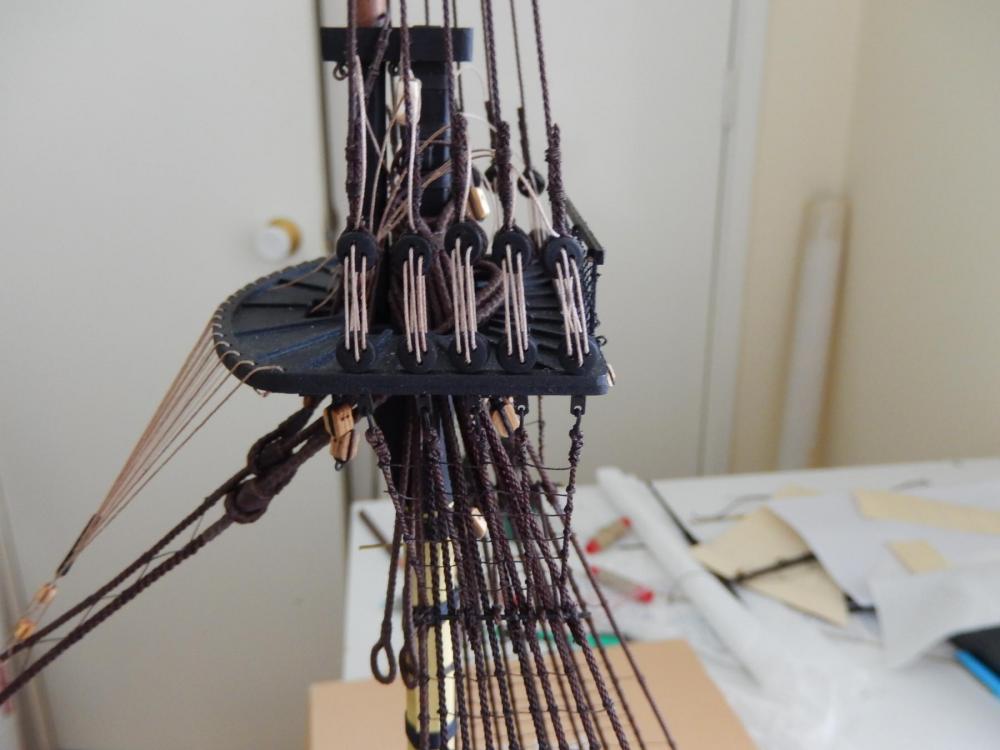

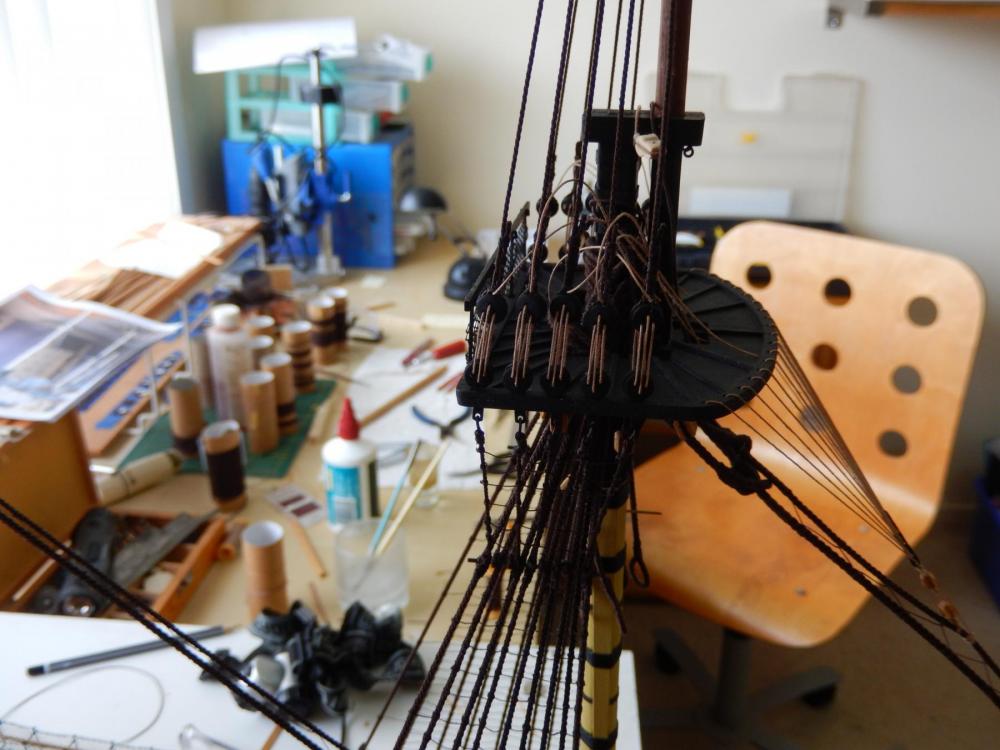

I have found credit in short supply - claim it whenever you can. The top gallant shrouds are tied off and they turned our fairly well to my pleasant surprise. This is the foremast before tying off: and after. The photos make them look a bit of a mess, but 'in the flesh' they are quite respectable. The top gallant ratlines for the mizzen are still to be done unfortunately. We're going to India on Sunday and that should keep my mind off the wretched things for a while...

