-

Posts

193 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Børge

-

Hi Sjors, that is looking very nice my friend, great job Børge

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Mario, this is beautiful. Fantastic details, all those small items I am out of words A+++ Børge

- 53 replies

-

- bounty launch

- model shipways

-

(and 1 more)

Tagged with:

-

Hi GTM, looked at your Smit Rotterdam, it is looking very nice, great job. The weathering also look great. Børge

-

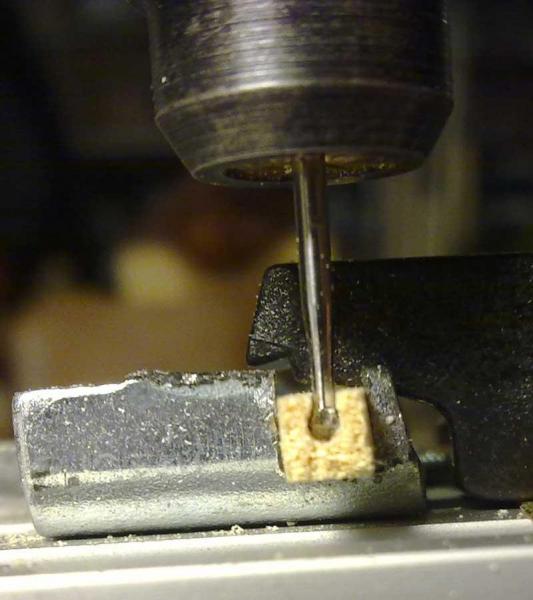

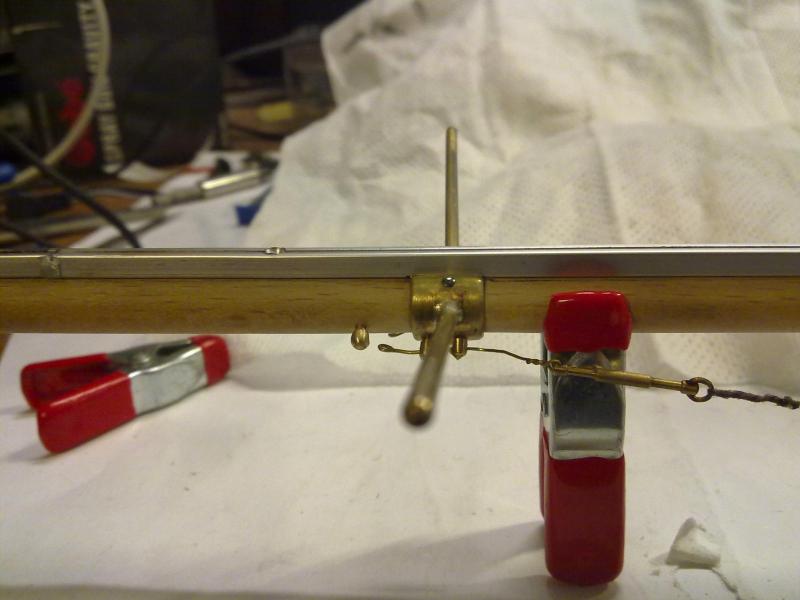

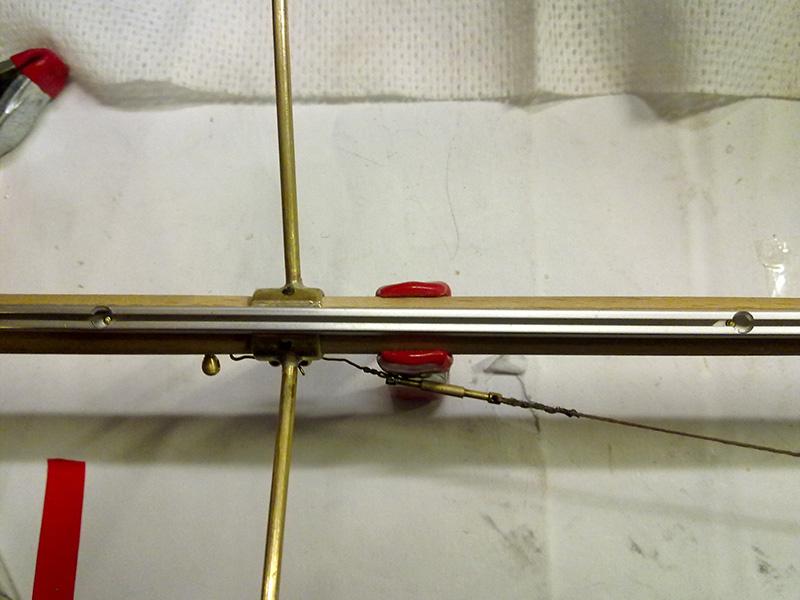

I have tried this in a very small alu U profile (3x4mm), and it worked perfect. Info from the website: www.alutite.se Alutite is a new complete method for thermal joining of aluminum and its alloys to replace welding riveting glueing etc. Uses Joining of aluminum and aluminum alloys in all forms, including cast and zinc alloys. Alutite goes to "build with". Alutite can usefully post-produced with eg. drilling and Threading. Alutite can be reused. Alutite lead-and cadmium-free and can thereby requirements of joints in contact with food and drinking water. Alutite is eloxerbart. Anodizing and coloring must be removed before work.

