-

Posts

2,882 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

A "do over" would certainly reinforce what I hope I've learned... just not looking forward to starting from scratch. It would definitely be better organized the second time. Can't seem to turn my back on the progress I've made to date. My NRG mentor suggested I might have imported the drawing to CAD and traced it versus trying to measure everything. I'd still have to contend with paper stretch but it would be faster and lines would align. Starting over??? Holy old bald headed Saint Dulabon... what have I gotten myself into?

-

Good morning world! I have been busy building my modelling table and dealing with summer. Getting back into all this with fresh eyes and I've noticed a few things I had done that I cannot recall "why". (a great advocating point in favour of the build log notes idea mentioned in another forum) Seems I have a double set of station lines and I've no idea why.. apparently I had changed something and left the original set in. I am trying to determine if I had erroneously used a wrong one anywhere I've measured (what I believe to be meticulously) off the drawing and laid out the keel, stem and stern posts and rabbet line along with shown scarf joints and they do not align properly. . At the moment I am extremely frustrated and am very close to shelving what I've done to date, chalking it up to a learning experience and starting over from square one. Another thing that has been nagging at me is the fact that I'm working off the Elephant plans but the Bellerophon contract has a penned notation (correction) to the length changing it from 168 feet to 170 feet long. This extra 2 feet (1/2" at 1:48) won't leave my mind... I cannot let it go. I will continue to try to determine if I can salvage what I've done or start over. I cannot adequately describe the feelings I am having at this moment Alan

-

what is the ideal modelling table?

AON replied to AON's topic in Modeling tools and Workshop Equipment

Thanks guys Can't wait to start building on it Drafting (draughting) table? I moved on from that about 25 years ago. Still have my pencils, compass and accessories, brush, sanding board, triangular scales, french curves......... Might even have a few sheets of D size paper in a tube. I'd need a cover ... and a place to put my model!! -

what is the ideal modelling table?

AON replied to AON's topic in Modeling tools and Workshop Equipment

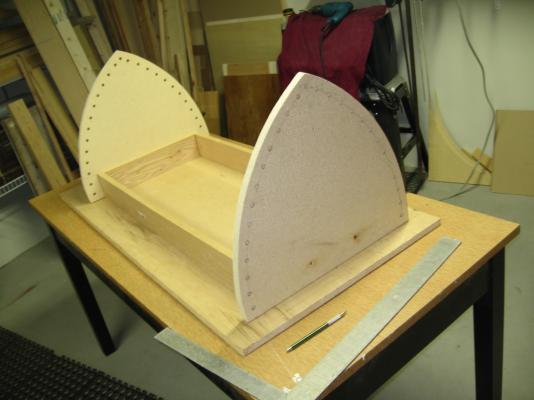

I managed to put in more time on my modeling table build and it is near done. (Pictures follow below) I installed the short cross braces at the bottom of the end legs These are held in place with screws and metal brackets below and above I then installed metal shelf hanging brackets (I had been saving these for years) Then built the shelf / long cross brace Cut the shelf and two stiffeners to length Marked off the location of the shelf bracket so the braces would be located just clear Chalked screw centre lines and outer edge of brace Clamped the brace to the shelf aligning it to the outer edge chalk line Drilled pilot holes, drilled countersunk holes and screwed in place Wood puttied the holes above the screw heads Installed the shelf and screwed to the bracket from underneath Installed the four pivot pin support brackets Cut my 3/8” diameter aluminium rod into 4 equal lengths Ground a radius edge on one end and taper on the other Bent a pull tab at 90° on the radius end about 1-1/2” long Installed the pivot table and tested it out … it didn’t work The holes were to tight and minor misalignment caused binding Opened up all the holes… yes all of them Now the pivot option works! Left to do… 1. Finish the table top edges 2. Paint 3. Final Clean up My breaking news: My darling wife saw my work spilling out of my play area and spreading all over the basement. She (who must be obeyed) suggested I need to enlarge my work room (don't have to tell me twice ... another project!!!... ????) Alan -

what is the ideal modelling table?

