-

Posts

876 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jond

-

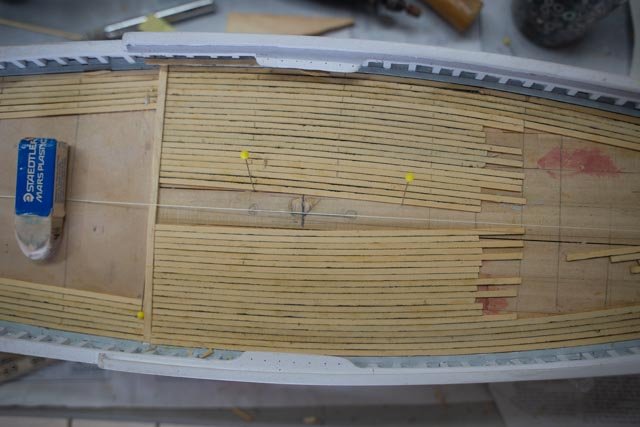

10 oops rework the deck based on review of photos I mentioned above a dumb move / oops. I was in a hurry and somehow laid out both masts incorrectly. Based on that layout, I shaped the rails and included the pin rails. I took the model to the garage, so I could peck away each day a bit while summer guests made working in the shop not convenient. I posted the installed decking. I should have just waited. Here is the sequence….. 01 returning to the shop, I proceeded to carry on and installed all the chain plates. Dumb! Back at my shop computer, which coincidentally I replaced my long-gone computer at this same time. We all know that resetting a new computer means another week that I should have waited. I finally resumed studying all the available images to figure out how the deck was laid out. As I mentioned earlier through the net I found the several collections in both Gloucester and Boston Library collections. I “borrowed thumbnails” and blew them up, scaled spars etc. I had previously shared the sail plan that I did in cad months ago based on a broadside racing image. Why did I not use that drawing when I located the Mast? Who knows 02-05 In these photos one can see the relocated masts and re-laid decking. The foremast wrong hole is amazingly close enough to the round fish loading hatch with which I will plug the hole. The main mast hole was plugged and covered in new decking. The pin rails and chain plates were all relocated and are back together. At some point I need to do more remedial work, especially the outer hull where the chain plates were removed. The pin rails will be mostly covered with coiled lines so they will work out. Going forward Photos 6-8 To plan the deck work, here are two cropped images that come from different internet images and sites. When blown up, they give a reasonable sense of what was on deck and where. I also have one of our Historical Society photos of the sister schooner Louise Howard. The similarities carry through after scaling and measuring the sail plan. So they both confirmed the error made and after the fix I am ready to move forward. cheers

- 48 replies

-

Thank you Rick and Keith for you comments. I just had a set back as I was reminded that haste may cause waste. I had hurried up to get to a point to move the model to the garage while summer quests were here so I could continue and install the decking . In that rush I made a big oops. I had mis located both masts. I am part way through the fix and I must say it is an ouch. I will post in a few days when I figure where I went wrong. My not having drawings did not help but I do have enough pictures , so it was me in a hurray cheers

- 48 replies

-

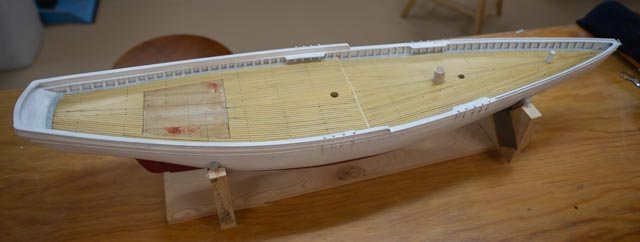

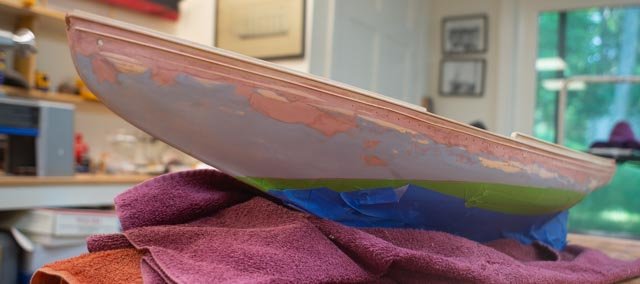

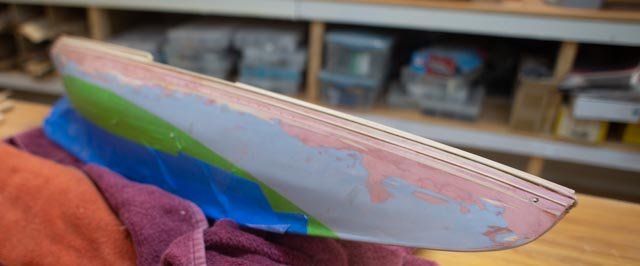

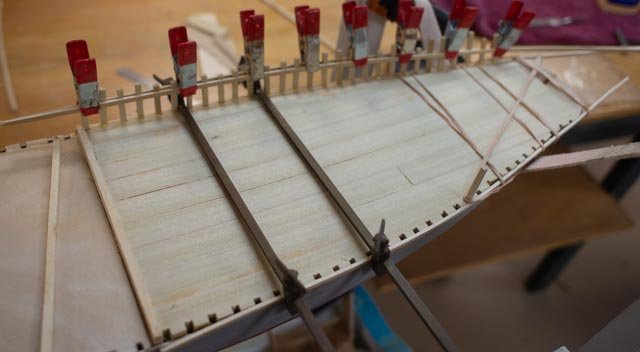

2 trying to get the hull done There are a few steps here as I follow all the folks who have gone before me on this build. I find it interesting that different approaches prevail. I have done a few things that got me where I am, but I see others were smarter. The outer planking is longer than the hull in my kit. I therefore chose to wrap the second planking all the way forward, tapering to make it work. Others stopped the visible planking at the border with the bow plating…..I conclude that they were better off. I followed the Kit’s guide photos and installed all the second planks everywhere before working on the ice bumpers. I see now that I have started the ice bumpers that my choice was not great. Those that run the top four outer planks = 20 MM, and then run the ice bumpers and do all that sanding with only inner planking in place, win the prize for smarts. I have chosen to try to work in darker stains since the outer planking is nicer than say bass wood, maple, or other typical planking. I can always paint black over it if it does not come out right…. One can see below my first go So, there is more to do but for a mid-point hull update, but it is the end of July so here are a few pictures 1,2,3 I found to install the thin outer planking a combination of pins, rubber bands and bent sticks all come into play. I show mid-way through, then the last plank opening and finally all planks in place Next up is the refinishing since believe it would be more than difficult to finish after installing the ice bumpers. 4, 5here we see the set up with the first 4 ice bumper planks. I taped off the area where I will glue the ice bumpers and metal plating on the bow. The pre-bending of ice bumpers is a parallel task. I believe 18 planks are needed. For the stain I compared an old can of what is labeled Jacoby with one labeled dark walnut. They are very similar, and I chose Jacoby. 6,7 Two coats applied: after the first coat the tape all came off. Then after the second coat it came off again. I chose to leave more stain on and not to rub it in either coat than I normally would as I am trying to get the darkest finish I can get. 8 I just bought a can of hand rub poly as I fear the tung oil will not like the handling during the next phase. I have about three coats on at this stage. Here it is drying and one can see the unabsorbed pigment came off in that rubbing. The jury is still out on the stained wood look as it has absolutely no relation to any scale and may take the eye away. we'll see. 9 here I have started to glue on the ice bumpers. I will remove the pins in the outer layers, but they are handy. It is easy to see the issues I will have next when I try to sand the bumpers. It is already August , so only a few more weeks before I travel north to the passage. Cheers

- 62 replies

-

- Arctic Exploration

- OcCre

-

(and 2 more)

Tagged with:

-

Keith thank you for dropping in. I must say following your build[s] has been wonderful. the back and forth of a few years back too between about 4 of you guys was great to read through as well. I was thrilled yu jumped in again and have opened the box for Erebus as I was curious what they would do. Your idea of fixing the bulbous hull was well thought out as well. best wishes as you can carry on. Jon

- 62 replies

-

- Arctic Exploration

- OcCre

-

(and 2 more)

Tagged with:

-

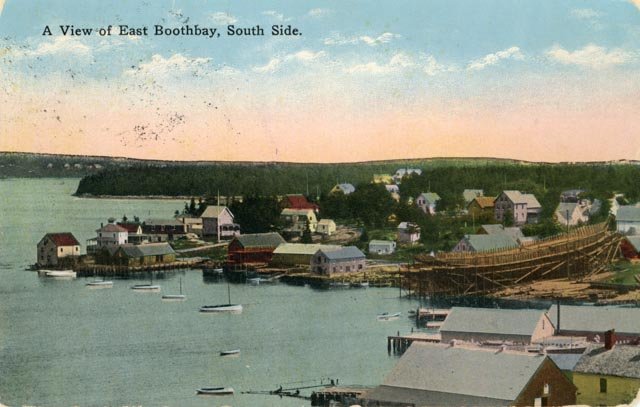

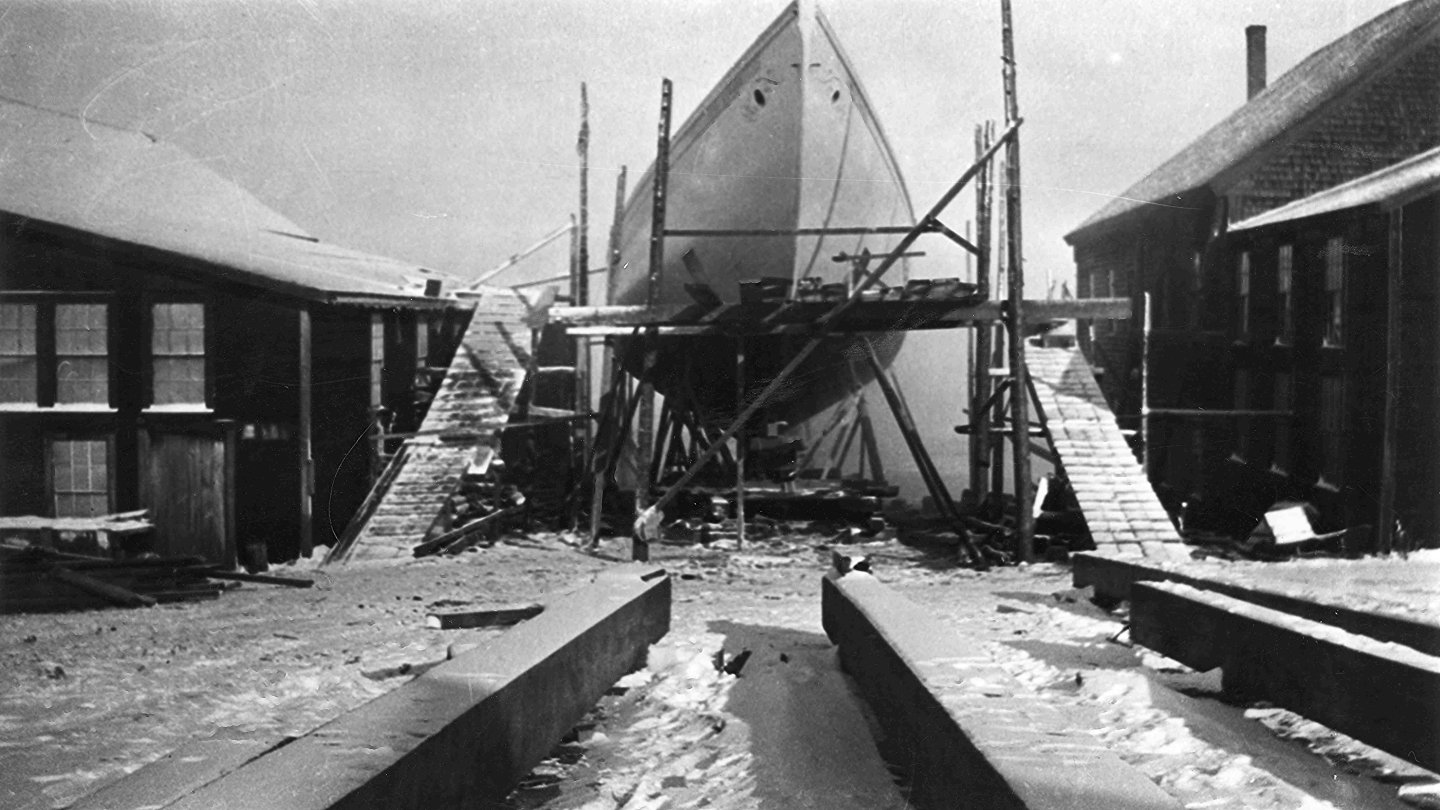

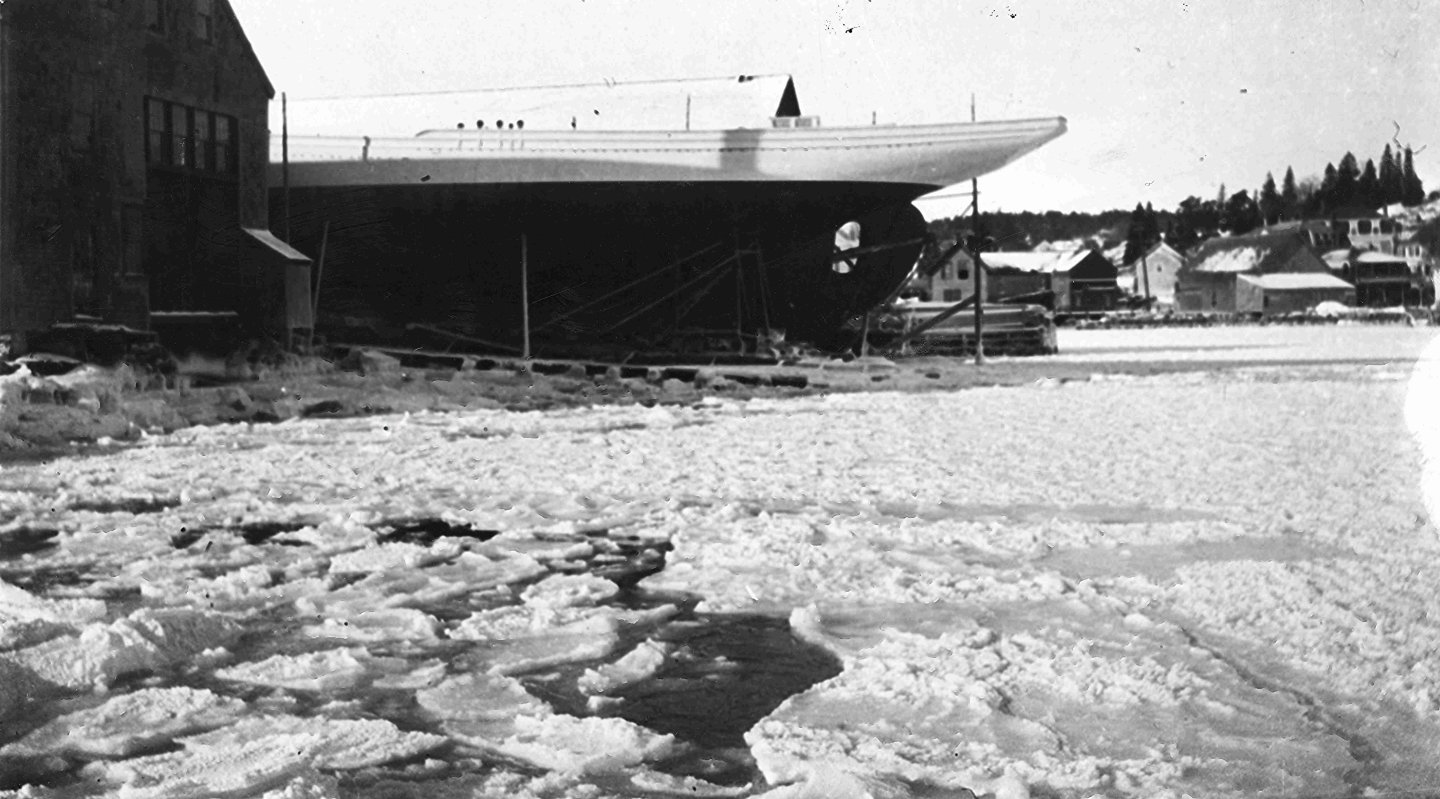

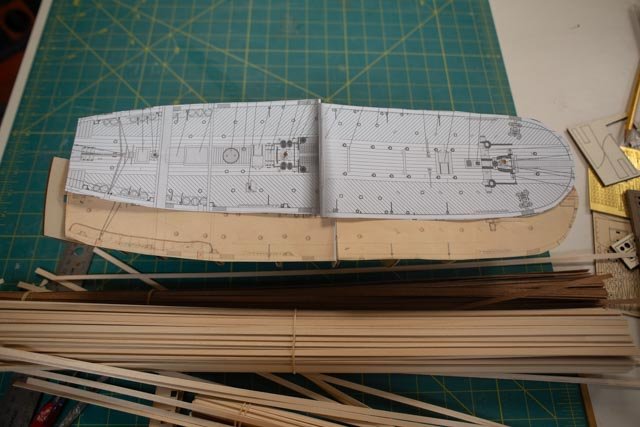

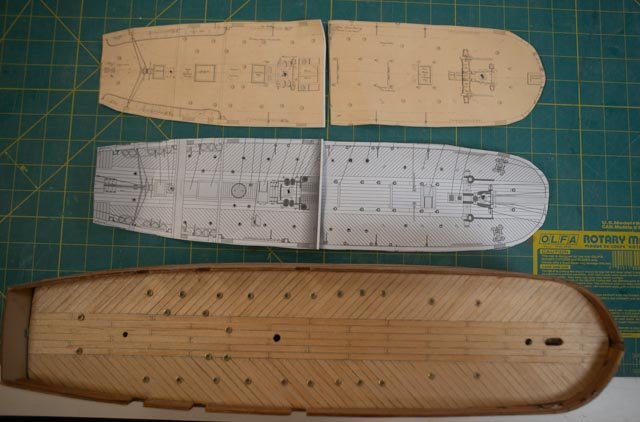

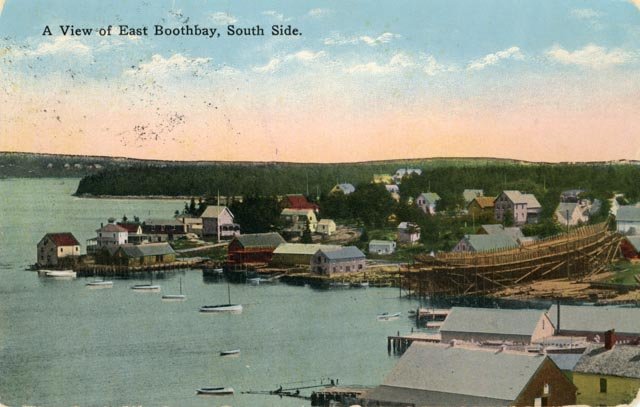

9 the deck As I move forward into the deck work, I am fully dependent on just a few photos to understand the layout. Fortunately, a couple of photos showed me the lay of the decking followed the waterway inward. As to the furniture we will get to those assumptions later. Before I share a progress update, I would like to revisit the history of the two sisters. Elizabeth and Louise Howard were both built one after the other. As discussed, Elizabeth was extended about 6 feet in the bow for that little push of speed. Louise apparently retained the McManus 1908 Oriel design length of 126 feet. 1 this view is one of the better views of the Adams shipyard. It was taken in 1903 with the four masted schooner Eleanor Bartram in the shipways. 2-3 Here are two views of Louise sitting on the shipway with the harbor frozen in 4 here we see Louise just after launching. In the background we see The Rice brothers’ yard with their 1918 steel hull dragger Alden Mills. That dragger was one of 6 that they built. Last year I built a model of the 6th one Harvard. Back to progress 6,7 I like to share my oops moments. In these two progress images we see that the predrilling of the main mast hole needed relocation. An advantage to running the planking inward from the waterways is one finds the real center. I stretched a thread bow to stern as the center became more evident, and that guided me in confirming the king planks location and the need to relocate the Mast hole. I dowelled the wrong hole and redrilled in the center. The benefit of 3/16” plywood under deck covered with about 1/8” poplar made this an easy fix. 7,8 here the decking is complete, and the sanding partly done. I progressively advanced in grits up through 320. There really isn’t grain to bring out in Alaska Cedar, but a rich color and shine that is hard to see in the photo. It is all amusing as the real decks of fishing schooners were really a mess. Also the summer invaders have gone and I am back to the model shop. 8-11 here are four images of the decking with two coats of hand rub Poly. I chose the poly because I find it more resilient to the abuse than the tung oil of my recent builds, which will occur while building out the deck. I also have started playing with the masts. all for now

