Diver

-

Posts

403 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Diver

-

-

-

When I arrived in Halifax in 1970 as a brand new Ordinary seaman the Bonny was still tied up in the dockyard, all though she was De-Commisioned. I was doing a Explosive Demolition course out at Portugese cove the day she was towed out on her way to the razor blade factory. It was a sunny but sad day. I think this would have been spring of 71, or maybe 72.

- NavyShooter and Canute

-

2

2

-

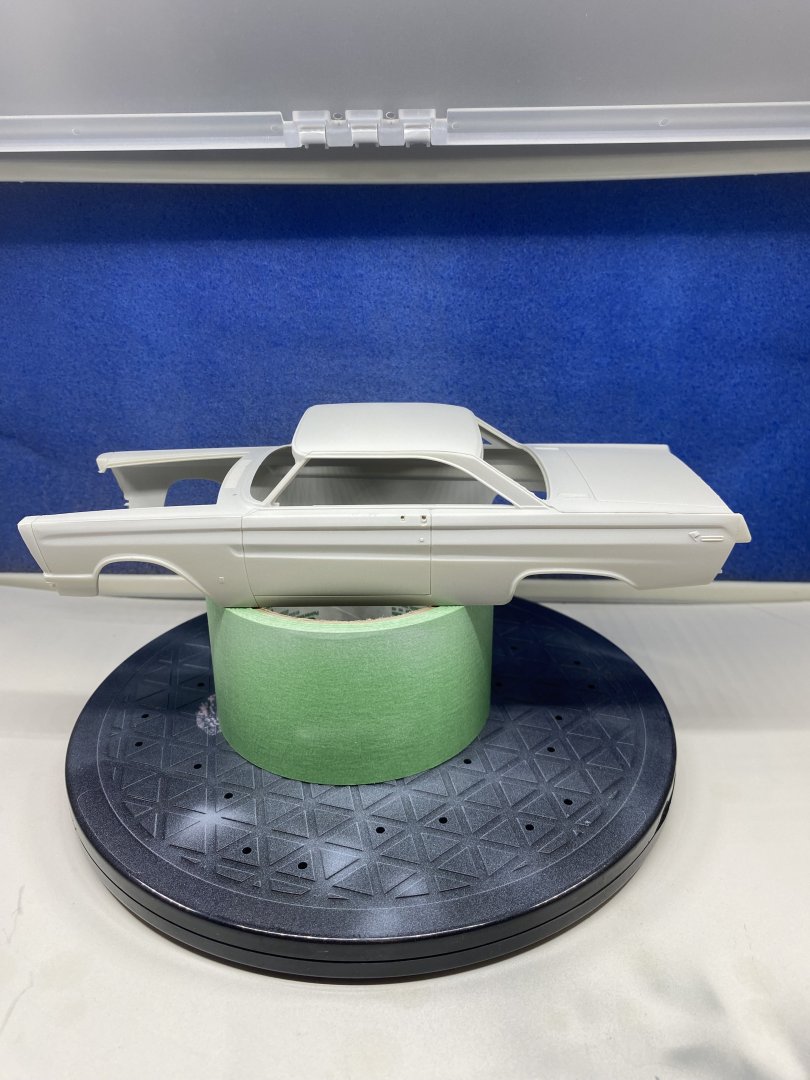

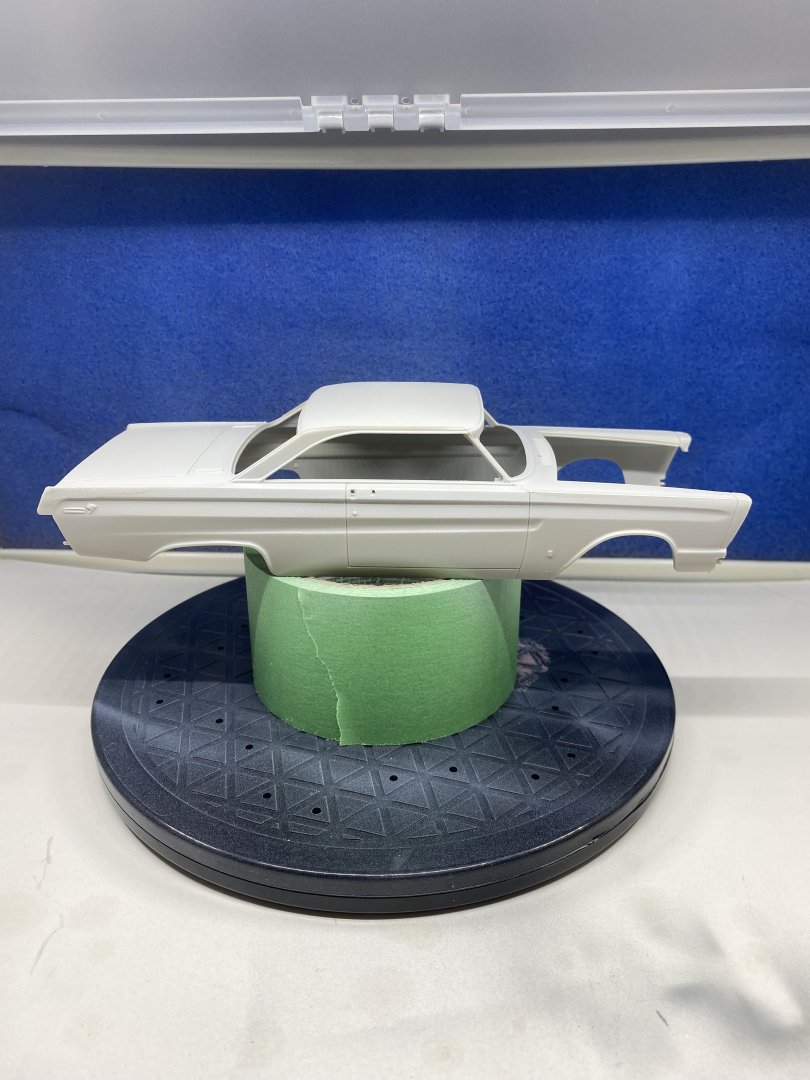

Put my new airbrush and paint booth to the test. A lot of trial and error to get the correct paint mixture and air pressure to spray an acceptable coat. I tested on some scrap before moving to the car body. I am happy with the results. I will let the primer cure for a day and then on to the colour coats.