-

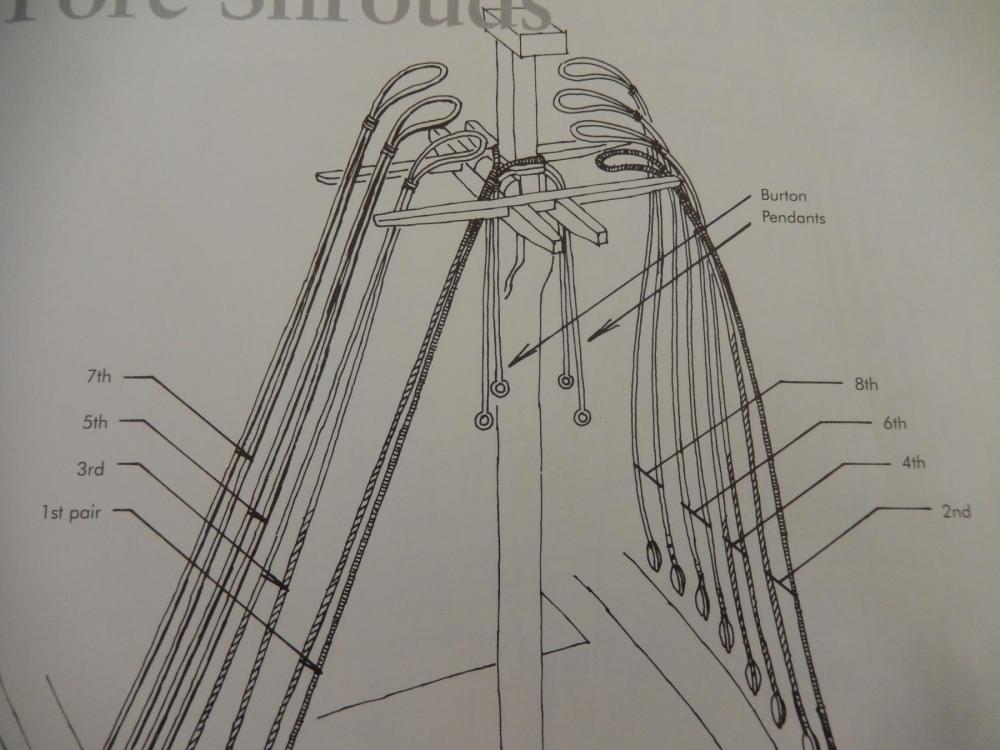

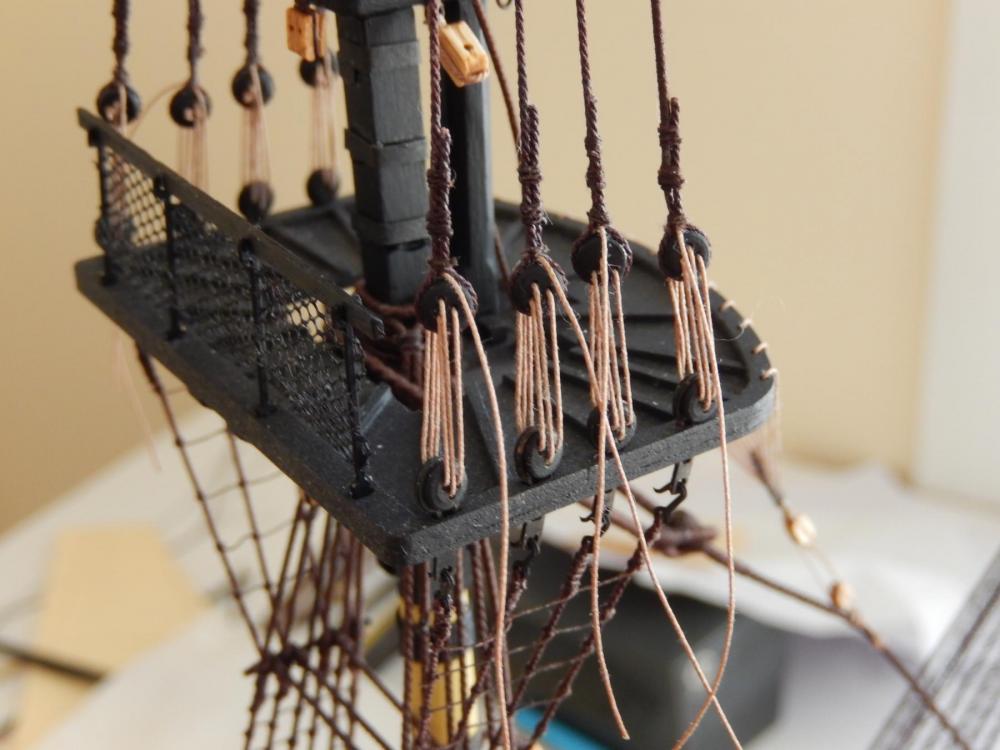

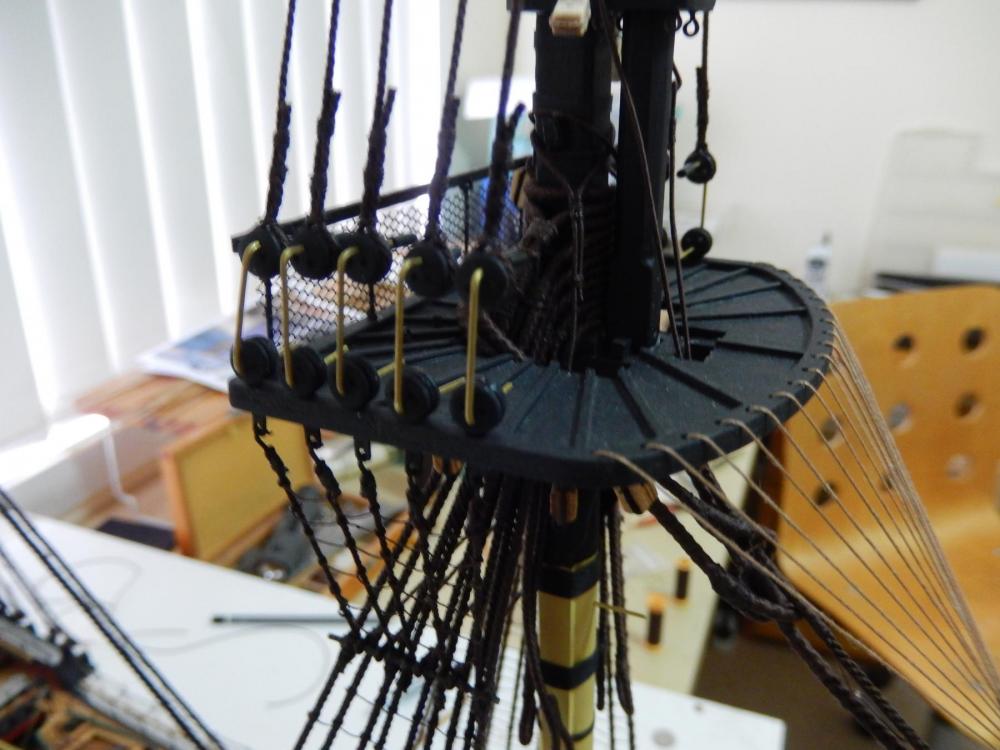

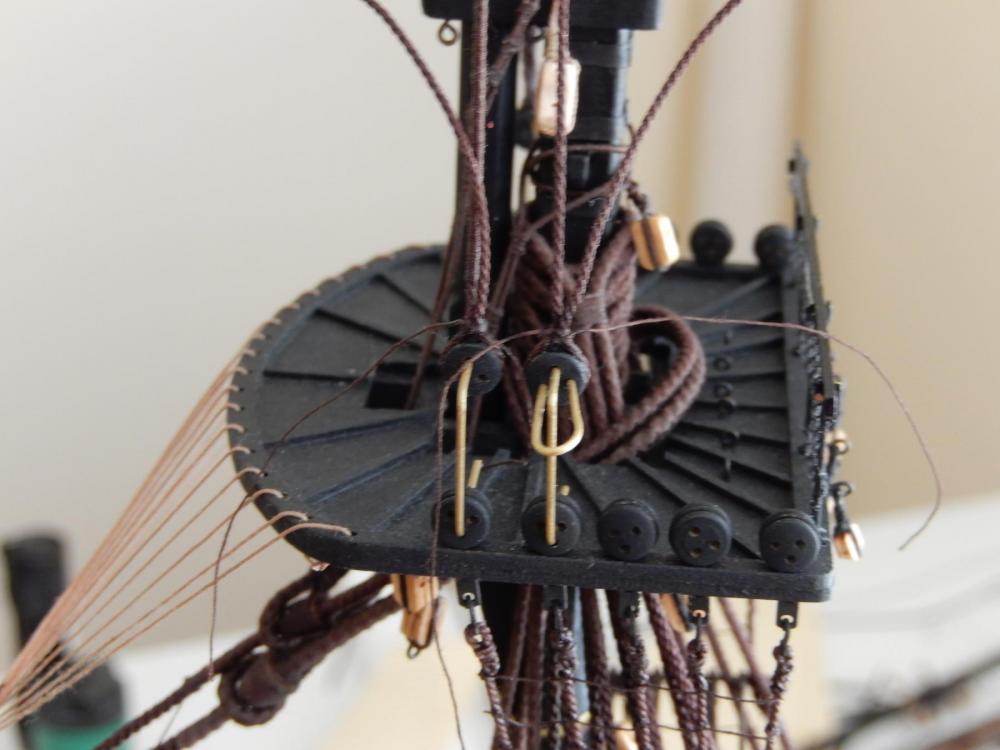

The top gallant shrouds are supposed to be tied off below the lower deadeyes on the cross trees. This didn't seem all that satisfactory, though I couldn't see an alternative. I looked in Petersson who shows (p.11) them tied off to a thimble which is lashed to a fitting (I don't know what it's called) attached to the futtock plates below the lower deadeye. I thought doing something like this at this late stage would be impractical. So the only thing to do of course was to have a look at how Arthur had done it - and there in his log was an excellent Petersson solution. (I think I dimly remember something about imitation and flattery.) First a loop was tied around the futtock plate - he mysterious yellow thing in the photo is an alligator clip keeping the loop taught - which was tied to a brass ring (the blackening came off in the process - touching up is needed.) The lashing was attached to the rings. Rings had been attached to the shrouds and the lashing was threaded through the rings. None have yet been tied off. The result has been adequate. Doing the thimble fitting earlier in the build would have been easier and would have resulted in a far better job. I have only done the starboard side so far, and there is still some tidying up, and minor adjustments to be made. Once the port side is done the lashings will be tied off, being careful to make sure the masts are not pulled out of true.