- 48 replies

-

1 The Beginning I join a group of recent builders of this model kit with enthusiasm. Not as to the model and building of it but to the story that it represents. I was very fortunate to have the opportunity to move to Canada in 2009-2012 and fell into reading Pierre Berton, a prolific writer and former TV guy. Reading all about the Klondike and then his book Arctic Grail sent me on a long adventure. My current library of Arctic oriented past, present, and future reading has grown extensively. I think to try to hit a few high points of those books and stories may take us too far adrift. This log is to be about HMS Terror, why I am building it and ultimately, with some pictures, how will it come out. So, to keep it brief…. Why the build? • After 15 years of on and off again study, reading well over 40 related books, I have decided to take a trip north later this summer and pass through the Northwest passage. I will include a summary of that trip after it happens in August to September. • Adventure Canada gave me an Essential Reading list that I have devoured, and hopefully one well known historian will join us on the cruise. • On a recent, May 2024, three-week road trip across the Canadian prairie to the Glacier Park and back home through Dakota Buffalo county, I read MSW logs each night of everyone who has listed the HMS Terror or HMS Erebus. It took that many nights as the logs are incredible. I learned something from every one of them and that is the value MSW. • Several of the more complete logs, by great builders, referred to the recent book on HMS Terror by the Museum Curator Mathew Betts. Combined with his log of partially built HMS Erebus, it’s great reading for both modelers and those with interest in the Antarctic and Arctic sailing. • The Idea that HMS Terror as a new vessel bombed Baltimore in 1815, sailed three complete circuits of the Antarctic and then went off to the Northwest passage is embellished, as Betts explains she was technologically the best of the best at each stage. • The Stephen King style book, HMS Terror by Dan Simmons is great summer reading. It was made into a mini-series but alas one must subscribe to another TV channel to watch more than the first episode. I recommend the first episode, which is free on Amazon Prime. The studio recreated a life size set of both on deck and below, with Matthew Betts advising them. It was great to watch. • Michael Palen’s book HMS Erebus is also a fascinating read on the “bomb vessel” or bark’s history up to her disappearance. • In recent years, Canada Parks and others have found both vessels where they sank near the King William Island. There are many books written of those findings and as one might say, the beat goes on. How to build • Over the past 10 years I have focused my study and building to the local mid-coast of Maine shipbuilding in our Boothbay Region. There are more than enough examples to build. There were 14 barks or ships to choose from in our little town. A fully rigged bark is on my list to try soon. That effort will involve more upfront investigation to get, or I should say adapt useable plans, as the records here are wanting to say the least. • I could have taken the HMS Terror plans that are available in the Mathew Bett's book and done CAD bulkhead thing and moved on step by step. I chose to take advantage of all the work done by others. I found the kit as an open box on eBay with a little discount. I was not concerned about any missing parts. I also have had fun buying other stuff that I will share as I get to them, the wheel, the small boats, possible walnut to replace hull planking etc. • My version will not likely come up anywhere near the great work by others already having gone down this path. I shall leverage their lessons learned and point out when I don’t follow their wisdom and get my oops. • I record my current thoughts at the beginning of the build, and we shall see how they evolve. I think I will leave wood more in a natural way than to simply paint it black. I am debating between diorama of ice bound or more complete pedestal display as others have done. If I use the sails in the kit, it is more likely to be as patterns for silk span replacement. If a diorama I ask should they be furled or stored below. • I have no idea where I will go with ships boats. The records say there were 12….wow one image shows one swinging from the yardarm while icebound. So not knowing really where this project may end it is time to get started. I am now actively doing two builds at a time. My idea is to have two different types of builds going so I can go back and forth. I also plan to take on the challenge to build more small ships boats and the like, something I really need to develop especially if I want to do a diorama. Start to build I just want to mention that for some of us Yanks, a 1:75 scale model causes a few inconveniences. If I were to scratch build, I would likely go with 1:64 or 1:48 to allow side by side comparison with say my diorama of Bowdoin. I also cannot seem to find 1:75 figures yet… I am still looking. First up was to take all parts out of the box and assemble the deck. I followed advice from others and took first the drawings that I thought were correct for the deck. After more review the Matthew Bett's book, I scanned the deck drawing from his book, which shows the deck furniture layout and more importantly the “lights” that need to be drilled based on his research. I took the little provided rivets and filled them with clear silicon to simulate the glass. I am amazed that one builder added lights to shine up through. That is well over my pay grade. So as I close this introduction I have the deck done and the first layer of planking in place. I am mid-way through the second planking and will share that soon. 01. The first picture shows the deck planked and the plan scaled from the British museum. My source was another log. 02 the second view shows the gray copy of the scaled scan from the Mathew Betts book. 03. here we see the two plans laid off to the side of the completed deck 04-05 here are two views of the underlay planking in place. I also have some filling and more sanding to do. The keel and stem are loosely dry fit. I note that the kit recommends they get installed after. I do not know how pinning the light planking will go, so I started the outer planking without them in place. All for now

- 62 replies

-

- Arctic Exploration

- OcCre

-

(and 2 more)

Tagged with:

-

Andrew. thank you for dropping in and sharing your helpful thoughts. I had learned that trick of tape on, paint on and tape off in as short a time as possible the hard way. Unfortunately on this build, due to the need to move from my indoor shop to garage [ for summer visitors , a hazard for us Mainers], I had not done enough dental work on the inside of bulwarks. That clean up added time and as I had no proper stand for the hull, I had to do one side, wait, rotate, do the other side , and then the top etc. The tape on the bottom stayed in place for several days. I did one final light coat of white with the hull upside down and removed the tape before it set up. the line seemed to be fine, but as soon as I pulled it, oops. the bottom of the keel had many nicks that probably occurred earlier in the process. I had to do a quick tape off of the white [ i uses tape sparingly and news paper] and redo the red spray. It was all done very quickly and lucky to say I had no issues. Now will the hardened enamel stand up to the constant handling as I carry on. I have never achieved that goal before and always seem to be repainting later without the ability to spray. Let's see if I can do better this time. cheers

- 48 replies

-

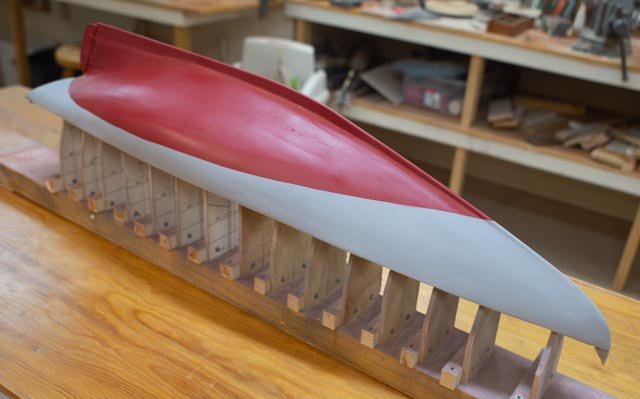

8 continue views of hull painting here the tape is removed the bottom retouched and off to show next up more cleanup and prep for decking

- 48 replies

-

8 time to get some white paint on her. As we are in the peak of summer, I am moving the work from my shop to the garage. Before moving, I was under a time crunch to get the bulwarks done with as much detail as time would allow, so that after painting there would be less disturbance. I also want the move to follow a change in activity, so I am taking only one box of stuff with me and not my whole shop or worse running back and forth. First up is that preparation. Then after the move yesterday out came the low-tech spray paint cans, “rattle cans” as I have heard them called. One coat of primer outside them three light coats of white. Inside just the white. I am studying the old photos to see if I need to repaint the waterways gray. Things that I would have liked to have done first include the chain plates, lips on the hawse pipe, perhaps forward cavils and more dental work to get all the fuzzy edges all gone. I added a trim strip as found in the launch photo. I will let it all sit for a day to harden up. Hopefully the enamel will last. My previous builds all needed much touch up. I want to learn how best to avoid that added process. While outside I will add the cedar deck and build a working cradle to hold her during that process. I am not sure how to mount her ultimately. She is not heavy but with the masts she will be over three feet tall. Brass pins drilled into the keel and then into a base I think is not wise for this build. I would love to figure out how to use acrylic to hold her as to me it is all about the ghost image. I don’t want a stained wooden cradle and I do not plan a diorama approach as i did on the Schooner Bowdoin. I will add some shots after removing all the tape. All for now…enjoy this brief summer.

- 48 replies

-

Thank you Keith. we all appreciate encouragement as we toil away. some of us definitely into the unknown. I am about to be invaded by family...they always like to visit Maine in the summer, so I am heading for brief change. I need to move out to the garage. something about the smell of glue.

- 48 replies

-

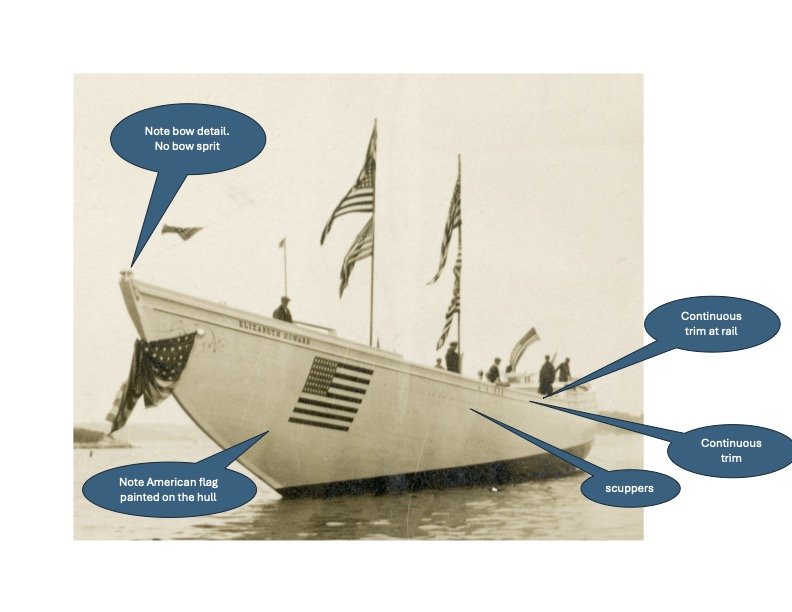

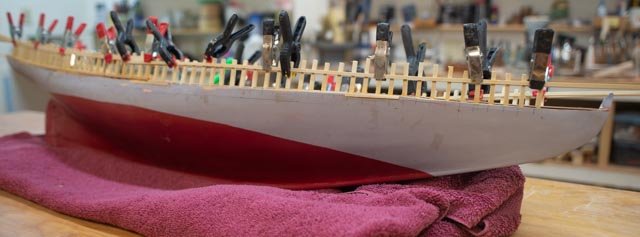

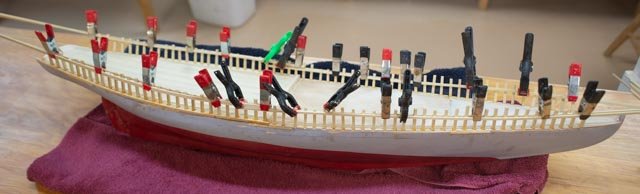

7 Bulwarks progress Occasionally, something serendipity happens. One of my many projects continues as we are digitizing our local historical society documents and photographs. I am overlooking the photos. We are up to finding 16,000 so far. What I mean finding is that as one opens a storage sleeve marked with a label, we find just one or several prints negatives etc. As views are different, the index grows accordingly. At the beginning of this build I shared the image of the EH as she hit the water during, her 1916 launch. Some details are in the photo, but not with a lot of clarity. Last week I found the following image that I have annotated for this build. The print was sitting in sleeve marked East Boothbay waterfront. I was thrilled to find it. I am not sure how to make the little trim strips, but I will try. Here are some progress images. I first secured a plank outside the raised deck, inserted the stanchions on one side at a time. I secured them with clamps on future plank stock. This process repeated four times and then the water ways went in. I filled in cut pieces between stanchions and then marked, drilled and set the scupper planks in place. Finally, I added the upper bulwark planks. I end this progress piece showing I have now cut the stanchions back to the underside of the future rails. Just for fun I share the image of the new cedar deck planking that just came from the Sawmill. I love their material. There quite a bit of work before I get that that stage, but it is fun to look ahead. The first of our crew has shown up too. Lots to clean up and then I need to complete the rails. The transom and bow need attention. I also want to lay out basic rigging so the side pin rails, cavits etc. can all be done before painting the topsides and the bullwarks. All for now

- 48 replies

-

6 launch the hull and install under decking I am doing a few new things in this build. Some steps may help, and some may not. We just must wait and see. First up there were about three more cycles of touch up putty, some more primer and sanding. Eventually at 800 grit, I called uncle. I took her back outside and gave her a new view of the water, before leaving on my second Canada adventure this summer. Next was to paint the bottom and launch her. I followed some advice and bought some “frog tape” that says it gives a sharp line. Here we see my low tech set up for marking the water line. I also decided to build and add the rudder now. I think the waterline is better than previous…yeh for Frog tape. To launch, I found an old RC sailboat sling in the shop to use. Before cutting off the bulkhead stands, I measured and marked a line 1 inch below the future rail at each bulkhead. There will be 4 stanchions between each mark. Then off with the stands. I then cut up the soft Luan plywood stand material to fill in for a complete under deck. A few extra hours here instead of figuring out where blocking will be needed for rigging eyes etc. The Holes for the stanchions are in as well. Finally, I am now in the process of the smooth under decking. This process means instead of perhaps 1/16 decking over many more hours off effort to get the under deck really nice, I use, 1/32 plywood and I ordered precut 3/64” cedar from the sawmill website. So, expecting a little sanding I am close to the 1/16th inch scale for the decking material. For the raised after deck I am adding 5/32 poplar. It will get sanded as well before decking. The cross beam at the step is cut down Alaskan Cedar. It is high now but i will sand it closer before decking. We’ll have to see how this under deck and stanchions comes out. Once all is in place and sanded to clean up. I will install all the stanchions and bulwarks. Then I hope to paint all before moving on to the decking. All for now

- 48 replies

-

Keith and Jerome Thank you both for dropping in and adding your kind comments. I have been away travelling again around Gaspe, Canada and it is good to be back home and back to work.