AON replied to AON's topic in Modeling tools and Workshop Equipment

GOOD MORNING ALL! I will admit I was concerned about sturdiness of such a narrow (24") work table when raised so high but am happy to announce this table is much more sturdy and solid than I expected. Once I have the shelf on the bottom the centre of gravity will be lowered and it will be slightly better grounded yet. I had even pivoted the table with the pins inserted to get a feel for the usefulness of the feature and it gave me that warm and fuzzy feeling of a thing done right. Even if used only a few times it will be worth it to me. The "walk around" versus the "Lazy Suzan turn table" feature was a compromise for space and further expense. I am feeling good about this decision also but have not glued the top down so I can instigate plan B at any time in the future. The 3" wheels that were purchased with the lift glide extremely smooth and easy, absolutely effortless. I just need the lighting installed overhead. It also took awhile to settle on 24" x 48" for the build portion as I was going to go 18 or 20" x 36" but after reviewing build scales and the fact I didn't want to do this twice 24" x 48" seemed practical with regards to ergonomics (comfort and arm reach) This is all about comfort for me, storage of the build while under construction, storage of the wee bits and pieces between my visits. The size seems too large at the moment but if I go 1:48 scale (which I am really getting serious about) it will be perfect. As usual I am thinking ahead to a "tent cover" to keep the dust off the build. -

what is the ideal modelling table?

AON replied to AON's topic in Modeling tools and Workshop Equipment

sorry no orders once this is built I start my Billy Ruffian build -

what is the ideal modelling table?

AON replied to AON's topic in Modeling tools and Workshop Equipment

Did some more work on the table this weekend. Following is a description of the work and some photos 1. built frame work for the pivot table (picture of set up to drill dowel pin holes) 2. assembled the sub table top to the frame (drilled and screwed) 3. assembled the finished table top to the sub top (drilled and screwed) 4. applied wood putty to the screw holes 5. assembled the tracks to the table top (drilled and screwed) 6. assembled the pivot table to the table assembly, Temporarily inserted the pivot pins and... they would not assemble. Lifted the pivot table to take a look and the very first set of screws (step 2 above) went through the pivot pin holes, effectively blocking them. 7. take all the screws out of the top sheet (this meant digging out the wood putty). Remove the four offending screws and insert shorter screws. Check that they were indeed short enough. Reassemble the whole thing a second time. 8. cut out my primary pin support blocks (the pin goes through this block first then through the hole in the pivot plate, then through the hole in the frame. This way the 3/8" diameter aluminium pivot pin is supported both sides of the pivot plate) 9, added furniture button gliders (the white round button behind the block on the frame) onto the stationary frame so when the table is pivoted the wood will rub against the glider, not wood on wood) 9. I also added a strain relief to the electrical power cord (the green rectangular shaped box over the black power cord) Left to do: - complete the pin support blocks - assemble blocks to table frame - complete and assemble the pivot pins - add the leg cross bracing and shelf - painting -

I managed to copy the underside shape of the hull onto paper and then cut and paste this to cardboard. The black mark on my profile gauge is the overlap I made on the profiles to assure everything aligned. I'll cut out the cardboard to make the template that will fit against the hull. I'll then trace the skeg profile I want to build onto to cardboard template. This will be fitted and adjusted to "look good". I'll then cut the shape from wood stock with my band saw and finally finish the shape with hand tools and a sander. Once fastened to the hull I will fill and blend the gaps with wood putty.

-

Thank you Bob. The measurements will help me scale my additions from any schooner photographs I might snag off the inter-web (including models here!) Alan

-

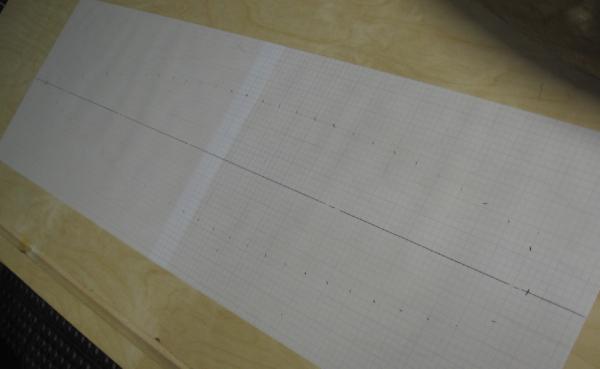

Here are the photos ... and yes that is my unfinished modelling table I am using The lift feature came in very handy! It is definitely going to get a lot of use 1. plotting the shape 2. chalking the centreline 3. drilling three tiny centreline holes 4. the plotted shape got to go time to work.

-

I set the hull upside down on graph paper and centred the stern to the bow using a square. I then marked reference (station?) lines at 1" intervals onto the hull and graph paper Now I have the top profile on paper and reference marks on the hull The model is 6-3/4" wide x 30-7/8" long (171 mm x 784 mm) I then got out my trusty chalk line and established a centreline along the bottom I drilled three tiny shallow holes on the chalk line as it will rub away This is my permanent (until covered) reference for the centreline My next step (tomorrow?) will be to use my profile gauge along the underside of the hull to trace the shape to transfer to a template. I did take some photos (to be posted later today) but have to get ready for my day job now. Hi Ho, Hi Ho, It's off to work I go............................

