-

Posts

26 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RodR

-

Thanks everyone for your encouraging comments. Now for the other side of the hull. Pat and Geoff, I hope to have that finished so that I can bring the model along to the next club meeting. Its amazing the sense of satisfaction that you get from doing something like this isn't it. Easy to see why it is so addictive. Cheers Rod

- 33 replies

-

- perseverance

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Hi Sjors, I would love to start on the Aggie tomorrow but as they say, you must walk before you run. I am very much a beginner and need to get a few easier models under my belt and gain a lot more experience before I tackle such a big and complex build. Thanks for the encouragement though.

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Hi David, Great idea using the exacto chisel to simulate the butt joints. Looks perfect and so much easier. I have those exact razor blades from my tool store so will give them a go and see if I cant clean up the deck a little. I used a cabinet scraper that I had from years ago but I think it needs sharpening. Thanks for the tips. Cheers Rod

-

Hi George, Your Aggie looks brilliant. Its so good to see so many build logs for this kit. Keep the photos coming. All the best Rod

- 83 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

HMS AGAMEMNON by PMG - Caldercraft

RodR replied to PMG's topic in - Kit build logs for subjects built from 1751 - 1800

Beautiful workmanship Pierre, I will be watching closely as I have this kit and hope to start it once I get a few more easier models under my belt. Cheers Rod -

Hi Sjors, Another great Aggie that I will be watching as it takes shape. By the way, do you have shares in the Proxxon company? lol. Cheers Rod

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Hi Pat, Glad to see your progressing again after your little mishap. Out of interest did you spray or brush on your clear coat on your hull? Cheers Rod

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Hi Mike. What a beautiful build. I am watching a number of Aggie builds on the forum. With so much information on hand I should have plenty of tips when I get around to starting mine in 2 or 3 years time. All the best. Rod

- 150 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi Mobbsie, Your ship is simply stunning. I have this kit but it will be a while before I have the skills and experience to make a start on it. I have printed out this entire build log for when I do start it. (just in case all the site content is lost again). Who needs instructions when you have a build log like this. THANK YOU. Rod

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi David, I will be watching closely to see how you deal with the plastic boats. I hope you don't mind if I copy your companionways. They look so much better than the way the instructions say to do it. Also how did you simulate the caulking on your deck planking? It looks very neat, especially the butt joins. I did mine with a 6B pencil but I found that the graphite got into the grain on the timber. I guess it gives it a more weathered appearance but the rest of the boat will look brand new. Cheers Rod

-

I still cant believe that this is your first model! Your workmanship is simply outstanding. What's your next model Ollie? Cheers. Rod

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Didn't get to go fishing today. My wife had other ideas so in between lots of household chores, I managed to finish the second planking on the starboard side of the hull. I ran into a bit of trouble as I neared the end and the last plank had so many undulations in it to fit the final gap, that it looked more like a snake than a plank! I cant believe how long this took me. Either I'm just very slow or there is a simpler way that I'm yet to figure out. I've given it a rough sand but will wait until I've done the other side before doing a final sand. In the DVD instructions it says to give the whole hull and deck a spray coat of satin estapol. Should I do this before adding the wales, stanchions and deck railing caps or after they are all glued on? I'm really enjoying building this model but cant wait to get to the deck fittings etc. This planking caper is hard work! Cheers Rod

- 33 replies

-

- perseverance

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Finally managed to find some time to continue with my hull planking. After doing the "easy" planks I had to begin the tapering process. I divided the remainder of the hull up into three sections using a planking batten as suggest in the article on MSW and this seemed to make it a bit easier. After what seemed like 5 hours I had completed a grand total of 10 planks! I hope I get faster at this! Anyway, I'm pretty happy with the way its turning out. After a good sand it should come out pretty smooth. If its raining tomorrow, I wont be going fishing so hopefully can finish off this side of the hull, so long as the better half doesn't find a whole lot of other jobs for me. Cheers Rod

- 33 replies

-

- perseverance

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Thanks Guys, I've made a start on the 2nd layer of planking this morning but I've already run into a problem. I've fixed two mahogany planks, followed by 3 silver ash planks as per the instructions but the join between the silver ash planks in particular is not perfect (see pics), presumably because the edge of the planks are not perfectly true. Do you routinely sand the edges of these very thin planks prior to gluing them to the hull to ensure that they join perfectly up to the plank above or is there another way to avoid this effect? Thanks in advance Rod