- 48 replies

-

5. Planking done up to the deck level Thank you everyone for their likes. I worked straight through to get this phase done before another Canada trip. Here we can see the planking to the shear plank is done, with its first sanding and prime coat. The primer lets me see all the dings and things that need fixing. So here we go 1,2 mid-way done and final stage 3,4 last planks are in place and glued. The new saw blades came, and it was again a joy to get straight and true unblemished planks. 5,6. first rough sanding done. 100 and 150 7,9 first glazing putty on and fine sanded 220 grit ready for first prime. 10,11 first filler prime on.. wow lots of dongs to fix this step will be repeated a few times before marking the waterline. Finally, two fun shots. 12 I aimed the bow toward the shore land rocks to keep her calm. Doesn’t she look just like a dolphin. The keel projects more on this design and that must have helper her hold the line going up wind. That must be why she was so fast. Surely, she wants to get wet. 13 In this final bow view we see the ocean behind beckoning her to go for a swim. I need to keep her calm for a while longer so back inside we’ll go once the primer is dry. We now start the tedious fill. sand , fill sand. progressively finer paper. until we cry uncle. Cheers

- 48 replies

-

Thank you Nils. I also enjoy looking through your work. I keep learning....unfortunately like my lesson on dull saw blades I also continue to forget cheers Jon.

- 48 replies

-

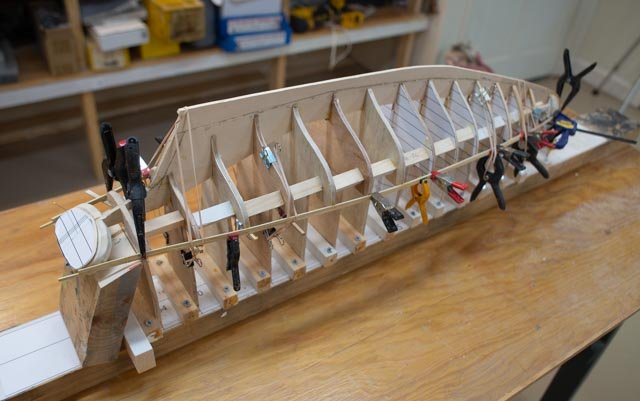

4 the yard and other related builds and starting the planking One of the main reasons for my builds is to help illustrate the story of the local shipyards. So this build represents the Adams yard some 100 years in existence after family members began both in East Boothbay and North Boothbay. They were near their end in 1916, but first let’s see what was going on around them. Several issues were going on across the Maine industry. • In the big picture, the WWI commencement and success of German U-boats caused a dramatic need for large 4 masted schooners starting by 1917. • The British trawling industry had evolved to steel hull and steam driven since the 1890’s. The American/ Boston market began that swing about 1908 ish. Rice brothers next door in East Boothbay had recruited a Naval architect from Bath Iron works and won a contract for a steel hull lightship in 1916. It would be followed by six steel draggers. • Despite the war, the movement into Maine summer cottage life fueled the demand for Power and Sailing yachts that had blossomed since about 1895. • The offshore fishing industry still had a need for large schooners and there were a few more years to go before the changeover to draggers. • More yards in town were expanding into steam driven commercial and some private vessels. Marine engines of small to medium size were being built at Rice Brothers and installed in several yards. • Maine yards were able to build John Alden, Crowninshield and other designed racing yachts more economically than southern New England., and that benefit steadily fed the local market. So when New York client Mr. William W. Howard went to Thomas McManus for two new fast schooners, Boothbay was not surprisedly recommended. Adams like Hodgdon and Rice Brothers in East Boothbay and Reed and Townsend Railway in downtown Boothbay harbor were all busy. A few new lines were sketched onto on an existing 1908 drawing and Frank Adams, fourth generation builder, was off building another schooner. Though it was late in his carrier, he had a few more builds in him. The Elizabeth Howard and Louise Howard schooners were launched in 1916 and 1917. As fast sailors they would typically collect fish in Nova Scotia and race it south. Louise, a slightly shorter version, continued until 1925 when she went aground in the Carolinas. Here are two images, one with the steam boat that ended service in 1912. They both are overall photos showing the Adams yard building a 4 masted schooner in 1903. Between then and 1916 the Rice Brothers yard to the far left expanded significantly to become the largest in town. Adams continued to build both schooners and a mix of other vessels, and Hodgdon in the foreground , though since relocated, is today in its 5th generation. Progress A little delay as summer has arrived. I just took a 3 week trip to see some of western Canada and buffalo at Teddy Roosevelt's National Park in North Dakota...much fun. We are now in the long planking sequence Not unusual for me, I ran into an oops. My slitting saw blade, purchased from Byrnes several years back, did not really want to slice any more through even 1/8th popular. I said to myself no worries I’ll just use the normal 36 tooth carbide blade and chop up more wood. …oops wrong? Perhaps that blade is old too, but what I realized after setting several planks was that they were a bit rough. They had dings and undercuts….a true sign of my amateur status in milling. I went online to find replacement blades and was very sorry to learn that Jim Byrnes had passed away. I was lucky to have met him once when he came to the NRJ conference, either in Mystic or New Bedford. His great attitude convinced me to try out his saw. It is great! Many of us are very lucky to have one. I tried again to search blogs thinking I am not the only person who would like to find blades that have a ½ inch hole for the arbor. Even more unusual the little inserts to make other sizes reduce to ½ inch. Finally, a very recent post said the site as open to sell blades. I immediately got some on order. In the meantime, I continued using “rough planks”. Fortunately, this model is all about white paint and I chose poplar for that reason. The extra dings and over cuts from that rough blade will eventually get hidden. To catch up, here is the set up and first planks: 1 here is the alignment and fixing of the bulkheads to the “ keelson assy” 2. here is the built up transom 3. here is the roughed in bow block 4,5 . here the fairing is done, and first planks milled. from the bow view we start to see the uniqueness of the stretched design 6.7 tada the first plank is on. 8,9 here the garboard is added. It was at this point that I did a light sanding to get off glue and stuff and realized the roughness of the planks and started looking for new saw blades. 10. I leave with a picture only another model builder could enjoy. Almost every clamp I own is engaged. Cheers

