-

Posts

758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jond

-

What a great question. I am going to do a little searching before answering. I'll be back tomorrow. they did both here over time. My gut says that bigger vessels with huge heavy masts were easier to rig on land and the ratio of the mast weight to the hull was less significant. Thus navy yards, clipper ships, the big schooners even here in Boothbay all had masts when they were launched. Think of the gin pole necessary for swinging that weight. Schooners by that time were still two masted and tended not to have masts stepped. Again a 150 ton fishing schooner is a different animal from a ship. Our half brig that we are discussing was about 320 tones, fatter and heavier, so less impact of the weight of a mast over the water lain during launch. stand by

-

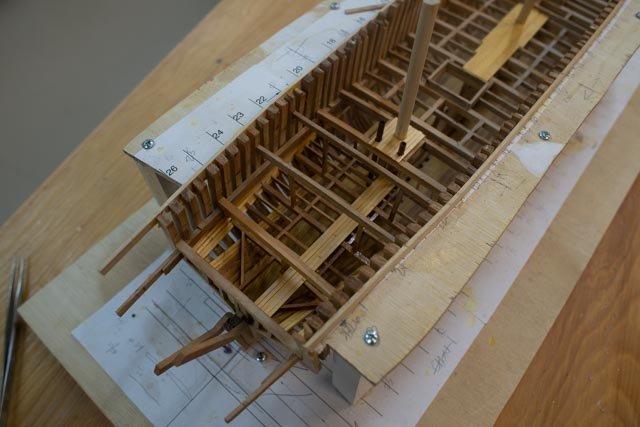

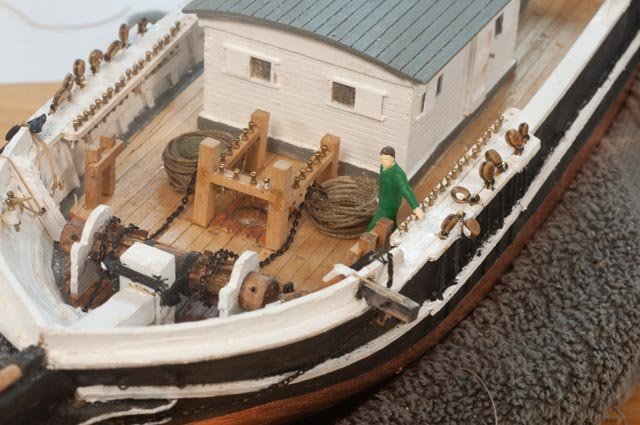

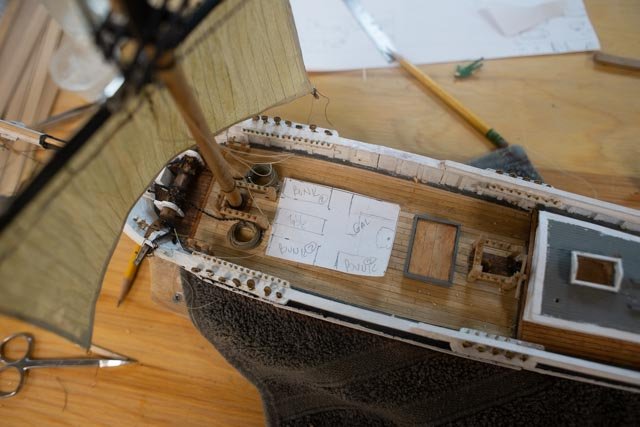

72 The jig is gone! The jig is gone! It is like calling “the British are coming” as Paul Revere rode into the night. I just wanted to celebrate. 1-3 Here are three views. In one we see a towel is the new temporary support Here we are a week or so later. 4 here we see the main framing of the cabin coming together. I need to think more about the size of the frames. Since there are no cross beams at the deck level, connecting the shear planks, and because there is no outside walkway going by the cabin, whose framing would have formed a truss, what to do? As I wrote in an early post this design was an issue as it was an unorthodox build. My current solution extends the full size frame up to receive the cross beams. now they are all in I would add knees below them and perhaps a shelf too. Thus the rigid square roof deck of the cabin, supported by four full size frames, is the structure that holds the vessel together. I will cut down the intermediate frames a little for the mid span and more for the quarter spans. In the painting, there are white painted side planks and very small portholes, not windows in the siding. Those little portholes suggest the idea, to me at least, that the structure goes up and across, and that is what I am trying to show. much to do and we had our first snow last night. At least that means no more yard work to interfere. cheers 5 here we see the upper planking. I have put the bulwark planking on to mark and rough sand the stanchions. I am still moving on with the cedar at this point. 6 here I have tapered the stanchions. now fine sanding to clean it up and fix some damage as I used the Dremel to rough sand and over cut in a few places. 7 this shot is the bow on view. Here one can see the opportunity for some diorama action one day. Next up is another plank and the main rail then to do the other side, complete the cabin frame and a little decking, lots to fine sanding and clean up before oil.

-

Thank You Wefalck I am of the same thought. As I researched the history of the local yard I learned that Hodgdon ran the mill. heck Hodgdon Mill was the name of the village until 1880 something. He also bought up woodlots up the Damariscotta River [ other side in Bristol Me.] and brought in much of the lumber from the local area. I used the Costello as it is fine golden grain and looks a bit like Oak. When I photographed the rebuild of Ernestina Morrissey they used the Dutch Oak and it was golden color just like the Costello. The red cedar was everywhere locally and gave some protection against the moisture. Today it is still used on premium wooden hulls I am more interested in trying to get things like the material representation authentic when I can. For me to have damages in the planking is something I am OK with, so I plan to let it be. cheers, thanks fro dropping in and happy holidays

-

71 how many sails and how much planking In this brief update I am confirming the plan for the additional fore sail on the small half brig. 1 here is Albert with the same sails as the Kate Cory whaler. I can understand for a slow whaling operation to avoid another fore sail. 2 here I have hung a potential third foresail. I like it. This vessel was a merchant likely sailing to the Caribbean and back. Most visuals are of bigger vessels say 20 feet longer and they all seem to have four sails. We only have another head stay, so let’s go put the third sail on. 3 ta da. All sails now on 4 now I need to add more pins. Oh well. There never seems to be enough places to tie lines. As to how much planking I am not sure there is any right or wrong. This is no admiralty quality build but a simple representation of a local vessel. For the bottom area I think I will continue to add planking more on one side than the other. Thus, one can see some frames and the backside of the ceiling on one side and the unpainted planking on the other. 5 Here the starboard side is planked enough to show the tie in with the transom. I think I will leave off much of the planks on the port side. An issue is look at the many damages!!! One thing I have learned is to regret the decision to use the soft red cedar on this small-scale application. I have built 6 hulls between 42 inch and 5 plus feet meant for RC sailing. In those builds I used 1/8” plus thick cedar strips. They were rough sanded, and resin coated before painting. A very different approach. Two Marblehead racers were left natural, and they are gorgeous. These planks are only 1/16” plus by 1/8”. The edges start off ok but damage so easily. If I were going to paint them, I could fix them. Since this is under construction, many tiny, damaged edges will show. A perfectionist would admit the mistake, remove all the planking, and start over. I am in a quandary over this issue. Since I need to work on another build with a deadline, I may defer this decision. As I write this on this sunny beautiful Friday morning, I am thinking I should change materials for the topsides, and maybe even remove the transom planking. I need to think about a better material. I would rather not use the Costello, yellow cedar or poplar as they are already other elements. I must first wait for the next rainy day and think again. I like the look of the cedar and its use survives today......was it used back then?? Cheers

