-

Posts

408 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alross2

-

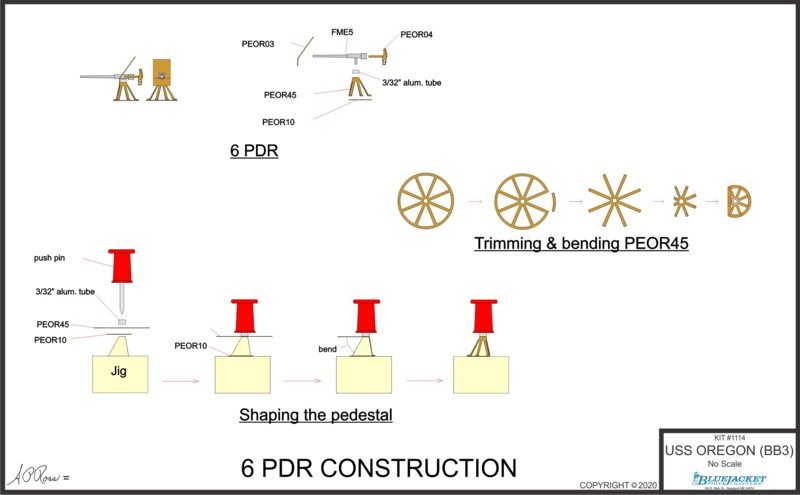

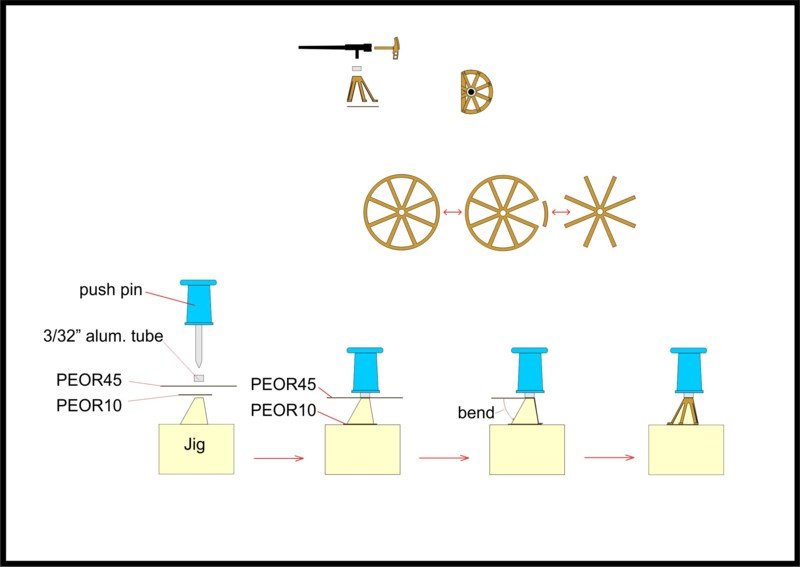

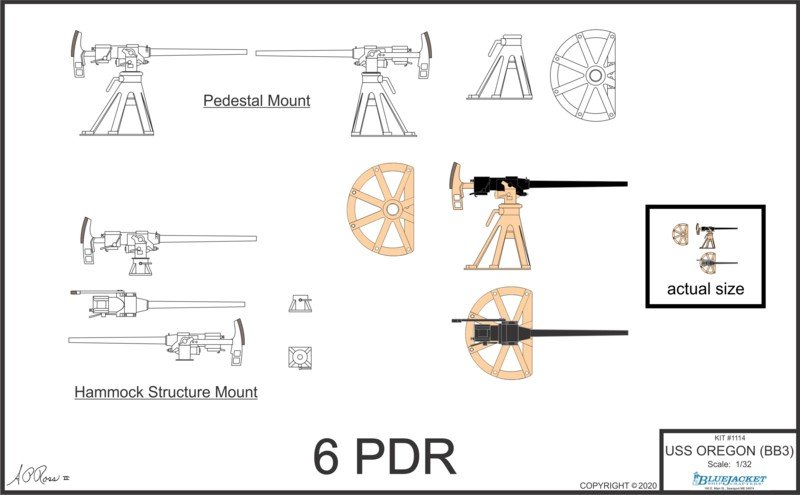

A couple more drawings today. These are for the 6 pdr guns, of which there are 18. This is in progress and will eventually show the construction details, most likely in a larger scale as no measurements are needed. For the superdetailers, I've done these in 1/32 scale, along with an actual size drawing.