- 48 replies

-

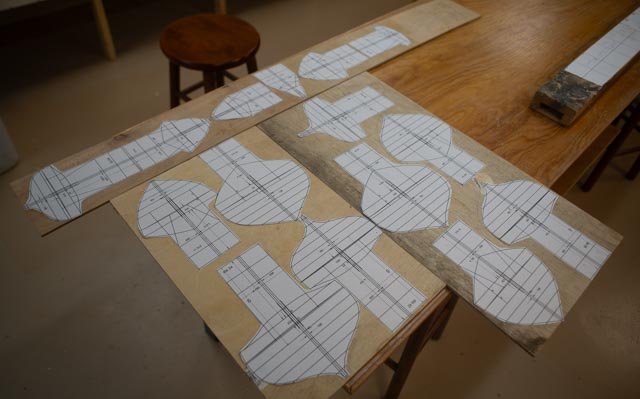

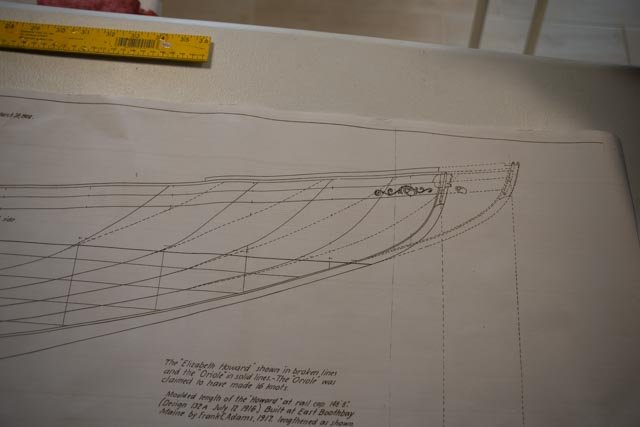

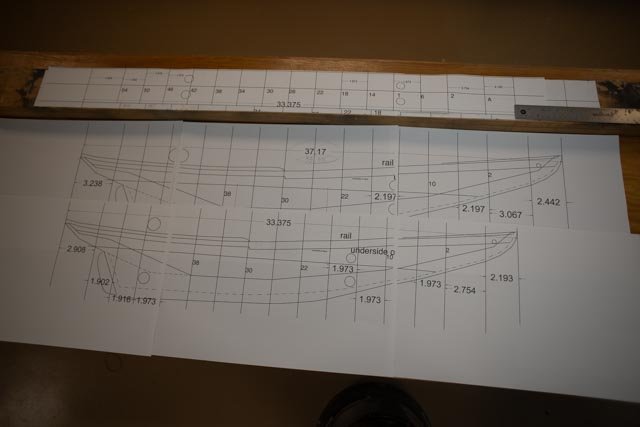

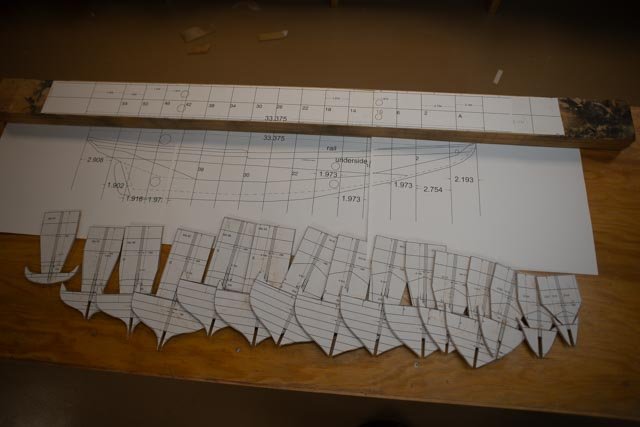

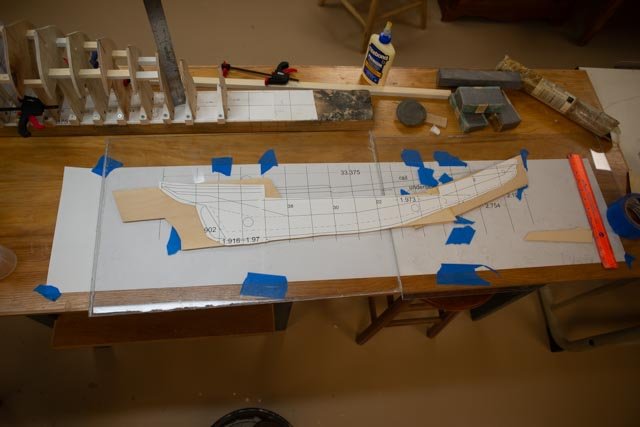

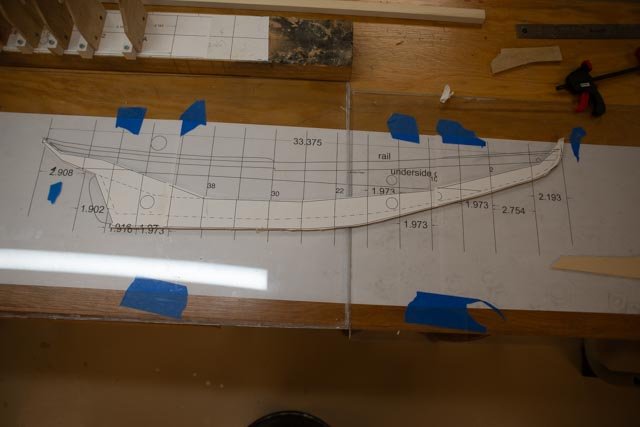

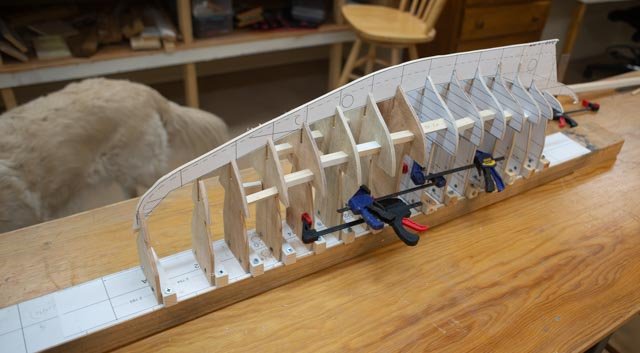

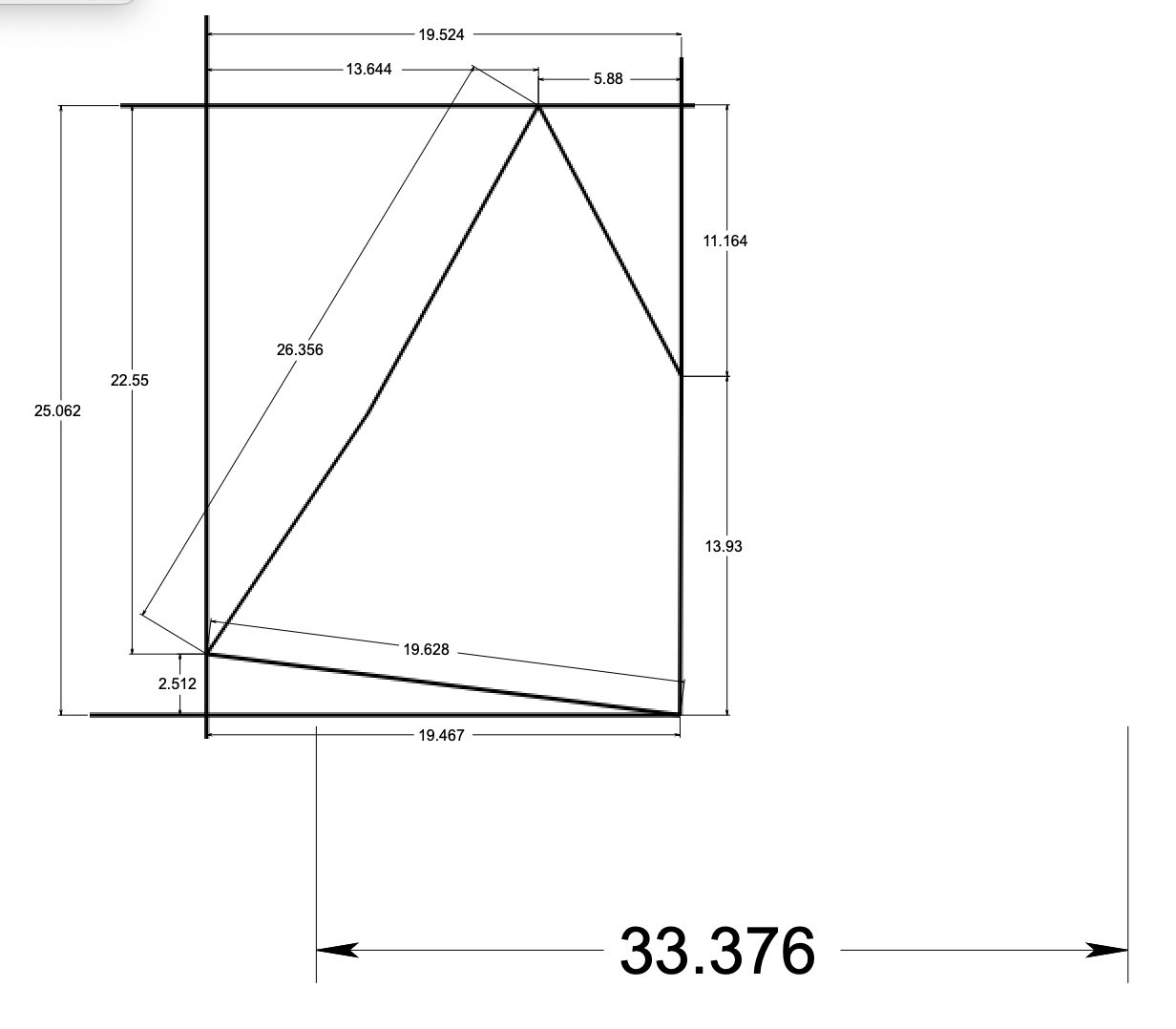

3 the hull framing I first, scanned the line drawing, embedded it into 2d cad, scaled, and then traced bulk heads. I chose to do this hull only as bulk heads because the affect I think is to have the unusual white hull and flying sails as the chosen image. I then scanned the Keelson on three images and embedded them in a 2d Turbocad drawing, then aligned and scaled them. Unfortunately, when I first did this, I was following the note by Howard Chapelle on the drawing that made it (148ft at the rail). Fortunately I re-read the NJR article mentioned above and learned that the best approach would be to shorten the vessel to 133.5 FT at the rail. Thank goodness for cad scaling. 1 Here are the stations all cut out and glued to luan plywood ready to cut. 2 Here we see the keelson assemble drawing and building board ready to go at 148 feet 3 here is the Chapelle note that set us on the path to 148 ft. 4. here are the dotted lines that extend the bow all above the waterline. Purely for speed, I am sure. Later measuring this extension, as in the article it is 6.5 feet. 5 here is the rescaled keelson assembly. I remade the building board template on the same drawing. Now the first cutting 6 Here are the bulkhead templates cut out 7 In this view we see the raised portion to support bulwark planking up to the rail. I struggled with this detail on my last build [ it was at smaller 1:96 scale] to remove these “tabs” after the planking. Since these must be removed to allow continuous stanchions at each frame[ 4 per bulkhead], as seen in the in the photo I found, I have decided to remove these tabs now and then add stanchions later. We’ll see if it’s a better way to go . 8 here I am doing something new as well. I chose to laminate the keelson assemble with three layers of basswood. I used solid maple last time. My reason was here there is more sheer to the assembly, so there will be three full joints. The overlapping allows a stronger joint both forward and aft. 9 Here after cutting out the keelson assembly one can see the considerable shear in this design. A butt joint would not have worked well. The other reason is the width of the keel in the section drawing is only 3/16 [10in} where other heavy fishing schooner keels were ¼ “ [12-14 inches.]. this keel projectys further below the hull than other schooners. We will address again later. 10-11 Here are progress images of a rough first dry fit as I approach the end of this phase. Next up will be to complete the frame and get the first planking installed. All for now

- 48 replies

-

Peter My life time admiral used to say....a lack of space is only an opportunity to build.....smile Phil thanks for the encouragement