-

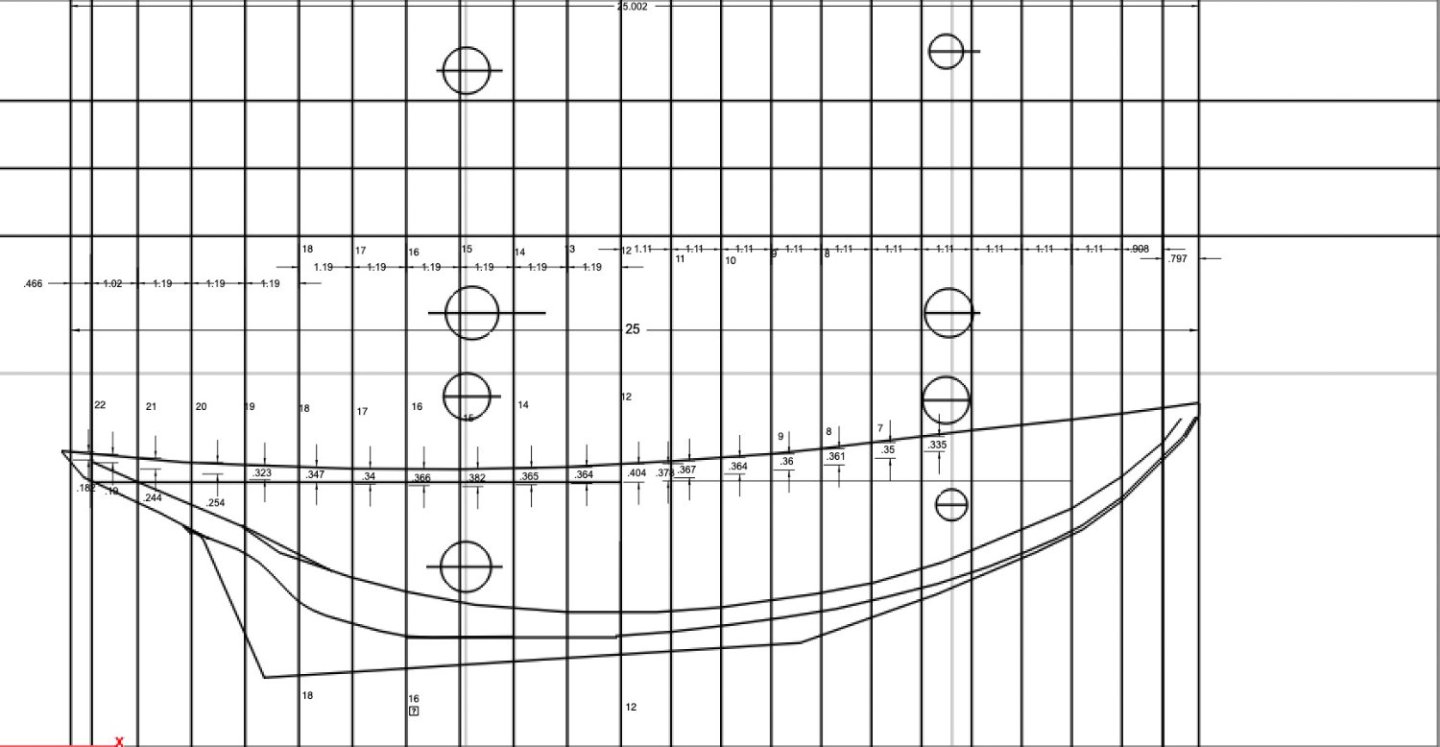

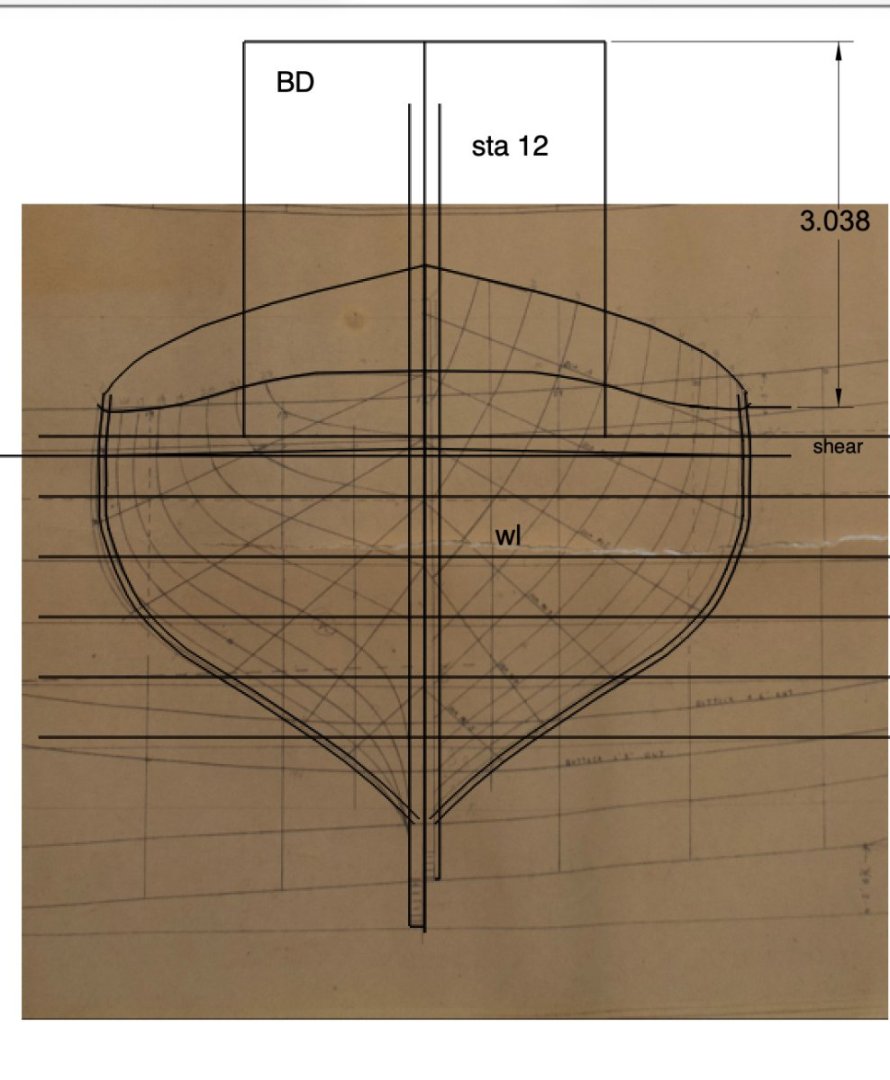

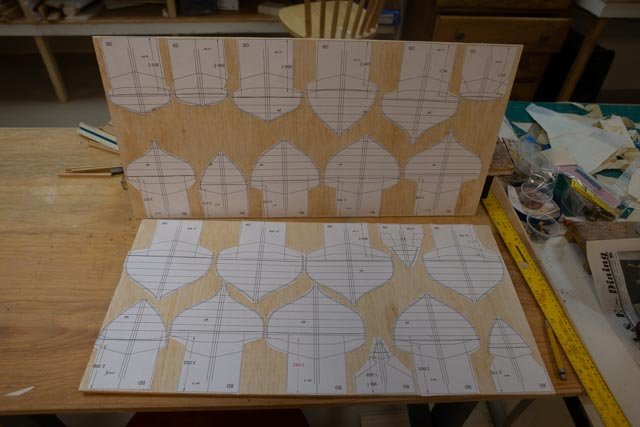

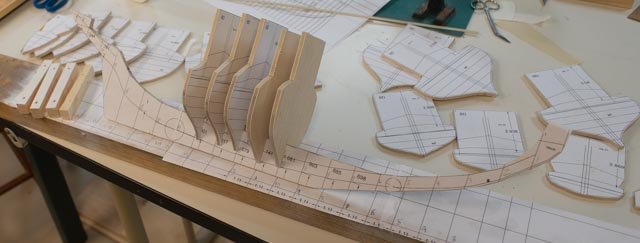

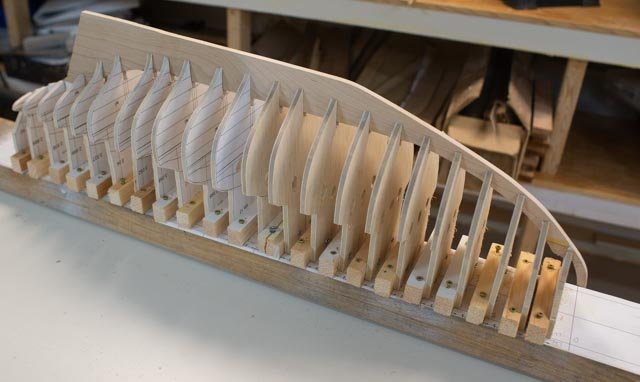

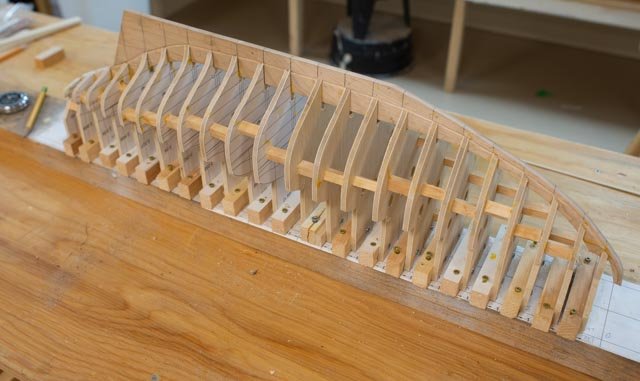

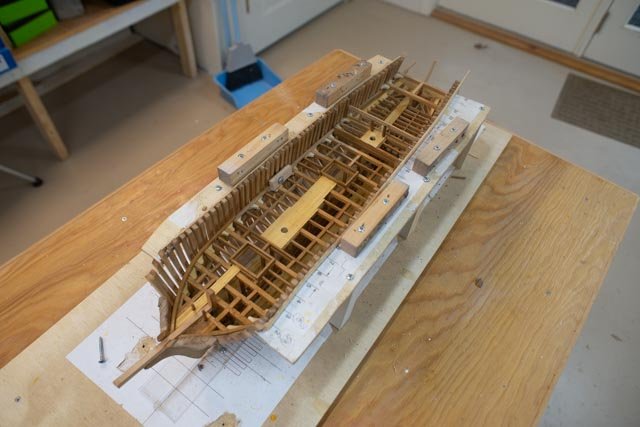

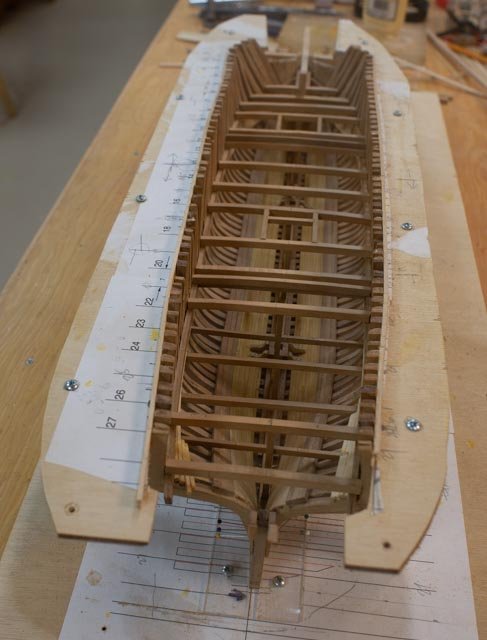

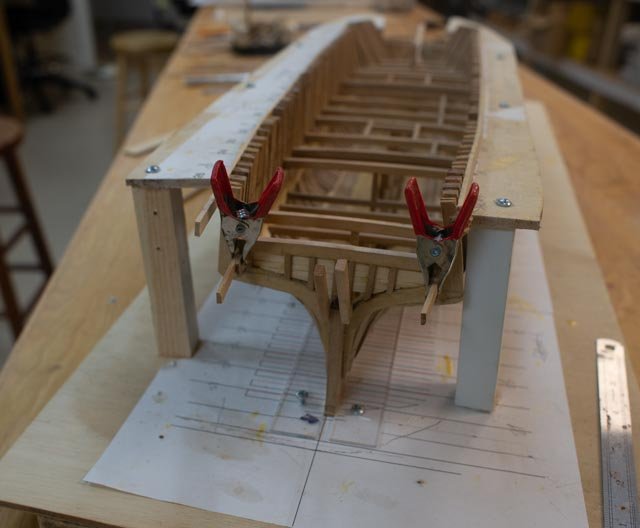

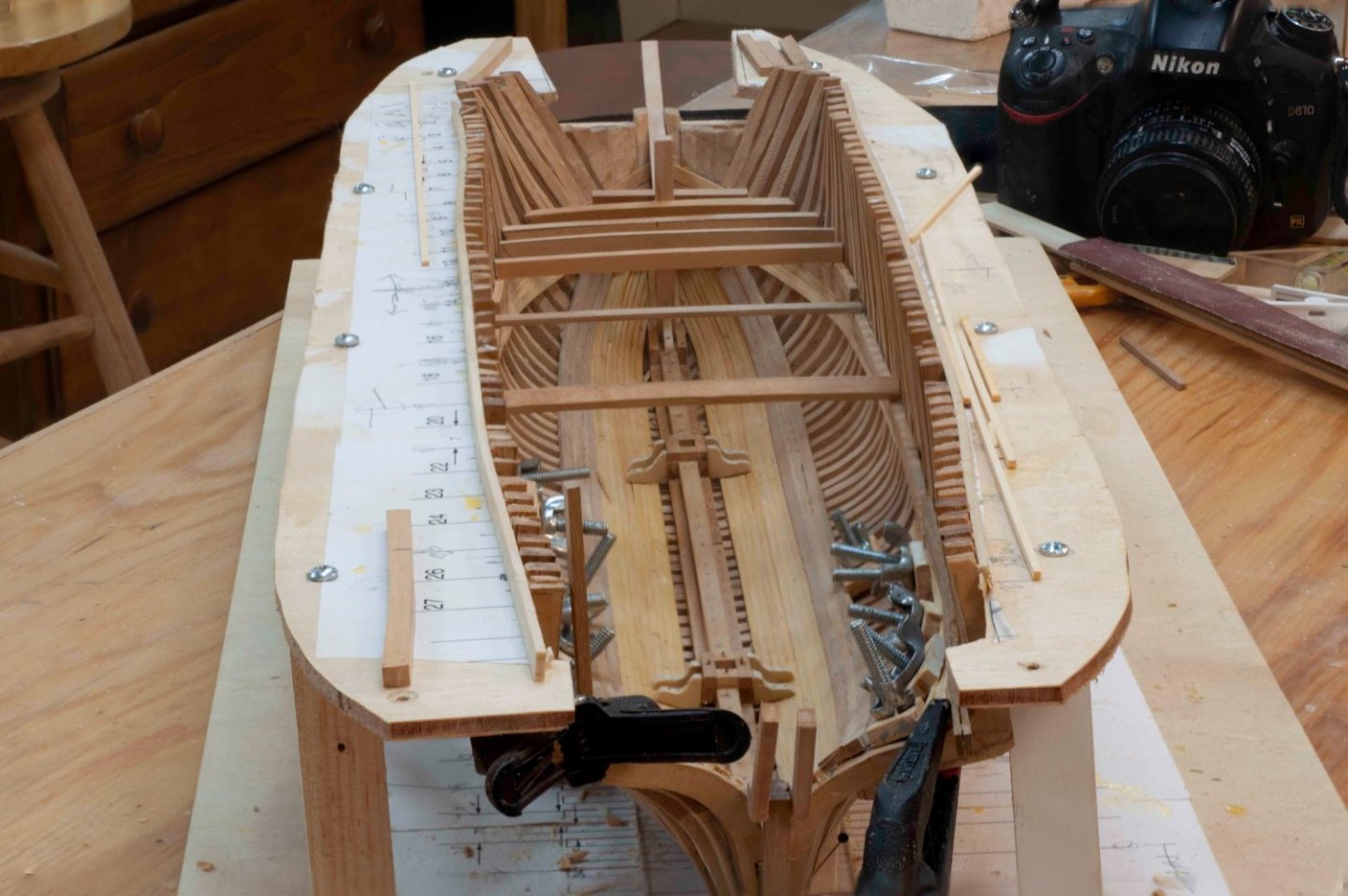

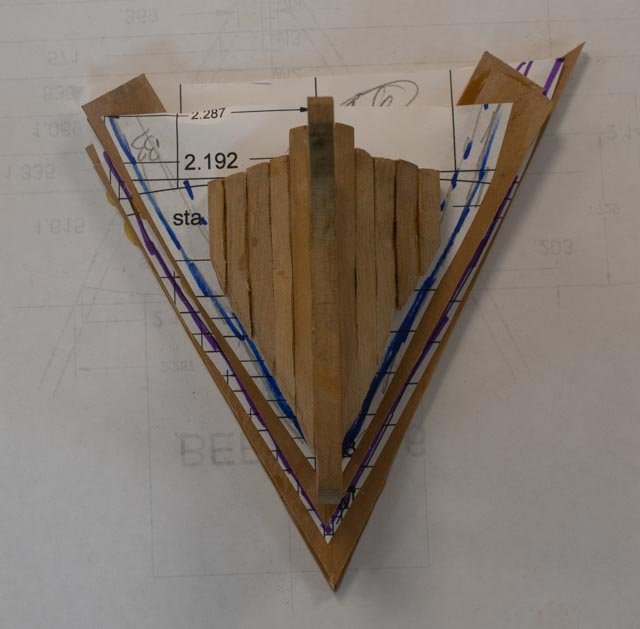

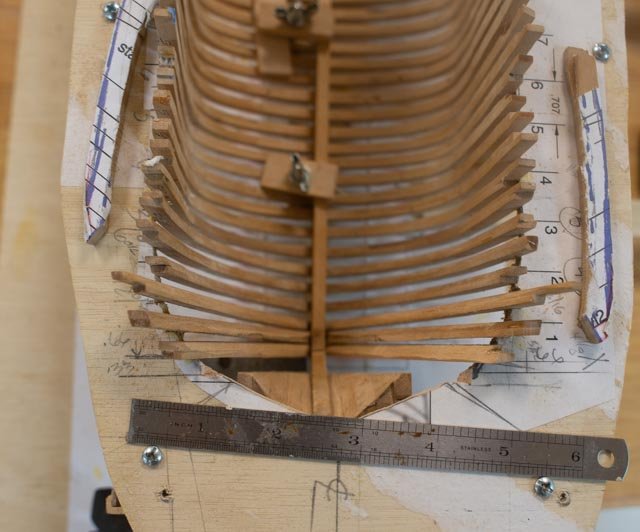

02 pre work There is a lot to do before this build can take over the shop. The biggest item is getting the build H G Berry, two Boothbay half brigs before it out of the way. Looking forward, the first thing to me is to plan out the build board and bulkhead strategy and the start to prepare material for them and the hull. 1. here I have a rough draft of what will become the pattern for the Keel/ keelson and back bone assembly. As of now I am planning to make this out of maple planks. The upper half of the drawing is made by extending the station lines and adding centerlines for the pattern to be glued to the build board. That way I am not remeasuring stations twice. The main prework is to make all the station bulk heads. 2. Here I have developed the standard for the stations to be cut out and set on the building board. This is one of 22 stations with the embedded photo from David Nutt’s plan of the lines behind. The double outer line is to account for trimming the planking dimension. 3. Here I have printed out all the stations and spread them out on a sheet of ¼ plywood. I had to buy it yesterday, as what I had left over was a bit warped. I think after getting another piece of maple for the keelson that for the most part I have enough material around to make the hull. 4. So here we are with all stations glued on and cut out. I then need to get the slot right for fitting the keelson assembly 5. Here I have rescued a past used building board. I have cleaned it up and glued down the pattern for laying out the frame. I also made up the blocks as reusing them proved not to be a good approach. So next up I cut out and sanded down all the 22 station bulkheads. I also made lots of blocking. 6. Here all the bulkheads are in, the keelson assembly is trimmed to conform, and the rabbet cut out 7. Here from the stern we see that patterns on the forward frame is visible so after fairing the bulkheads, the lines should survive…..a little hope here. I also learned to make the blocking soft wood and small enough to both hold a clamp while planking and able to be cut out later. 8. Here from forward we see the patterns on the forward side of the aft bulkheads which again are intended to survive fairing. In both cases I made the bulkheads 1/16” smaller than the lines to accommodate planking. This update means as of early December we are making sawdust. Next up will be to fair all bulkheads out, select material and mill out planking and get going on that process.