- 33 replies

-

- perseverance

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Ollie, you have done such a beautiful job on the hull planking, it seems such a pity to cover it up with copper plates! cheers Rod

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Thanks Matt. In the end I decided to plank the stem, keel and stern post. It's not as good as solid timber but looks a lot better than the plywood parts that came with the kit. It has also given me a pseudo rabbet into which I can butt the second layer of planking as the instructions just say to epoxy the keel, stem and stern posts on after the second layer of planking is completed. Because I had already faired the false keel at the stern I had to add some filler to ensure that the 2nd planking layer will be level with the veneer I just added on. I haven't had much time to do much work on her this week due to work commitments but I have most of the day set aside tomorrow to make a start on the second layer of planking. Hopefully I will get most of it done tomorrow. Thanks for the tips. Rod

- 33 replies

-

- perseverance

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Hi Mat, Your model of the Perseverance looks really nice. From the photos, it looks like you planked the keel and stem post? I added the plywood keel and post but didn't really like the look of them and was considering planking them with timber to match the hull planks. Banyan suggested to remove them and build solid timber one instead but I'm afraid I might make a mess of the planking trying to get them off now. Cheers Rod

- 33 replies

-

- perseverance

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Hi Pat, Yes, I really enjoyed last night's meeting. Seems like a very nice bunch of guys and I was made to feel very welcome by all. I can see that there is a lot of experience in talent at hand so hopefully I can learn a little each month. Thanks for the tips on the second planking with the map pins and the balsa and rubber bands. I will give both a go and see how I go. Where do you buy the Titebond? I have looked at Bunnings but they only seem to stock Aquadhere. I've been using the fast set Aquadhere so far and it seems to be working well. I will PM you and get your contact details as suggested. I would certainly welcome your expert advice as I progress. Thanks for the advice on using the medium CA Alistair. I used to scratch build planes and used CA a lot back then. I understand what you mean by making sure each plank is tapered, curved and beveled before you actually try gluing it. It makes sense but I do have a question. I have just read the articles on MSW about spiling planks. I think I understand how to do it but how do you know when you should do it? Cheers Rod

- 33 replies

-

- perseverance

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Ollie, I am relatively new to the site and to model ship building but I read through your log last night. You are doing a beautiful job considering that this is your first model. I too am doing a Modellers Shipyard kit and the instructions call for gluing the keel, stem and sternpost to the finished layer of planking. I see that you have installed them prior to doing your second layer. This makes more sense to me and I will do the same. I really like your idea of the wide push pins. I was wondering how I was going to hold the planks in place without actually putting holes in them. Problem solved - Thanks very much Keep up the great work Rod.

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

I learned a valuable lesson tonight. Before asking a question do a search on MSW first. I wanted to know whether to use contact cement or white glue for the second planking. I should have realized that most of my questions will have been asked by hundreds of others before me and its simply a matter of searching properly. I finished the deck planking tonight so now onto the part that scares me the most - the second planking of the hull. No room for errors now. Wish me luck!

- 33 replies

-

- perseverance

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Hi Bindy, I looked at "The Mermaid" also but I just liked the look of the Perseverance, especially as it has two masts versus one. It is the same skill level (2) and the guys at Modellers Shipyard didnt feel that it was beyond a newbie, especially with the DVD instructions. Its also substantially larger for not a lot extra cost which you can offset by borrowing my DVDs instead of buying the set for the Mermaid. Cheers. Hi Geoff. Yes, Leon Griffiths has lots of good tips but I cant help thinking that he should have put a shirt on when making the DVDs. Seeing him sitting there in only his stubbies certainly cracked me up. Cheers

- 33 replies

-

- perseverance

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Thanks for the encouragement guys. For the second layer of planking do you prefer contact cement or white glue? The contact cement method worries me as there is no opportunity to adjust the fit once the planks are laid. If you go the white glue, how do you hold the plank in place as I dont want to stick pins through the planks as per the first planking. Thanks again.

