-

Posts

2,867 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

Monday 03 November 2014 Completed drilling all the stanchions Had to scrap five halves as the holes were too close to the edge Flattened new pieces and will drill them tonight. Also started on a bow gunwhale/combing to assist in holding the bowsprit in place Not much to look at/show as yet. Just traced the outline onto scraps of maple. Developing my plan of attack in my minds eye. Also The plaster wall lath my son is tearing out of his home was thought to be ash but in fact it has been found to be eastern hemlock. I passed a short piece through my planer and edger last night and I am left with a beautiful finished piece 0.32" thick (8.1mm) x 1.37" wide (35mm) It has got me as excited as the oak base had. I think I'm in love. I'll be grabbing more of this from his wood pile before he burns it all!

-

Mike If I may make a suggestion .... Think of it as an opportunity not a mistake! You get to solve a puzzle by having to think outside of the box. BTW - I might have done the same thing Alan

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

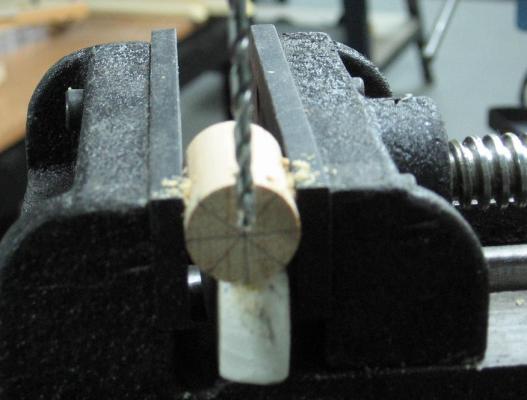

Sunday 02 November 2014 Managed to get all stanchions (and a few spares) ready to be drilled through. First I punch marked the hole location with a nail I ground a sharp point on. Then I drilled a dimple into the stanchion with a #66 bit in a pin vise so that when I go at it with my dremel the bit will not wander. I will start drilling them all through tomorrow night.

-

Thank you! I was very concerned with the possibility of having taken too much off one side when shaping or ending up with a wiggly snake like surface. It is not "perfect" but I believe it is because I know where the "issues" are. I dare not shape it any further or my concerns will come true. Stripped the jackets off the ends of the wires last night for the stanchions. Going to clamp the flats, drill the holes, shape the tops and cut into two pieces today. Thinking ahead to the rest of the deck and bowsprit.

-

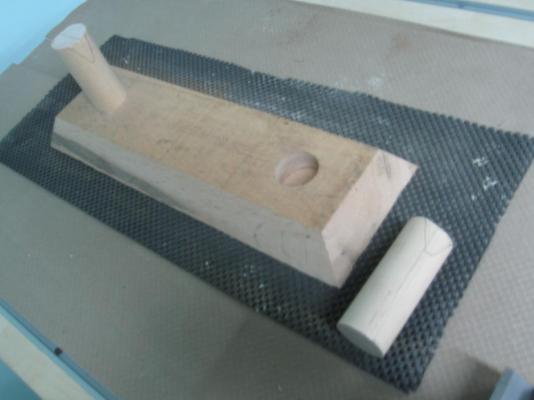

Saturday 01 November 2014 Completed the base also Rough cut the vee notch with my bandsaw then rasped, filed and sanded Had to cut 1/8" off the longer aft post to have her berth level I have planed and sanded the base after these photos nothing is glued as yet The oak looks fantastic... I think I'll stain it and paint the posts white Very sturdy! I am happy with this.