-

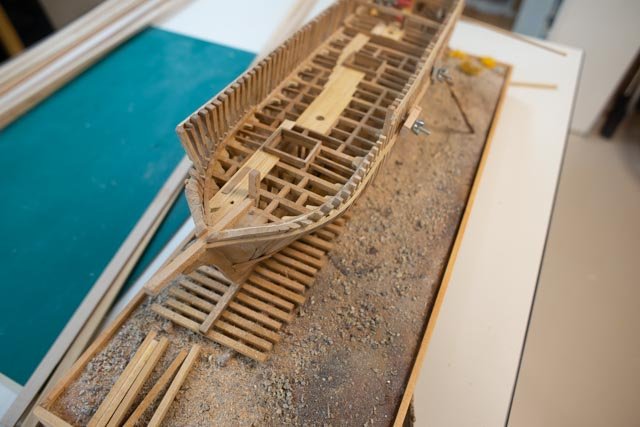

70 thanksgiving update this update shows a little progress on the different areas as we try to close in on determining how much more we can do before the next build takes over.__ small half brig Albert 1. the upper main stay sail is in place 2 the main topmast staysail is in place The large half brig H B Berry 3 I starting planking on the hull 4 I completed the stern framing and will begin partial planking here too. 5 starting to make a compromise stand. i use spackle as underbase and gather fallen sticks for the timbers. 6 here is the base under paint on the spackle with main way logs in place and planed 7 here I have added main coat of sand and gravel with a little sawdust etc., and I have started to set the railway cross ties. For fun I set the hull on top. 8 bow view. Here I will have more planking on the starboard side. I have started cutting the frames above the shear planks. I am still figuring that process out and have oreder sam small cutters to try to improve the process. 9 in this stern view we see the railway is off center. This placement gives us the opportunity, at a later date, to add in some building detail like a ramp, or a gin pole or some type of activity. All for now

-

The Schooner Blue Dolphin BD 01. The Beginning I start this new log with a little nervous excitement. Fortunately, it is only 'father time' making it scary. The story of the Blue Dolphin I am finding is quite interesting, but my knowing a principal character in this play and having the possibility of meeting more of them is really exciting. The big fear for me is the short deadline to prepare for a conference next June to celebrate the three schooners that combine both Boothbay Harbor, Maine, and Arctic Explorations in their history. First at the highest level let me offer the plan for the panel discussion next summer. There were three schooners that fit the bill. The first was Bowdoin. She was built here in 1921 and returned many times while leaving for or returning from the far north. She was recently replanked here in 2018-19. While here I got to climb all over her with Will McLean her captain and I built a diorama depicting her in Greenland in the spring of 1924. In more recent times, she sails here most every year, normally for the same Windjammer week that would include our panel discussion. The second was Ernestina Morrissey. There are many connections of people that will come out as we tell this story. In short, her long history included many seasons sailing in Greenland especially 1935- 1940 when a local summer resident / college student was on her every summer. She came to Boothbay again in 2015 to be completely rebuilt. I had the fortune to climb through her many times and meet the crew that did the work. I built another diorama depicting her in her 2021 rebuild. The third will be Blue Dolphin. The connecting history is the owner who bought her in 1949 and led scientific expeditions from Boothbay to the arctic from 1949 to about 1954. The owner and captain David C Nutt Sr had sailed on Effie Morrissey, was the executive officer on Bowdoin in her early WWII days, and then captained the Blue Dolphin. His son still lives here and has many memories to share. I will be building a model of her in the same 1:48 scale of the other two, to present as part of the panel event next June. Ah then JUNE!!!! … the downside of this venture … That means I need to get to work right away. I need to put down or at least drastically slow down the build I am doing now and jump into this build with only 5 months to do the work. Blue Dolphin brief History So first let’s look a little more at Blue Dolphin and see what we must do. What do we know, and where are plans and photos? She was designed by William Roue and built in Shelbourne, Nova Scotia in 1926. Mr. Stephen H Velie Jr of Kansas City retained William Roue, the architect of the well-known 1921 schooner Bluenose. The charge was to design a 100-foot version of Bluenose to be fit out as a yacht for ocean cruising. The vessel was built in Shelbourne, Nova Scotia in 1926. The owner kept her there until 1933 and reportedly took long trips north. In 1933 Blue Dolphin was sold to Amory Coolidge of Boston. In the first year she was chartered by the Ralph Chandler family, who sailed on a five-month cruise to the Galapagos islands and back. Nina Chandler Murray was a 13-year-old part of that family and in recent years has published a book, The Cruise of the Blue Dolphin detailing their family adventure. ( a fun read) In 1942 the vessel was sold to the navy for $1 and she was assigned to be on station in Casco Bay off Portland Maine. One might recall Bowdoin was similarly taken over by the navy. 1. in this photo we see her with a cabin built around the helm [ Maine winter duty is cold!!!]. The Navy painted her white. She was repainted black when she came to Boothbay after the war. In 1949 Blue Dolphin had been decommissioned and was sold to David C Nutt Sr. , a summer resident of Boothbay Me. David was an active participant in the arctic exploring world and for roughly 5 summers led scientific cruises to the arctic. Records of these cruises are part of Woods Hole Institute archive, Dartmouth College, and other groups. As mentioned above, Captain Nutt had a history that ties together our three schooners who frequented Boothbay Harbor and the arctic. Who was David C Nutt Sr. David C. Nutt Sr. as a student at Dartmouth College sailed every summer on Effie Morrissey, now Ernestina Morrisey, with Captain Bob Bartlett from 1935 to 1940. David is mentioned several times in the history of the Effie Morrisey and fondly remembered by Bob Bartlett the well know skipper. Bowdoin. David Nutt Sr became the U S Navy exec. officer on board Bowdoin during her early WWII days. They were surveying to find the best airbase locations in Greenland. David left after completing that mission and went to the pacific to continue ocean surveying as part of the Pacific campaign. When he returned, he found Bowdoin committed to return to Capt. Donald MacMillan and Blue Dolphin available. After buying her, Blue Dolphin came to sail out of Boothbay in 1949. After 5 years of northern cruises, she stayed in the harbor until the early 1970’s. She was then sold and moved to the great lakes. More on that story later. Where to get drawings???? David Nutt Jr. is a neighbor and friend of several years. David was a professional boat builder. One of his joys after selling his business, and by the way sailing for four years around the world with his whole family, was restoration of classic racing sailboats. David restored my Boothbay Harbor One design, a 1941 classic 21-foot beauty. More on the story in my BHOD log for the two 42-inch RC models I built a few years ago. There were many views of his work included in that log. I contacted David a few months ago when the possibility if this schooner project came up. David owns, and kindly shared with me last week, an old print of the lines of Blue Dolphin. He also built a Half model years ago. The black paint on the hull is the same as on the real schooner. 2. David Nutt sharing his old print of Blue Dolphin 3 David Nutt’s Half model of Blue Dolphin he built many years ago. So, with about 25 photos so far from the internet and the local Boothbay Region Historical Society along with these plans, we are ready to begin. First up I embedded the squared-up photograph in my 2D cad. David said he has many more on deck photos and we hope to get to see them this winter. My intent would be to try to depict the 1950 sailing version as it applies to our town. Much to do to get ready

-

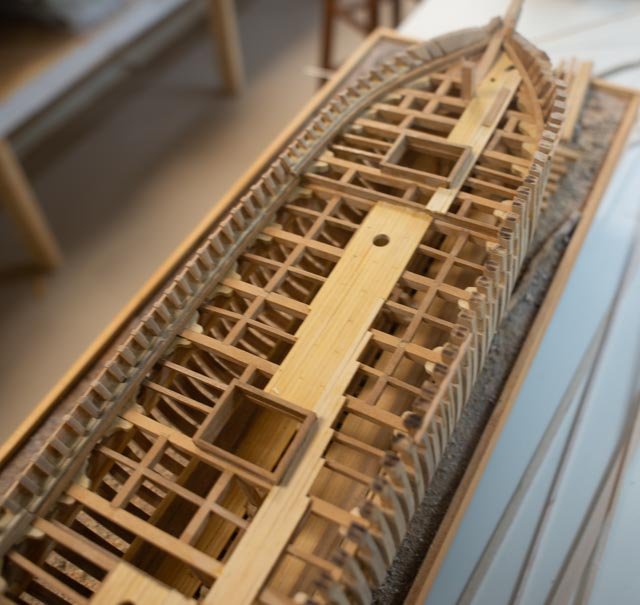

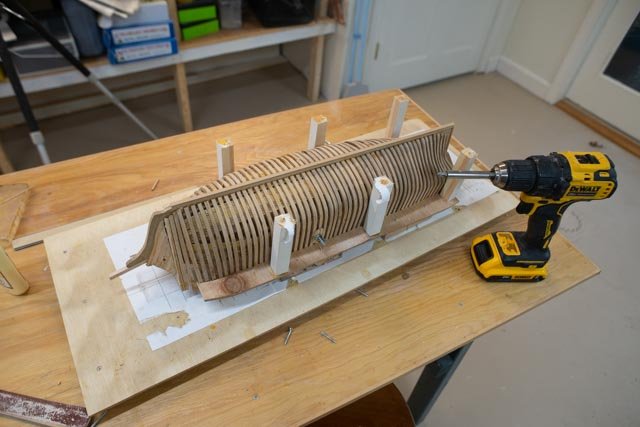

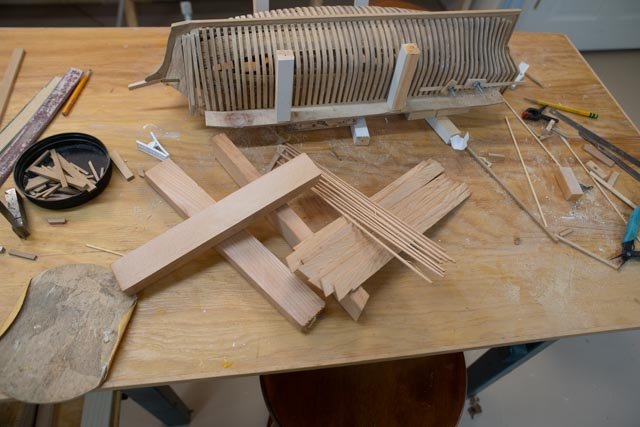

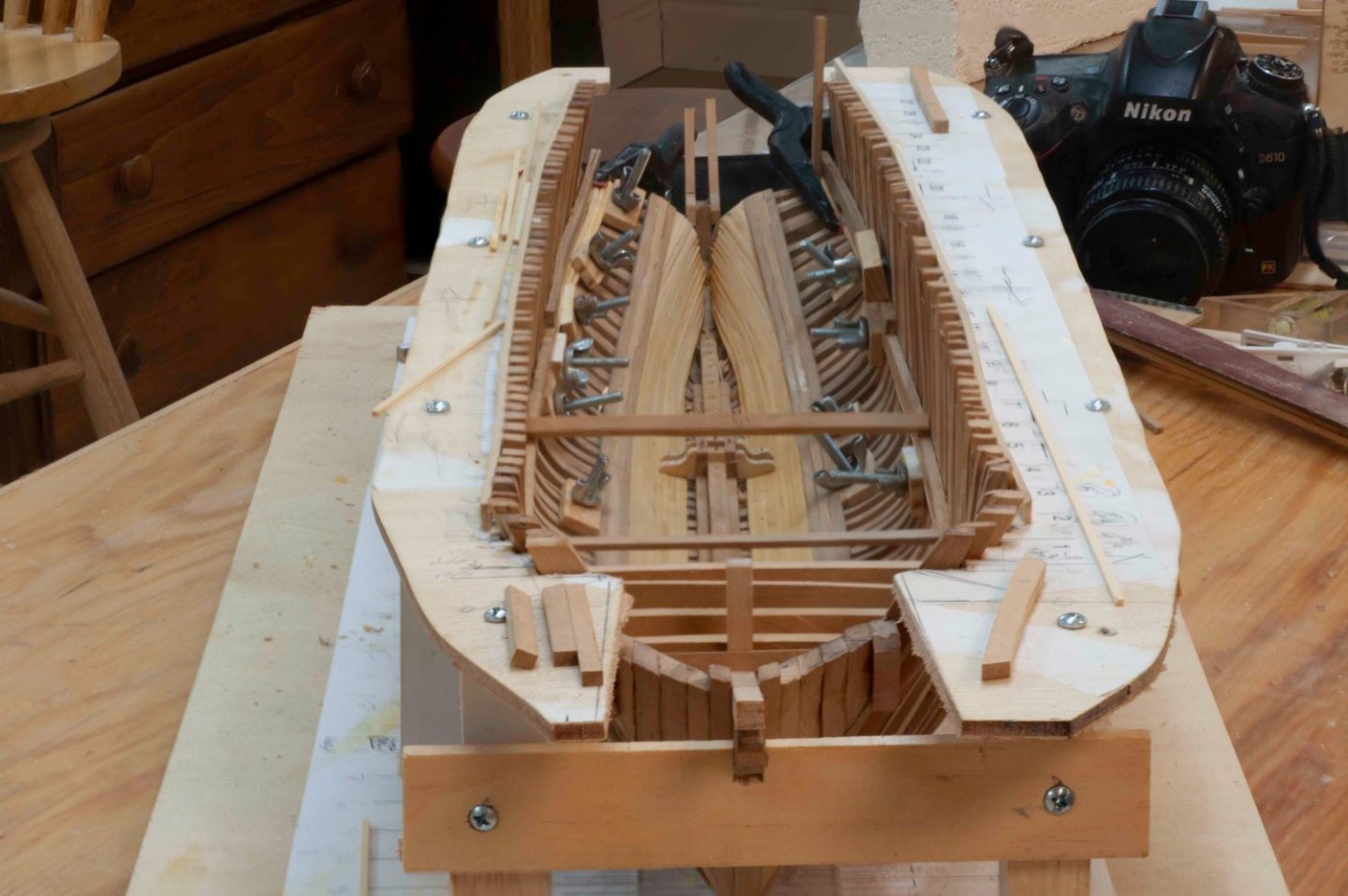

69 H G Berry comes out of the jig. Yippee. As I said in my last post, I need to focus on having a plan to manage my time, so I can get this model to a respectable point as I transit to the next schooner with its tough deadline. To complete the large brig, I must get to a minimal condition before I can set it aside to build the next schooner. current status: • Insides below deck is basically done. It needs more cleaning and oil. • Framing to the deck mostly complete. I need a few more waterways after the stern members have been completed. I then need to cut one side of each frame very carefully just above it, so I can then build the shear plank inboard and outboard. Then shape the stanchions and build up the bulwarks to the rail. I am very worried about this procedure as the frames are glued and the glue maybe stronger than the wood. • Planking. I will do perhaps the first inch or so covering where the ceiling already is in place. I may then have the shear planks and bulwark in place and then add some upper planks. I am also still debating on material. See below red cedar. • On deck….I plan to build the framing for the two cabins as soon as I get planks on. That should be it. • Stand and display…. many options for now. Unfortunately, I am likely to defer on the shipyard and use a simple board for now as there is not enough time left in the year. Here are visuals of coming out of the jig and planning the planking: 1 first up is to remove two more legs and screw them on top for supporting all when it's upside down 2 Here we turn over the jig and unscrew the remaining legs 3 ta da here we are free at last 4 the legs come on and come off and move when needed. In this view I can finally see enough of the stern area that I can figure out how to build it 5 here we see the bow I will first go over the whole thing with a sander to get the frames faired as best that I can Planking 6 I built a stair to the back deck this summer and have lots of red cedar cut offs. I cut them up to make model rough stock. Here I have next milled 3/32 + a hair thick stock and then sliced it off using a 5/64 stock that I bought for the yellow cedar ceiling planks as a guide. This gets me more that 4 inch thick in scale and allows a little sanding. 7 here I have laid a few planks to see the color and overall look. I like the color. I also like the fact that even today eastern Maine red cedar is a material of choice for planking lobster boats. I would accept criticism re the slight visible grain that blows the scale. Anyway, I used it in thicker pieces for my RC hulls and like the feel of it. 8 here I laid out the three battens [ just pencil marks for now]. The largest width works out to be 14 planks for each zone. The tapering for the bow is about 5/6. I plan to lightly sand as I go 9 here I took the first two sections of waterway and cut one of the two frames to leave behind the stanchions. I then laid out the planks that will go right under the shear plank and determined cutting one plank to a square will perfectly fit for the transition to the higher bow and stern decks. [just to the right of the blue tape] well... there are many weeks of work here......I need to get going. cheers