- 48 replies

-

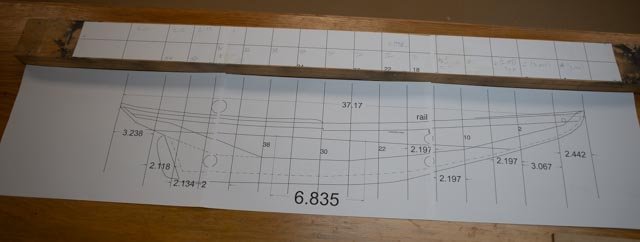

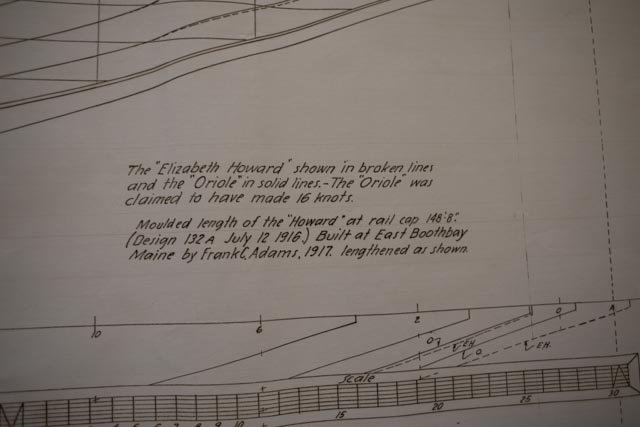

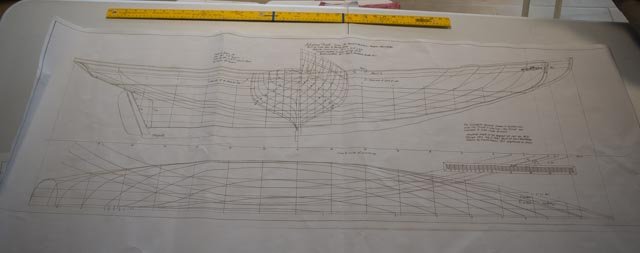

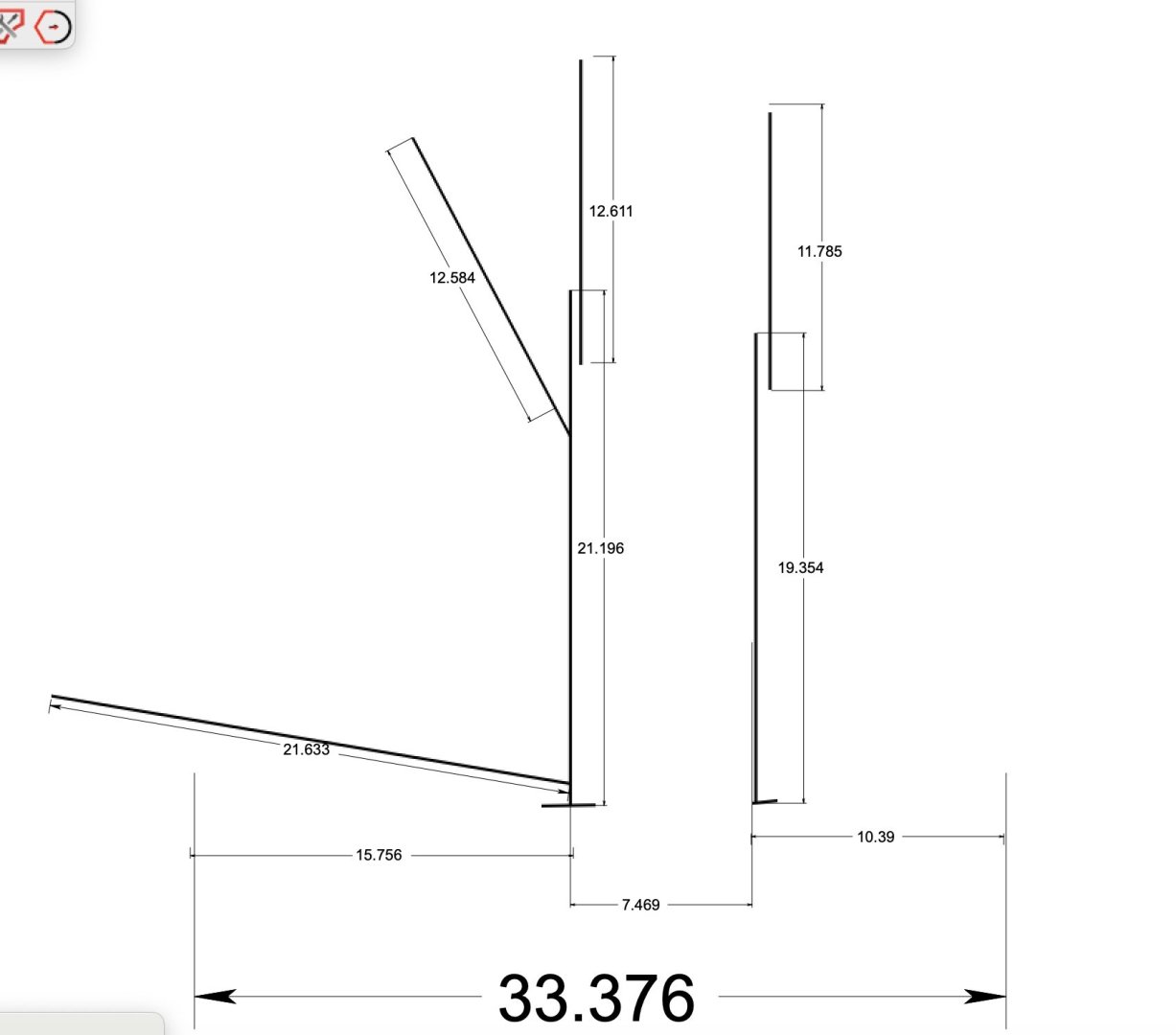

2 First up are the sources for drawings. I went to the Smithsonian catalogue and ordered the McManus design for both Oriole and Elizabeth Howard as prepared by Howard Chapelle. Note this is actually very easy to do once you have hold of their catalogue. It is unfortunate that it is not on line….[I think]. 1. Here are the hull plans they shipped. They are basically at 1:32 scale just off a hair. Before we get to the hull let’s gather all the other info we plan to use. There are no surviving drawings of the on-deck configuration nor sail plans, but artistic license should warrant a “close enough: / generic finishing above deck. So let’s find some photos. Here is before bowsprit and racing with a bowsprit. 2. this view is one of two images I am after….note there is no bowsprit in the image. This shows the working vessel. 3 here we are racing in all her glory….the likely choice. The other option having no deck plans could have been to use the great hull drawings and do all the in between framing and show it in the yard under construction. I chose not to follow that approach for the "White Ghost" of Maine. I think it is the sailing image of such a short lived thoroughbred racer to be the better way to go, so off we go. To complete my outreach at this point for the above deck, I will use two photo documents and will annotate them. Once again, I have taken a broadside photo and embedded it in cad and scaled it. I found it strange with the subtle roll to starboard of the hull in this image, the masts are absolutely plum. I will add a bit of a rake as can be seen above. 4 . here is screen shot. 5 by example of the next steps, here is the spar plan. 6 here is the first sail plan. I will later do one for each sail. Where like this mainsail where they are larger than tabloid 11”x17” my printer limits, I have added coordinates to lay out the pattern manually. Smaller sails will simply be printed. To place furniture on deck I will use the 1919 photo of her in the water swamped to give running on deck dimensions for the cabins that are visible. There are also a few online images for Bulwarks etc. 7 Here is the partially annotated photo of on deck. 8 here is sample of online deck views . Yes that is Columbia with I assume Captain Ben Pine ahead of us. I will then use Gertrude Theobald and Columbia plans that I have rolled up somewhere [ the once upon a time to build list] for added guidance. More on that when we get there. Cheers

- 48 replies

-

Allan ah you are right again....good eye to the other old guys...thanks Druxey.