-

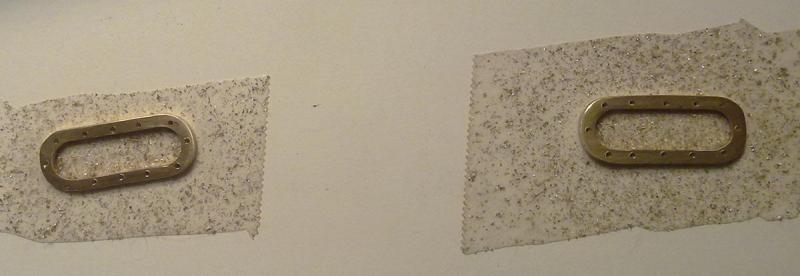

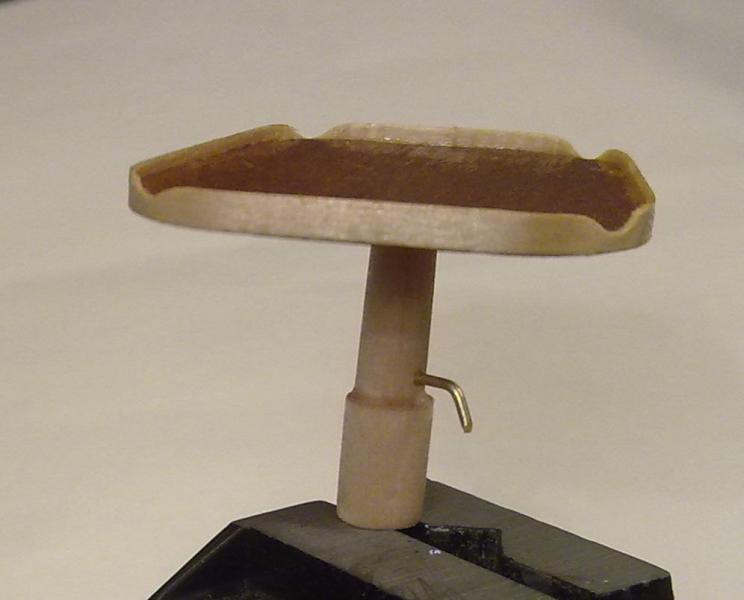

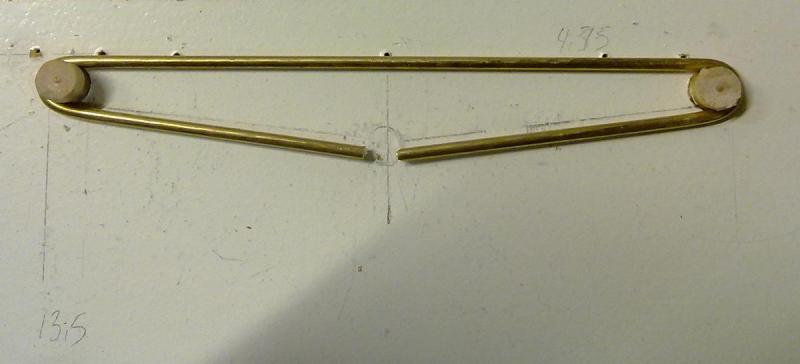

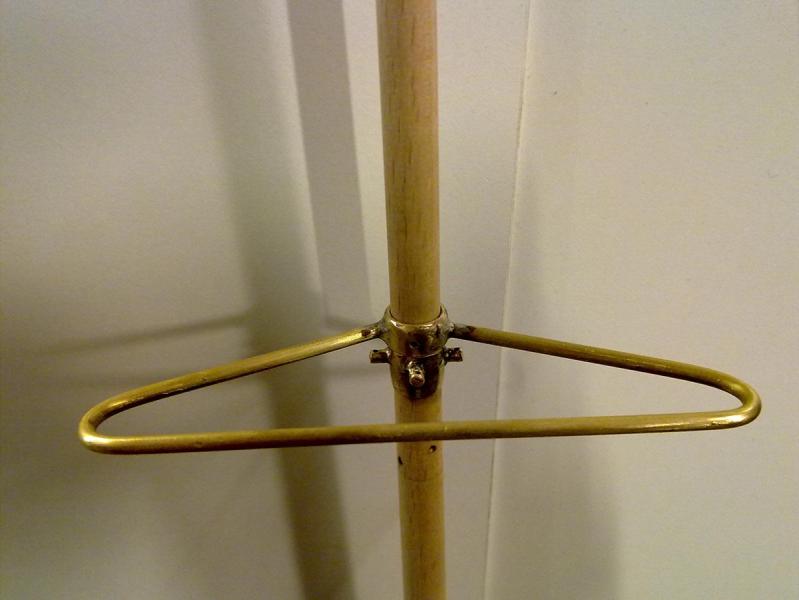

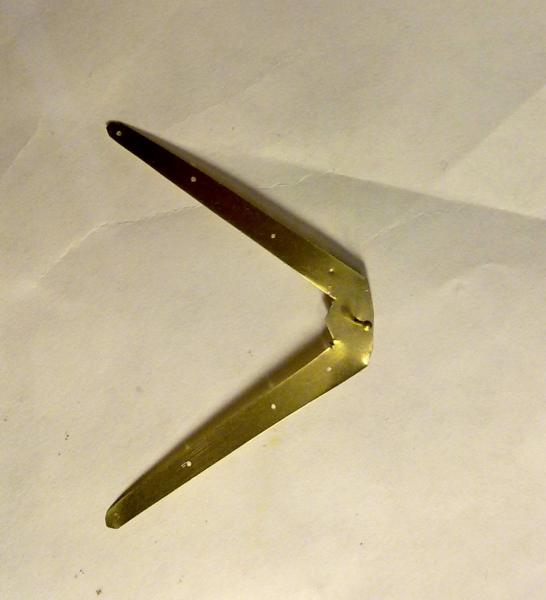

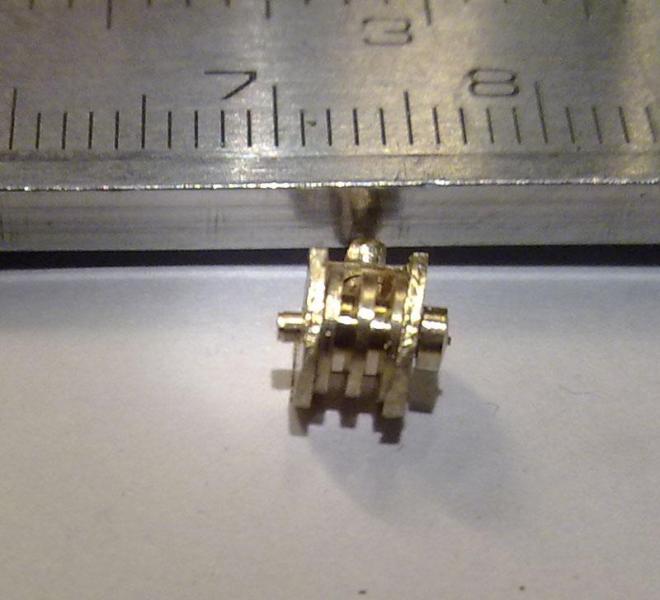

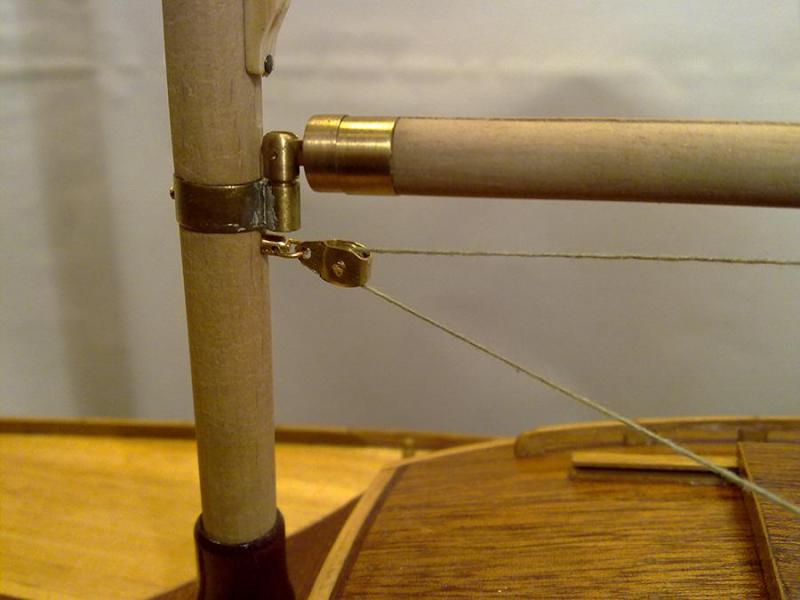

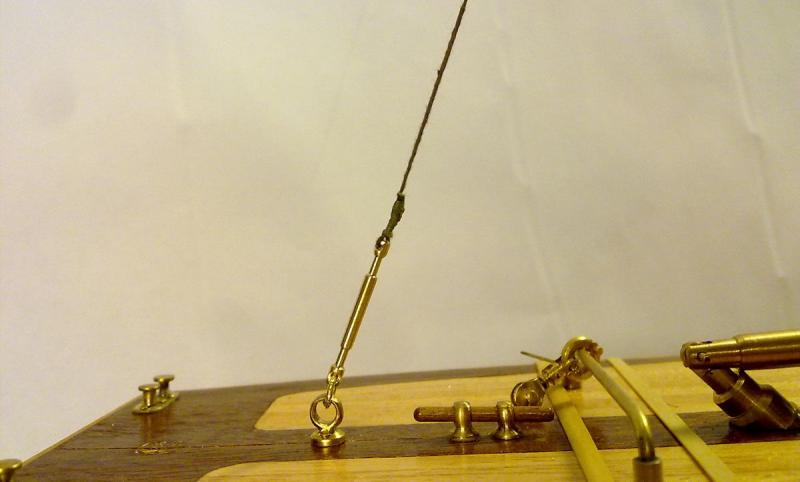