-

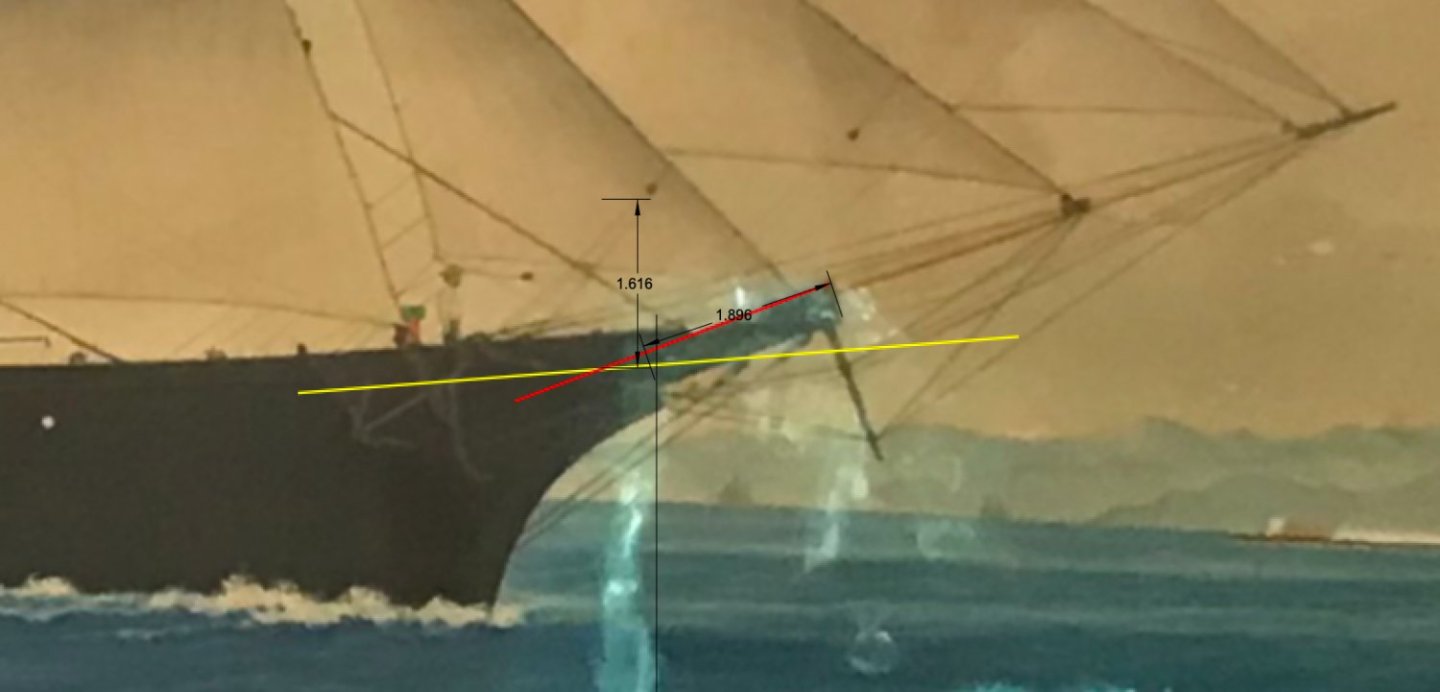

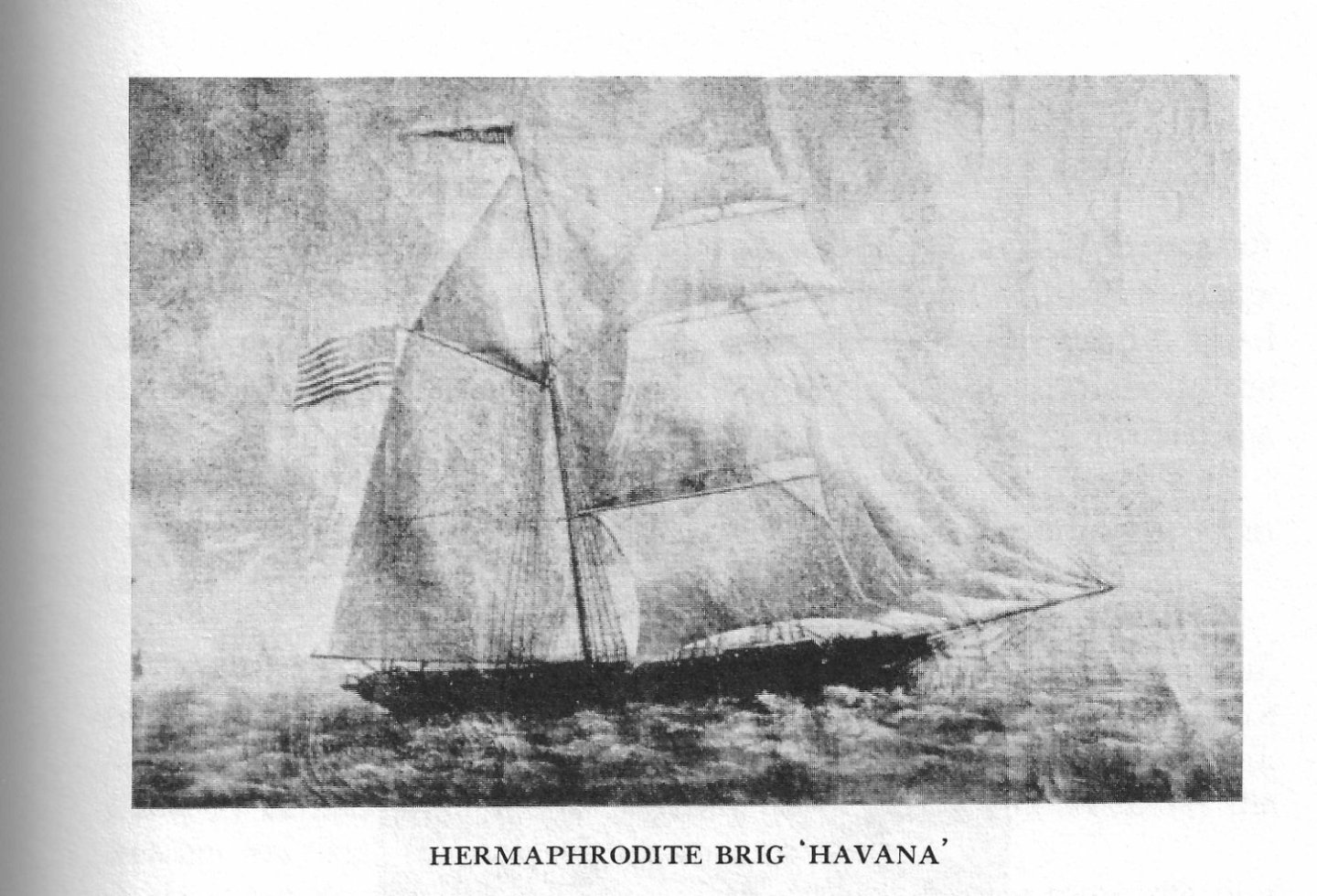

68 general updates on two brigs and then Albert sails As we move toward winter, I need start managing my time. I had a new project in mind to follow this one and thought that sometime in the winter I would wrap this one up and start that one…..oops!...... After discussing the plan to combine a new schooner model with two others, the Bowdoin and Ernestina that I-built a few years back, and then prepare and tell part of the story of three arctic schooners from Boothbay, I just got pressured to have it designed and built and then with a research paper present all next June. I will talk about it in the beginning of its log but just want to say ouch. I am researching for it now and have started its drawings. I will open the new long next month, but want to get this one closer to the endzone. For now, I need to carry on and get these brigs as far along as I can. They do not have a deadline but it would be nice to get them presentable. I should be able to complete the small one as I am into rigging. The framed model completion will depend on how far I go and whether I simply set it on a board or try to build a shipyard around it as I did with two past models. More on that decision as we get there. To complete the small brig, I need to do the following: • Complete and bend 6 sails. Two more are now in place and tied off, so four to go • Make and set coils on lines…..started but little progress. There are about 80 to do. • Complete standing rigging. Just a few more shrouds and ratlines on the main mast and repairs for the head stays • Set cabins after lines are all done. Simple when ready. • Build two small boats. This item may get deferred until I am building small boats for the next schooner. • Build stand. I must decide what to do. I like making ocean with a hole for my sailing models. The cost of acrylic however has skyrocketed, so I am passing on that approach for now. More to think about Here are a few visuals of Albert 1 Here we see the next two sails, 2 of the 3 main staysails, bent on the small half brig 2 Here we see in the painting of Torrent that is the 112-foot 320 ton version that sports four head sails. The whaler plans for Kate Cory only showed two. I have decided to add a third head sail. Many of the images I have seen od half brigs show three and I prefer it. The only other Boothbay sailing image I have is Havana at almost 220 tons vs 123 on our small Albert; she had four as well. I think adding the third makes sense of proportion on the smaller sized vessel. 3 Here I quickly took the lines and roughed out some small poplar stands. I am dry fitting them on the spare hull. These will make up a temporary stand, so that I can move on. Cheers