-

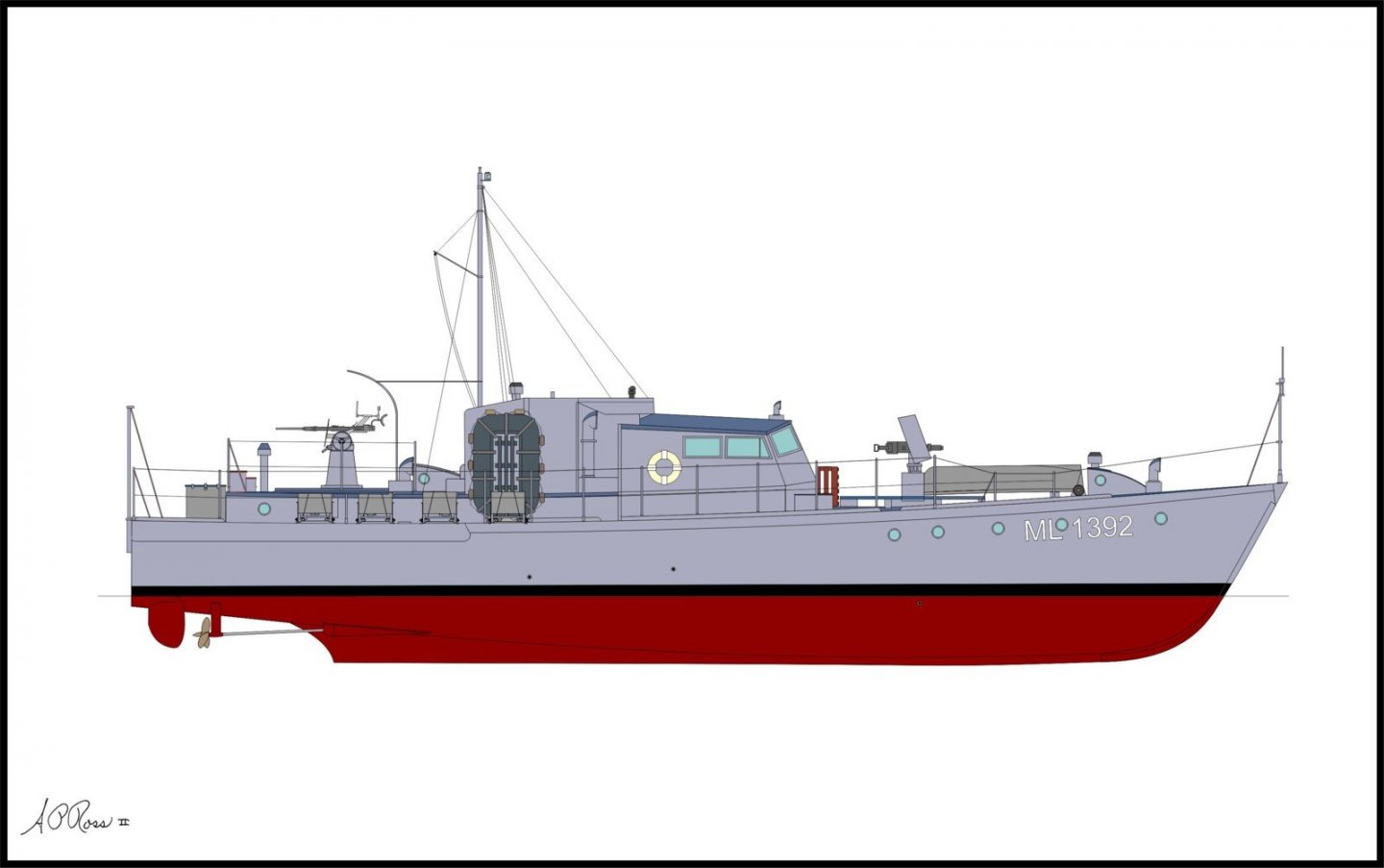

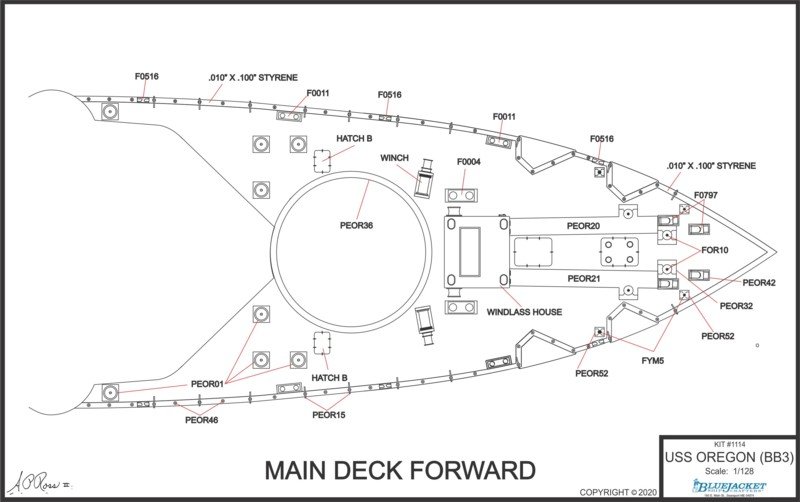

One or two of the plans will be the normal large sheet (the general arrangement plan is 28" x 40"), but most will be in a spiral-bound booklet of 11" x 17" pages. The drawings on the smaller sheets will be full size, so measurements can be taken directly from them. The smaller size is just handier to use and doesn't take up a lot of workbench space. It also isolates each component, making it less confusing than an overall drawing. The large sheet (not quite complete) showing the overall model. I still have to add rigging and a few other details. A few of the 11" x 17" sheets will have a couple drawings due to the small size of the item being assembled/built. Most