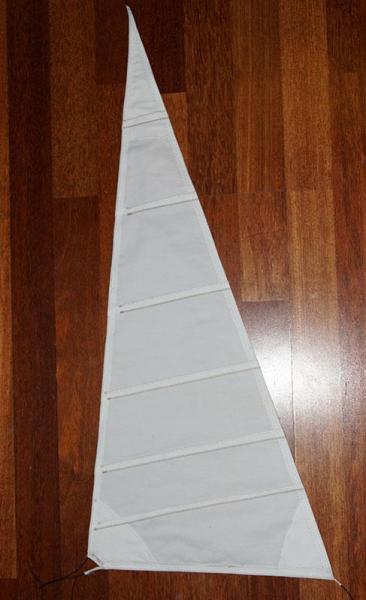

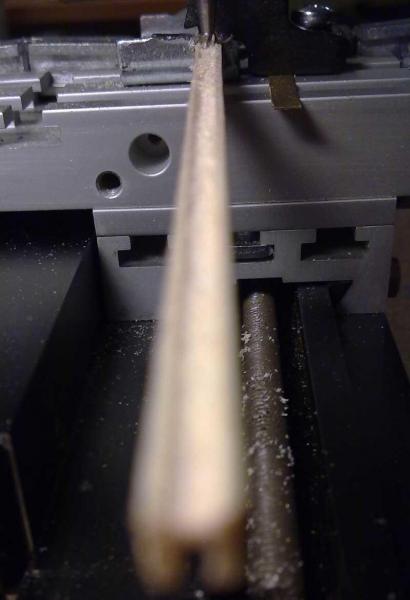

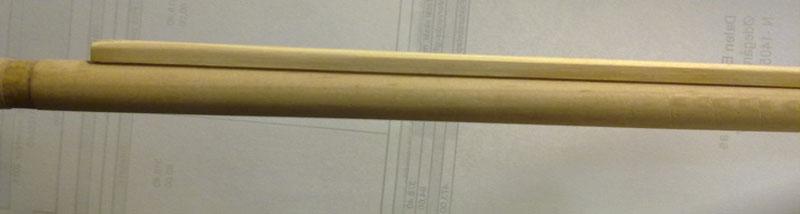

Pictures from making the channel for the main sail. Started with a wooden channel, but it was to tight for the sail when inlayrope was installed, so it cracked I then went for a aluminium profile, and that was working well. Had to find a way to connect