-

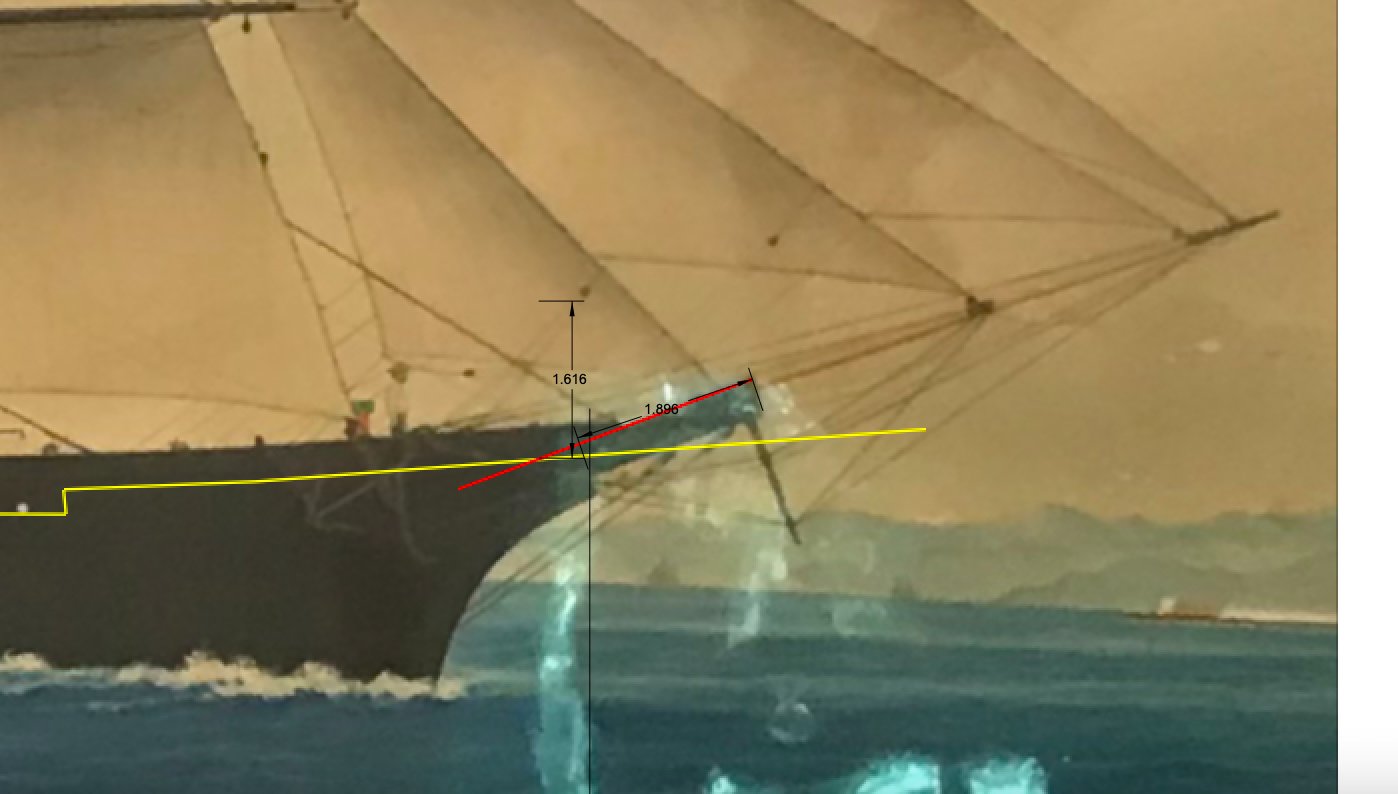

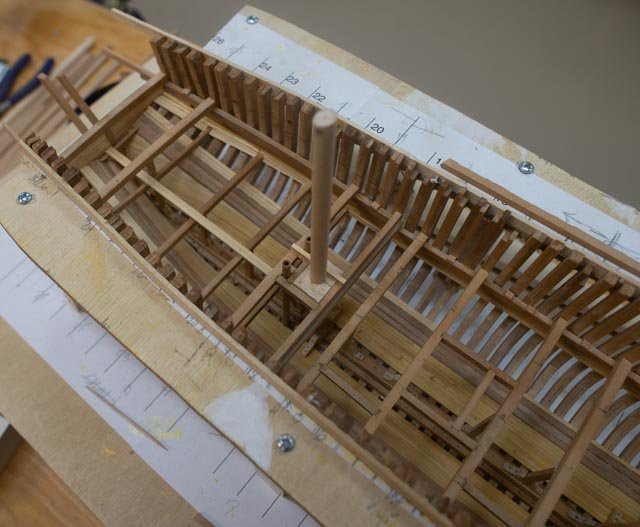

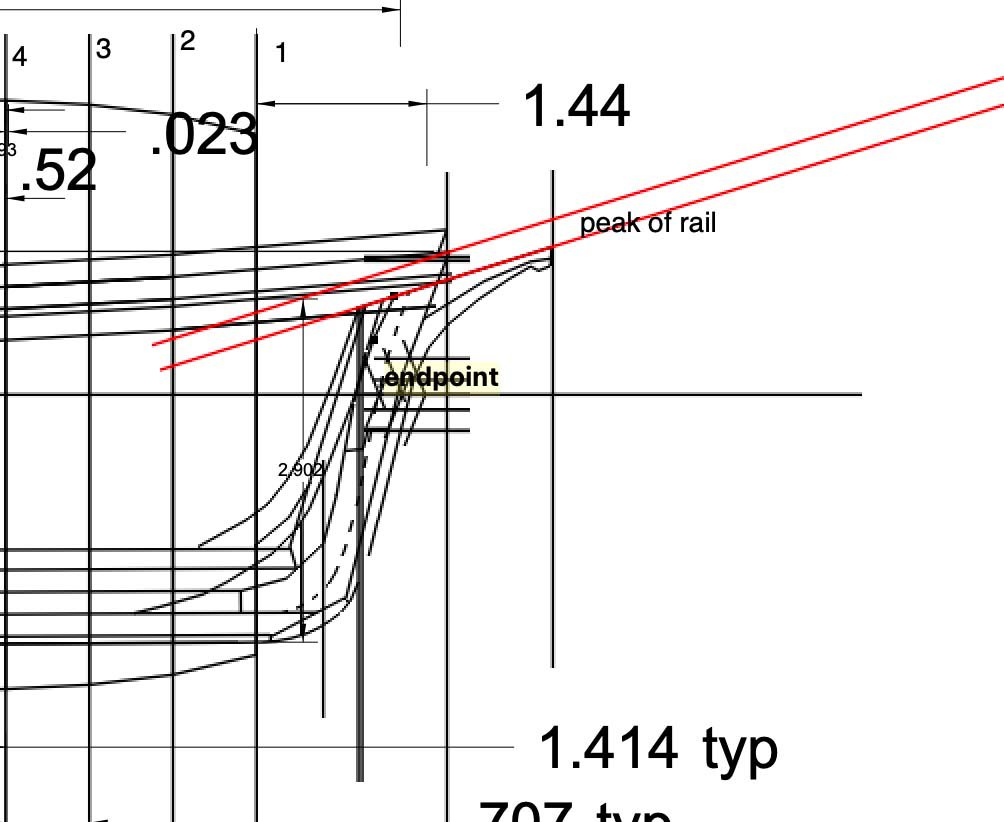

67 completing deck framing on HG Berry At some point, I need to turn over the hull and get the outside faired and some critical planking on. I believe with the deck frame in place and both the shelves and waterways glued, I should be ok. I would hate to get too far and then lose some of the detailed frame yet is it is so easy to just keep going. Today we are looking at what I would like to complete. Before moving on. First a few details 1 Here is a detail of the bowsprit coming aboard and hitting the Samson post. Based on the angle taken from the painting as I discussed earlier this happens just below the deck level. the framing al came together. I want to be sure most of it is seeable once the deck is on. 2 here we see the detail of the log pump. I posted a query on the deck furniture forum to see if anyone knew more about them. No one has yet responded. In a search in that forum I found one person knew they were indeed hollowed out logs and often elm. We definitely had elm trees here, so maybe that was it. Oh well onward 3 sizing the hatches is a bit of a guess. 4 I love the view through all to see the mast step. I have the dowel in place and left it there on my last diorama. 5 here is my day of producing a myriad of knees. I a making 40 to cover the main beam connections. I hope it works out Now overview and planning what to do before turning over 6. the foredeck. I think I am complete here for this phase. The waterway is being glued.I started adding tung oil and find it a great improvement. The framing across the anchor chain hawse will be drilled out after turning over. I drilled through the hull then added the deck fill in, but cannot get the drill between the build board and the hull to drill back up and in. I will also do something for the windless framing once the outside work is done 7. this shot is before knees and waterways are in place. I need them before flipping. I also need to decide what I am going to do for the transition of frame to stanchion above the waterway. I hope I will be able to cut them down. I found on Schooners the stanchion was added to the side of the frames , so this will be a new challenge for me. 8 work on the aft cabin will continue to complete the forward bulkhead. I started the cabin top frames, but they are delicate and may better wait. 9 The stern, transom et al. I have looked into these many times. I think I will have an easier time once I turn things over and then can see it from both sides. The frames need a lot of fairing and doing some of that first should help with aligning what is affectively one of maybe two more split frames. I made theoretical mid frames, but they just don’t look right. I did figure it out on a schooner once, so I hope I do this one too. Carving a block for a plank on bulkhead is a dream. Thank goodness it will be on my next build. All for now. time to blow leaves off the yard.

-

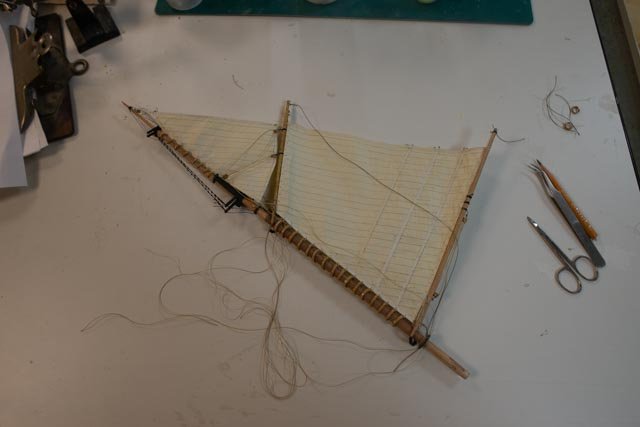

66 let’s get the spanker bent and main mast set on Albert I mentioned before that I prefer to sew sails to hoops and connect most running lines while the sail is resting on a flat surface. I learned that while making much bigger RC sails, but feel it is quite useful when working with the fragile silk screen. Here are a few shots of that process. 1. here is the set up. I first lash sail to the boom and gaff. I then add the parrales to the jaws to hold all in place. I then carefully sew the sail to each hoop. There is a string run up the luff to reinforce the edge of the sail. A wire is along the leech, and sting is on both head and foot. 2. Here the spanker and the main topsail are in place and most of the loose lines are connected. 3. Here I literally just set the mast in place. Note the cabins are off to make rigging easier. The aft cabin shows the clearance under the boom. is OK 4. Here is a progress shot with most of the lines dropped to their correct area and the fore cabin set and mock up boat. 5. Now we see what a half brig is all about. Half brig and half schooner. All for today

-

Request for info on log pump I am building a model to represent a brigantine built in 1855 in Boothbay, Maine. I have read that these vessels were called half brigs here, but that is another story. We know the yard and the builder. We also know the builder was one of four Seavey brothers. Two of his brothers worked next door in two shops. One was a spar maker and the other built blocks and log pumps. Considering the location, the relationship etc., I have assumed the log pumps were utilized. I am doing an open frame under construction version of this half brig, H G Berry and I have decided to show something. Here is a photo of the model as it sits now. The two pumps are simple a bored-out dowels. I debated but did not add joints and bands. My curiosity is up though… to better understand what a log pump might have been. Let me first say open internet searches have not produced anything yet. I know that during this same period, 1850’s, as the great stands of trees were being consumed, that masts and spars were often made up. Therefore, the skill to do so would have been right there in the spar shop next door. To make four or even six 10-12-foot-long length carved out strips and then banned them together might have been easier that whatever it meant if one had to bore a hole say 10 feet down a log. Enough of my jabbering. I started this post to see if someone out there may be only one of two clicks away from one who knows something about these pumps. If you do, I would love to learn Thanks

-

65 update on HG Berry. Brig under construction Last time I made an update, I was still adding ceiling and thinking about the next stage of framing. I continue to try to follow the Crothers book, but my work is a bit of free form. 1 here is an overview of the deck framing with beams resting on shelves, 3. in the aft section we have an unusual side to side main cabin. That means a clear interruption of the main level deck beams connecting at the shear line. I have dropped the large beams to the bottom of the cabin sole. More to come later 4 manufacturing knees. I am not sure how far I will go adding knees. One should try this though as it is truly amazing how many there would be if one added them all. The ¾ inch poplar stock gives me 5 at a time, so I do two giving me 10. Hopefully 8 make it through and into the model. 5 here I have added the bulkhead that separates the lazarette from the extreme aft section that houses the rudder chain. 6 here is the mid-section. you can see the first knees and connecting beams going in. 7. in this view it is easier to see the impact of the main cabin to the framing. There are two main beams that are not connecting the share line, interrupting the affective horizontal truss. In normal design the side walkway framing around the dropped cabin is an affective small truss compensating for the loss. The wide cabin makes this alternate not possible, and a clear weakness for stormy weather. As an old engineer, this layout bothers me….. but they built it! 8 here is a detail of the bow section ; we see stanchions on the keelson rider with fore and aft knees going in. I was thinking of a lower bulkhead to separate the chain locker like in the schooners I have seen, but it would be a bit of a guess at this point, so I won’t. 9 here I have built up the main mast deck frame. I cheated though. I learned in the two schooner rebuilds I watched here in Boothbay that they use nested 6x6 members through which they cut the hole. I used a little plywood since it is buried under decking. 10 here I have set a few planks on the cabin sole. They carry aft to include the lazarette. That will be accessed from the cabin. In these last two photos one may notice the bored out hard wood dowel to represent two log pumps. In the history of the shipyards that I did this summer I learned that the brother of our builder had a shop next door where he built these pumps. He also with another brother-built blocks. So surely, the pumps were included. I could not find however any technical information of the concept of a log pump and hope to find some. Example: were they built up of strips and caulked and banded or really just a hollow log?.......I hope to learn more Cheers

-

Wefalck you probably noticed in photos the main mast coming on and off the vessel as i progress. I will take a few photos of adding sails. I learned before to sew the sail to the hoops , and lash it to the boom and gaff while it is laying on the desk. I then tie on the various lines and lift the whole thing into place. so far it works well. I am probably two weeks away from that step. I will have the stay sails to go on right after that , and they will be done in place. topsail schooners are the best of all worlds I believe for sailing these waters. I have a few projects in the way but will also build on one of these days cheers

-

64 update on Albert…the sailing brig Just a few shots to show that I am working away on the side to get this model done Since last time I have added the 3rd and forth sail to the foremast and brought all the lines down. 1 here we have the topgallant set 2 here it’s hard to see but the lines are coming down and getting tied off 3 and here we have the royal set and some of the bow sprit rigged 4 here I can see I need to work more on the sail shape. 5 in this view we see the work on deck is coming to an end. I need the boat rack and boats for the fore cabin. Off camera I have started making the remaining 7 sails, and the first ten coils. Update on H G Berry tomorrow

-

63 set up for transom and Bowsprit Since my plans are limited and unspecific toward framing, I need to look ahead a bit and determine how to make up the two ends of this vessel. First up ....where am I as I do this step. Here are two shots using the merge/ blend layers so we can try at least to have the whole length of the vessel in focus. 1. looking aft I have installed the lower ceiling and bilge keelson / stringers. I say that as in this smaller vessel they are together or combined. In Crother’s book he shows this and on larger vessel cross sections they are separate. I have added the shelves under the deck clamps and a few ceiling members there as well. I have a few more to go in the aft section I may get ambitious and hang a few beam knees, and they fall inside the ceiling as I understand it. 2. looking forward the different woods show up. Poplar is the current knees over cedar ceiling and Costello frameworks now to the task 3. here on the only line drawing I have; I projected the bowsprit angle as it comes on board. It clearly penetrates the deck as it come inside the stem. It then hits the Samson post below deck. 4. in the painting of the Torrent, we confirm this arrangement and angle. I also took my dimension for the projection. 5. Here on the line drawing of a similar Bath Built brig I have been using, I have studied the angle, and size of the transom. 6. here on the painting of the Torrent, we see two things of interest in the transom. One is a reminder that on this vessel. and the H G Berry that was recorded to be similar, the cabin comes side to side. There is no deck level passage aft to the wheel. The H G Berry , our model, will not carry the cabin aft with chains to the forward wheel. Regardless, there is still a difference in the stern shape that I will need to figure out 7. Here on a temporary jig, I am experimenting by compound bending the outer frame pieces. We’ll see if it works. 8. Looking down at the bow I have used maple for the Samson post and bow sprit. I have started to rough out the deck beams. I will focus on the fore deck first. I am not sure how much decking I may install. Perhaps the center 1/3. We’ll see 9. Looking down on the stern area I have more to do before adding the transom. I will build a bulkhead at the after end of the ceiling to separate the " Lazarette that contains the chain and " tiller" from the wheel. I am debating the access route. more later I will also figure out the lower deck for the main cabin. A lot to think about. I do not expect to get it right the first go…..smile • Cheers