-

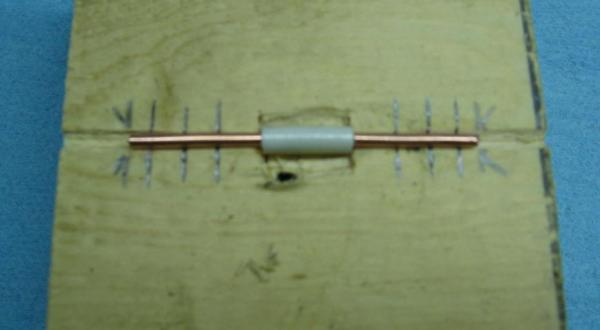

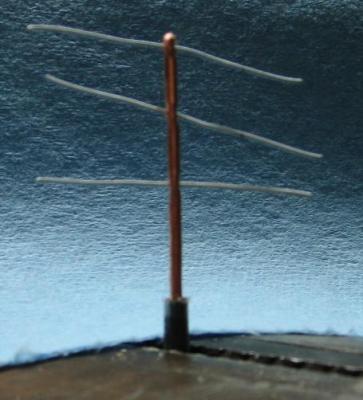

SATURDAY 01 November 2014 HORRAY! I did it I successfully repeated the stanchion drilling process The problem was it needed parallel flats on both sides to lay steady I removed the jaws from my vise and clamped flats on both sides at once Flipped it over to do the other end as one wire is two stanchions when cut in half. This time I used a #66 drill bit, slightly smaller I think I will only put in two handrail wires as three looks to be too busy

-

Thank you Bob My first (and successful) attempt was done with the drill twist on both bits exposed completely (full length) My second (failed) attempt was similar All successive trials were choked up as short as possible to minimize the buckling effect on the tiny thin column (drill) as I figured as you suggested it might give me more control. Darn thing skips away on me! My flattened surface isn't flat enough? My guide dimple isn't deep enough? I am not steady enough? I am going to give it another go this weekend. Make sure I am well rested and take my time. Hope to have it mastered... must practise some mental Yoga before!

-

Good morning Druxey YUP... you are absolutely correct (as usual )... it has to do with the round stock and a wandering bit. I need a good flat surface and managed to accomplish it the very first time and since have not replicated it. I am not prepared to throw in the towel just yet and purchase square stock... I'll give it another go I did try my son's plunge mill bit and it might work if I managed an X-Y-Z clamping rig... Otherwise it does not work for me Possibly my speed was wrong too? I'll have to get my son more involved before I scrap this idea.... he seems to love a challenge Thursday 31 October 2014 Had a clear vision of the "simple" crutch mounting base and decided to get-er done - I took a piece of heavy hard and weathered shipping skid stock (1-1/2" x 5" oak) and cut it to 16" length on the table saw - bevel cut all four edges at 30° - used a 1-1/2" brad point bit to drill blind holes (1" depth) for the 1-1/2" maple dowels - copied the skeg shape to the dowel to mount Charlie to it I will yet need to: - cut the sloped Vee notches in the dowels with my band saw - shape to fit, radius the edges of the notch to make it look a little less harsh - cut dowel lengths to suit to assure Charlie berths with a level deck - mill the top and bottom of the base plate, radius the edges and then sand all surfaces - glue the dowels to the base

-

Thank you for the words of encouragement Bob. Haven't gotten anything done since last week. Popped my back out Saturday morning and made it back into work yesterday. Managed to survive the day and took the evening off. I need to get my homework done for the sail making seminar on November 7th, 8th before I do anything else. My son (the machinist) leant me a small plunge type mill bit to possibly machine some flats onto the wire using my drill press. I am game to try anything once... or twice.... or....

-

I have had a nail pusher for finishing nails and used it around the house for years Mine looks more like the second one The nail loads inside the barrel... but I wish the pusher was magnetised to hold the nail in place... the barrel would need to be a different material (300 series stainless steel?) If I don't get it up to the wood carefully it slides out (I plug the end of the barrel with my finger) I like it because it can be a pain holding a small finishing nail and trying to tap it with a small finishing hammer... tweezers or no tweezers... I use to use needle nose pliers to hold the nail

-

Wednesday 22 Oct 2014 Because of my problems experienced with the stanchions I spoke to a working associate in our shop and he lent me a pin vise that I could put in my drill press chuck to possibly keep the drill steady (half the problem)... but I was too busy with other things in the evening to try it out Thursday 23 Oct 2014 Continuing to have trouble with the stanchions..... I took a long finishing nail and ground a very fine point on it to try and mark the drill spot better prior to hand dimpling the spot with a pin vise I had the drill press belts adjusted to 600 rpm where as my dremel operates at about 1000+ rpm at its slowest speed The pin vise mounted in the drill press chuck was of no use as it spun off centre (wobbly) I also cannot seem to keep the copper wire steady (presently holding (clamping) it down to the board with my finger) I need to have a better way to hold the wire down and steady and also hold the drill steady Tried a piece of wood dowel as opposed to the copper wire and it seemed easier but was not as good looking (to me) as the wire was I ask myself: Why was the very first attempt so easy and now so difficult?