-

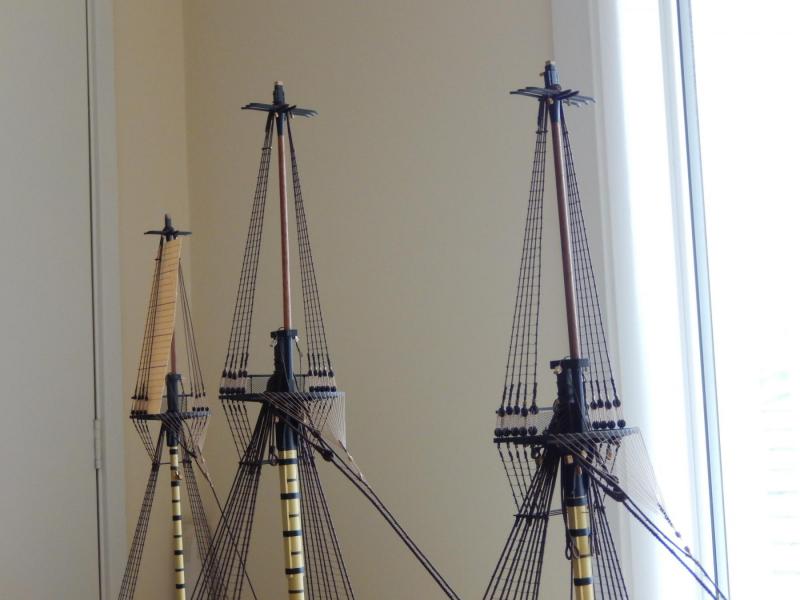

The ratlines for the fore and main topmast shrouds are now finished. Those for the mizzen are still to be done. At this stage I think I will put on the top gallant masts for the fore and the main. All the related rigging for them has been prepared, and doing the mizzen ratlines doesn't bear thinking about at the moment. I will be going away for a while in a couple of weeks, and may wait to do them until after I return - though it does provide an incentive not to come back. Here is progress such as it is. The fore. The main. A dab of paint is needed on the ends of the brass wire, and I just noticed the the fifth ratline from the top needs adjusting. This is how it all looks at the moment.

-

Glenn: I think you mean part 180 - the poop rail end pattern. It's on 5mm walnut sheet 2421/B. Arthur: If you can spare the time would you send me a copy please? I'm afraid my approach to the build has been more hindsight the foresight and it's come back to bite me more than once. There are still some bits and pieces that are yet to be attached and your list would still be useful. You may still have my email address. If not I'll PM you.

-

Hi Glen. I just realised I replied in my log. Have a look and see if it helps. Good luck. Bob (rmc)

- 101 replies

-

- victory models

- amati

-

(and 2 more)

Tagged with:

-

Do you mean parts 99, 100 and 101 - the forecastle capping rails? If so, they are on 1.5mm ply sheet 2412, the one with the stern facia for Elephant/ Bellerophon.