- 48 replies

-

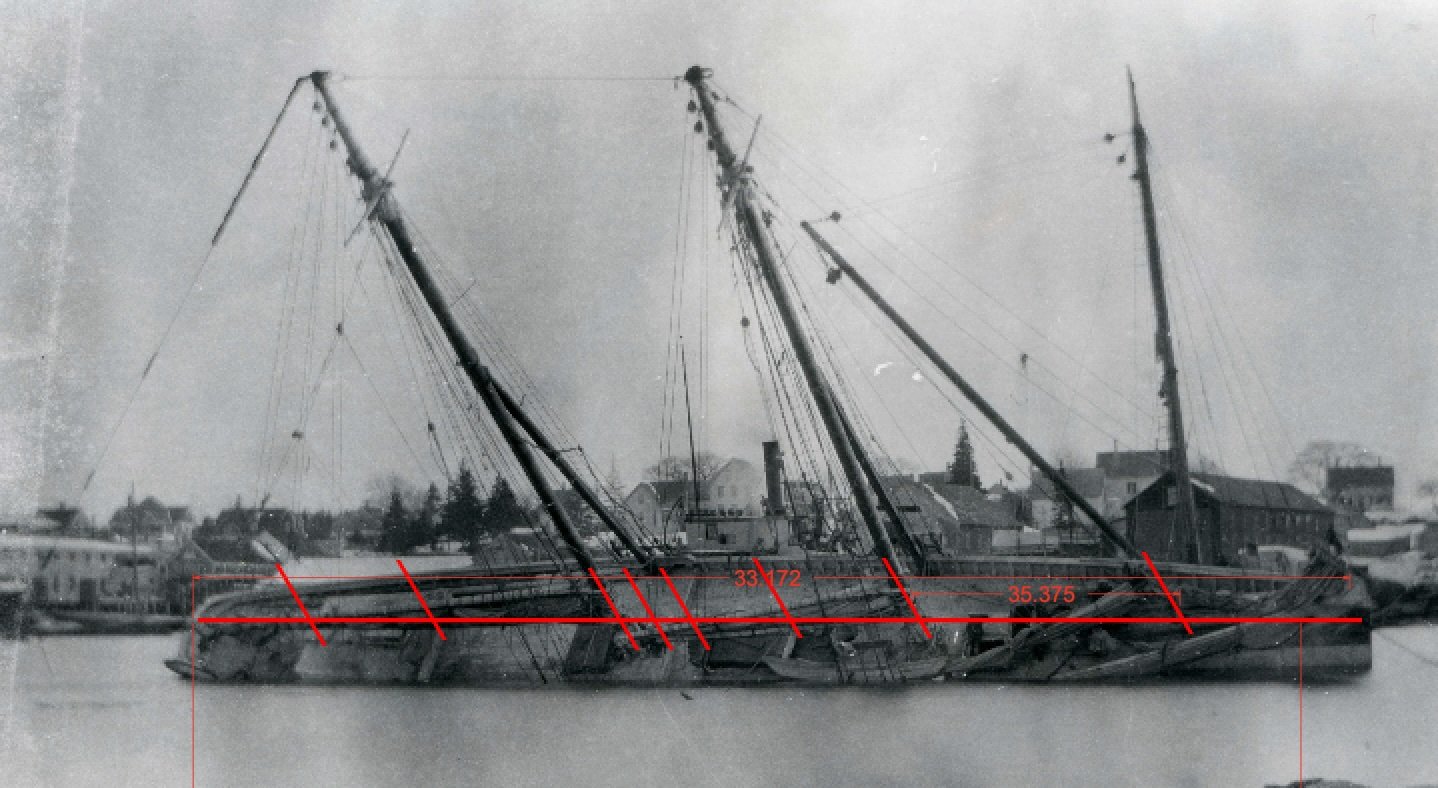

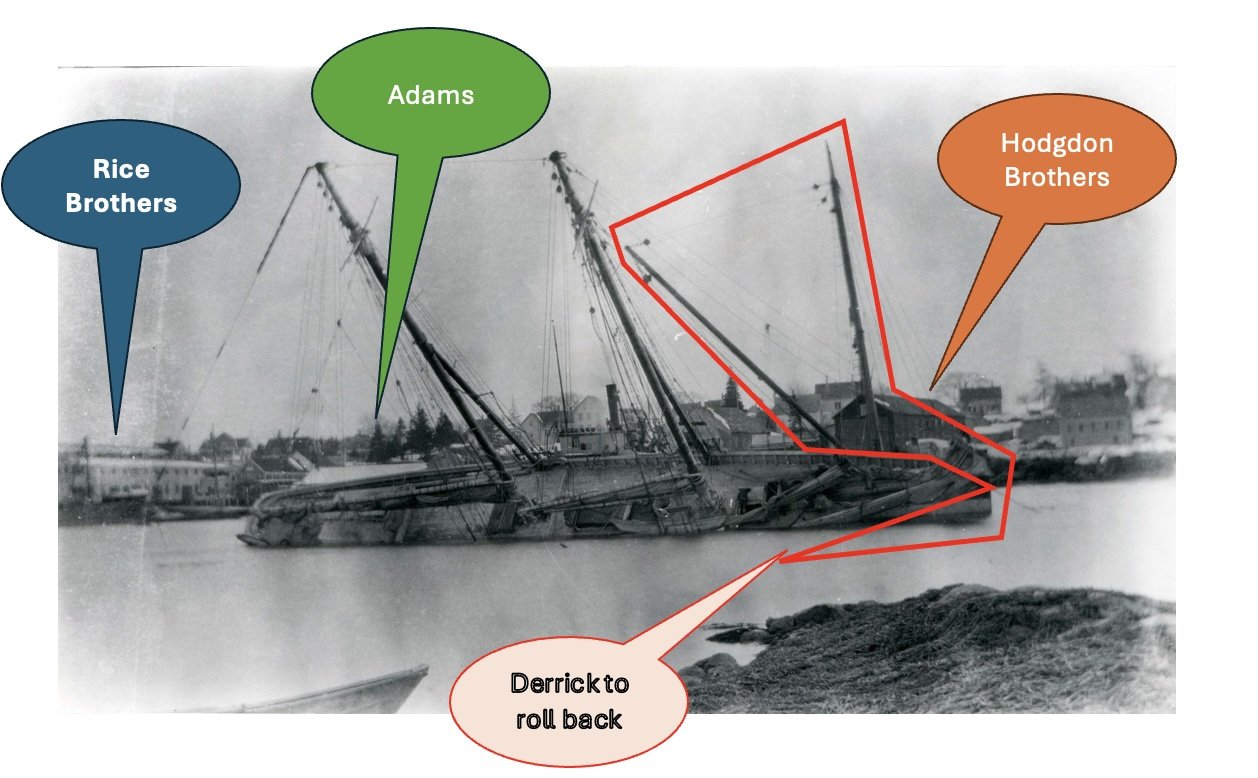

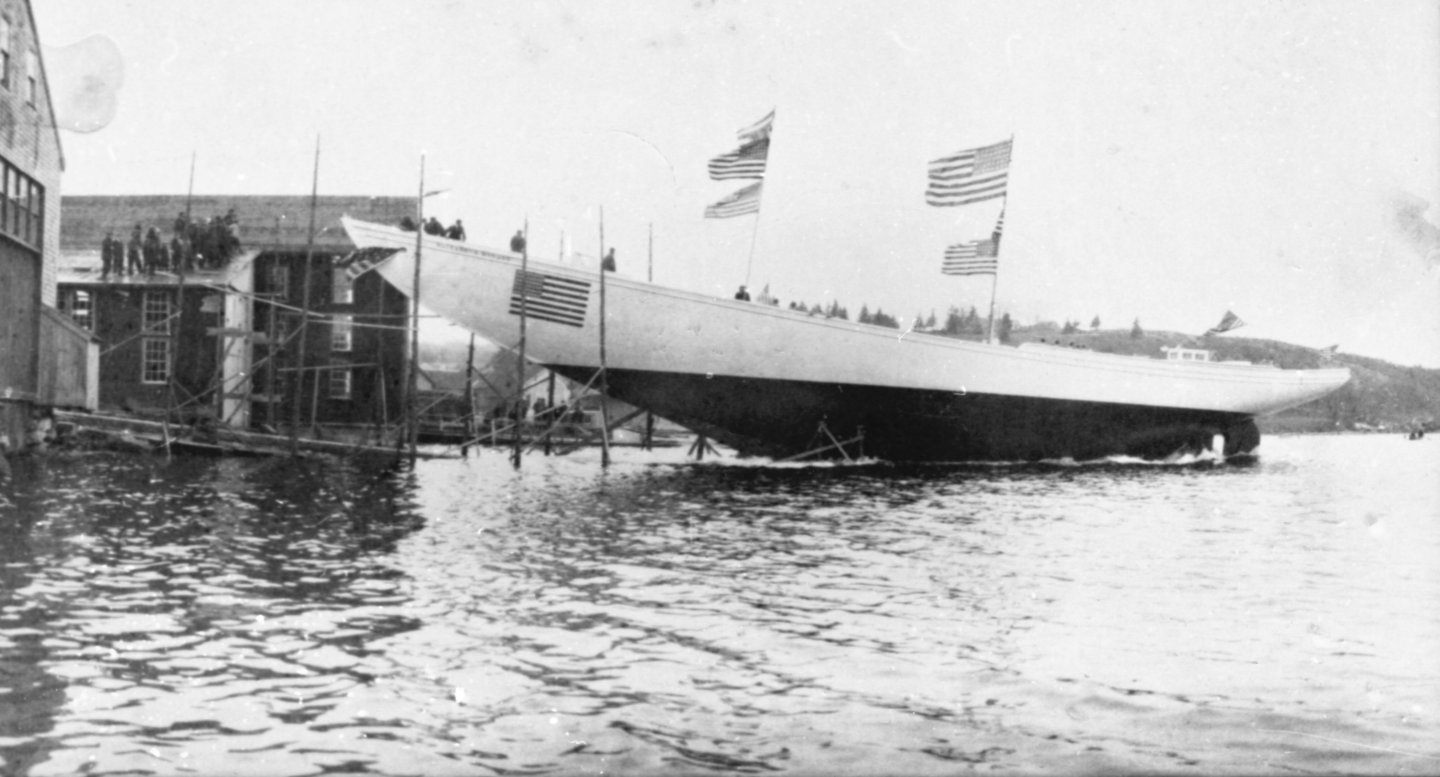

1 part b the oops revisited. Thank you all for your interest. the short answer is Allan once again is right on. I add this reply to the first post. I am happy that I will be able to answer the query as to what is in the photo of the January 1919 accident. Fortunately, there are a few more views that I share here. As the story goes, three years after her launch she was sailing by on her way to Boston and decided to come into the yard of her birth for a pit stop. The crew at the time were most likely not local Mainers, Boothbay at any rate. When they anchored, they were over a ledge, and unfortunately, they all went ashore for a break. Town is about two miles or so away and out of view. As the tide went out, over she went. See these two added photos. 4. looking East across the Damariscotta River 5 Looking west toward east Boothbay. That is the Hodgdon Brothers yard in the view. I took the image I shared before and annotated if for the record. In this view of interest, one can also see all three of the 1919 active yards of East Boothbay. One can then see the derrick barge beyond the hull. Presumably this photo is after they had pumped and rolled her back a bit. If one looks clearly ,as Allan did, the lighter colored bow is there. 6 here we see the annotations. In these early days she sailed as designed with no bow sprit. That appendage came later when racing. Just for fun I share a more recent photo of other sailors “ from away” coming into Boothbay and anchoring over a ledge….oops. 7. sailors “ from Away” fortunately, this event ended well as reportedly the crew had a nice evening in town and then about midnight, at high tide, Sea Tow got them away. Cheers

- 48 replies

-

Rick. always a pleasure to hear from other Mainers. Your work on Flying fish is incredible so I am honored.

- 48 replies

-

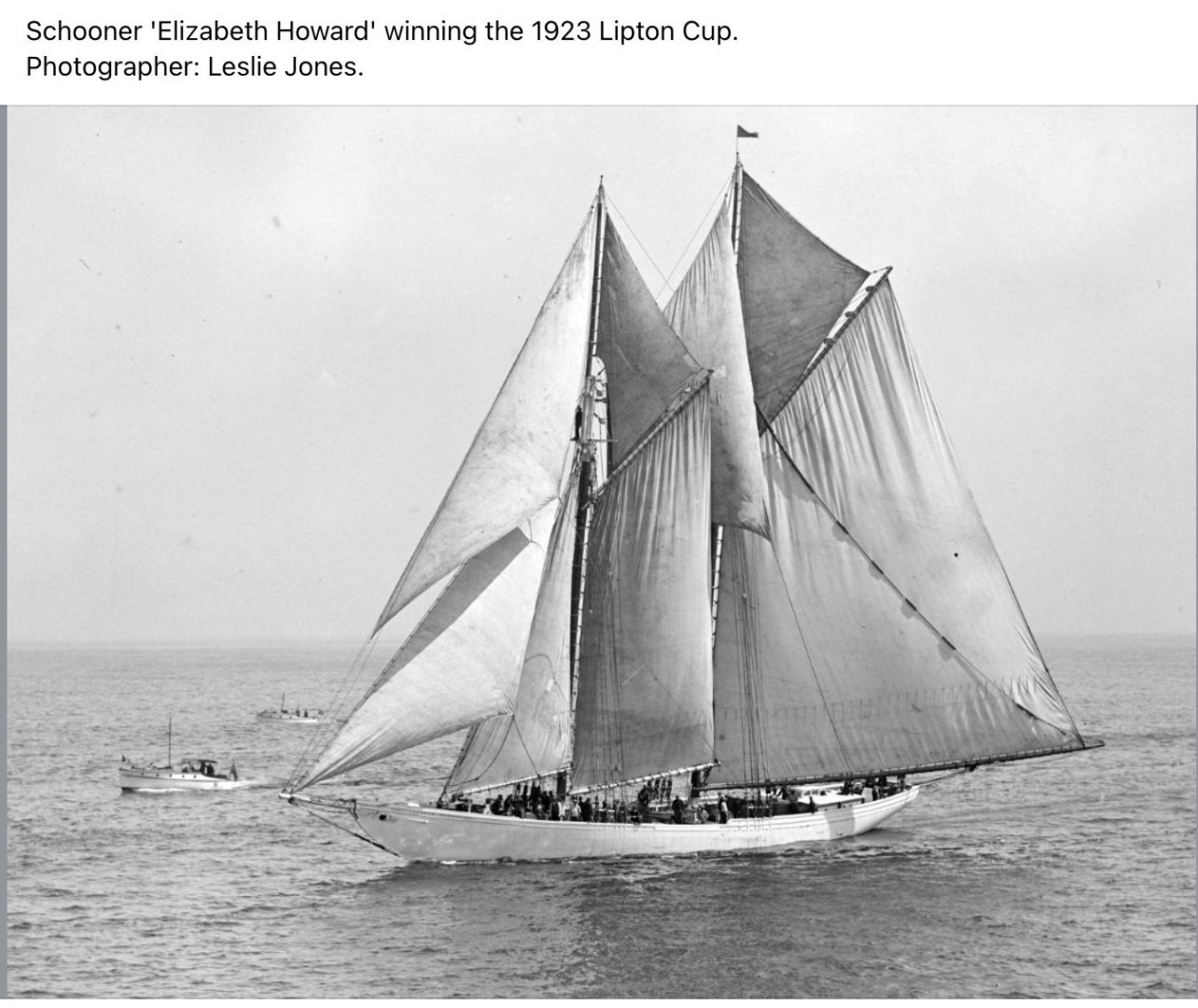

1 The beginning This part of a build tends to take the longest time. I have been mulling over modeling this schooner for at least 5 years. Where to begin? My introduction to her was seeing two pictures at our local Boothbay Region Historical Society. One view was of her launch and a second of an accident later in the same home harbor. 1 launch day 2 oops inexperienced crew perhaps better said " from away" anchored over a ledge, and we have 10-foot tide. The story and other images are in our local newspaper as a history article. It was January 1919, and she was full of fish. They pumped her out, took her to town, unloaded the fish, and raised her on the railway. All was well so then back to work. She was more of a hauler of mackerel than a fisherman in those days. Having recently completed my big Bluenose I moved onto other builds. Then a few years later I learned about her racing history….wow and from Maine too! 3. great view as she completed the Lipton Cup race in 1923 with Ben Pine at the wheel. this image came from Facebook site for the Fisherman Festival in Gloucester I then fell into an article from NRJ vol 46 starting on page 12. A member, Daniel Turner, did yeoman’s work to uncover the story of her mysterious length. Unfortunately, there are no surviving records from the Adams Shipyard here in Boothbay. Paul Adams, a grandson to the last builder is past 95. Sharp as a tack, he came to my talk a few years back on the history of the Boothbay Shipyards and sat in the front row. He corrected a spelling in one of my slides but alas when talking after he had nothing to do with the yards. As a matter of record, they had closed by 1921. Back to the story of why this build. I am trying to build things for each of our yards. The Adams family shipbuilding started about 1810 and ended 110 years later. Pinky schooners first and then many schooners, a few brigs, a ship, and other vessels ending with some tugboats and a motor yacht in 1920. Their last sailing vessel was the 3-masted schooner, Priscilla Alden. launched in 1918. I started to build a model of that schooner a few years back, but the records here showed a discrepancy in length of the Priscilla Alden, that I documented there and had to make a choice of who to follow. I chose to defer and build another schooner, the Ada Cliff built across town. Having recently built two steel hulled vessels I felt it time to go back in time a bit and take on another Schooner. I have about 5 of them on my to-build list and the White Ghost looks like a fun place to start. I highly recommend any schooner lovers out there, especially any Mainers or Bluenose people to chase down the NRJ article The Schooner Elizabeth Howard and enjoyed it. Ten years ago, I built a big Bluenose [ 1:24 scale]. I went to Lunenburg twice over that build and fell in love with the saga of the Fisherman’s Cup Races. In several books they talk about the challenger, but some focus was given to the field of contenders. More so when like the Starling Burgess designed Schooner Mayflower owners tried to enter. What they had built was truly a racing machine that only looked like a fisherman. She was kept out of the races due primarily to the small volume below decks set up to race and not to collect fish. It is interesting to note that one of the schooner Elizabeth Howard’s options was to be sold to the schooner Mayflower owners to use as a match boat if Mayflower ever would be qualified for the Fisherman Cup. There is a bit of fate to this story too. The Schooner Elizabeth Howard was bult in 1916 and was quickly followed by her 126-foot sister the Louise Howard in 1917. To satisfy her owner, Thomas McManus took is 1908 design for the schooner Oriole and extended her bow. As said above…she had to be fast! In her early years she was known for speedy long runs full of fish that she typically bought in Nova Scotia to race south. She was reported to do 16 knots in a good blow. When the Fisherman Cup races became popular in 1920, her owner wanted to get involved. The problem she had at first was that she was not associated with the Gloucester in-crowd. With a New York owner, and having been built in Maine, she was not accepted to enter the races. After the 1921 loss to Bluenose the Americans were scrambling for the next year rematch. The top two schooners to contend amongst four were Henry Ford and Puritan. The Puritan, designed by Starling Burgess, was launched in March 1922. As part of her prequalification, she was off to the grand banks to fish. Disaster struck and she was lost in her first summer. Ben Pine [ future Columbia and Gertrude Theobald skipper] was preparing to race her so now he was looking for help. After Elizabeth made a reported amazing fast sailing return trip to Boston from the banks and the schooner Puritan was lost, Ben Pine, made arrangement to get Elizabeth qualified. He then took her on and in 1922. In the best 2 of 3 series, she raced but broke a topmast on the first day and was beaten by the schooner Henry Ford in light air on the second day. The Schooner Henry Ford competed for the Fisherman’s Cup but lost to Bluenose. Elizabeth won the Lipton Cup races in 1923 but after that win, Ben Pine moved on to the new Starling Burgess designed Columbia. There is a large collection of photo images of these races on the Boston Library website. Elizabeth’s distinct white hull surely makes an impression, and it is easy to see how she got her name…the White Ghost. The unfortunate end of her story connects her fate to the schooner Puritan. It was later in the fall of 1923 when just like Puritan, she was lost off the coast of Nova Scotia. What was her length? Let’s look at her lines for a moment. Daniel’s NRJ article touches on the racing and then proposes a solution to the length mystery saga of the Elizabeth Howard. She was designed by the renown Thomas F. McManus. Howard Chapelle includes the lines of Elizabeth Howard shown annotated over the lines of an earlier 1908 schooner Oriole. The schooner Oriole was 127 feet at the rail. The only change was to push the bow forward [ in scale] 6.5 feet. The only reason to do this would be for speed. she started as a knockabout [ no bowsprit]. The confusion comes from a note on the Chapelle document stating the length at the rail being 148. The short version of Daniels work is a follows. • A Fisherman Cup racing vessel must be less than 150 feet. • The reported bowsprit added to Elizabeth was 14 feet long. • If one scaled the Chapelle drawing showing the extension one gets 133’6” • Add the bowsprit and you are under 150 at the recorded 148 feet. Go with the 133’6”. I think that is more than good enough and it is what I will try to build. All for now