- 33 replies

-

- perseverance

- modellers shipyard

-

(and 1 more)

Tagged with:

-

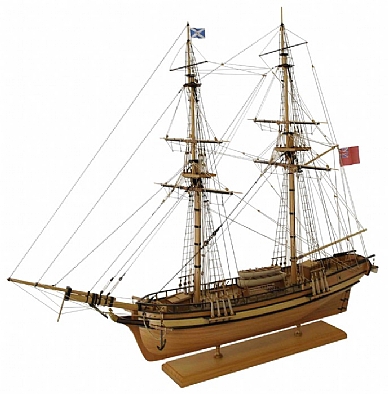

This is my second attempt at a wooden model ship after failing miserably several years ago - basically as I had no idea what I was doing and the kit I attempted had very poor instructions. I chose the Colonial Brig Perseverance for two reasons: According to the guys at Modellers Shipyard, it's not too complex and ideal for a beginner, and It comes with a 3 DVD set showing a "master model maker" construction the model from start to finish. This really appealed to me as at the time I began, I had not discovered Model Ship World and really needed some guidance. Here is the DVD cover and a photo of the completed model (not mine!) As I am a new modeler its difficult for me to comment on the quality of the kit although the timber certainly does not seem to be as high quality as the timber in the Corel Unicorn kit that I started some time ago. The limewood planking varied considerably in thickness meaning a lot of sanding on the first layer of planking but I don't know if this the norm or not. Also, the silver ash deck planking varied considerably in width with some pieces 3mm, some 4mm and some 5mm wide. Again, is this generally normal or not for a kit???? Unfortunately I started the model before I discovered MSW and therefore I don't have any photos of the early stages of construction. I bought myself an Amati keel holder which has been very helpful. The bulkheads all fitted nicely to the keel and the fairing process although it seemed to take forever went smoothly. Fitting the false deck also was a breeze. As I am sure most beginners find, the first four or five planks went on very easily and I thought to myself, "this isn't hard at all", but soon I was needing to taper planks and to bend them laterally which I found rather challenging especially around the transom and onto the deadwood area. I only needed a couple of stealers and made them (like wedges) as per the DVD instructions but I have since learned that tapering them to a sharp point is not really authentic. I guess it won't matter for the first planking. I used one of those Amati plank benders which crimp the planks to illicit the bend and it worked just fine but I found that later when I came to sanding the planking that the crimps showed through. Perhaps I am not using it properly and squeezing to hard??? Anyway, after several nights, I finished the planking. Overall I was fairly happy with the result as there weren't many hollows or gaps to fill although I did need to fill a little where the planks transitioned from the hull to the deadwood as I was getting a bit of "clinker" effect. Not sure how I should overcome this??? I made a big mistake of using a mixture of undiluted white glue and sawdust from the sanding to fill this area however when it dried it was so hard that I had to sand it for ages and ages to get it down to a smooth finish. I also sanded too heavily on one side where the planks bend around the tuck to the transom. I realize now that this was because in the DVD, the instructor crimps the timber to make the bend but then files it to about 1/2 its original thickness. I didn't take this into account when I started sanding and before I realized, made a nice little hole in the planking. I still need to give the whole hull another sanding but will wait to do this until I finish the deck planking and a few other little jobs. I really enjoyed planking the deck apart from having to color in all the deck edges using a 6B pencil. Because the deck planking is only 0.6mm thick I found that it kept cutting the pencil lead off. Although the instructions call for laying the decking in one long length, I decided to cut them into 100mm lengths to get a more authentic look. I came unstuck because all the planks were of various widths and therefore I had to try plank after plank until I found one that matched the already glued plank perfectly in width. Next time I will keep each cut plank together with the others that come from the same length to avoid this problem. Another thing that seemed odd was that the instructions called for installing mahogany strips to the inside of the bulwark which I duly performed and then the installation of the deck. I had to cut and sand all of the edge planks very accurately so that there were no gaps between these planks and the lining of the bulwark. I would have thought that it would be easier to install the lining to the inside of the bulwark after the deck planking has been laid as it will cover up any small gaps. Is this generally the correct order to do these two tasks??? One thing that is troubling me is that the instructions state that I should epoxy the stern post, stem post and keel to the hull after I finish the second layer of planking. I note that in many of the build logs on MSW these items are fixed after the first layer and then the second layer of planking is butted up against them. This makes more sense to me. Any advice greatly appreciated??? So this is where I am up to and where I will commence adding photos and no doubt asking lots more questions. I have included some photos of my model below. Its a bit rough but I am hoping that my second layer of planking will be much better and hide all of the mistakes I made in the first. Thanks in advance for any hints and advice.

- 33 replies

-

- perseverance

- modellers shipyard

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.