of the 11" x 17" sheets will have a single topic to be addressed. Both the main and superstructure decks have the positions of the various components laser-etched on them, making placement a bit easier than trying to measure everything.

-

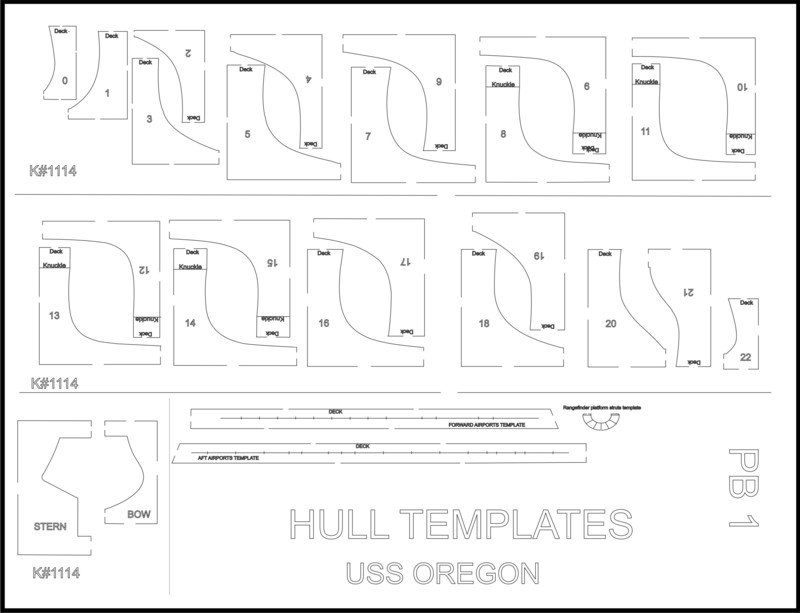

Today is going over the drawings day, checking out what's already done and what further ones are needed. Because this is a solid hull, I'm including hull templates that are laser-cut from poster board. It'll save the modeler a bit of time and expense. In addition to the hull sections, there are templates for drilling the air ports, the stanchions, and a few others. There are two more sheets besides this one, those being the plan and profile with stations.