-

I have found the following charts quite useful over the years and so thought I'd share them below are links to three charts DRILL SIZES http://www.accuratebushing.com/pdf/ENG-FractionalChart.pdf AWG (WIRE GAUGE) SIZES http://www.calmont.com/pdf/calmont-eng-wire-gauge.pdf STEEL WIRE & SHEET METAL GAUGE SIZES http://www.mesteel.com/cgi-bin/w3-msql/goto.htm?url=/info/carbon/thickness.htm

-

- drill sizes

- wire gauge

-

(and 1 more)

Tagged with:

-

Tuesday 21 October 2014 Drilled ships wheel spoke holes in a new length of 7/8" dia doweling It may seem silly increasing the size 1/8th of a inch but I think it will look better I also decreased the size of the spoke holes so the spokes will be thinner than the outside wheel handles that will be separate add on pieces I have ordered a 14 (dia) x 17 (dist between ctrs) wood turning lathe and will wait for it to finish this piece along with any tapering of masts and spars ( www. general.ca - model 25-114QC MI variable speed (250 to 3600 rpm) It will take up to 2 weeks to arrive I also ordered the 40" extension, 4 jaw scroll chuck, and set of mini chisels This should complete my workshop. I think my glorious tool buying days may really be over this time Having some issues with the stanchions It is quite difficult drilling the holes in the wire and keeping them properly aligned. The wire also curls out of straightness ... not the end of the world as this can be rolled back to be straight but if the handrail wires are not aligned I am concerned it will present very poorly. Haven't given up yet as I like the "bling" factor the copper wire will add but I have a plan B (wood dowelling) Completed the sanding of the hull and have started sanding the deck I will need to add wood filler to cracks here also.

-

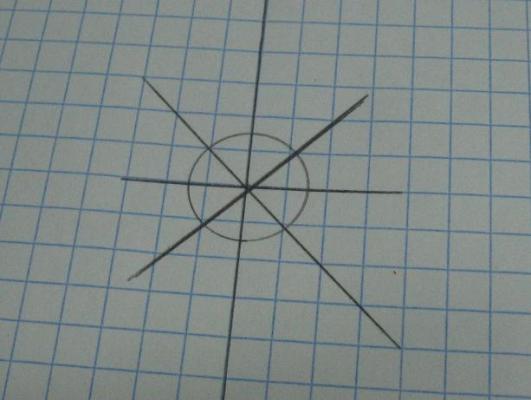

Monday 20 October 2014 Did more sanding and hopefully a final spot application of wood filler Will need a final sanding with progressively finer grit paper The lower rudder mounting block is attached and I am happy with the look Attempted the ships wheel Created a template to mark the spoke locations and transferred the marks to 3/4" diameter dowel The holes are located 1/8" in from the edge, half the thickness of the wheel (1/4") Aligned the mark to the drill Drilled four holes through for eight 1/8" diameter spokes Not happy with this first attempt (threw it away) Need holes to be smaller yet for smaller diameter spokes between the hub and outer wheel The outer spoke grip will be thicker diameter and shaped a bit to look more realistic Good news is I got the "go ahead" with the idea of painting! Also asked about any name going onto the hull, as we are calling her Charlie should I apply it? The answer was yes.

-

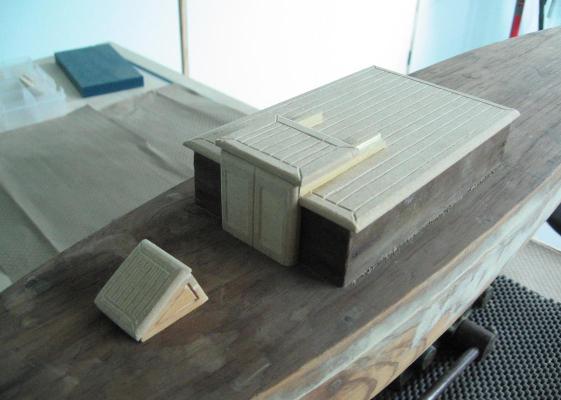

Sunday 19 October 2014 completed the second sanding completed the wheelhouse, cabin roof and door dry fit to the deck did a test oak stain on a piece of scrap and did not like the results glued the rudder lower block to the keel and will drill and pin it tomorrow will start the stanchions and the ships wheel next