- gsdpic, GrandpaPhil, DocRob and 7 others

-

10

10

-

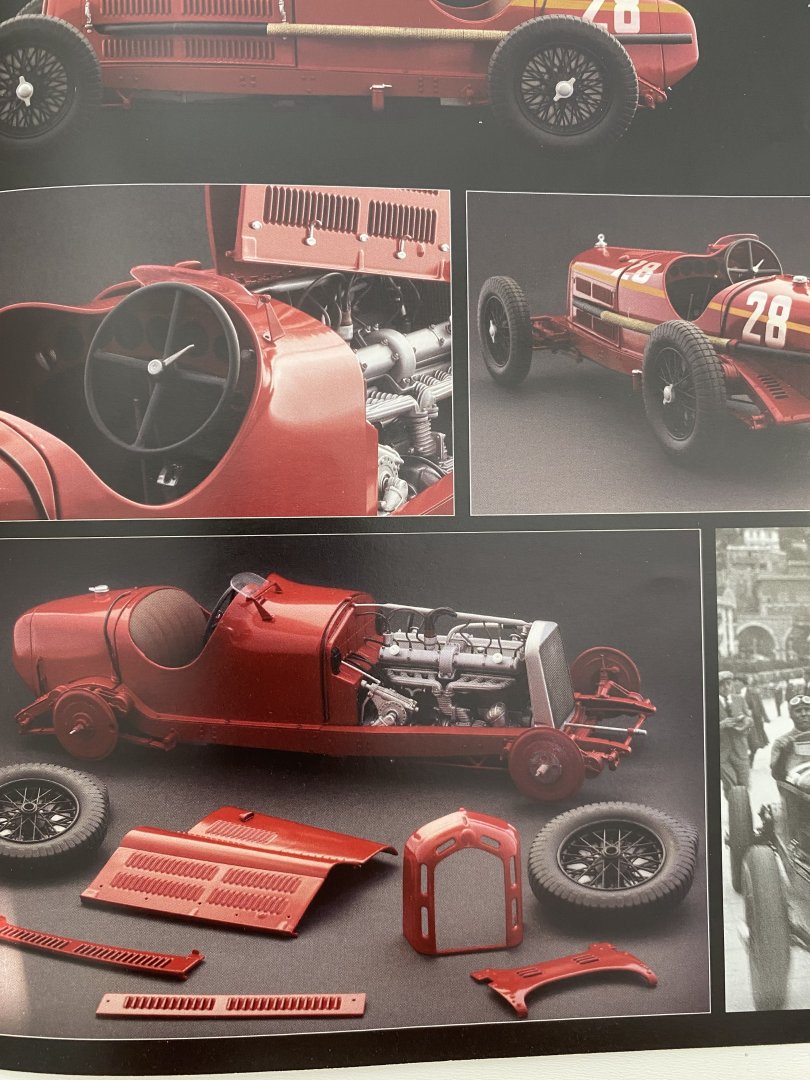

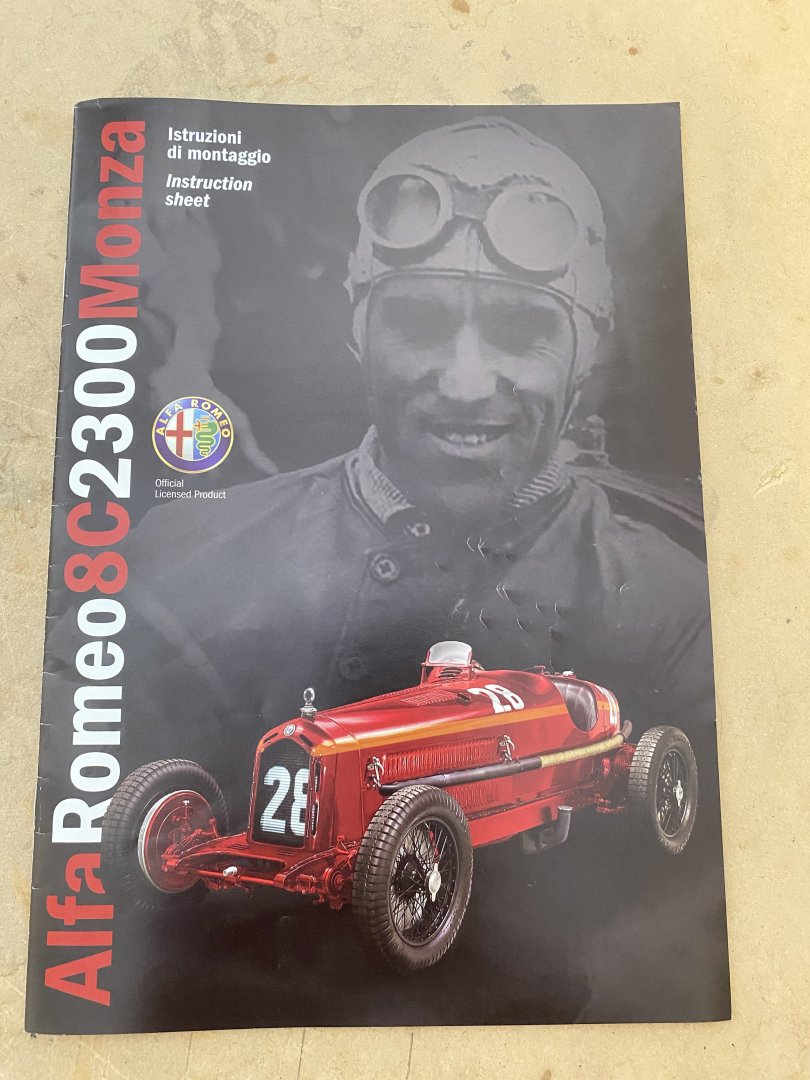

To improve my skills in dealing with small painted parts I purchased this kit from Echelon hobbies in Brighton Ontario. This will be used as a learning curve before Continuing with my 1/12 scale Alfa. The colours used may not be accurate but they are what I have. At this stage I am not ready to attempt spark plug wires but that will come later. The kit is a 1/25 from Moebius models.