-

The Refit of the Schooner “CHARLIE” 16 June 2014 I have taken on a diversion project which is to complete a build started by a co-worker’s step father whose health has deteriorated to a point he cannot manage it. My working associate does not want anything too fancy. At present the build consists of the hull cut from a solid piece of wood the deck cut from a single piece and nailed to the hull the cabin walls made from four mitred pieces nailed together The general shape of the hull somewhat resembles the BLUENOSE but this weekend was one where the gentleman could recall some memory of the vessel and he stated it was not any particular boat. Link to photos: http://modelshipworld.com/index.php?/topic/7009-help-please-identifying-sailing-vessel/ My intention is to complete the shaping of the hull, add a rudder, put a roof on the cabin, add a metal hand rail around the deck edge, add masts/yards/gaff/boom and some rigging. Then mount it on a simple base and cradle assembly. My first task will be to establish the centreline on the underside of the hull and copy the profile, transfer it to stiff cardboard, prove it to the hull and then create a “skeg” template for the piece to be made and added to the underside. As for the vessels name: CHARLIE is how the gentleman refers to everyone whose name he doesn’t know or may have forgotten. CHARLIE just seems fitting (considering the gentleman's condition) and I have to refer to it as something besides “that boat of yours”. Meanwhile I have to finish the build of my modelling table (got my saws back from my son yesterday) and I continue to plot out my keel, stem and stern post for my build of my HMS Bellerophon.... mow the lawn, wash the car.... and fit some fishing time in there somehow. I just might have to give up my day job to make time for all this.

-

Druxey: "grasshopper" that put a smile on my face! thoughts of dear old David Carradine (I still think Bruce Lee would have been the better kung fu master) Chief: Re: time spent on my actual build This build is still in the planning/layout/research stage and takes 100% of the time I put on it for now I cannot comment on anything other than the whaler I did 14/15 years ago where I was intimately familiar with them back then so research was minimal and I practically jumped right in after receiving the print from NMM and the photos from my CPO at HMCS Quadra that summer. Alan

-

Good morning Druxey Thank you for following. I see you are everywhere on the forum and cannot imagine the time it must take I greatly appreciate your and other modellers visits as it somehow puts me at ease. Recording the measurements and plotting the points is a bit tedious but I will admit joining the dots is fun (is that weird?) I attribute it to the fact that I can see myself getting closer to starting the actual model. There have been some frustrating moments... one major one being trying to read and then make sense of Ree's or Steel's. I am approaching it as I've done many a new challenging task at work, divide and conquer. I break it up into much smaller but manageable frustrations and overcome them one by one! I will also admit I had not factored in the demands of the new season taking me away from all this.... I hear the grass calling me again but (as I am certain you can attest to) it is much more enjoyable being out in the sun then basking in the ice and snow! Take care Obi-Wan! (did I just reveal my age?) Alan

-

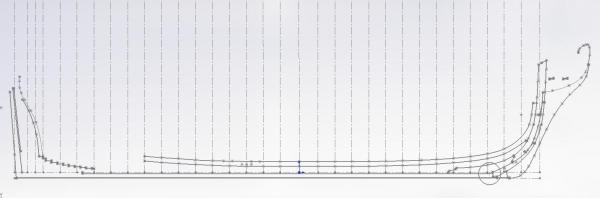

Some minor KEEL, Stem and Stern Post layout progress taking place as I take a break from building my modelling table. I had taken a multitude of measurements off the plan and am now plotting them to draw the lines to establish the various pieces and the rabbet line. The circle near the bow is to remind me of something that does not blend well in that area... I need to double check my dimensions and/or redraw the polyline to more reference points. I am also having some problems at the bow drawing in the edge in the area above the gammoning holes as the plan does not distinguish any detail of this surface edge. Looking at Ree's Plate X, figure 1, ( I understand they are very similar to Steel's) there are two dotted (hidden) lines that I believe the lower one is what I need. This area does not look anything like the Vanguard or Bellerophon kits I see being assembled on the forum. - block for the figure head is not stepped - two round bobstay holes versus three - another round hole up above the inboard gammoning hole Alan

-

what is the ideal modelling table?