-

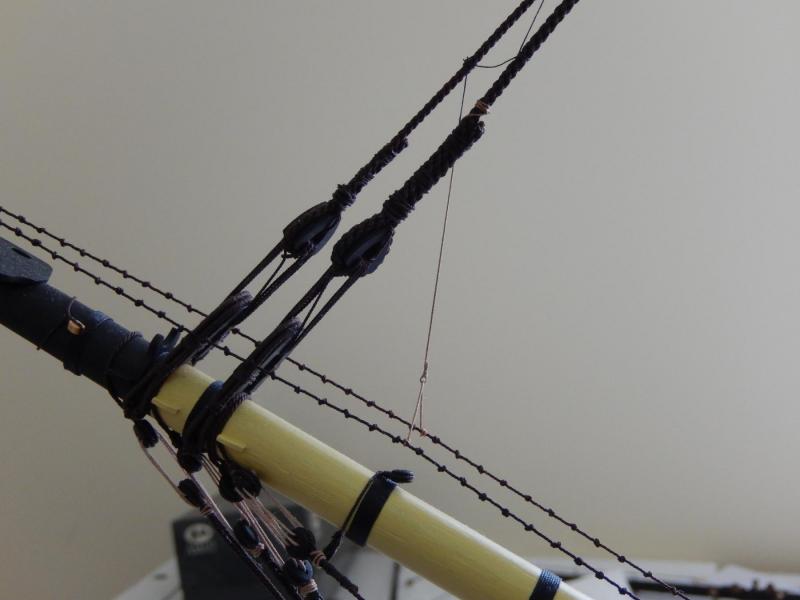

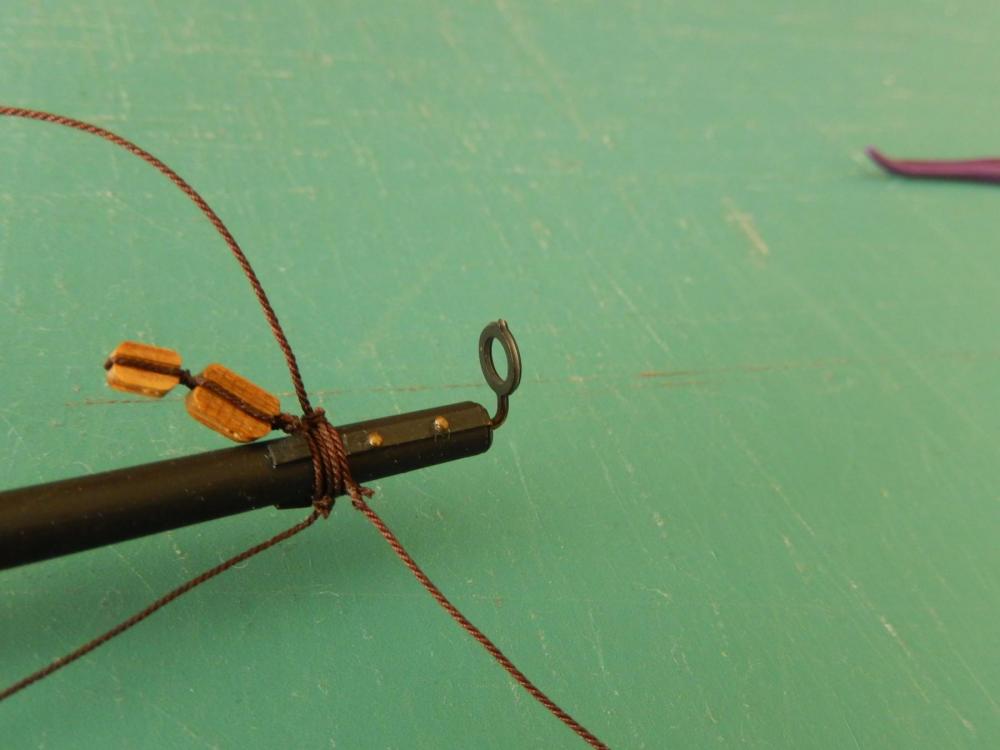

While doing my best to avoid tying ratlines I finished off the hand ropes on the bowsprit. I was concerned to get the same tension on both ropes and came up with the following solution. I'm sure it has occurred to others,but perhaps this may help. First a loop was tied to the thread that would hang down from the fore stay. Thread was then tied (two half hitches) to one of the hand ropes and threaded through the loop. It was then tied to the other rope. The hanging thread was then tied to the fore stay providing the appropriate tension to both the hand ropes. The loop enables the adjustment of the tension of the thread so that it is the same for both hand ropes. On the painful subject of ratlines, here is progess on the fore topmast shrouds. The top gallant shrouds shrouds are also in the works. I have fitted the shrouds to the fore top gallant mast (this was done off the model). I intend to drop them through the holes provided in the cross trees, and to finally make them off below the dead eyes on the tops. (The top gallant mast in the following photos is dry-fitted.) Is there a better way of doing all of this? Suggestions very welcome.

-

Allan: My Petersson is the 'Rigging Model Ships' 2000. It doesn't have this illustration. Thanks again.

-

Alan: I certainly hope so. Fortunately the top gallant masts are only dry fitted at the moment so that I can attach the shrouds off the model without too much difficulty. Had they been finally fitted (and I was just lucky I hadn't) it would have been fairly difficult and rather nerve wracking to do it. Thanks for taking the trouble to help.

-

Thanks very much Jeff - it solves the problem for me. Alan: I looked at the illustration in Petersson but it isn't very clear - and I had some conflicting advice.