-

Allan Thank you for following up on this idea that the adventure is ongoing and the model is only a part of it. As a side note I followed a lead one day and went onto Thrift Book .com. when one types in a search topic, one gets lists of older books as opposed to Amazon or B&N that focus on recent publications. I found a 1948 publication....The Maritime History of Maine. by Rowe. It was an excellent read and I learned much more of the overall downeast region and the different ages of sail. Lots of fun cheers

-

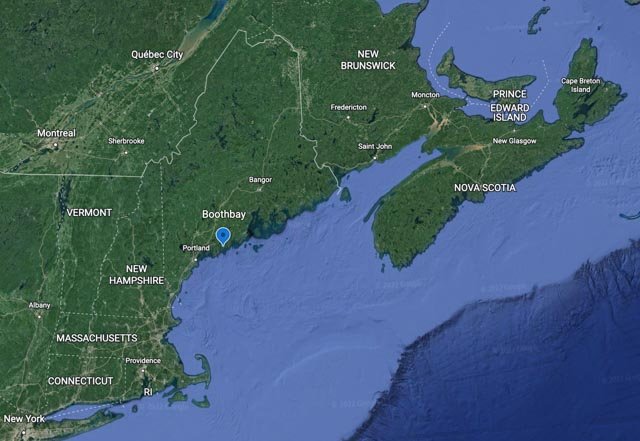

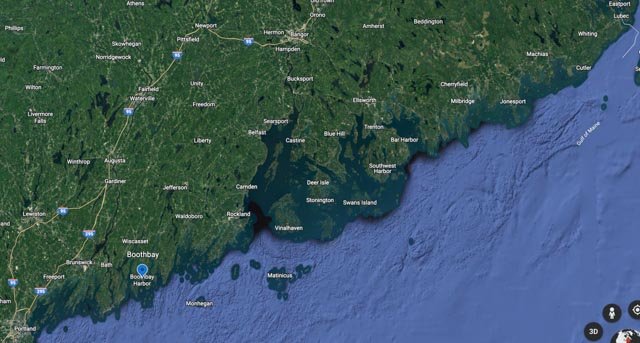

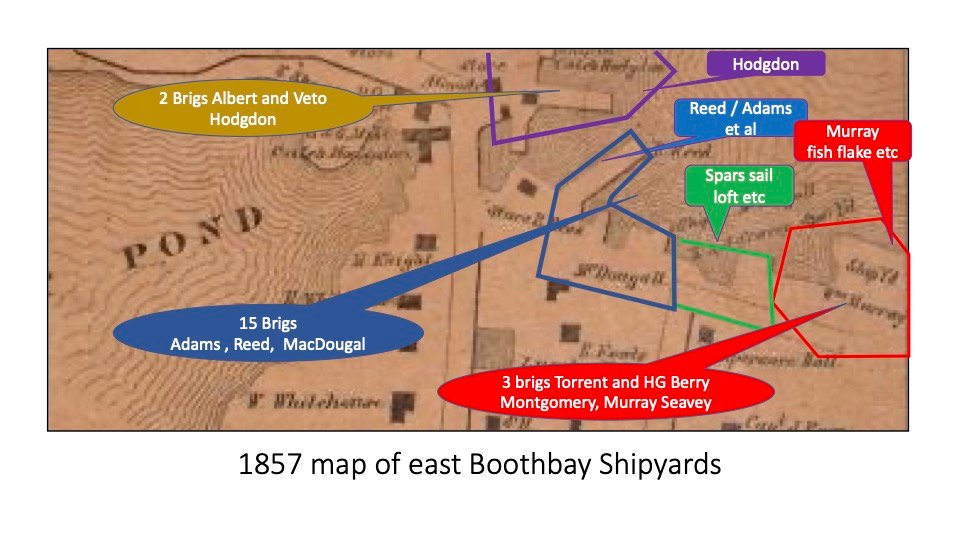

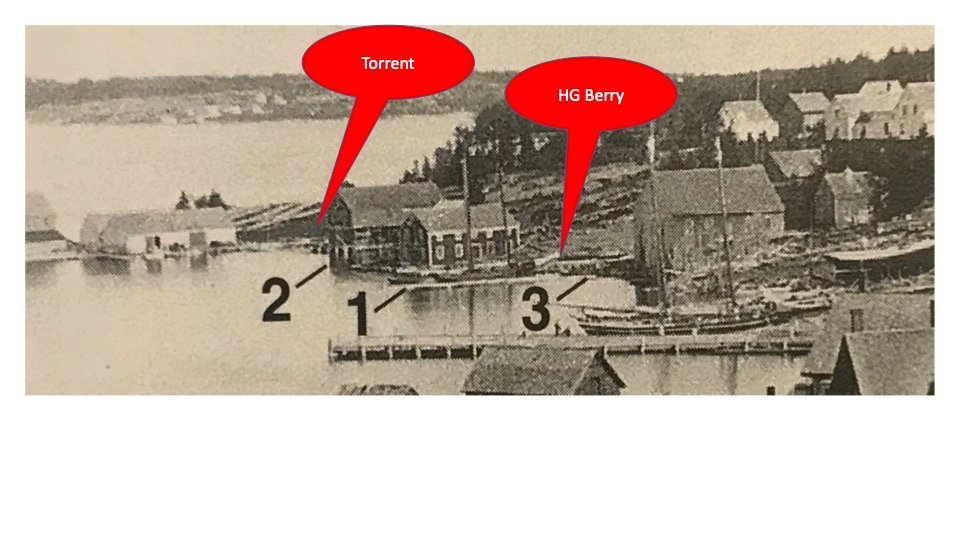

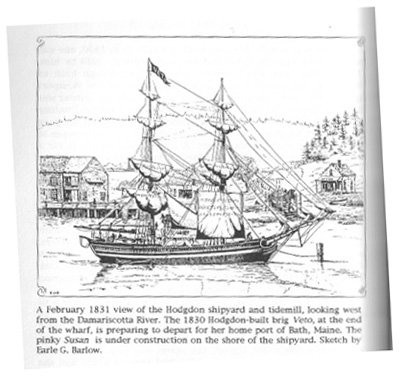

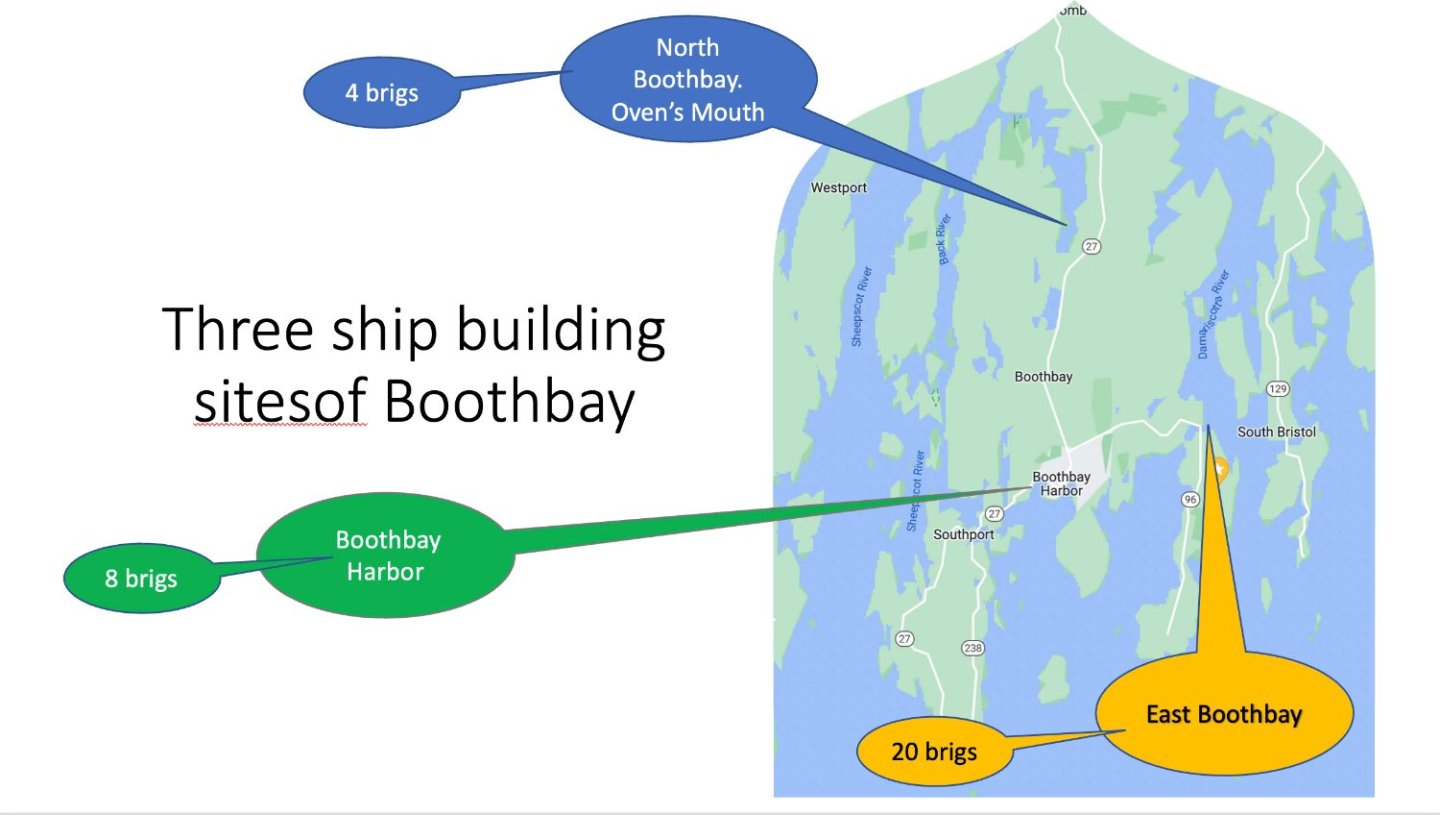

62 history of yards that built the brigs of Boothbay In my first posting I said I would tell more about the yards that built the 32 brigs of Boothbay. My reason to delay was that at that time I was still doing my research to give a talk about the first century of ship building here in Boothbay. I have pulled together some points, more a summary of the findings relating to Brigs, which is related to this build. The earliest vessels built in Boothbay were small to medium schooners as early as 1760. A few were in the revolutionary fleet that was sent to take Castine in 1779. They did not do well but that is another story. 1) For those from away here we see where Boothbay is located within New England. 2) Here is most of the Maine coastline. The major center of ship building was up and down the Kennebec River including Bath just to our West. Bath Iron Works is still an active navy builder today. 3) Here on our peninsula, between the Sheepscot and Damariscotta Rivers, we had three areas of Shipbuilding. East Boothbay was the main center; the others were active in early years. a) North Boothbay was active 1810 to 1852. They built there originally for protection from the British, but when vessels got bigger, they moved to join East Boothbay works. They built 4 brigs and a bark there. b) Boothbay Harbor was active from 1840 to 1920. It was mainly the big boom that lasted ten years before 1857 when 6 to 8* brigs were built downtown. Then in the WWI boom years, 10 big four masted schooners were built. Today there is an active 700 ton marine railway and large vessel repair center that recently rebuilt Ernestina Morrissey . * there are a few brigs that lack building sites, but it's suggested some were built downtown. 4) This map shows the yards of East Boothbay between 1825 and the crash of 1857. I refer to the colors in the following text. a) Purple on top: Hodgdon started in 1816 before moving to East Boothbay in 1825. They are still running strong with Tim Hodgdon of the fifth Generation is charge. They built two brigs in the early years but returned to their bread and butter of schooners through the remainder of this period. the yard today is a marina and Hodgdon are in different facilities. b) Blue on the left: The Benjamin Reed , Adams et al yard built most of our brigs as well as a few ships. They ran until 1920. The yard is still active today c) Green in center: this area included sail loft, spar yard, block, pumps, coal, paint etc. Up to eight different businesses over the years. The Seavey family also built a few vessels there and next door on the Murray land. It is our build's H G Berry that they built . The multiple lot yard was reconsolidated after 1920 and eventually sold to the town. It is the Shipbuilder’s Park today. d) Red on the right: this property started as the Murray lot. Several vessels were built there including our sister Brig the Torrent , each by a different builder. The yard grew extensively in the 20th century and is very active today. Let’s add a little more description to the early East Boothbay yards that built most of the brigs purple Hodgdon yard 2 brigs The first two brigs were credited to be built by Caleb Hodgdon in 1825 and 1830. That yard, never built another square-rigged vessel. They were very successful building primarily schooners through century. The two brigs, Albert and Veto were very similar. They were 71 feet and 120 tons. Albert was built first and little information on her exists. 5. Veto in front of Hodgdon Mills 1830….built in 1830, she was first a full brig. We know she was sold to a merchant in Bath in 1831 where she was registered. It was recorded that in the early years, 1825 onward, that William and Andrew Adams leased space at Caleb’s yard. They worked there and in other yards for the next 25 years. Perhaps, since their future included several brigs and even ships, they were the actual builders of Veto. Often the owner of the yard took credit for the build. 6. This compilation shows three vessels being launched at Hodgdon. Our first two early brigs were built here but since then many great schooners. Note the Bowdoin in 1921 and one of their three masted schooners around 1890 Blue Benjamin Reed/ Adams/ McDougal yard Between 15 and 20 of the 32 brigs may have been built here. William and Andrew Adams worked mostly here but also built in other yards. Also, their relative John McDougall joined them from north Boothbay in 1852. Together they are credited with 12 of them. As stated above, Benjamin Reed the landowner is also credited with a few. It is not clear how he participated in the actual build. Several other brigs either have no builder listed or one-time builders. Again, investors were often listed as participants in the build. Green. Seavey yard amongst multiple users. This yard included up to eight different businesses. During the period of the Seavey family a few vessels were also built here. 7) This view is from behind the Hodgdon yard looking east into the Damariscotta River, we can see in the 1893 photo where our two big Brigs were built. H G Berry was built by Seavey, so this could have been either the yard to the right of the sail loft that they owned [ red sign] or near the Murray property where Torrent [red sign] is shown. The two vessels were very similar and only one year apart. My point is either way, one build 1854 and the second 1855, and both the same size, there had to have been much similarity. Red …. Murray. Charles Murry was the rightful builder here and he built one known brig and a few barks before the 1857 crash. It is believed that the other builders-built Torrent here, as well. Unfortunately, the captain and one of the investors are listed as builders. It is the connection of the family land owner Montgomery and Murray intermarriages that suggests this site. 8. here is a view of Havana. She was a mid sized half brig at just 100 feet and 221 tons. she was built downtown Boothbay Harbor 1853 by Charles Sargent one of our more famous builders. He was attracted away to the Portland at the end of the crash in the early 1860's. Not part of this build but he built our best ship too. now back to work