-

A test assembly of one of the exposed 6 pdr guns, less shield. It's a bit rough, but I was fiddling around with the pieces trying to figure out the best assembly sequence. It came down to lightly gluing the base and pedestal to a piece of masking tape around a stick, inserting the gun peg though the hole on the legs, gluing that assembly to the pedestal, cutting away the arcs holding the ends of the legs, bending down the legs with a hobby knife, gluing them to the base, and trimming them with the hobby knife. The tape is removed from the wood and trimmed away from the gun. It's a bit of a fiddly process, but comes out fine if you take your time.

-

The actual ELCO Parts Catalog for the real 80' PTs. I have a hard copy and also have it as a PDF, along with a PDF of the Higgins catalog. Al Ross

-

There are a lot of airports in the hull and little looks worse than a wavy line of them. The kit includes laser-cut templates that are taped to the hull at the deck level with drilling dots that are inline and at the correct depth below the main deck. Once taped in place, an awl is used to mark the centerlines. The holes are drilled out with a 5/32" drill bit, lengths of aluminum tube are inserted into the holes and glued. When the hull is finished sanded, the tube will be flush with hull sides.

-

One of the initial challenges I came across in the early stages was the prominent anchor bills. They are angular and have some difficult angles where the wedge shape meets the vertical walls. I tried carving them into the hull, but wasn't satisfied with the outcome, as they weren't exactly the same. So, I decided to cut a channel across the hull and laser-cut inserts that ensure consistency - worked much better. There are two pairs of lifts that allow the builder some adjustment capability incase he/she didn't shape the hull quite to specs...🙄 The inserts are separate, as well, so the angle can be shaped before they are inserted. Once the basic assembly is complete, the hull is filled and finish-sanded to shape. A laser-cut deck of glued-up decking will be fitted, so the lamination does not affect the appearance. These are the inserts, before (left) and after (right) shaping. Lasered lifts for the anchor bills. This is what it looks like much later in the process.