-

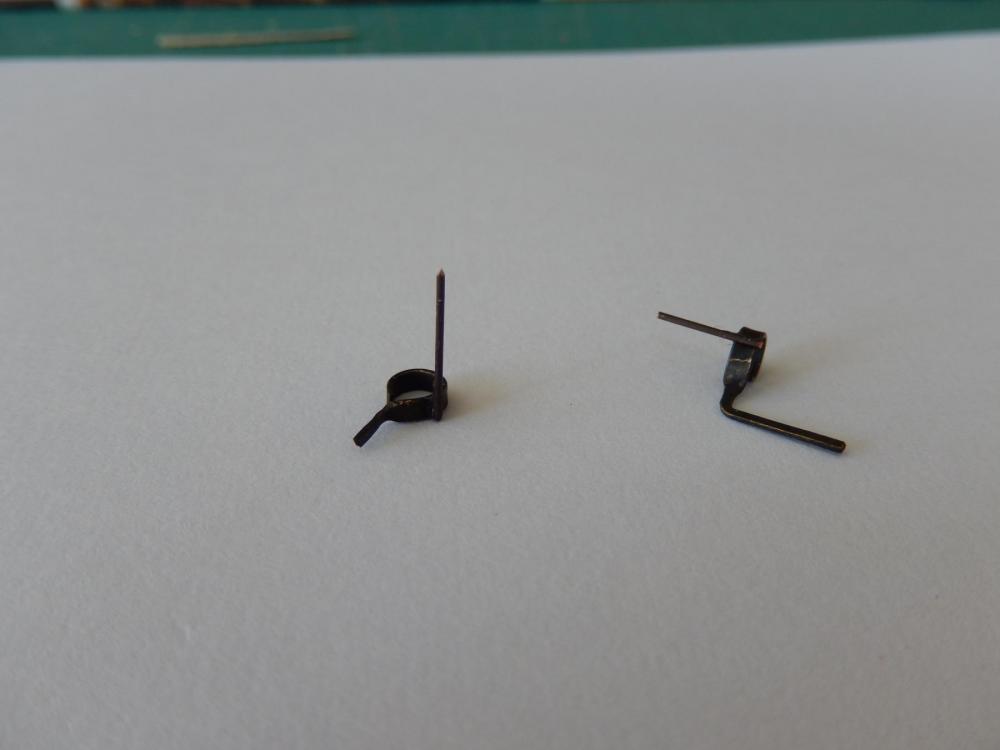

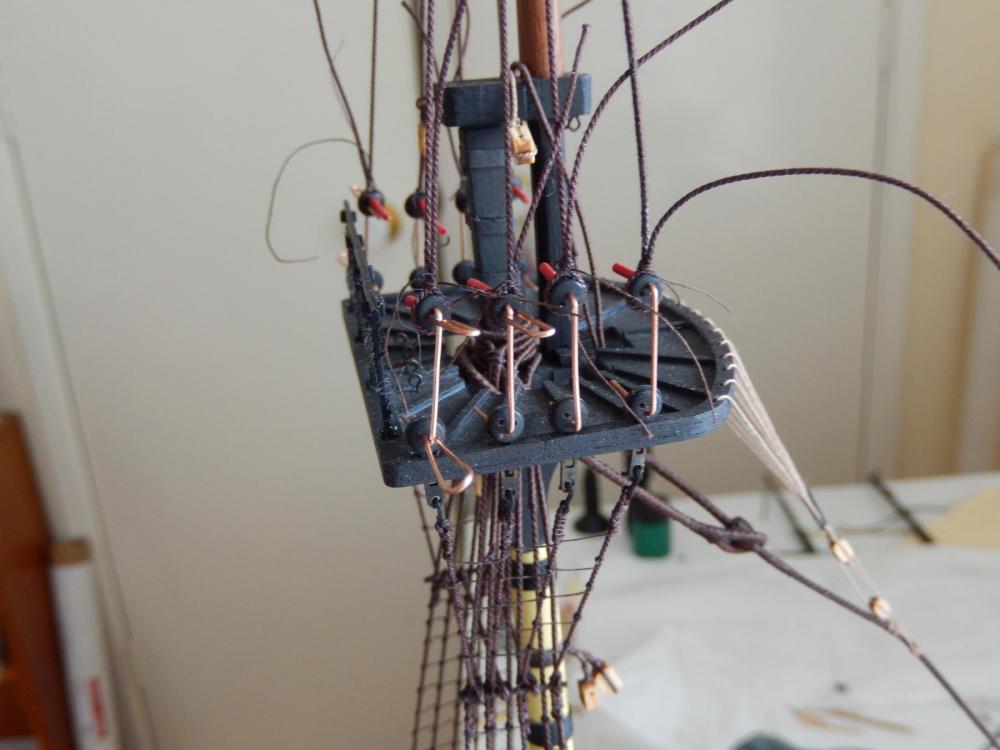

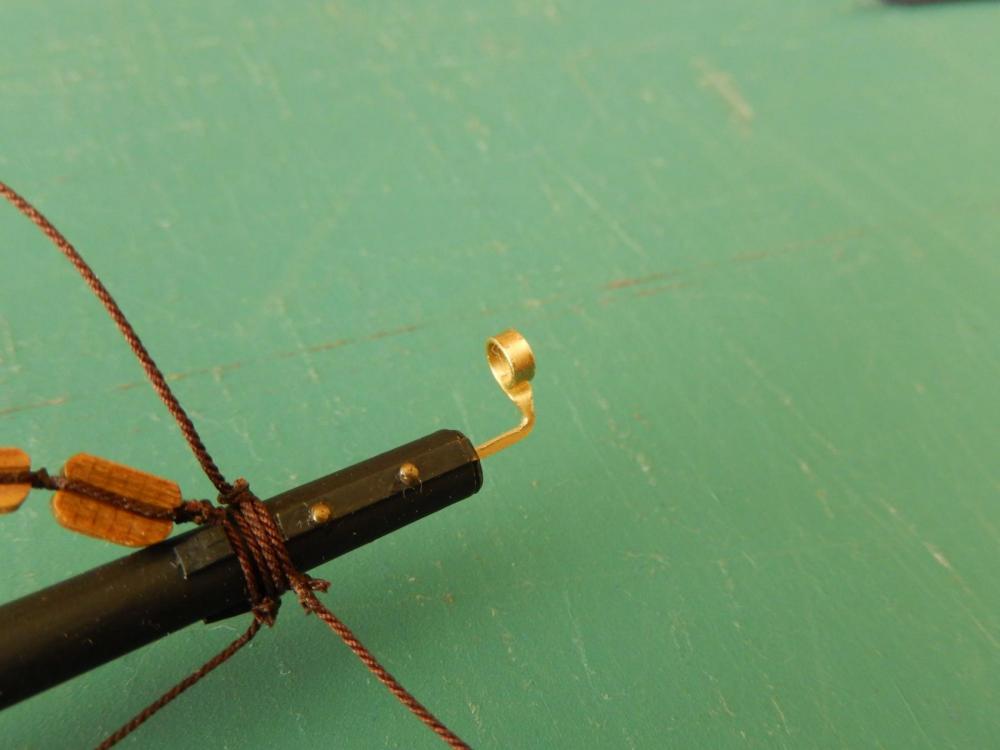

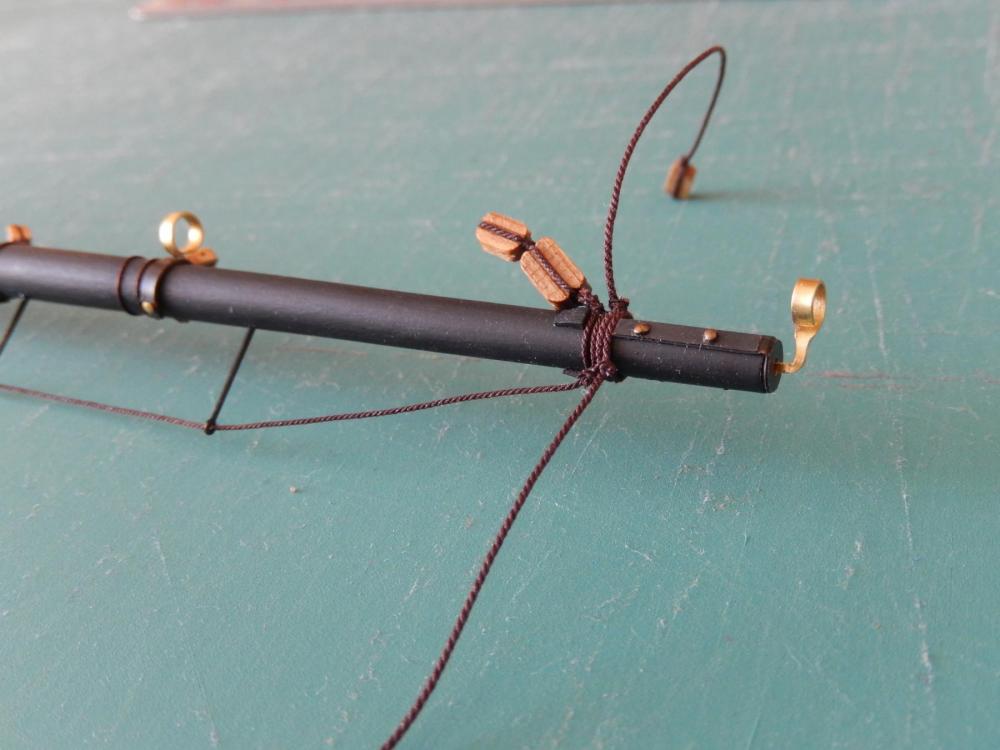

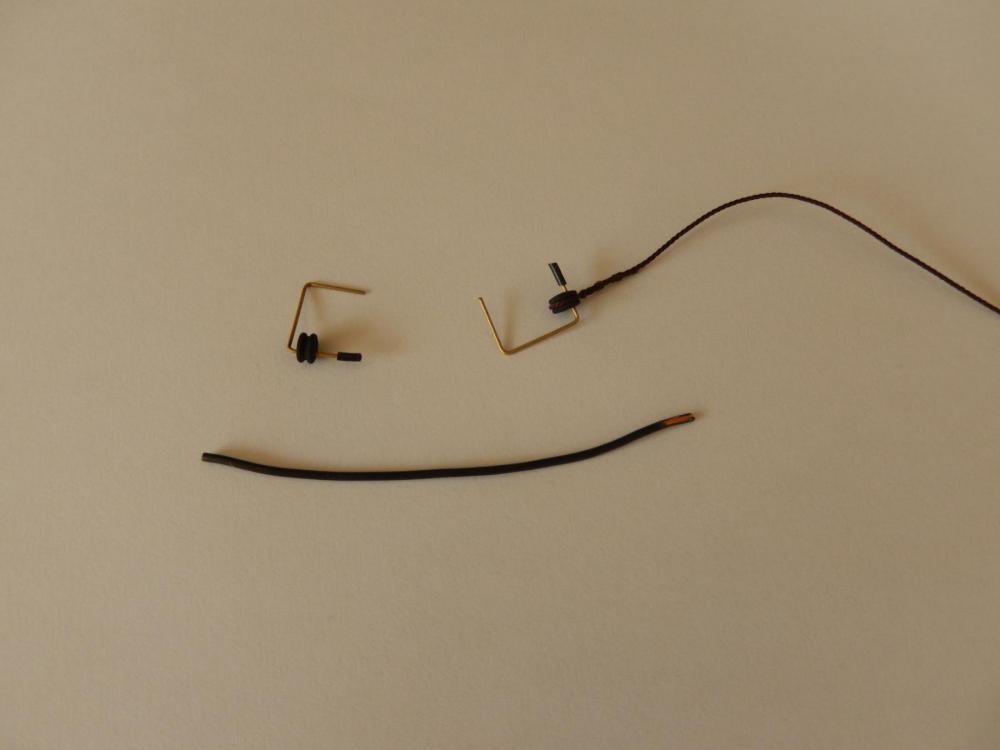

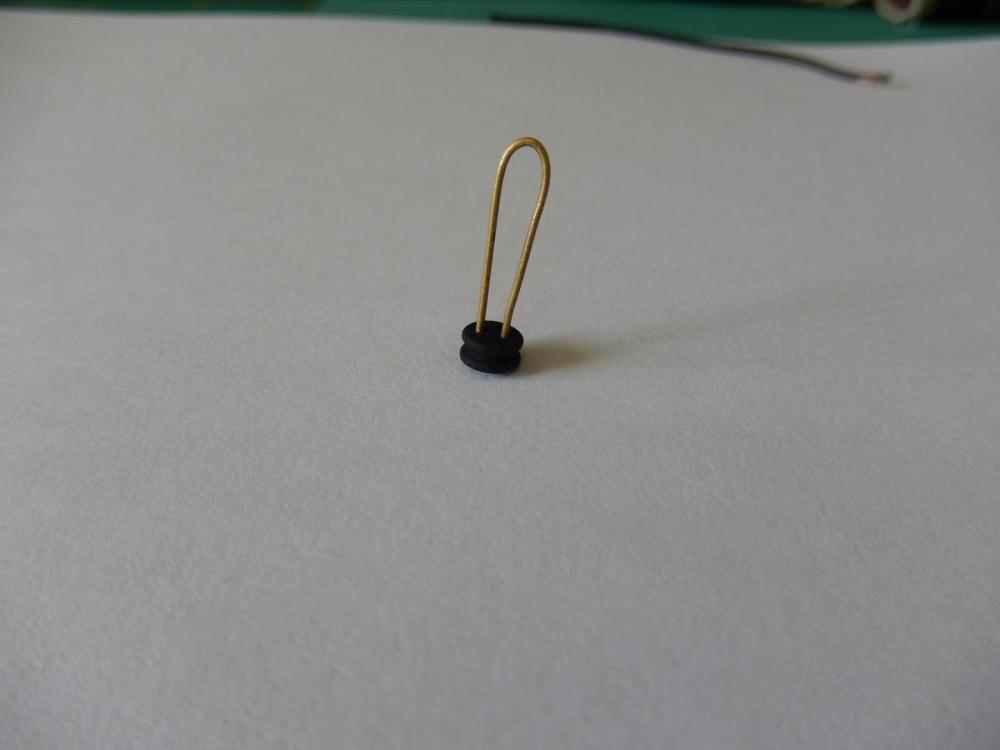

The stun sail boom irons look as if they will come out surprisingly well. I have only done the irons for the main yard so far, but so far so good. (This is, of course, the kiss of death.) I have put dummy hinges on as Arthur suggested, following as best I can the illustration shown in Petersson. I first blackened the brass then used gel CA to stick on the hinges for both irons (copper electrical wire (approx.0.75mm)) and for the inboard irons a clasp (a flat piece of brass strip recovered from waste from the kit's brass etchings). It wasn't possible to fit a clasp to the outboard irons. In gluing the fittings to the irons it was best to cut off a piece of wire/strip longer than necessary - it makes it easier to position it. Then once the glue is set, cut off the surplus. Here is how they turned out. PS: I would be grateful for advice regarding the shrouds mentioned in my previous post.