-

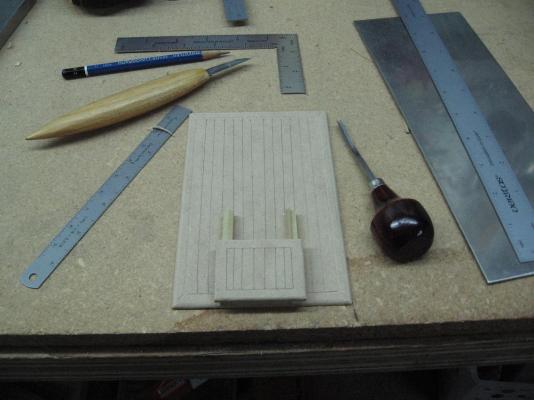

Saturday 18 October 2014 Completed the first sanding of the hull and fine tuning the shape and blend of the skeg to the hull Re patched and will give it another sanding Sunday or Monday Completed a trial stanchion with the 14 AWG wire and one out of three holes was good. The wire is too small for me to locate and drill properly and then too much material is removed so wire strength is compromised. I've decided to stay with the 12 AWG wire and also calculated the spacing necessary for the handrails Made a jig out of scrap wood to allow me to stamp and drill the wire at a reasonable consistent location The jig set up allows me to do two at once with one 2 inch long strand of wire I'll cut them in two pieces when done I also prepared 32 pieces of wire, 64 stanchions (a few extra)... so ready to start. I made the wheelhouse. Took three attempts to get it right. This needs to be gently sanded after I scrape the edges down a bit. I am also working on the main cabin roof. The edges have been given a radius and am presently carving in slat joints. When done the whole thing will be roughed up a bit with sand paper

-

Friday 17 October 2014 Completed the third and last band for the rudder. These need to be cleaned up a bit and nailed on but I won't be doing nailing for awhile for two reasons 1. my son has my propane torch nozzle so I cannot yet heat up the end of a length of wire to attempt to roll it over to create the button head of a nail. 2. due to the many colour tones on the hull I have my friend thinking about allowing me to paint the hull to make it look better. I would not want to fix any copper bits to her if I'll be painting I attempted to create a handrail stanchion using 12AWG copper wire (0.0808" dia.). Ratios of model to photo to actual Bluenose length suggested 18AWG wire (0.0403" dia) might be a better choice to simulate a 3" diameter stanchion but as this is my first attempt I thought I'd make it easier on me. - I cut a length and bared a portion of the wire - I created a small flat on two opposite sides (if I can say that for a round wire) using a Robertson screw bit (the square one) and light taps with a small hammer - using my pin vise and a #60 bit I created a dimple in the flat to drill a hole (keep the bit from wandering) - using my dremel and a #59 bit I drilled holes through the wire - I rounded the top of the stanchion off on my wet grinding wheel - inserted short lengths of 22 gauge (hobby) Bright Wire to simulate the handrail cables I think it looks fairly believable. Now I need to calculate proper lengths and spacing and try it on 18AWG wire. I also have determined Charlie is a bit shorter than the Bluenose so if I have trouble with the 18 ga wire I might stay with the 12 ga ... keeping my options open.

-

Thursday 16 October 2014 Made a few attempts at banding on the rudder and settled on the following... - AWG12 copper wire - cut about 2 inch long piece and removed cover to reveal bare wire - hammered flat to a consistent thickness (or thinness!) - clamped straightest portion (as it curled like a snake) in vise between two wooden plates. - used pliers to grip and bend the curved portion to be straight - readjusted the straightened band in vise and filed the edges to be straight(er) - used a string to measure length of banding required by wrapping it around the rudder at the location the banding would go. - Cut the band to length - Measured the centre, held it clamped at centre with needle nosed pliers and bent the band around the pliers as this seemed to do a better job of making a good bend than my wire bending jig. - fit over the rudder and shaped the grip bend with only finger pressure - removed the band and bent the legs inwards to grip the rudder blade better - reassembled to the rudder - gently tapped the band with the wooden end of an old screw driver to shape it tighter to the corner radius of the rudder - removed the band and bent the legs inwards once again for a better grip - reassembled a final time I've one more band to make Presently thinking of how to create a faux nail head on a thinner gauge copper wire to affix the band to the rudder I might try warming it up a bit and pressing it onto a metal bar to roll the edge over that'll be tomorrow after I make the last band