-

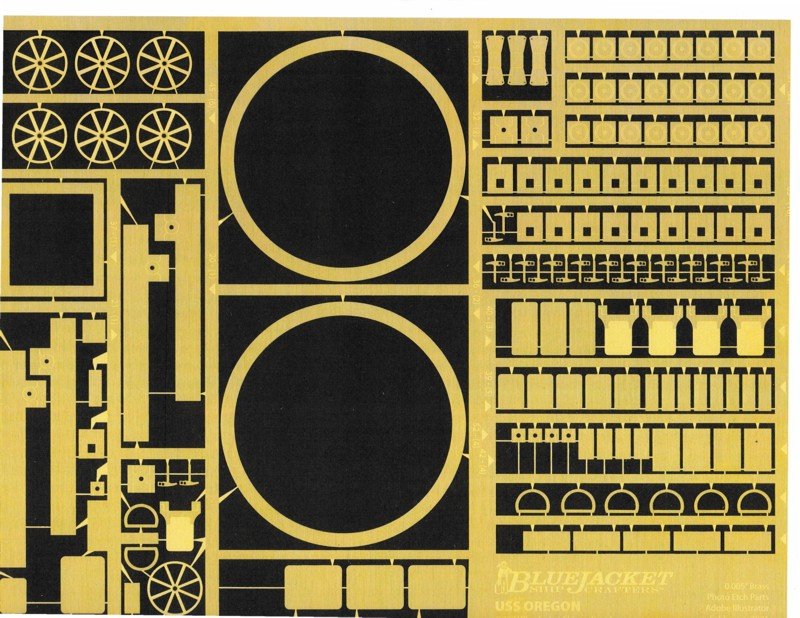

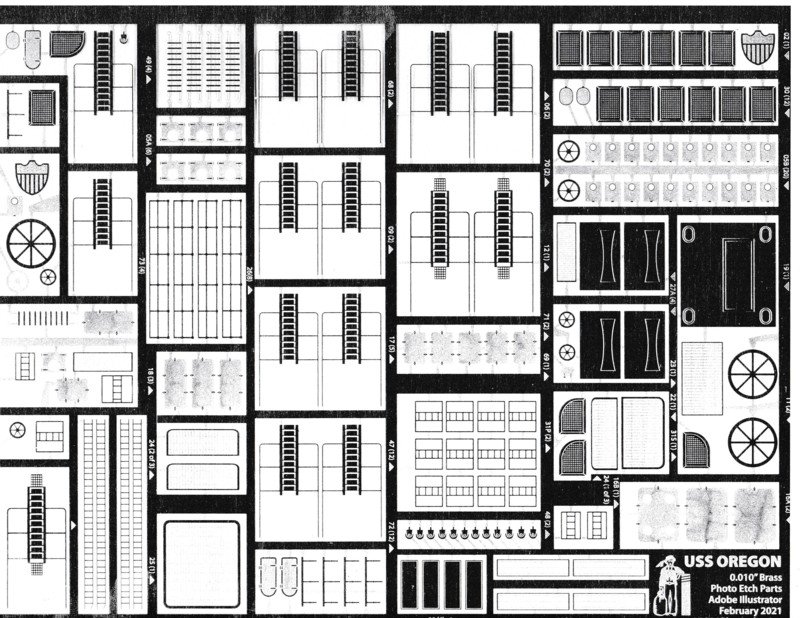

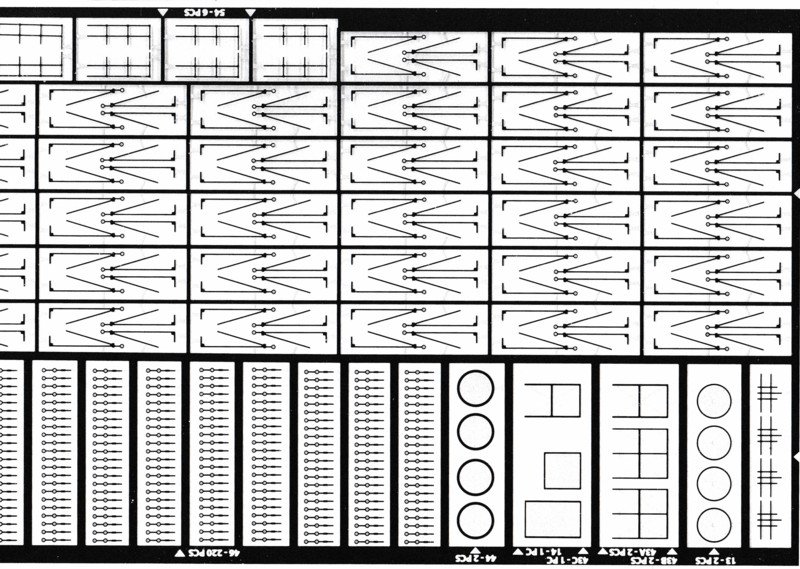

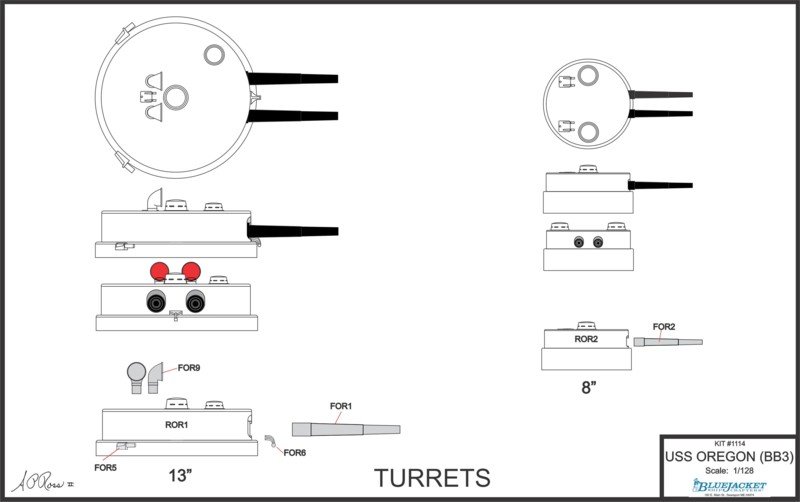

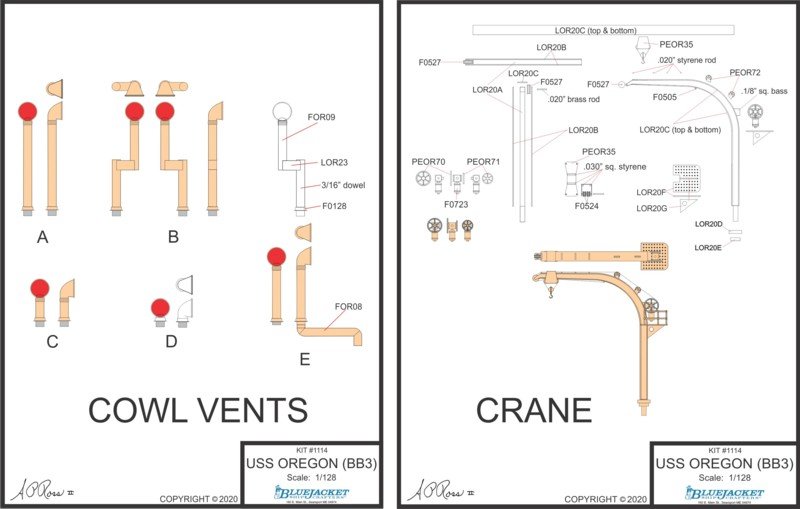

The photoetch for OREGON arrived Thursday and I checked it out today, so Tuesday I'll be back on OREGON. The development log (DLOG) for WYOMING will go into hiatus for a bit. The development of the OREGON kit was fairly well along before I decided to create these logs, so I'll be including some prior work just to give you an idea of what transpired before. The photoetched brass comprises three sheets: .005", .010", & .020". Here are partial scans of each sheet (reduced): .005" - turret rings, 6 pdr shields and shoulder rests torpedo tube covers, deck plates for various fittings, crane parts, coal scuttles. .010" - inclined ladders, gunner's grates, jacobs ladders, bow shield, 6" casemate covers, hatch covers. .020" - awning stanchions, main deck stanchions, railings, searchlight platforms, binnacle tower.