-

On 9/27/2025 at 12:22 AM, Racersonly said:

and auto racing enthusiast and competition driver (40 yrs of amateur sports car road racing) now old and retired from working and racing. In my retirement, I’ve revived my love of model building. Most of my 100 plus kits are of race cars. (Go figure) But, as a 6 year Veteran and Petty Officer in the world’s finest Navy, I’ve done a handful of ship builds too. Most of them are of warships from my era. I found and assembled resin kits of the two destroyers I served on, an aircraft carrier, a battleship, and my only sailing ship was a very small and simple Bonhomme Richard. (I don’t remember the manufacturer.)

A couple of years ago, I was gifted a Revell Cutty Sark from a friend who bought the kit but he never got around to it. I didn’t realize that Revell made this kit in two scales. I got the smaller scale. (1/220?…..please correct me if wrong) I’m pretty deep into the assembly and should be rigging soon. This is where I’m may need some advice.

Peace/Love, (old hippie) ✌️

Jack

Worlds finest navy, Must have been the RCN.. LOL

-

I believe that Douglas Bader was flying a Bulldog when he crashed and lost his legs.

- AJohnson, Jack12477, Old Collingwood and 1 other

-

4

4

-

Thats great news. It is so easy for a country to lose its history due to lack of funding. We can not always rely on private funding and donations.