- 48 replies

-

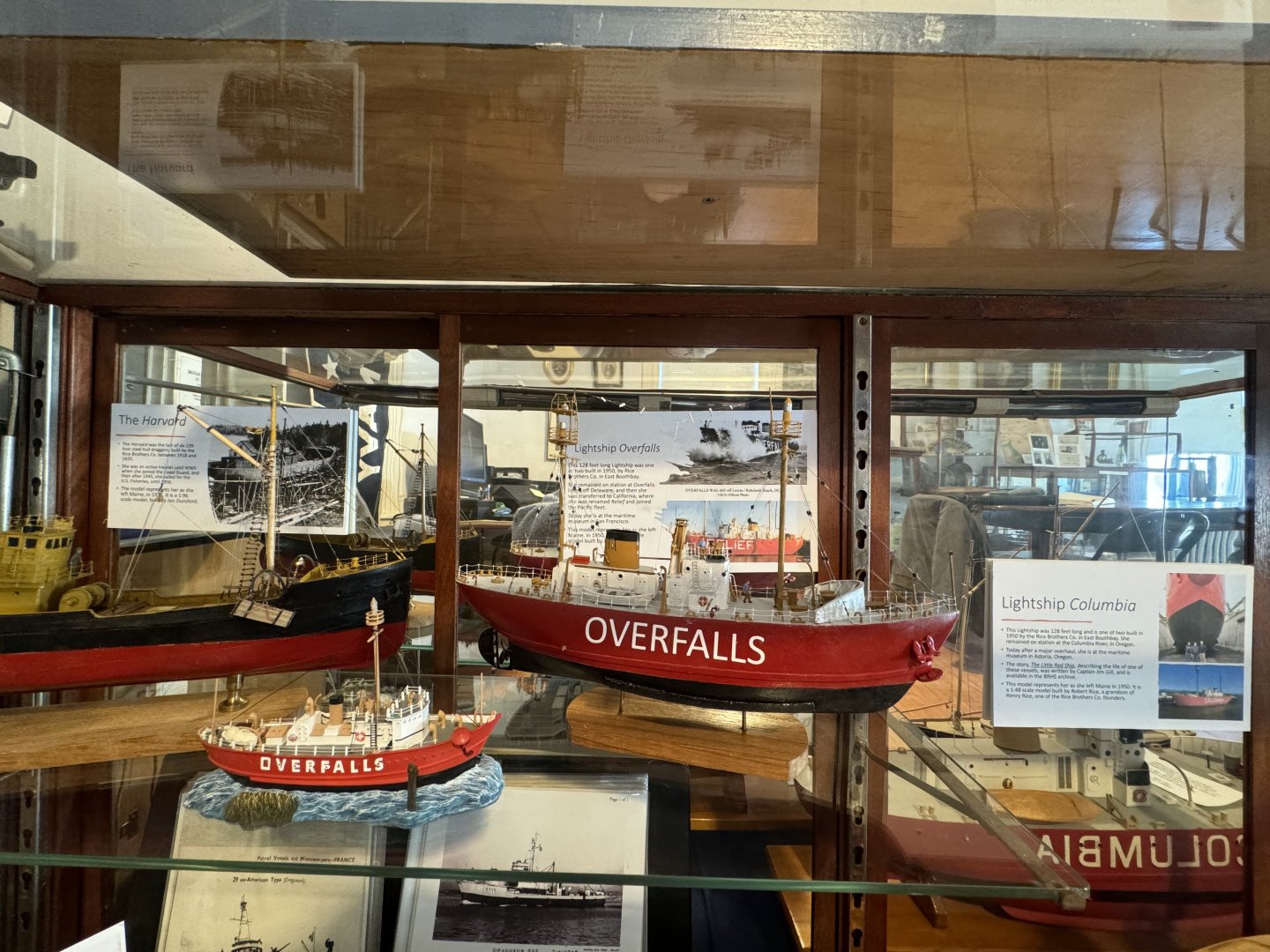

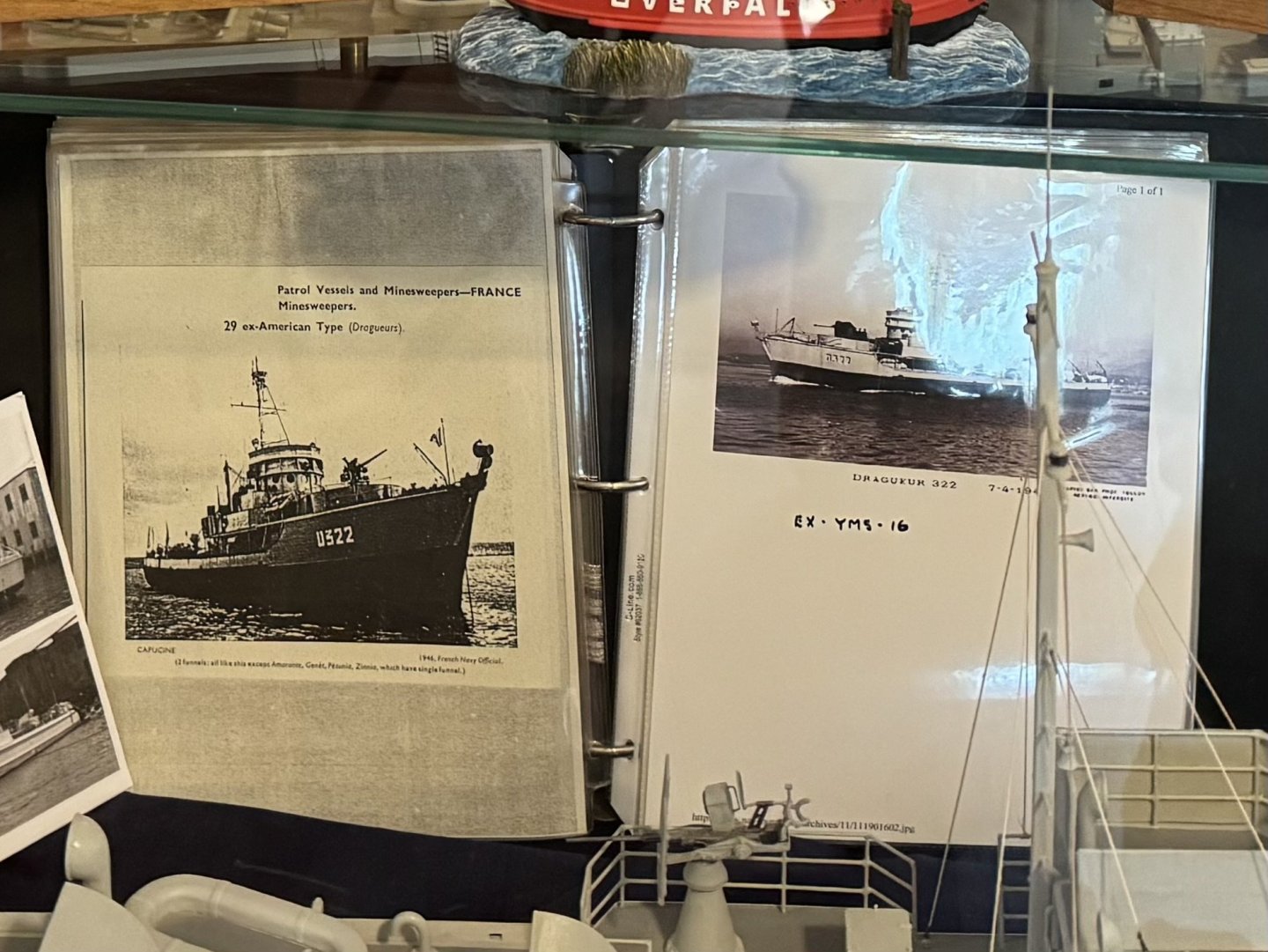

9 The end It has been several months since setting this model aside to wait for its partner. Both this model and the Dragger Harvard of the Rice Brothers shipyard are now on display at the Boothbay Region Historical Society for the summer. I will give a talk in July on the History of this yard and its people and that event will end this effort. Here are a few images of the display. They include my two models and three made by Robert Rice , grandson of the founding Rice Brother Henry. Robert recently donated his collection to the society including these three models and 20 volumes [ one sample in photo] of photos, news clippings and other data tracking the 70 years of their work. the yard not only built 4 US :ightships, but 11 subchasers and 11 minesweepers during WWII. the yard today ois the very successful Washburn and Doughty yard building many sea tugs. I am now off to another build and look forward to more sawdust

-

12 The end...... It has been a while since i last updated this log, and now I am planning another build, so I thought I needed to add the display photos of the completed model and close this log. I include a batch of 10 photos I took a while back. Unfortunately the crew had not yet arrived. This summer we are celebrating the Rice Brothers shipyard at the local Boothbay Region Historical Society. As I have shared in the log previously, I have been meeting regularly with Robert Rice the last living heir and grandson of the founding brother Henry. Robert has also donated much of his work to the society this spring. Here are 2 photos of the combined display showing his three Models along with my two. I will give a talk in July and then it will be done. Here are views of the combine collection and my contribution. on to the next one...Jon

- 41 replies

-

- steel

- beam trawler

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.