-

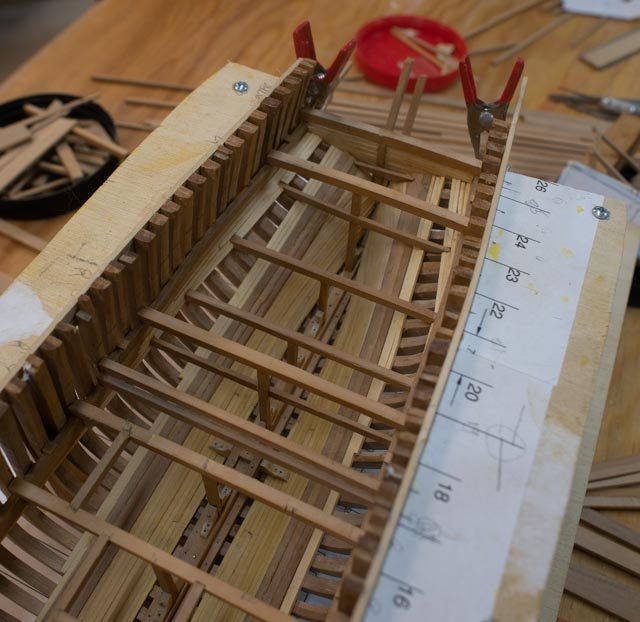

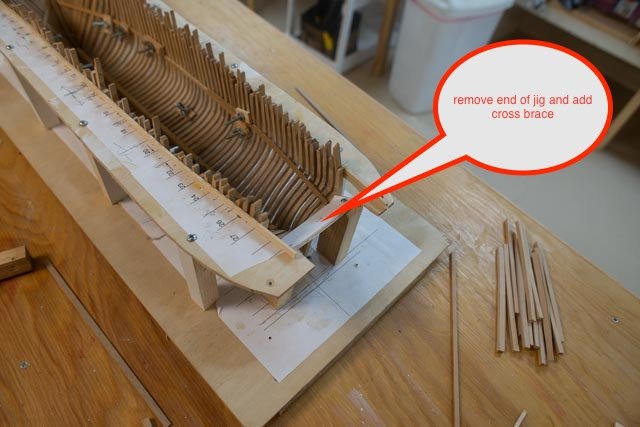

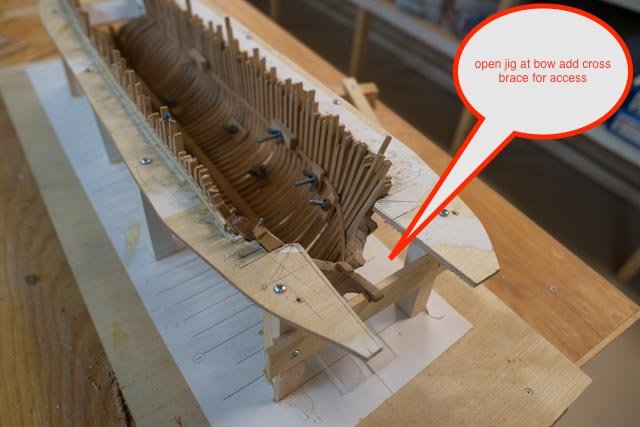

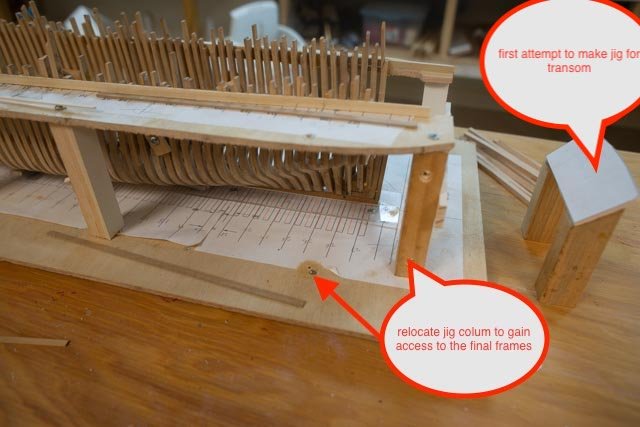

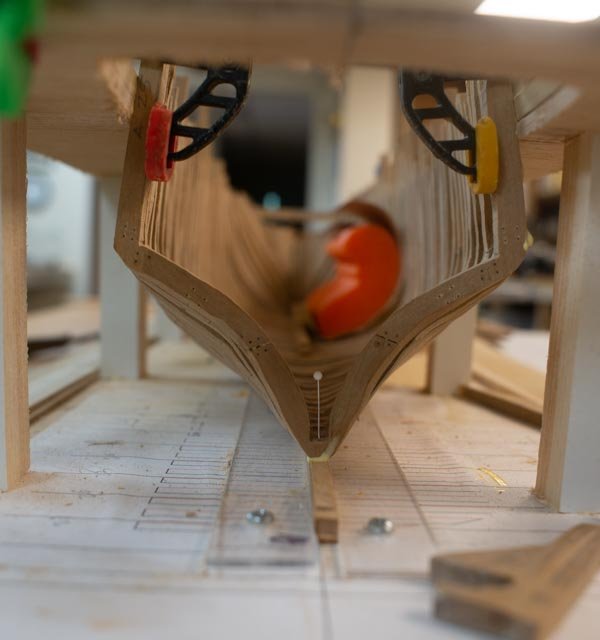

61 update on the larger half brig HG Berry Since getting the new light I am so much happier looking inside the hull. The frame are done. The transom is not. I will get there. First I want to stabilize the hull with all the other internal work. First up are changes to the jig that was needed to help me progress. 1. As I was completing the frames, I needed to move around some of the jig columns. They are screwed top and bottom so moving them was not hard. I also need to figure out a jig to facilitate building the transom. As I have no drawings I am studying the Crothers details to figure out what to try. 2. Here I needed to remove the end of the jig and add a cross brace for now 3. Here at the bow the same story. I need access to build out the bow. 4. In this photo, the last with bad lighting, we see the clamps are in and the ceiling started Now let there be light 5. Here I am checking the deck clamps for level 6. Here is a shot of the blank I an making for mast step knees. I made two to get ten knees. I am using poplar 7. In this progress photo we see the long process of building out ceiling and other internal work. I just can’t say enough about the benefit of finally having for less than $100 great light. now for some more history

-

60. update on the rigging of the small half Brig Albert It is time for masts to go on and be set. I believe the best approach will be to do most of the foremast work before setting the main mast. Having the half brig and half schooner rig makes that a bit easier. 1. here we are setting the dead eyes for the fore mast shrouds. I am not sure how much the fore course sail being in place will affect me with ratlines. 2. The shrouds and ratlines went OK. Now to look at what we have on deck. The fore cabin, “Caboose” as I learned, has been resized and I think it works. please note in this photo all is a bit dark 3. Here I have hung most of the lines on the fore topsail, so as I attach it, much of the delicate work can be done. We’ll see how it goes. I have the main mast and cabins here for the photo but will remove them until I complete the foremast work. ditto on notice the darkness in the photo A few days later we have the fore topsail all in place. I got tired of not having good light on the center project table and bought a new 4-foot LED strip that affords one to change both intensity and color. I love it…I can see inside the hull!!!! 4. Here we are looking in normal indoor lighting. 3500 K . Some people like this more traditional look, however. 5. Here is the same view with the switch to daylight. 5000K. I love it. The blue is just a big cut up cardboard box with blue latex. A few details 6. I am following the Crothers guide as to what line goes to what pin. I try to mix up the thread colors a bit as well. It is going to be tough to get all those little coils in place…we’ll see 7. Here if one looks closely all those lines are in place, leech line, clew line, reef tackle, sheet, lift etc. Note there are lines on the first 7 pins on the P & S sides and 4 at the mast rails.I am not very good at judging the size of the thread to use. I do not like however over heavy lines. I beefed up the lifts, topsail yard halyard and sheets. The rest are all thin. 8. Here all the topsail lines are on and fed down to pins. I used black line for the sheet chains die to the small scale. I kept chain for the top gallant halyard. 9. The bunt lines are there, but the thin thread does not show up well. I will use darker thread on the top gallant I remember this process is a learning effort for me, so if each build gets better I am happy. next up a little history on the yards and start of the insides of the larger half brig

-

59. complete setting the frames at the stern of the larger brig I believe the real celebration is the whiskey plank. I cheated and had an extra dram to celebrate the last frame. Still lots to do but here we go. 1 moving aft I had to remake a few frames and get them meaty enough for the bevels. Here I lined them up to start a little preassembly sanding 2 here came another. This was also the step to verify where the full frames would stop, the space above the keel be filled and the frame was going to become the first half frame. 3 in this view I have done all the full frames. I also started the inside fairing up forward. 5 now it’s time to set up the stern post. I had to make a new one. 6 in this view the keelson and its rider are connected into the sternpost. There is also a new filler to receive the last three half frames 7 the first half frame is installed 8 here all there half frames are installed pinned and glued. Notice how big they are at this point. lots to sand 9 Ta da. All frames in place…yippee 10 it looks like a good bit of sanding once we get the insides set up and can get rid of the jig base. All for now

