-

Posts

408 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alross2

-

Made two new templates for setting the chain plate angles. One is for the forecastle mast, the other for the other five masts. The top of the template corresponds with the slots in the channel while the bottom corresponds with the bottom of the chain plate, You just align the top section with the channel slots and use a pin or ,020" drill through the bottom holes to mark the position of the lower part of the chain plate.

-

Starboard aft rail with all stanchions in place. Each stanchion has a slight inboard cant to it, so it's best to simply place but not glue then into their holes, then align them one by one with the top rail taped in place, The pegs on the stanchions will be snipped off flush with the top of the rail and will be covered with a .015" laser board cap rail.

-

Working on the channels this morning They're laser-cut with the chain plate slots included. They're easy to set up as the second slot aligns with the center of the mast holes in the deck. The chain plates will be cut to length and a template will be provided to set them at the proper angle. The turnbuckles will attach directly to the chain plates.

-

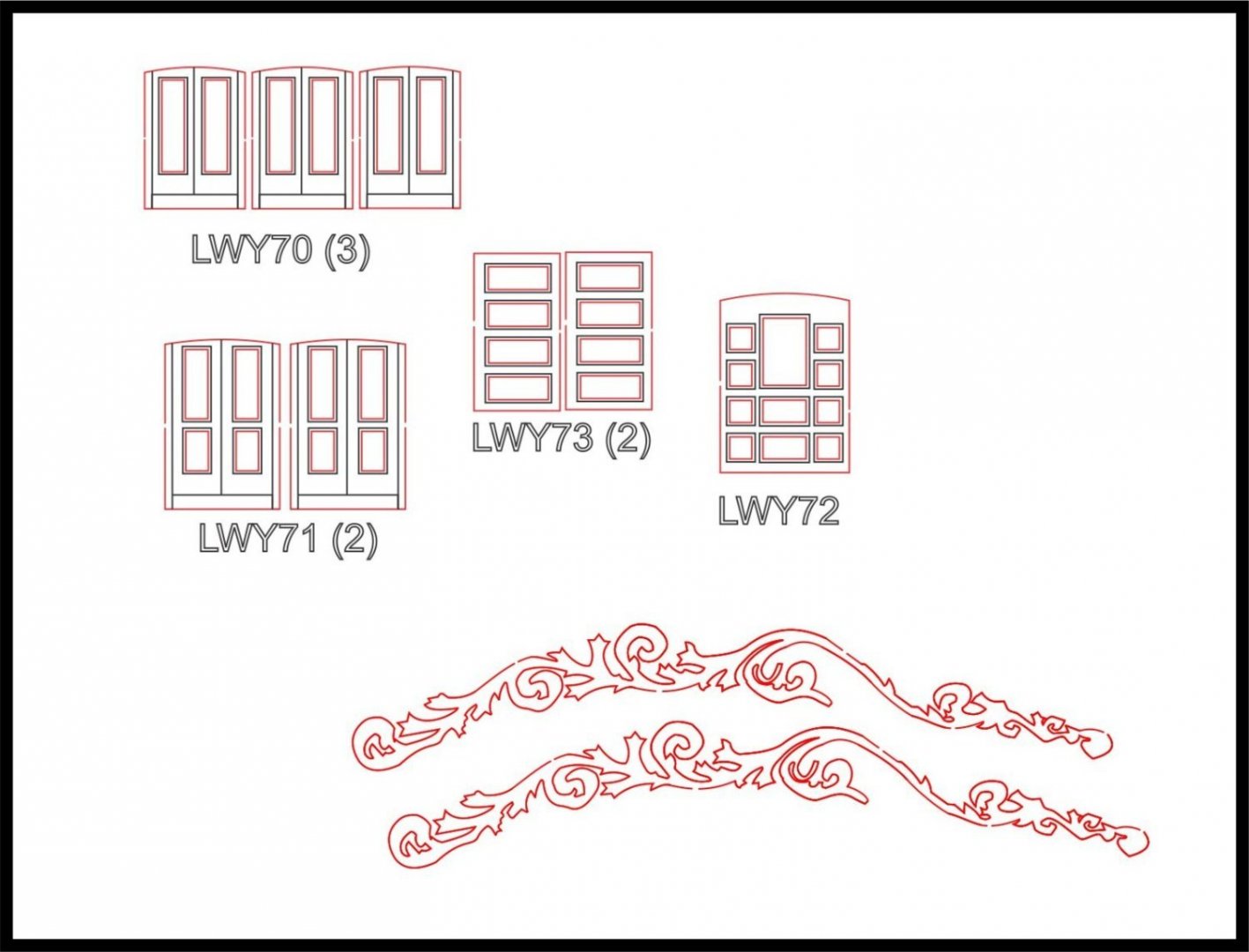

Experimenting with the mast. The bands are black construction paper that will be cut from lasered strips. They are closer to scale thickness than britannia and look like wrought iron, so you don't have to paint them. The items between the blue tape and the doubling are 24 sail hoops lasered from .015" laserboard. The T shaped object is the laser-cut glut. Once that is attached, a black paper strap ("barn door") will finish it off. The boom jaw rest is five pieces of lasered 1/32" ply with a copper tape chafing plate.