-

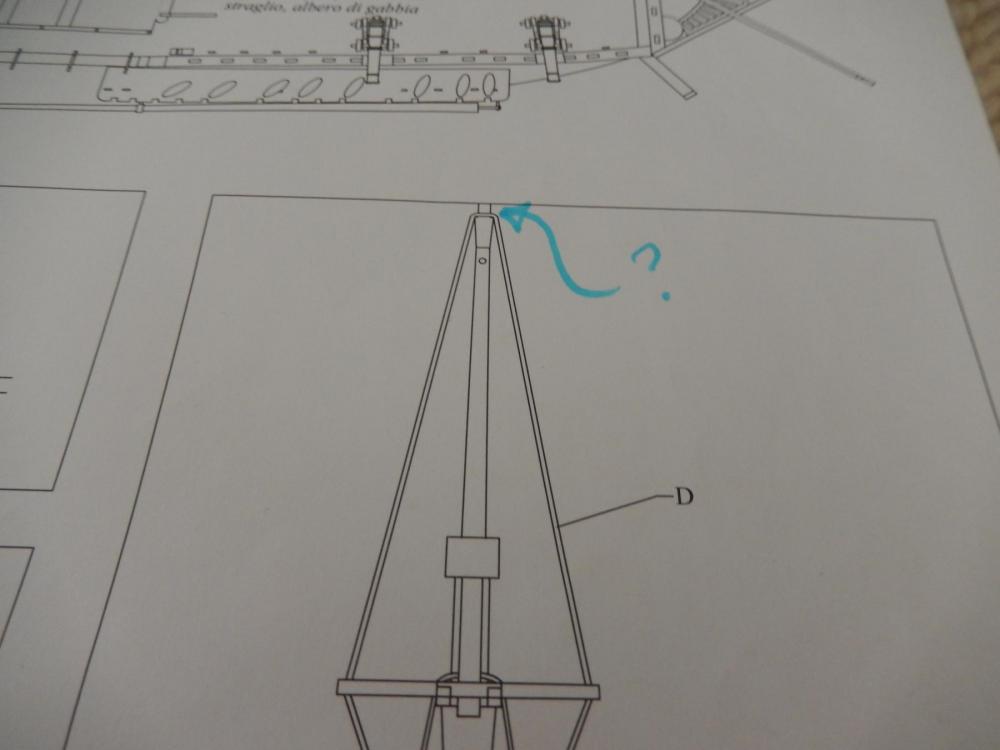

Help needed - top gallant shrouds. I am having difficulty finding the appropriate way to attach the shrouds to the top gallant masts. One source suggests they are tied on using clove hitches which seems odd - or are they attached in the same way as all the other shrouds? An added problem is that the holes provided for the shrouds in the cross trees are too small for the required 0.5mm thread. I did not have the foresight to check before mounting the cross trees to the masts. The Syren thread I am using is supposed to be 0.45mm and that did not fit through either. All of this necessitated enlarging the holes to 0.6mm while perched up a small ladder so that I could see what I was doing. This is not recommended. For those not at this stage - check the holes in the cross trees BEFORE you attach them to the masts!

