-

Posts

904 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by drtrap

-

-

Hi,

In regard to these comments about copper bottoms, I don't particularly like very bright copper, but I don't like the mottled blue and bright finish seen in many pictures. I have done one or two bottoms using copper tape, not individual tiles, and did not have trouble with discoloration. Tape doesn't need cleaning either. What I did was use garnet shellac, somewhat darker than the usual orange shellac, immediately after finishing the application, both to protect the copper and to tone down the color.

Chazz

....shellac?

What's that Chazz?

Thanks

Stergios

-

-

-

-

Dan, Von Stedina

thank you so much for your help.

I'll try to manage the issue with another product I'm waiting for, just to compare its action on the copper.

I'll keep you informed, thanks again

-

-

Hi all

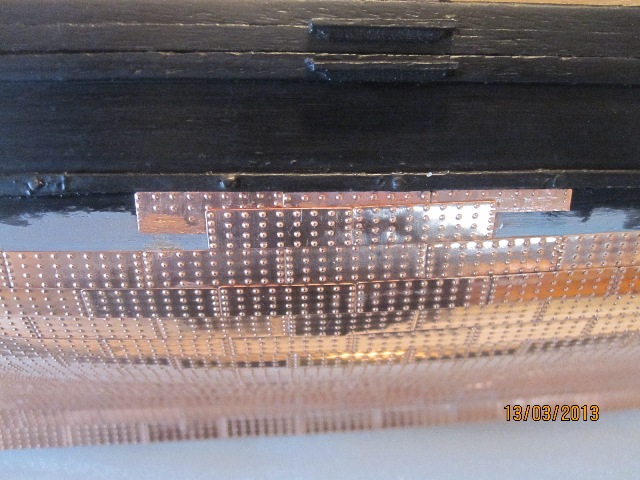

I'd like to show you these pics, taken two days after the 3rd, final application of a special shining ointment for metals.

How you can see, some "dirty"-corrosive spot arised despite me intense care to apply the cream onto the whole surface of the tiles.

My aim was to "seal" (after the cream application and polish) my shinning coppering with two layers of varnish for metals just to protect the copper against the odidation etc....but know I really dont know what to do...

Any help/suggestion from anyone copper-specialist on this issue? How can I solve this problem with those two-speed corrosive tiles?

Thank you so much in advance.

-

...and the result with the new bow grating angle.

I lost the close up photo, but one thing you can just see in the bottom picture was the enlargement of the slots for the gammoning. As supplied, these slots were not long enough to allow the gammoning to be done properly but it was pretty easy to extend these using a needle file.

Hi Jason, I'm still have'nt understood why you did extend the slots of the gammoning. I think that its geometry, position and fitting would have been the same one way or another...

Thanks

-

Did you use the polish on all the tiles? Whatever you do it's probably best to do across all the surface as that will get rid on inconsistencies. I know I used the cleaner even on areas that didn't really need it just ensure the fish was consistent.

Yes, I've applied the cream on all the surface just to create a unique and acceptable appearance. The point of concern is that (and why..?) there are two-speed corrosive tiles...

Thanks

-

-

Hi Jason, I'm still in work now, I'll do it asap.

Thanks

-

Mmmmm, two days since the last application of the polish cream and some corrosion tiles- spots make me feel at least uncomfortable. There is a noticeable difference by looking the copper's surface between those spots and the other, "healthy" coppering...

I was ready to apply a metal varnish to "seal" the tiles but now I don't know what to do...

Any advise, from anyone?

Thanks

-

Absolutely nice and clear work jason.

I'm so delighted in following!

Stergios

-

Could you please help me with the pintles and gudgeons of the rudder ? I'm trying to locate these parts in the kit but is'nt easy as I can't find their reference number in the list...

Ok, got them!!

-

Could you please help me with the pintles and gudgeons of the rudder ? I'm trying to locate these parts in the kit but is'nt easy as I can't find their reference number in the list...

-

I used acetone - nail polish remover, wire wool used carefully wont scratch the copper that you would notice, just be carefull about leaving the odd strands caught in the copper. If you are worried about wirewool try a small piece of a scotchbrite pad, these are used commerically to clean circuitboards in processing.

I still wouldnt use polish even using a tooth brush to remove the residues as you will be adding water which will be trapped behind the plates and you will stand a chain of getting water stains if it drips out.

Thanks again Norman.

-

I just cleaned the plates with some fine wire wool and a little solvent, polish of any kind will leave unsightly residues in the plate gaps. If you lacquer the copper after a time it will tarnish in any small area where the lacquer is not perfect seen it so many times in brass fittings etc. I prefer to see the copper discolour naturally but in doing this you must remove all traces of an fingerprints as these will tarnish must faster and really leave unsightly marks - I know this all too very well from my days in the printed circuit industry as a quality manager.

Norman, theoritically I was considering wool wire as a dangerous tool, because of possible scratches on the cooper tiles after use the finish with it...

On the other hand polishing with paste leaves such unsightly debris as you say between (and on) the tiles. I'll test the wool wire in practice, trying to make clear first the nature of the solvent you have used. Waiting the brand or type of it, thanks

-

I just cleaned the plates with some fine wire wool and a little solvent, polish of any kind will leave unsightly residues in the plate gaps. If you lacquer the copper after a time it will tarnish in any small area where the lacquer is not perfect seen it so many times in brass fittings etc. I prefer to see the copper discolour naturally but in doing this you must remove all traces of an fingerprints as these will tarnish must faster and really leave unsightly marks - I know this all too very well from my days in the printed circuit industry as a quality manager.

Hi Norman and many thanks.

Which kind o fsolvent did you use?

I can suppose that I must be very careful with all those chemical-good standing with the copper.

-

Hi Stergios, nice to see an update, looking very nice. I smiled looking at your picture at all the copper plate cuts offs on your work mat, I'm still finding these on the floor!

Yes, the plates will oxidize/tarnish over time. I think acid in skin oils speed up this process which was why I did a final clean to make finish consistent as fingerprints had become quite noticeable in places. I quite like the look of the tarnished metal as it lends a sense of age, but as always its down to personal preference.

Hi Jason and thanks.

I don;t remember quite well...Have you used anything else except the polishing liquid/paste (Noxon, I think...)?

-

-

Thanks a lot mates, I'll do my best....

-

Jason,

When tiling the bottom edge of the keel did you trim each tile to the correct width?

Hi Jim,

how didi you cover the bottom edge of the keel with the tiles?

The width of the side tiles & the keel is a bit narrower than the tiles and I 'm thinking what to do...

Thanks!

-

-

Can't help you for the moment Jason...

I'm many steps behind you....

Coppering wear

in Building, Framing, Planking and plating a ships hull and deck

Posted

...too late, Garward!

Two layers of varnish are already...in situ!

Thanks anyway.