-

Did you know that the tryworks kit that comes with BlueJacket's 1/24 MORGAN cross-section kit is also available separately? While it looks rather complex, it is really quite an easy build. There are about individual laser-cut bricks that are applied over a laser-cut frame. The pots and stacks are cast resin.

-

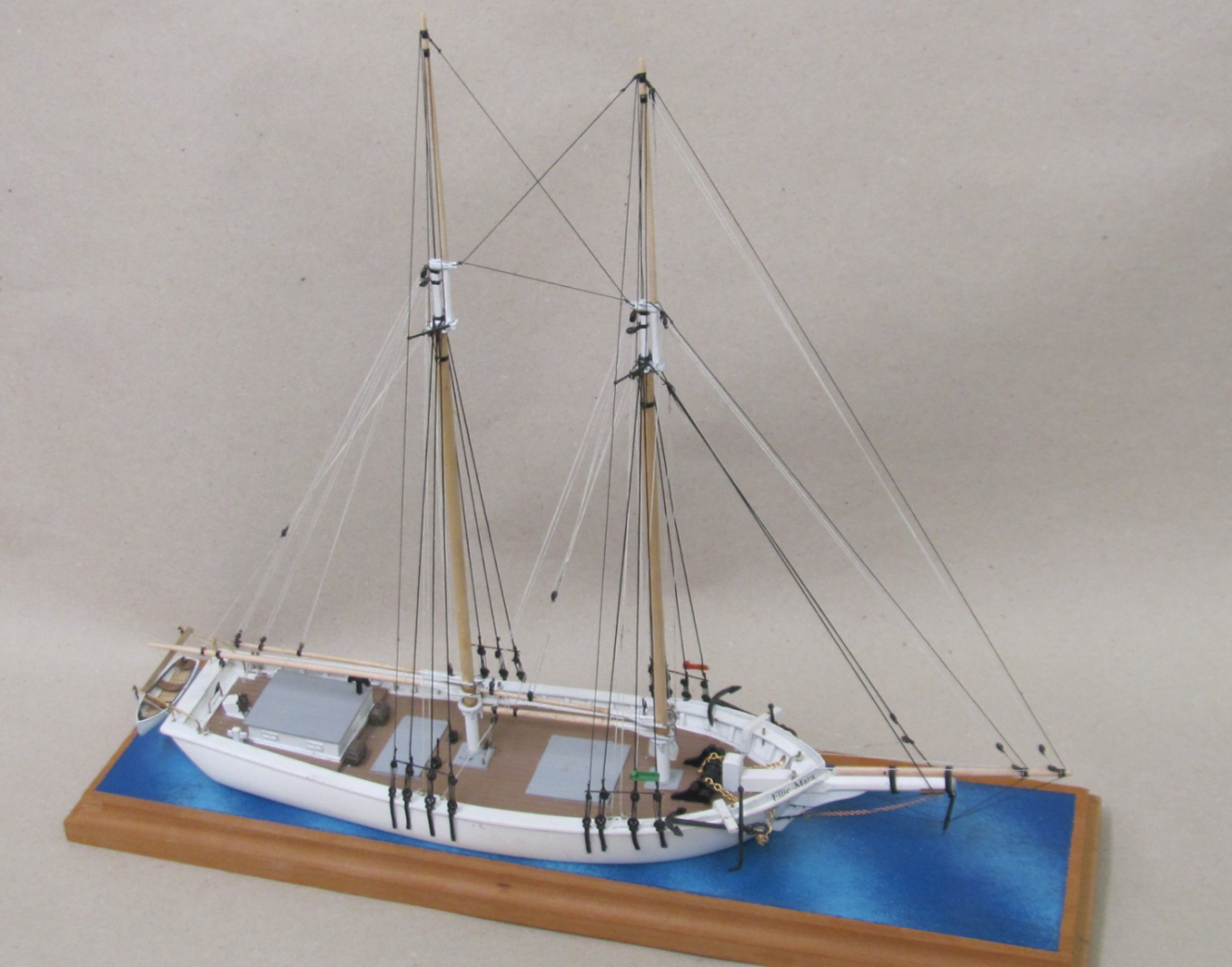

Here's a little surprise I didn't tell you about. This is a side project I've been working on while also doing WYOMING and OREGON. This is an HO scale waterline kit of a generic centerboard schooner. It is based on MATTIE/GRACE BAILEY and is named ELLIE MARA after Nic's daughter. The hull is cast resin with laser-cut details and the usual britannia fittings. Overall length is about 14". It should be in production in a few weeks. Contact BJ for details.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.3674f42d93cb5def630c9c055acf3858.jpg)

.thumb.jpg.a7ce083fd35d2e2fc18aa9acd3835da9.jpg)