AON replied to AON's topic in Modeling tools and Workshop Equipment

Ahhhhhhh British Columbia aka God's Country .... unless you are speaking to people from Alberta -

what is the ideal modelling table?

AON replied to AON's topic in Modeling tools and Workshop Equipment

Pete Nice workshop... and room left over to park your car! (When needed mine flows out of my designated play area in the dungeon to the rest of the basement) Some how I would not have thought snows shoes and San Diego, California would go together -

what is the ideal modelling table?

AON replied to AON's topic in Modeling tools and Workshop Equipment

I managed to get quite a bit done this weekend as the following photos will show. 01 drilling holes in legs - using the sticky back templates provided with the mechanism made this step considerably easier 02 wiring - ran wiring to each of the three electrical boxes 03 wiring - installed the plugs and plates; had to run out to Home Hardware to get a 3 prong plug for the end of the feed wire as the one I thought I had seems to have walked away. 04 mounting legs - everything lined up perfectly; I used socket head cap screws and a flat washer to give me some additional bearing surface area against the wooden leg so when torquing the screws they would crush into the wood a little less 05 laying out mechanism - It was a bit tight as I hadn't allowed for the electrical outlet boxes in my plan; had to skew things to fit 06 securing mechanism - they had provided tie down straps for the tubing (these screwed to the table but no screws were provided); wiring cable sticky back holing slips were provided but I was uncomfortable applying these to the wafer board as I wasn't confident they would hold so I used the extra cable straps. They had provided two screws for the control buttons but I could only use one on each as the other hole was under my frame. 07 table down - this is as far as I was able to go with the assembly 08 table up - raises 15-3/8 inches (390.5 mm) from 30-1/8" to 45-1/2" (767 mm to 1156 mm) in 24 seconds. The lowering was uneven as the far side did not have adequate weight on the cylinders. I placed the model table tops on the table and added a bit more weight and tested again and it all worked fine. When I complete the table assembly it should have enough weight to it. 09 table - a shot of the table with the modelling half placed on top I will not be able to make the frame for the modelling half for another week as my son has borrowed the cut-off and circular saws for the re-modelling of his home. This will allow me to concentrate on my ship modelling - establishing the rabbet line. I have taken a quad-zillion measurements off the plans and have been plotting them out in my 3D model. Hope to be posting there again soon. Alan -

It was a pre-release notice and won't be out for a month yet I am locked in on the $CDN price (always more in Canada versus the states) and if it drops (as if that ever happens) I get the lower price. I am very interested in reading her story and having not seen the first printing I hope it will be one of those few books I cannot put down

-

what is the ideal modelling table?

AON replied to AON's topic in Modeling tools and Workshop Equipment

Thank you Pat. It is a wonderful feeling to see a mere thought and then vision develop and transform into reality. Now that it is beginning to resemble an actual table I cannot wait to see it finished... this is when I have to reel myself in a bit to avoid doing something really dumb For instance, I don't know what I was thinking when I was going to drill the lift cylinder mounting holes with my hand held drill and the legs bolted in place. It would never have aligned properly! I took the legs off last night to use my drill press... this will keep them parallel with the surface. I also double checked the new metric bolts .... they are the correct ones! Oops! Should have answered your question... eh? I am thinking one shelf across the bottom with store bought clear plastic (see through) containers/drawer units on it. I use these for my carving tools at the moment and they seem to work for me -

what is the ideal modelling table?

AON replied to AON's topic in Modeling tools and Workshop Equipment

Some photos from last night Just wish I had managed to mount the lift cylinders I did get out this morning and picked up some real M5 x 25mm bolts and washers at Fastenal -

what is the ideal modelling table?

AON replied to AON's topic in Modeling tools and Workshop Equipment

I managed to assemble the fourth leg last night Drilled and carriage bolted them to the frame Took out my M5 x 25mm bolts to fasten the cylinders to the legs Found the correct drill for the M5 bolt by drilling a hole in a scrap piece of wood and fitting the bolt through. (the markings on my drills are worn off and my vernier calliper is at the office) Something looked wrong. Put the bolt up against the leg and it was a 1/2" longer than the leg thickness. The blind tapped hole in the cylinder is just over 1/4" deep Measured the bolt and it is 1-1/4" long Took the bolt over to the cylinder and tried to screw it into the hole.... no go. The bolt isn't an M5 thread! That put a damper on progress (note to self: never ever believe the marking on the box) -

what is the ideal modelling table?

AON replied to AON's topic in Modeling tools and Workshop Equipment

I managed to assemble two more legs last night One to go, then I'll mount the lift and provide more pihotos

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.