the two lenghts i was using. Welding was out of the question, to small. Then i searched the net about soldering aluminium, and found a great solution for this purpose. Alutite is a alloy for heating with a open flame, and melts before the alu melts, works like soldering, and is strong www.alutite.se Børge

-

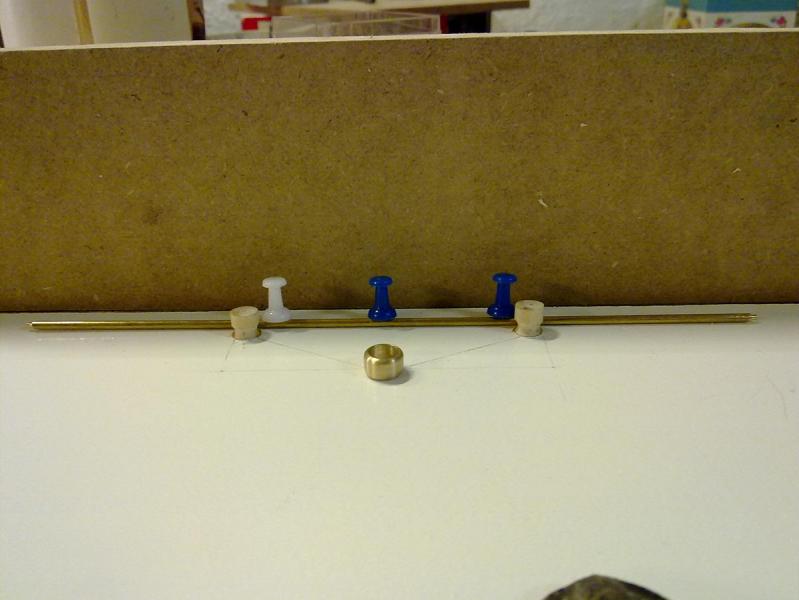

Solder brass rod for deadeye

Børge replied to cog's topic in Metal Work, Soldering and Metal Fittings

Silver soldering on brass works like a dream, i you have multiple items to solder on thar sam object, get solder with different melting temps. i have used this for my fitings, and it workd great. Børge

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.