-

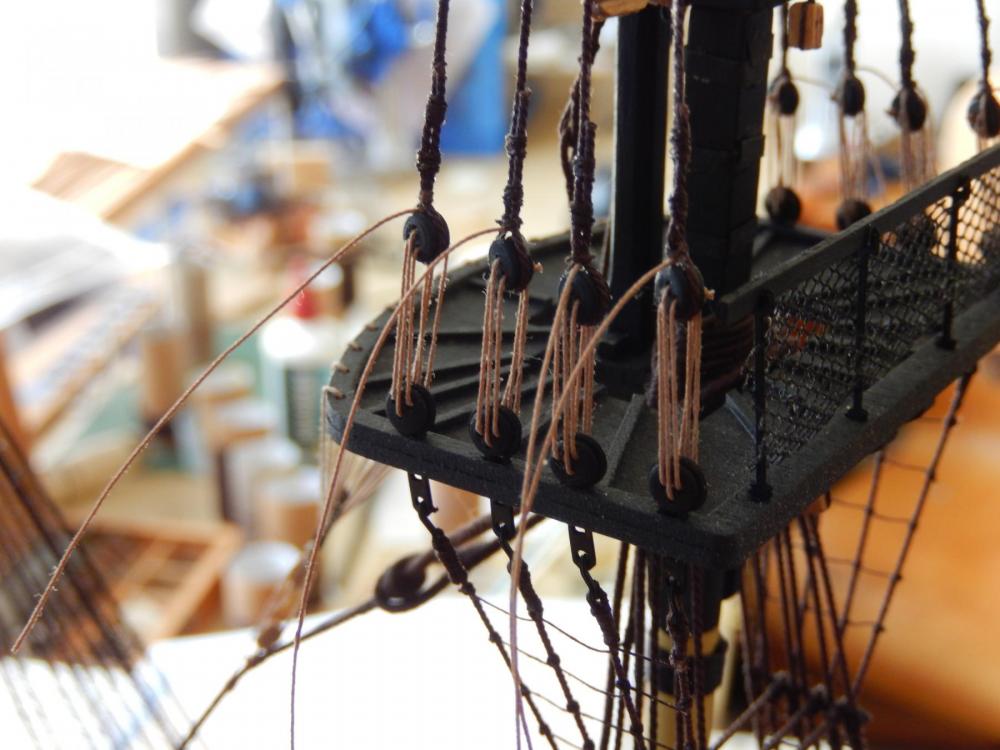

Progress has been made on the top mizzen shrouds. The dead eyes are quite small, and as a consequence the job has proven to be rather fiddly. The last set of lanyards refused to behave and it took me as long to tie them off as it did the other three sets combined. Once that was done, one of the other sets of shrouds became unacceptably limp and needed to be redone. I did not rejoice. Incidentally, the only way to make the Syren thread stay in place while tying the lanyards is to make it soaking wet. Here are some of the steps towards completion. This looks a bit like a dog's breakfast, but it does work. I have finally tied off the lanyards and am waiting for the glue to dry on the knots. While waiting, I decided to see if I could do anything to improve on the stun sail boom irons provided in the kit. Like Arthur (aew) I think they are not really satisfactory. Unlike Arthur, soldering is a completely alien concept to me. I bought a length of 2mm brass strip to play with. Here are the results. Nothing has yet been glued, so comments/suggestions are very welcome. This is one of the irons from the kit. The hole for the boom appears to be far too large. (The yard has not yet been touched up.) This is one of my experiments. I used a pair of round nosed pliers, a hand held vise, and a fairly fine file.

-

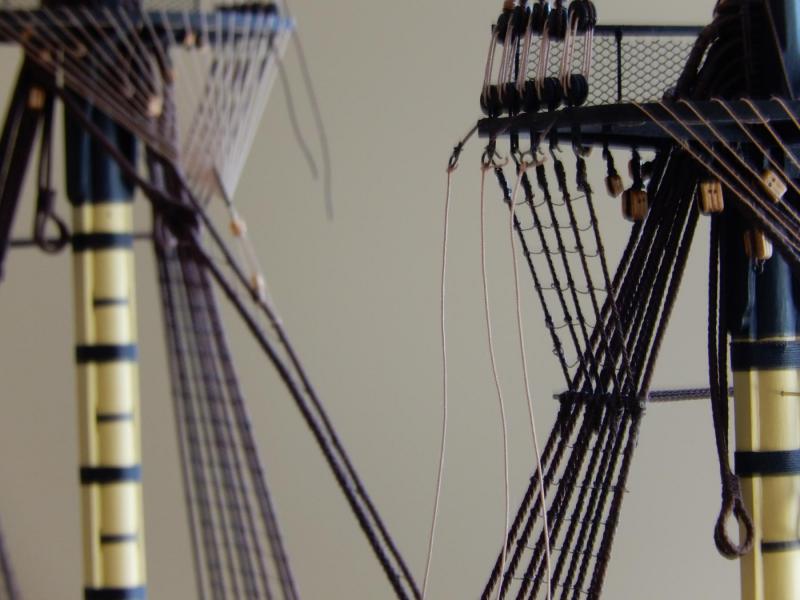

The lanyards for the fore topmast deadeyes are now tied off. They have come out fairly well. The shrouds for the main topmast are complete. I decided that I would cut off the thread for the ten lanyards all in one go. This was not a good idea. Somehow I stuffed up the measurement and cut them all off about 15mm too short. I still may be able to use them, but tying them off will not be easy at best. The extra 15mill would make all the difference. I am loath to discard the thread as I am running a little low on that particular Syren thread and getting some more will take 2 or 3 weeks. Here are the main topmast shrouds in the works.

-

The lanyards for the deadeyes on the fore topmast are now essentially done. I will not finally tie them off for a few days to let every thing settle down. As well,some adjustments may be needed once the shrouds for the main and mizzen topmasts are done. While quite time-consuming, the process has gone smoothly. The method described in my previous post has worked well, though in writing this of course, I'm asking for trouble.