- Kusawa2000 and Knocklouder

-

2

2

-

-

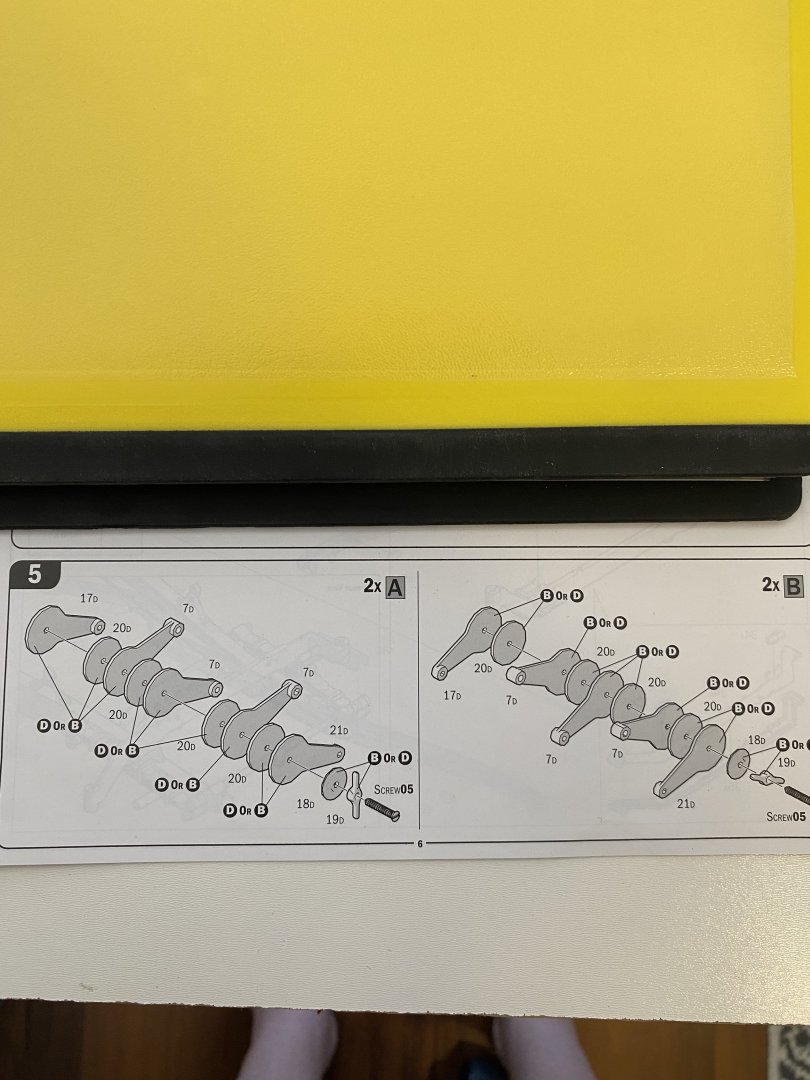

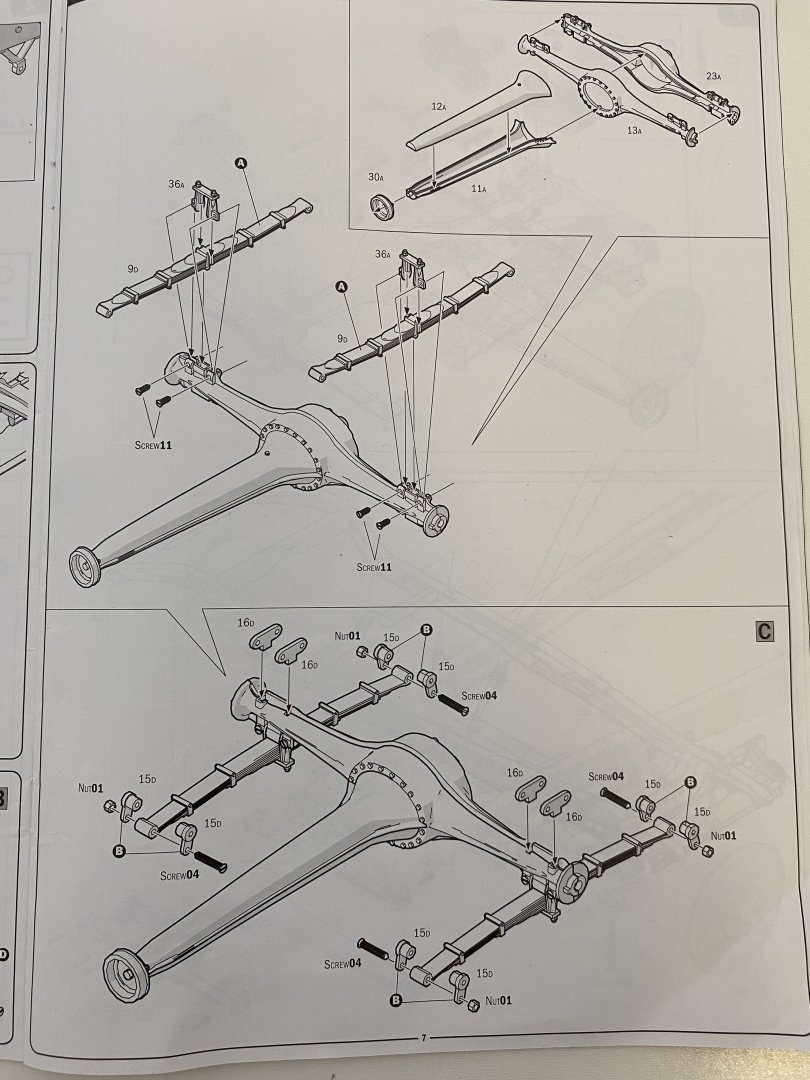

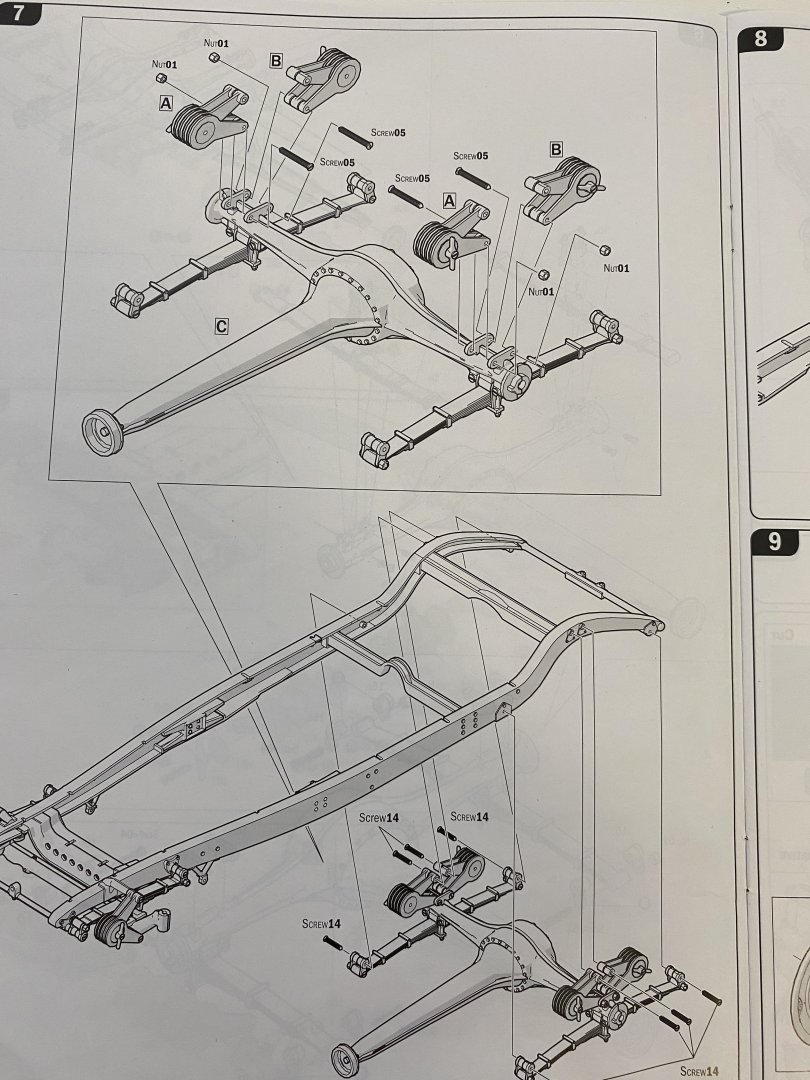

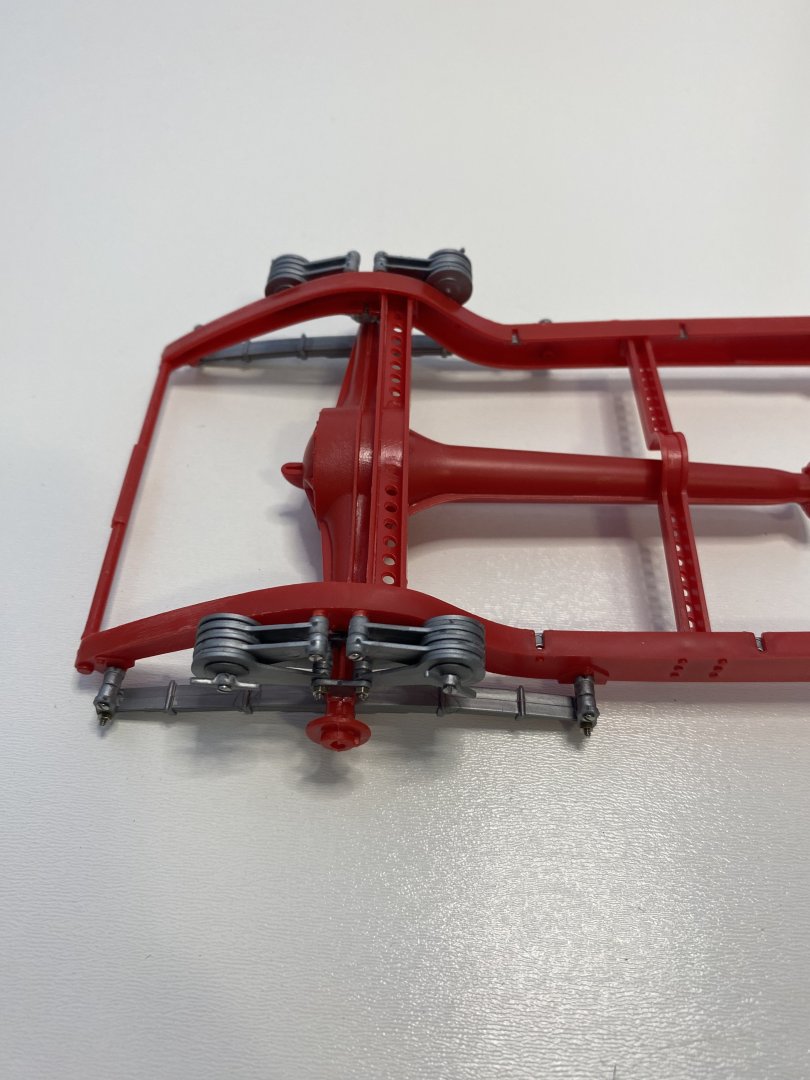

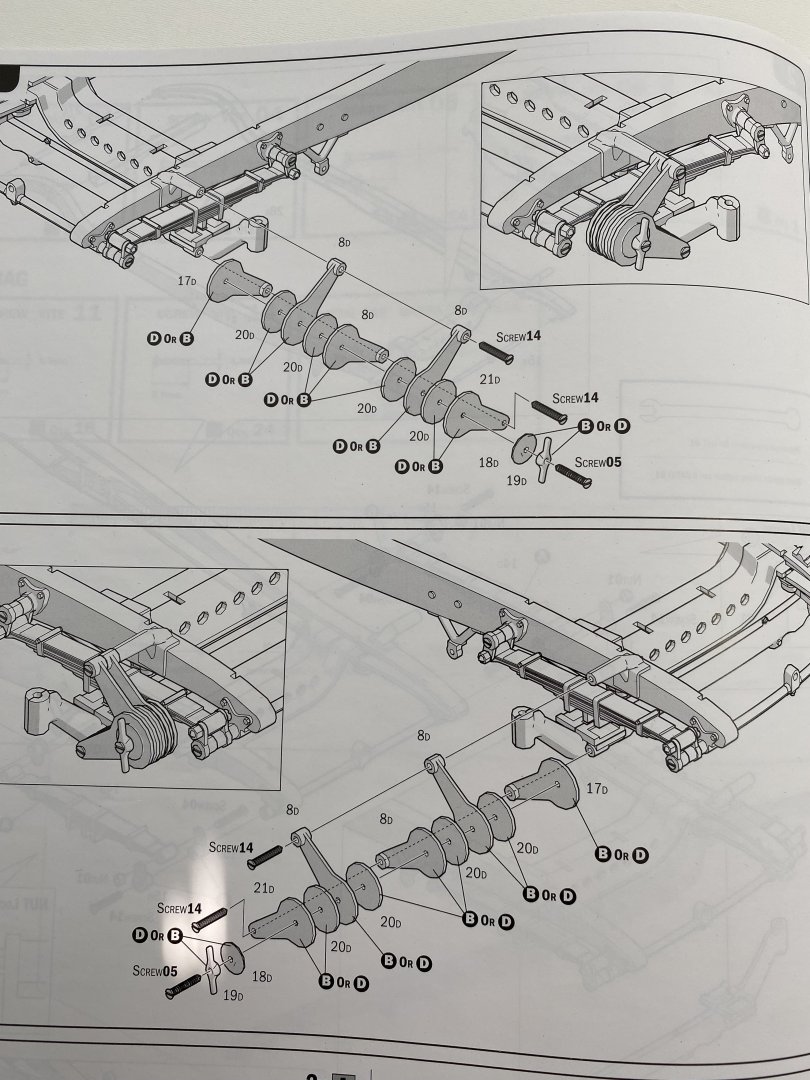

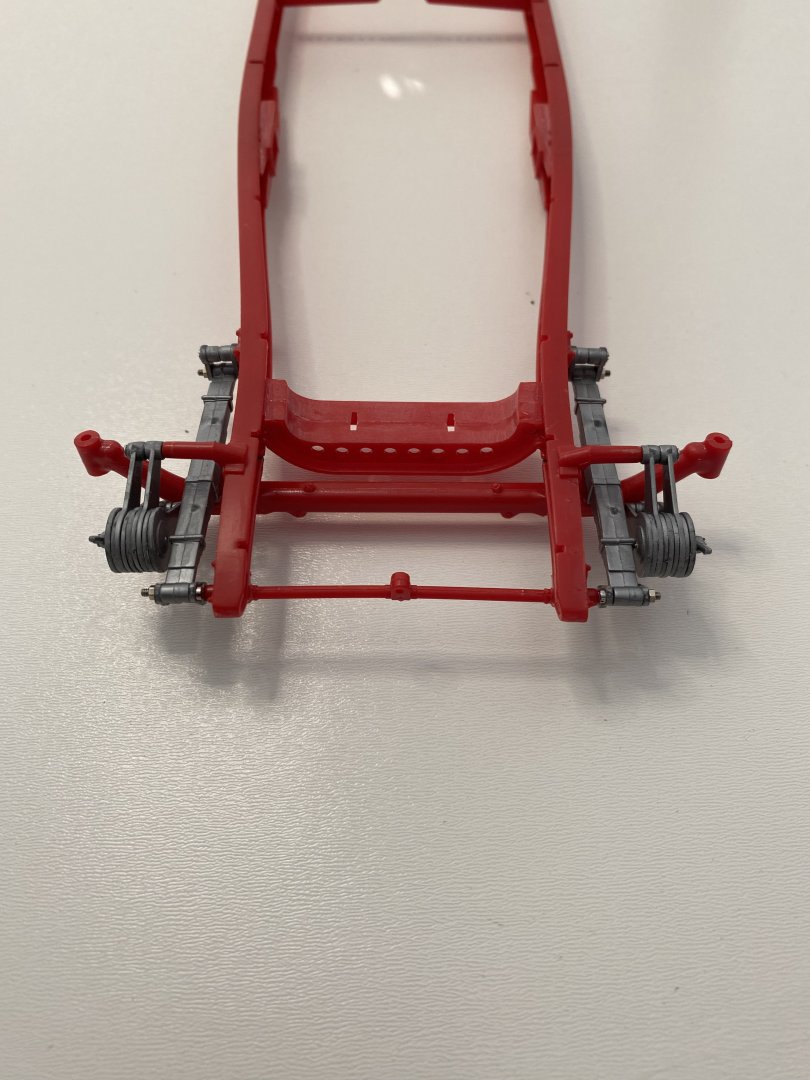

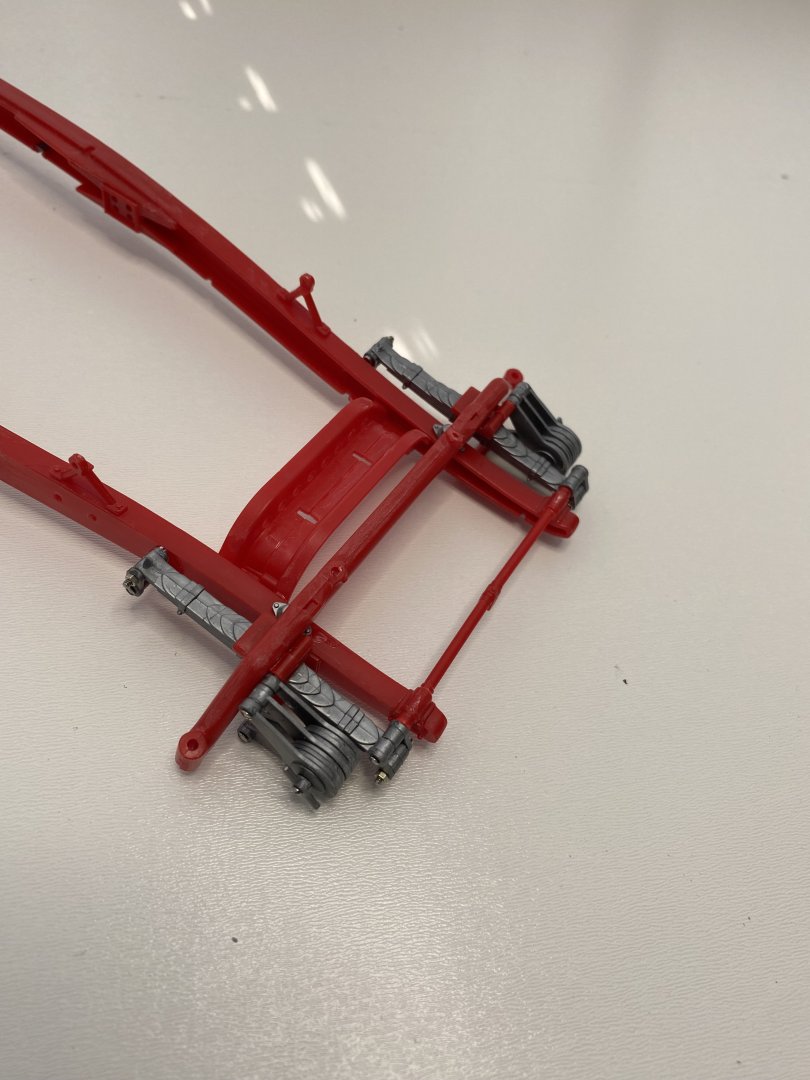

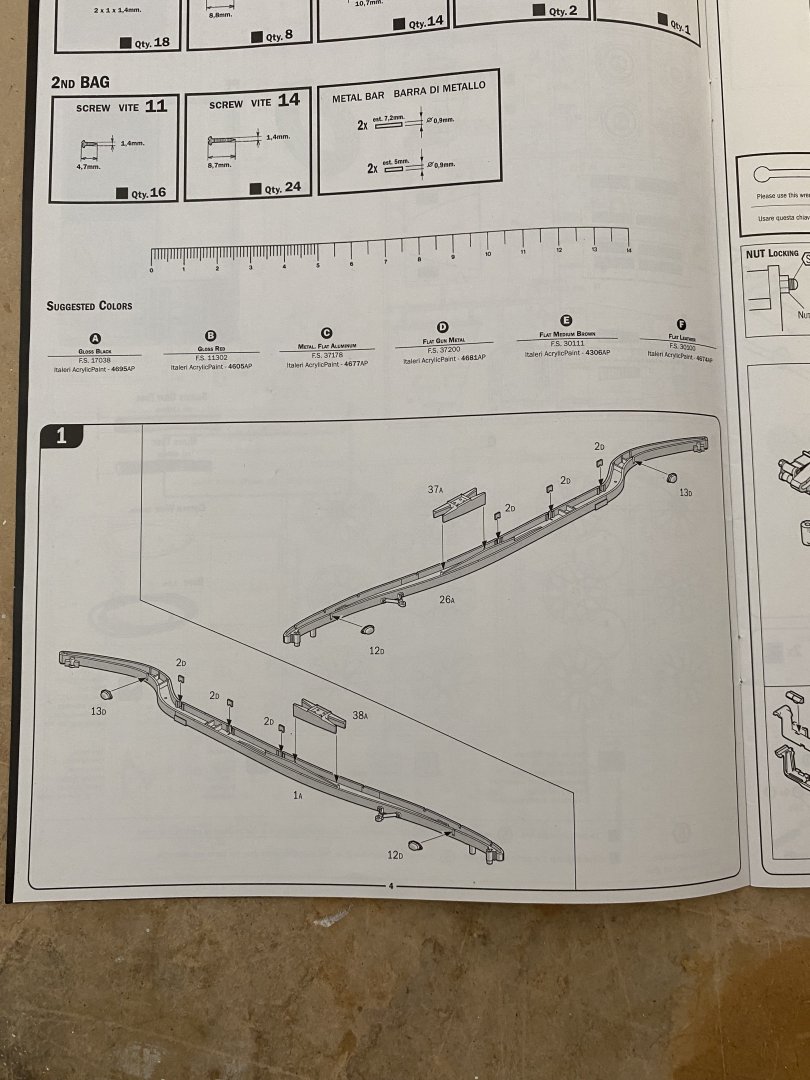

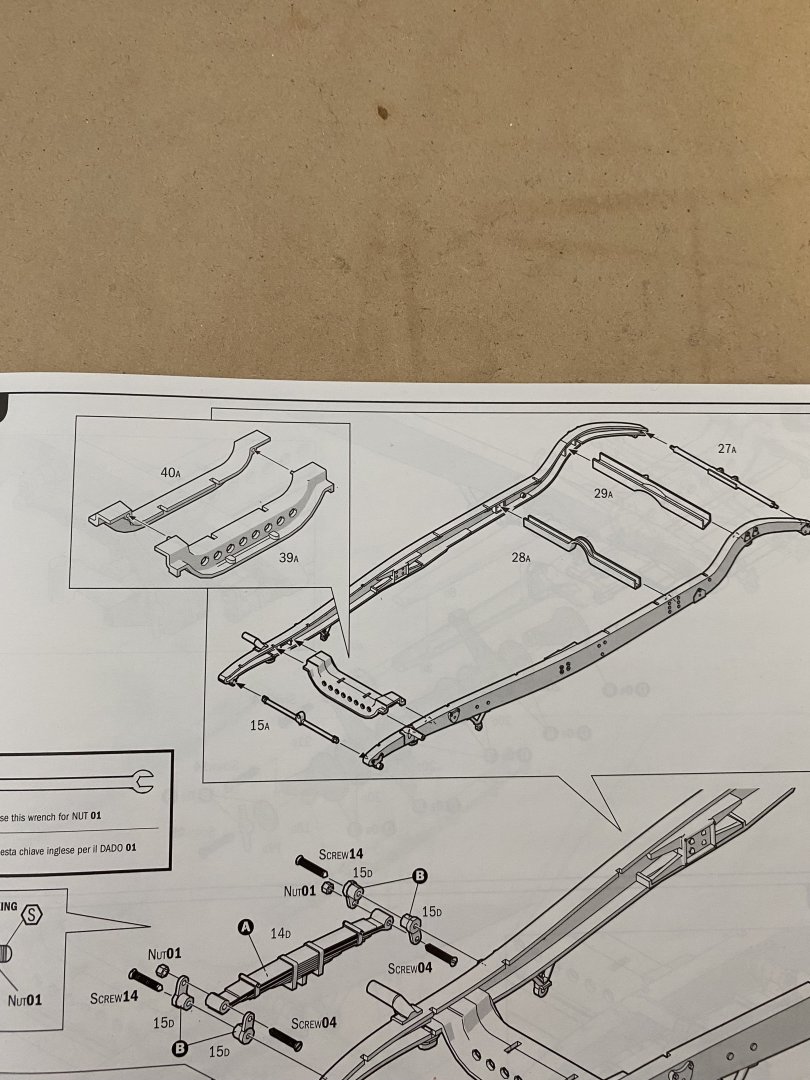

Steps 5, 6, and 7 complete. I now will wait for my airbrush set up before going any further. I will start on the engine but will only do main pieces and hand paint smaller items like hoses, distributor etc. This kit is all produced and have not run into any problems , yet. I do require my back kit magnifier for the tiny nuts and bolts.

-

On 8/8/2025 at 9:47 AM, wefalck said:

If it's not too late: I would scrape off the moulding lines from the parts! Makes for a much more professional and realistic looking model.

Thanks for pointing this out. I have disassembled the front suspension and scraped the mould lines. I have started on the rear springs and scraping was much easier before assembly. Once the rear suspension is installed the build comes to a halt as I wait for my airbrush set up. Will be picking that up in Ottawa in early September.

- Old Collingwood, Canute, Jack12477 and 1 other

-

4

4

-

- Canute, GrandpaPhil, druxey and 7 others

-

10

10

-

-

I am going to call this build Finished. The small boats ended up in the garbage, new ones will be ordered from AL. I started this build with great enthusiasm but that was lost when I ran into problems with some of the materials, and lack of drawings. The videos are a great help but drawings would be better in my opinion. No mast lights are provided with the kit so I used plastic thumb tacks. This build gave me great frustration at times and complete joy at others