-

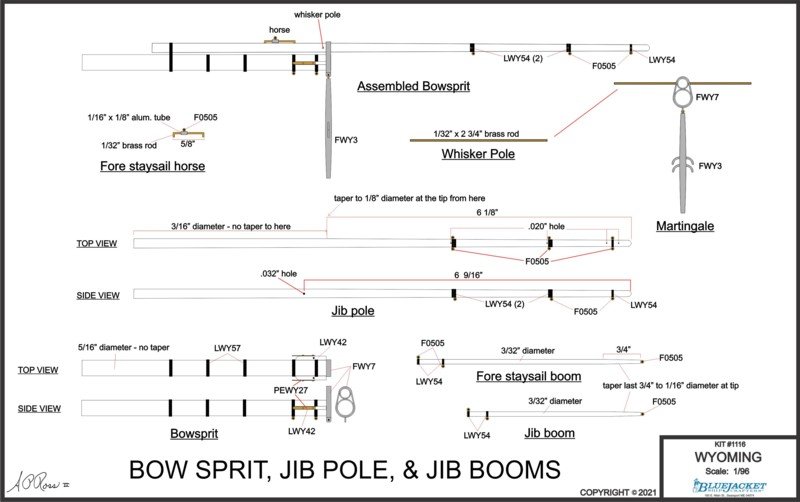

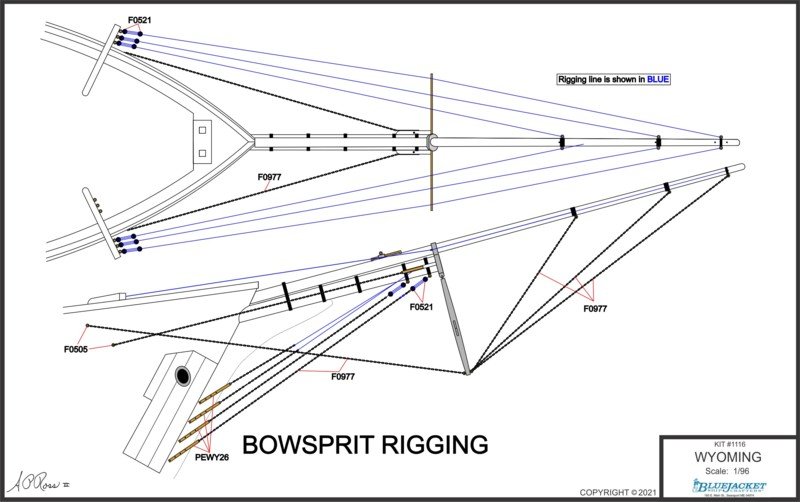

Started approaching the rigging drawings this week. The actual standing and running rigging sheets will be full size showing the entire vessel, but there will also be the isolated detail sheets. I've changed the bowsprit construction sheet a number of times and am finishing up the first iteration of the bowsprit rigging 11" x 17" sheet.

-

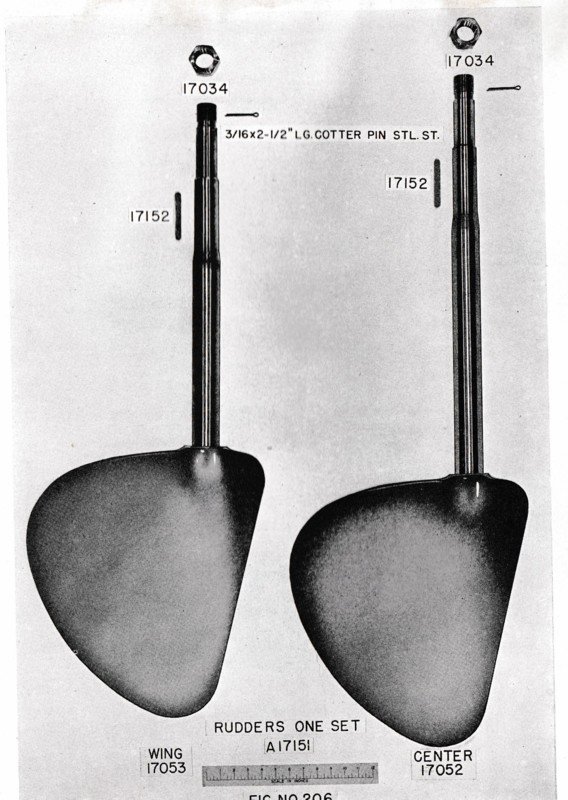

Just as a reference, these are the actual rudders for an 80' ELCO. This is from the ELCO parts catalog.

-

You did a nice job with the joints between the pilot house segments. Like Gary, I love the understated grace and look of these boats.

- 100 replies

-

- pauline

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Charles W. Morgan - Model Boat Kit | Blue Jacket Shipcrafters, Inc. (bluejacketinc.com)

-

The chicken coop was a bit of a fun part. It's mostly lasered and the slats are all panels to ensure consistent spacing. The vise consists of 8 or so pieces and is large enough that you can thread the screw and have it operate.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.9975170ec5c899c748a843b512d9aa90.jpg)

.jpg.d522da60cbed0a397643d1dada06d639.jpg)