-

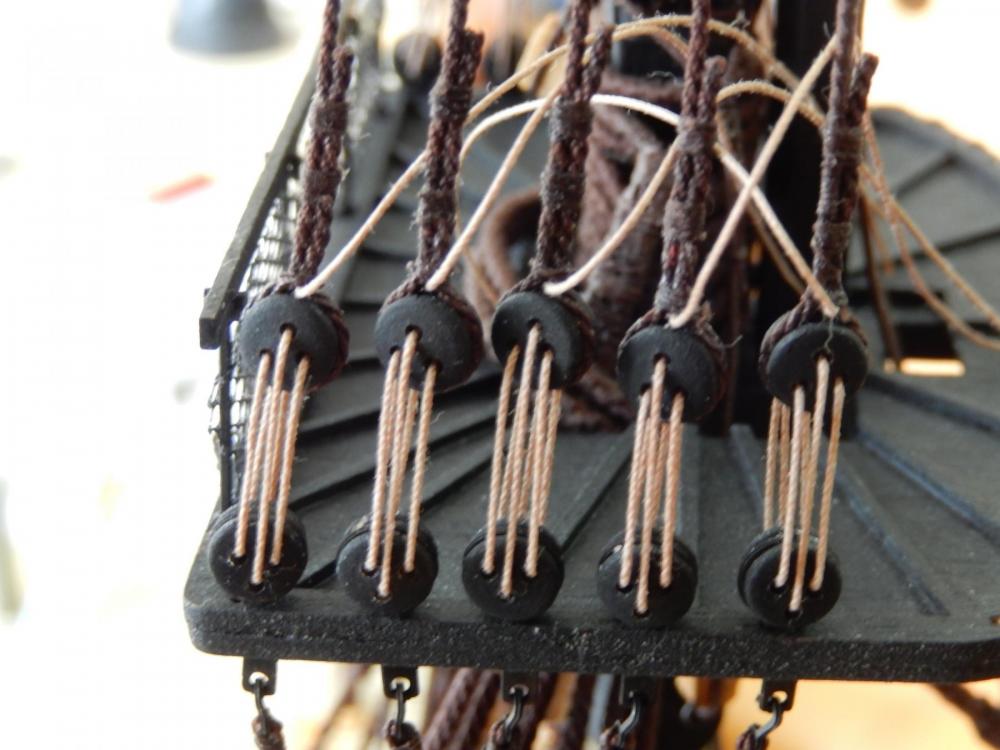

Progress has been made on the topmast shrouds. I have gradually found a fairly easy way to space the dead eyes which had caused me quite a bit of trouble. The following may help others who have also found difficulty. First, often when I inserted brass wire spacers through the upper holes in the dead eyes, the wire would fall out at the crucial time. It's very frustrating. Now I use plastic covering of copper electrical wire as a stopper. It fits perfectly and solves that problem. Second, in making any adjustments, the deadeye tends to rotate, so that the holes are in the wrong position. A piece of wire bent so that it will go through the two lower holes enables you to twist the deadeye to the correct position. Once that is done I use a a pair of spring tweezers to pinch the two shrouds above the deadeye ready to knot them together. Incidentally, the quality of many the deadeyes supplied is quite poor. The holes are all over the place: about a quarter are unusable: and about half are just adequate. Here is a set ready to take the lanyards. (I have made slight adjustments to these since taking the photo.)

-

I wish I had had your foresight Jose. Regarding the netting, by the time I was doing the third one I had almost gotten the hang of it. Had I to do it again, I would do a far better job. Too late now .....

-

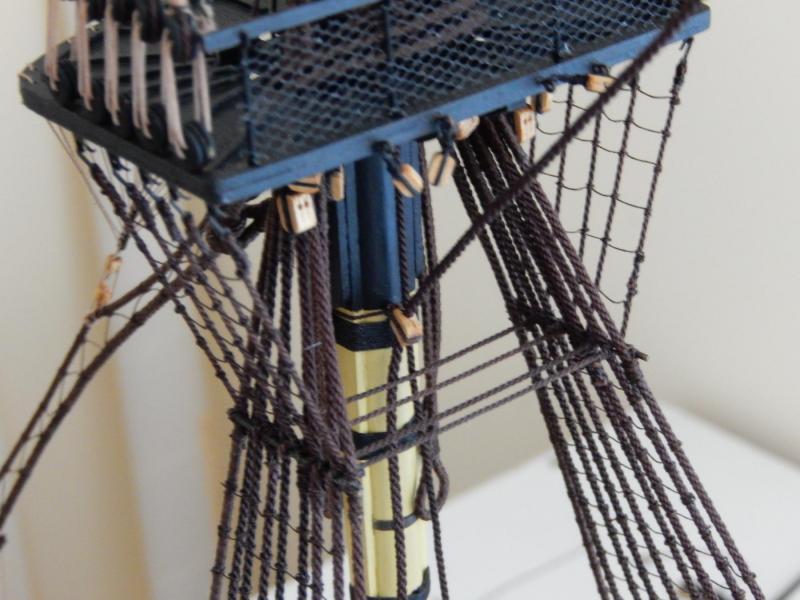

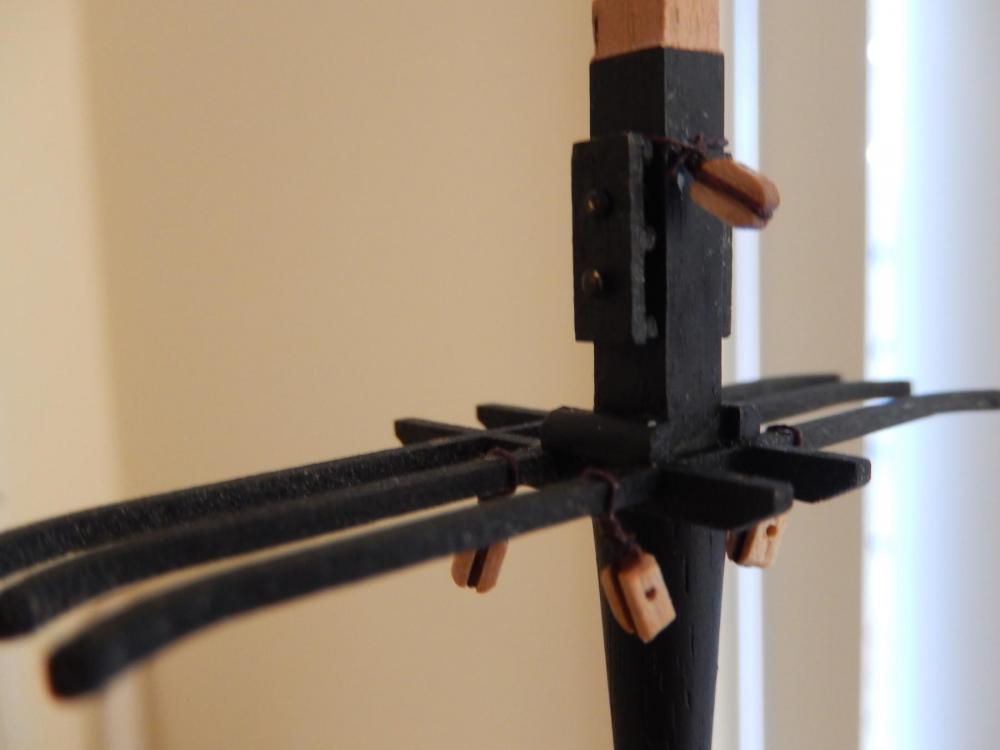

The cross trees are now fitted. The photo shows the top gallant masts dry-fitted. The sheaves and the blocks are fitted to the top masts where necessary, and this was a mistake. The shrouds have to be fitted over the cross trees and the sheaves and the blocks already fitted make things difficult. Moreover the sheaves were fitted accurately according to the plans, which does not leave enough room to fit the shrouds and the stays. Had I shifted the sheaves up about 3mm (possible to do) there really wouldn't have been a problem. This is progress to date. The more I see how large the it is, the more I have no idea what to do with the damn thing when (if) it's finished. Below are a couple of the cross trees fitted with sheaves and blocks. The gap between the bottom of the sheaves and the cross trees is 3 or 4mm. Unfortunately six loops of shrouds (1mm thread is specified) have to fit there, as well as the stays. I am using fractionally thinner Syren thread (0.86mm but I am serving it - which will make it close enough to 1mm. I guess it will turn out in the end. There is a bit of good news though - the ratlines for the lower masts are finished.

-

Well Jose, reasonably well so now I am glad to have done it, but it was all a bit of a pain. Cutting the material accurately was time-consuming and quite difficult.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.