-

-

- hof00, yvesvidal, king derelict and 2 others

-

5

5

-

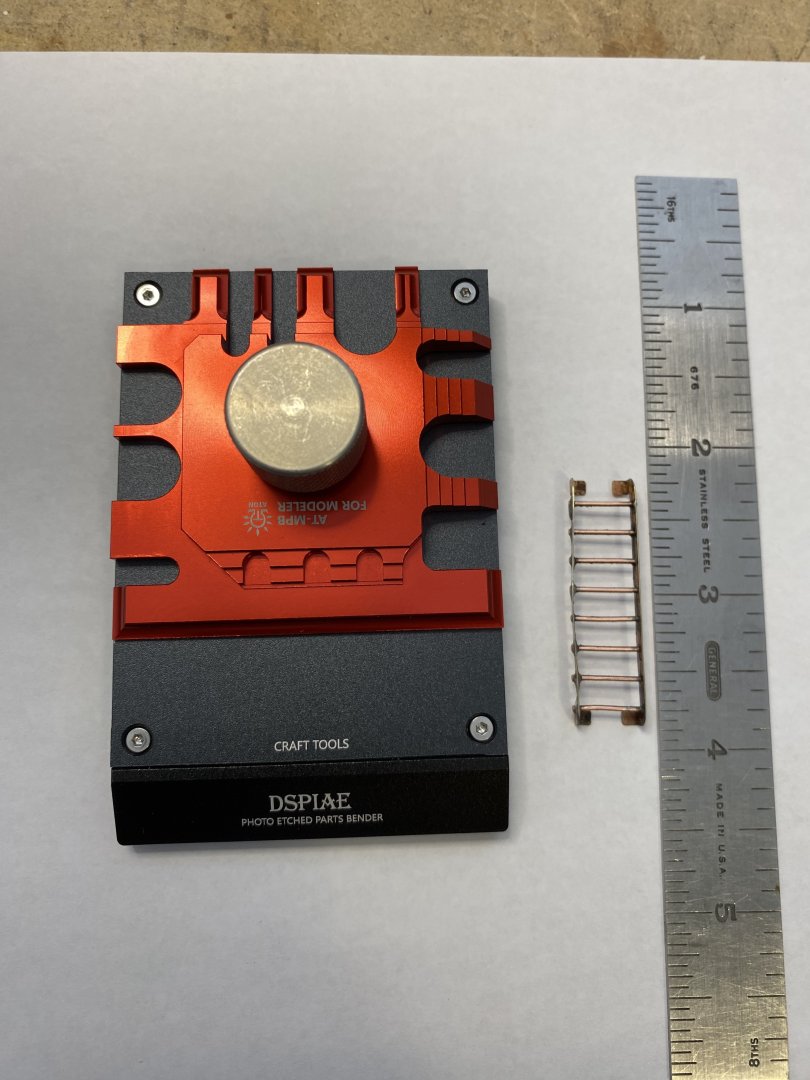

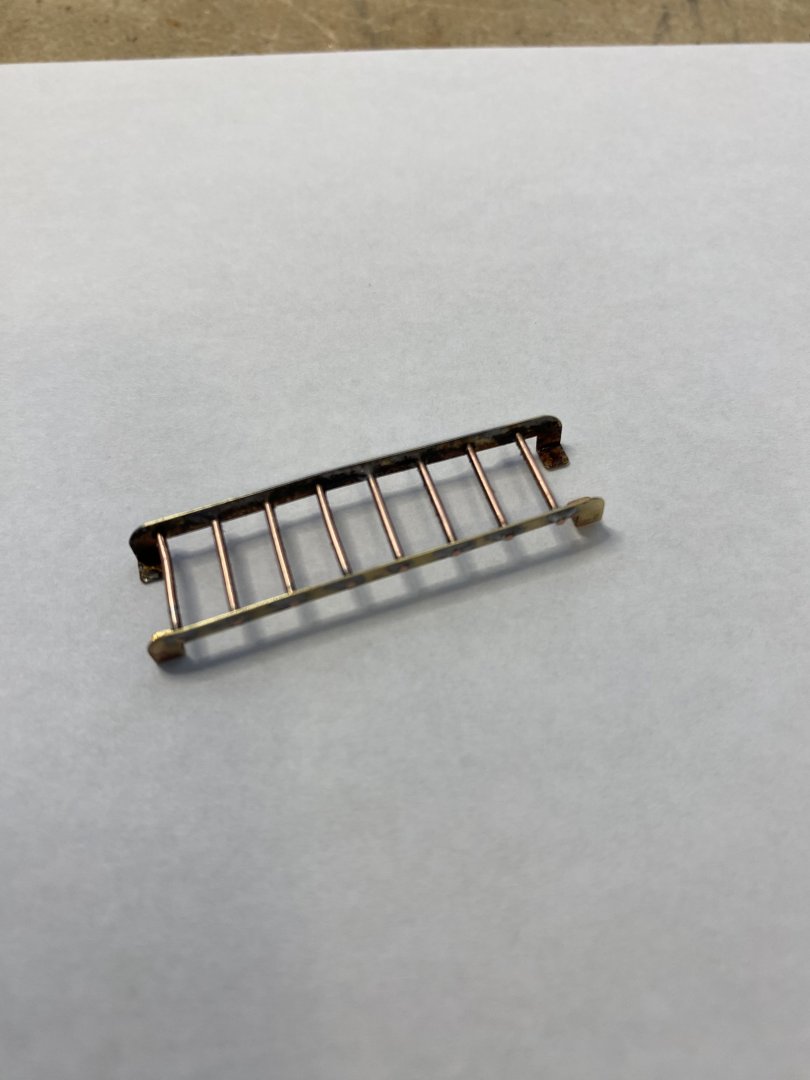

I just purchased the DSPIAE photo etch bending tool so the ladders and other parts could be shaped . The tool is well made and worked very well. Unfortunately the operator not so good. After bending the ends of the ladder I twisted the steps in the wrong direction. When trying to correct this the steps broke off. The sides were drilled and some copper wire cut and soldered in. It’s not perfect but with some paint it will be acceptable. The towing deck of the tug is pretty much complete, now it’s onto the boat deck.

- hof00, king derelict and yvesvidal

-

3

3

-

-

3 hours ago, Diver said:

Looking at these photos it appears the capstan shifted when I glued it down. I used CA and Titebond so I don’t think it can be moved

-

-

Welcome aboard. I am a novice builder having completed the Medway Long boat by Syren and am in the process of doing the Sanson Tug by AL. What I have found with the video instructions is that they leave out some important steps. An experienced builder would think of these. In my case it was bevelling the planks on the hull. If I had not built the Longboat that came with very detailed instructions I would not have known to do this. In hind sight I would have viewed the videos numerous times to to see if the steps were in a logical order, case and point, the gunwales and deck/pilot house would not have been installed til after the hull was planked. Good luck with the build.

-

- ccoyle, king derelict, digby and 3 others

-

6

6

-

I am using the AL acrylic water based paints on my SansonTug. The paint is quite thick and does not seem to flow very well. If you brush on paint in one direction and then come back with the brush it pulls the paint away. The hull is well sanded with a primer sealer applied. Is there away to thin the paint to slow drying time and help it flow better? Thanks

-

- eatcrow2, yvesvidal and king derelict

-

3

3

-

- yvesvidal and king derelict

-

2

2

Lotus 72D by DocRob - FINISHED - Tamiya - 1/12 - Plastic/Metal - The Legend

in Non-ship/categorised builds

Posted

Sorry to see this happen to you. My question to you is, were the joints glued with CA or plastic cement? Your answer will effect how I proceed with mu Alfa Romeo.