-

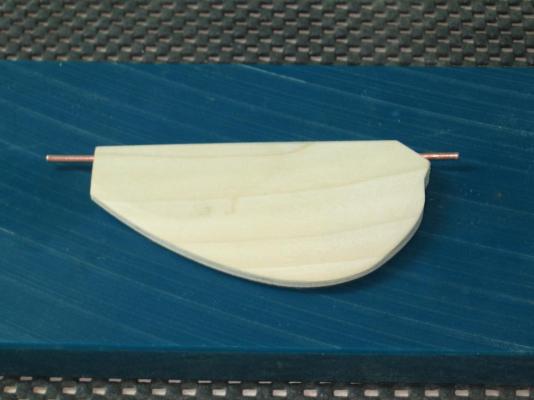

Wednesday, 15 October 2014 I bought a fresh new tub of LePage’s wood filler and my best friend suggested that to keep it fresh I should cover it with plastic wrap, push it down onto the wood filler to push out the air and then put the lid on. So I’ll try this. If it does not work the suggestion to add water seems like it should work but I’ll need to do this before it starts to harden too much otherwise it cannot be mixed it. On with the work at hand. First I filled all the cracks in the hull… and there were a lot more than I put on her. I’ll let this dry for a couple days before I sand it down and reapply a second coat. I then started on the rudder. Having printed a couple images posted on a Bluenose build from the forum here I had a hint of the shape. Took my block of wood and traced the image with my French curves. Mine is a bit more bulbous but I like it that way. Then it was cut out on my scroll saw and sanded to shape. I got smart and wore a dust mask this time as the last time there was quite a bit in the air and of course I was too stubborn to stop and put one on. Drilled holes in both ends for a short length of copper wire for mounting and then made the small missing block that is an extension of the keel for holding the lower end of the rudder. I will not install this until I have the hull sanded to final shape. The lower wire will be cut shorter! Gugeons and pintles yet to be made but I'll wait to get the keel sanded to final shape first. Gave some thought to the simple cradle. Of course I want to do something different but it has to be simple so looking around my scraps I found some 1-1/2” diameter doweling that should work nicely!

-

Monday. 13 October 2014 Ate my fill of the Canadian Thanksgiving Day meal followed by a healthy slice (or two) of pumpkin pie. After having gotten my expanded play room in working order (and learning where I put everything all over again) I must get going on the Charlie refit as Christmas is right around the corner. The good thing is the working associate does not expect it to be a 100% complete and first class job as he suggested eye hooks and … a strange shudder just went through me. Completed the other half of the skeg as far as I dare go with it. I find it is all to easy to chase the other side and then find you’ve gone too far and now you have to re-work the first side to match and…. Tuesday, 14 October 2014 After my darling wife and I took a long morning drive along the Lake Erie shore line to get some photos of the fall colours I went back to Charlie and cut the skeg out of the block with my band saw. Sanded the top side on my belt sander and then sanded a flat onto the underside of the hull to help them both fit up a bit better. I drilled and pinned the skeg to the hull with doweling after having applied a small amount of wood glue to the hull and the holes. I’ll need to fill gaps and blend with wood filler and generous sanding to complete the marriage of the two pieces. My plan now is to complete a simple support cradle as was requested to rest the schooner on and then start on the rudder. I intend to use old copper electrical wire for the gugeons and pintles. These will need to be hammered, filed and formed into shape. Once the rudder is attached I’ll cap the cabin and build a small wheel house and ships wheel. I intend to install stanchions along the deck edge once again using copper electrical wire and silver hobby wire of a much smaller gauge. Then I will install the masts, gaffs and booms. I will have completed my sail making course by then and will decide whether to add sails to hide the lack of full rigging as I may certainly have run out of time by then. Wednesday, 15 October 2014 I will have to run out today for wood filler as my small tub has dried up. Does anyone know the secret of keeping the tub from drying out? I thought of storing the tub upside down (like paint) but as it is not liquid I cannot see this working Possibly I should by tubes rather than a tub as with a tube I can squeeze out the air and then put the cap on.

-

somehow there is always more time in the winter months!

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.