-

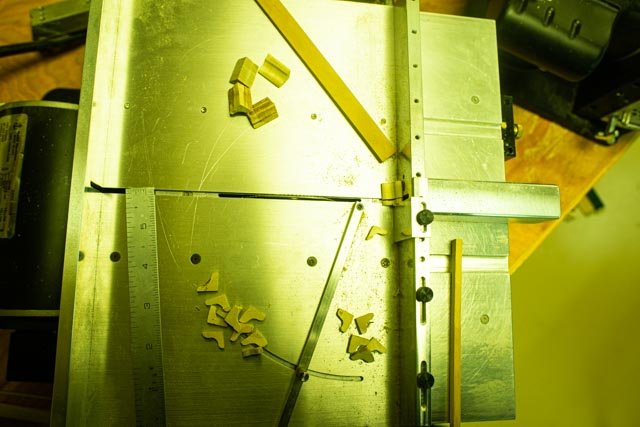

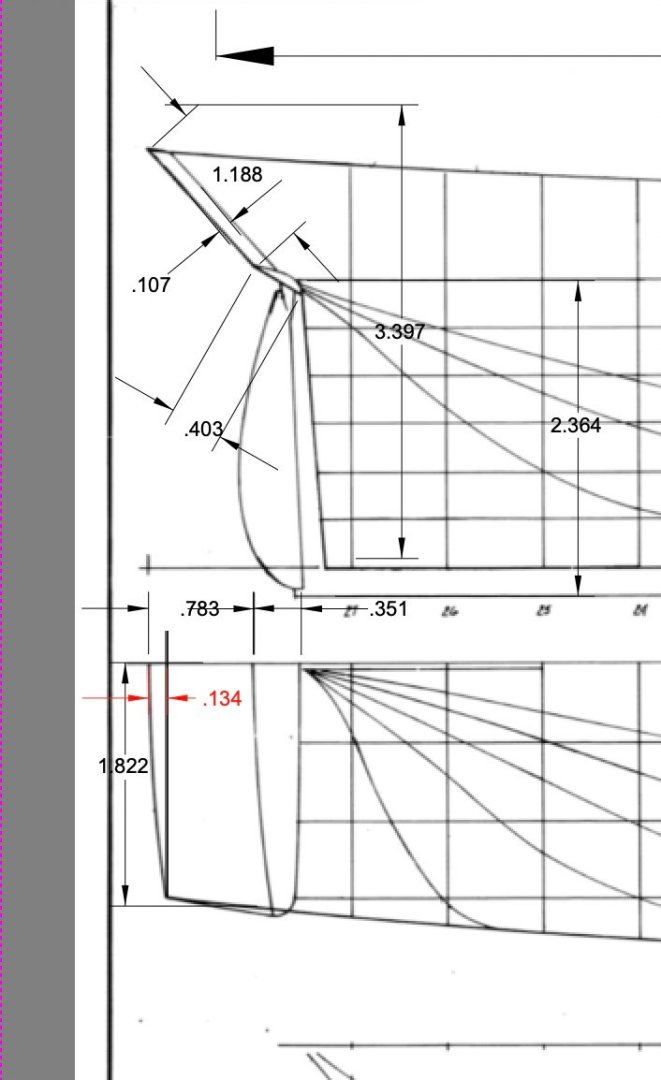

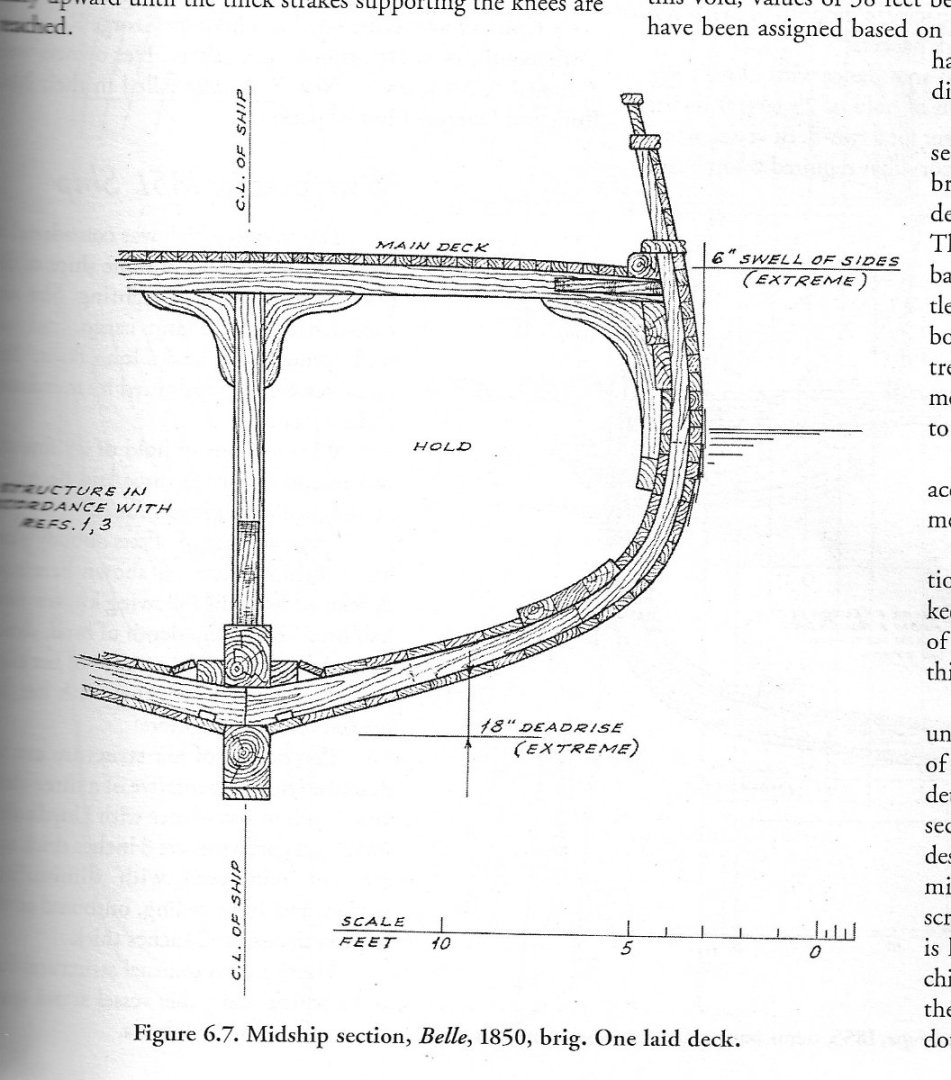

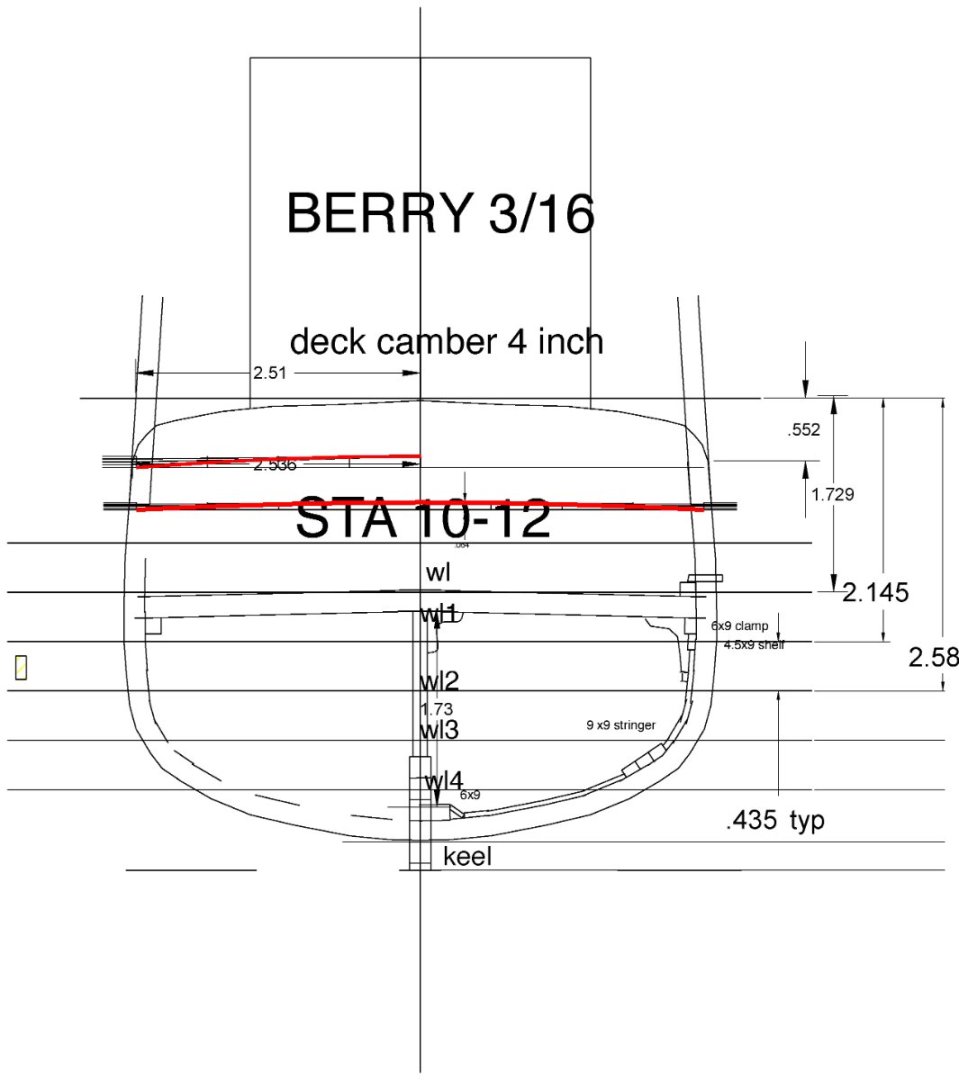

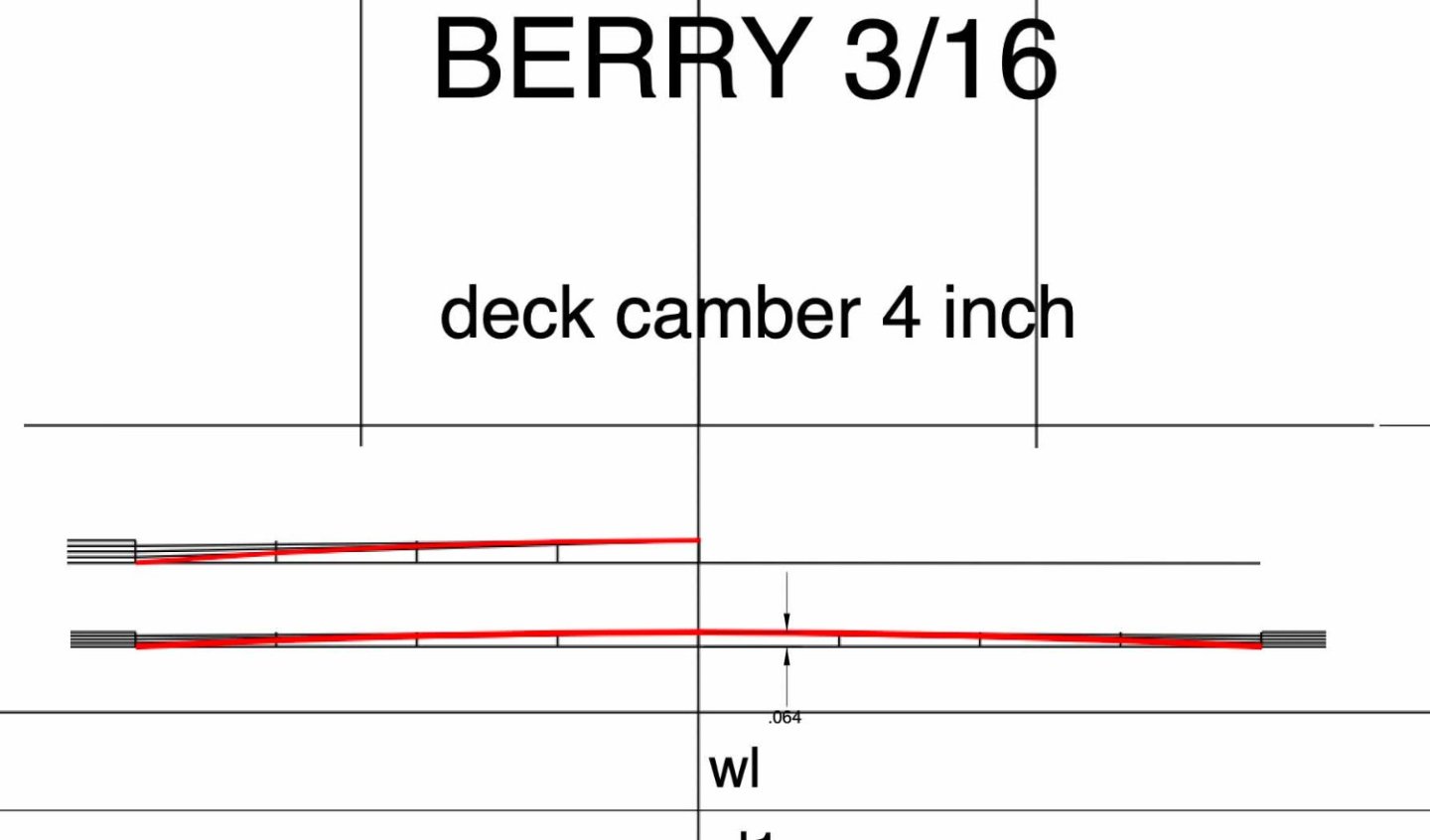

58 time to figure out the deck framing for the large half brig H G Berry The plans I was able to obtain for a similar sized brig did not include much detail. I am basically using the Crother’s book and former experience of the Maine built schooners of similar size. This hull in not that much bigger than a schooner of similar length. That gives me a sense of size of frame deck beams etc. I thought that I need to reference something more specific before cutting up the remainder of my precious supply of Costello wood. 1 this cross section comes from the Crother’s book. It is a cross section of a merchant Brig that I will follow. 2 here I have taken the center frame layer and annotated it. I can then measure and get a sense of the right sizes for the knees, clamps, posts , bilge keelson members etc. The book includes a table with the beam sizes offered and they make sense to me. Since they are doing more than simply holding up the deck they are listed as 12-inch deck beam spanning just under 9 feet. I will do every other one with a smaller one without knees alternating. The knees on the center post and beam end reduce the effective span from almost ten to perhaps 7 .5 - 8 feet on average . This actual span suggests 12-inch beam to be quite heavy. 3. From this drawing source and a comment in the text of a different chapter that a 40-foot merchant vessel would have a 6-8 inch camber I have decided that 4 inches would be best. In the red curve we see how little that camber is. 4. here I am using a the “camber”curve and sanding the tops and both cutting and sanding the bottoms of the beams. I then passed the beams upside down through the thickness sn=ander to try to get them as close to right as I could. 5. here I have cut out a lot of potential knees. I did this in a piece of 3/4"poplar, so it's not too bad if I need to throw them away and start again. I also thought a different wood might be better anyway. I understand the deck horizontal knees were often pine. These Boothbay Shipyards rough cut most of their timber on the other side of the same Damariscotta river and milled the lumber at the local Mill. This oak at this time was still plentiful and pine and fit supply overwhelming. 6. before we begin the next step, I wanted to celebrate that the crew just showed up. They are diecast toy road workers whose roll will be adjusted to shipwrights. for a welcome aboard, let them dig

-

Wefalck thanks for your comment. I totally agree. Much of the difference between a 75 foot and 110 foot long brig is in the bow area. I show the anchor line as part of the explanation of how tight things could be. As I am tying off the multiple lines for the square sails above, just image; working the jib sails and taking in a square sail at the same time. They would have been on top of each other. regards

-

57 layout of the forward deck and set the mast on the small half brig Albert I thought it important to get the ‘furniture’ and big items done on the fore deck so I might set the fore mast. I have gone as far as I dare with the main course sail without being able to tie off each line as it is added. I also need one final look to resize the fore cabin. 1. Here we see the anchor gear with the port side anchor stored aboard. I thought there just is not enough room to lay it down as on a ship. 2. Here we see the other side and tightness of the area. Using Crowther’s pin lay out, I saw the need for all the pins on the extended foremast fife rail. More on that later. 3. Here I added the 12-foot-wide cabin. As it needs to crowd the back side of the fife rail, we also see the narrow access around its sides. It just does not work for me. 4. Here from the other side ditto 5. After setting the foremast, I removed the cabin and redid a small floor plan reduced to 10 feet wide. We get 6 bunks and tight common table. Much like a sailing yacht of today. the galley stove needs to be centered so the boats can ride either side on the roof. 6. I made up a cabin block that will be clad and have placed a quickly whittled boat to simulate the massing. I plan for two boats to ride on the cabin. 7 here is the completed log pump. I shoe it because the little side spout is the only soldered brass tube on this build.....I think Now that I have set the fore mast in place, I need to plan how best to sequence the rigging. If I add all those leech lines, clew lines and bunt lines every pin will get used. I think it better to start with the inside most lines and work my way out. That would make the lower mast shrouds come after some of the running rigging. We’ll see how it goes. I also worry of the push and pull to the sails, so they don’t end up all wrinkled. That is why I feel it better to add the upper sails in place. All for now

-

56 update on the bow section progress of the larger half brig H G Berry I am learning quite a bit here as I push through. First up I realized that the loose fit of dry fit would only get me a little way in the progress. I soon knew that I needed to commit and get the bow section fixed, so I could then build the cant frames to tie in the two sides of the gap I then realized that I needed to break up the keelson and rider into manageable pieces and install them along the way. I also found that another round of making the cant frames was in order. I went to the next scored joint on the keel and cut it through. I then found I needed to hurry up and to get about 4 more frames in place, so I could get that first two keelson sections done and the first rider in place. That first rider ties the stem together and is important. let’s see how it went 1. In this view I have cut down the keelson into its first section and tied together the forward stem assembly and the keel and it is glued 2. In this view the second keelson section is being glued 3. Here the first rider piece is going in 4. Here we see the first rider section is in and glued 5. Here was the square set up to make the stem plumb 6. Here is my next attempt at making the two cant frames 7. Here looking down I have lightly glued the first cant frame to hold it as I fix the second 8. Looking from the inside I remain mostly concerned regarding the inside sanding access once I tie it all together. 9. Here from the inside we see all forward frames in place. I have started gluing in straps to better support the frames above the jig for inside sanding. I hope it works. 10. Here is the new bow on view. I am comfortable that I be able to turn the hull over and sand these outside. Hopefully this does work out. I am thinking it makes sense to slow down and start to lay out the deck and rail lines. I have started adding temporary “ clamps’ above them to strengthen the whole thing to allow sanding before I try to install any of the real structure. All for now

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.