-

Posts

574 -

Joined

-

Last visited

About mrcc

- Birthday 06/11/1964

Profile Information

-

Gender

Male

-

Location

Calgary, Alberta

Recent Profile Visitors

-

Thanks Peter… yes, at the end of the day (with the few models I have done), I think it best to glue the masts in. Cheers,

-

cotrecerf reacted to a post in a topic:

Order of Mast Assembly

cotrecerf reacted to a post in a topic:

Order of Mast Assembly

-

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Baker reacted to a post in a topic:

Order of Mast Assembly

Baker reacted to a post in a topic:

Order of Mast Assembly

-

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Knocklouder reacted to a post in a topic:

Order of Mast Assembly

Knocklouder reacted to a post in a topic:

Order of Mast Assembly

-

Luckily my low back is very strong! Thanks for the replies...

-

Thanks for your input… Mamoli’s instructions for rigging is over 4 sheets and each sheet references additional blocks and items to attach to the masts and yards. I will really have to study them in detail so I don’t miss anything.

-

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Thanks Rich, thanks Pfalzer! I have a “game plan” at this time and appreciate your help and suggestions.

-

Thank-you for your input! I appreciate it...

-

Knocklouder reacted to a post in a topic:

Friesland 1663 by mrcc - Mamoli MV24 - 1:75

Knocklouder reacted to a post in a topic:

Friesland 1663 by mrcc - Mamoli MV24 - 1:75

-

mrcc started following Chris Watton and Vanguard Models news and updates Volume 2 , Order of Mast Assembly , HMS Agamemnon by Henke - Caldercraft - 1:64 and 1 other

-

I have a couple of kit builds under my belt, but not sure how to do masts that have multiple elements to them. I scoured this specific section of MSW without a clear understanding. The question is glue the lower portions of the masts FIRST, securing them in their respective mast holes in the deck and then build the top mast, and then the top gallant mast subsequently (adding all the blocks and fittings as you go up at each section of the mast), making sure all are in proper alignment as they build up or whether to build the entire masts off the deck and then place them? Not sure on my Mamoli Friesland what is best or ideal given the very limited instructions on this matter?

-

Wonderful build Henrik… read your build log from beginning to end. One question, you mentioned dry fitting the upper portions of the masts, but at this time, are all your lower portions of the masts glued and secured in their mast holes in the deck? Not sure on my Friesland, whether to build the entire masts off the deck and then place or build up the masts from the bottom up, section by section?

-

Gaffrig reacted to a post in a topic:

Lynx by Gaffrig - Panart - Scale 1:62

Gaffrig reacted to a post in a topic:

Lynx by Gaffrig - Panart - Scale 1:62

-

Lynx by Gaffrig - Panart - Scale 1:62

mrcc replied to Gaffrig's topic in - Kit build logs for subjects built from 1801 - 1850

Everything is very nicely done! -

Baker reacted to a post in a topic:

Friesland 1663 by mrcc - Mamoli MV24 - 1:75

Baker reacted to a post in a topic:

Friesland 1663 by mrcc - Mamoli MV24 - 1:75

-

petervisser reacted to a post in a topic:

Friesland 1663 by mrcc - Mamoli MV24 - 1:75

petervisser reacted to a post in a topic:

Friesland 1663 by mrcc - Mamoli MV24 - 1:75

-

mrcc reacted to a post in a topic:

Wasa 1628 by Knocklouder - Billing Boats - 1:75

mrcc reacted to a post in a topic:

Wasa 1628 by Knocklouder - Billing Boats - 1:75

-

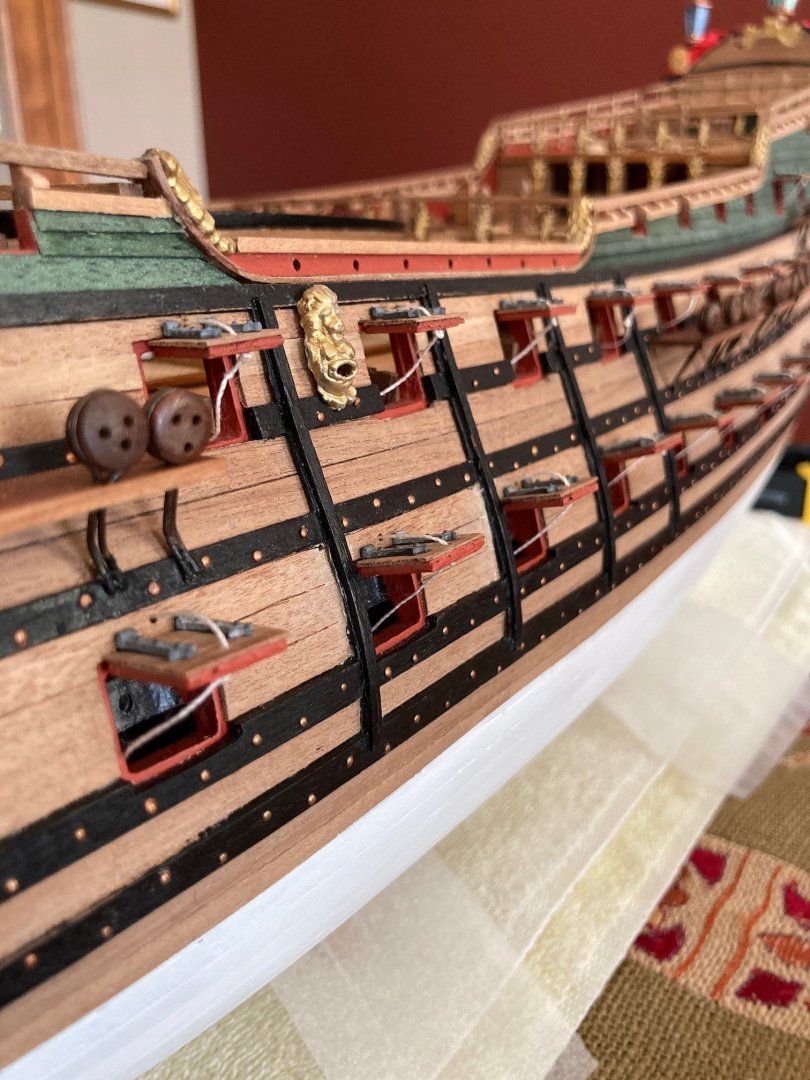

And some pictures of the full hull as she sits at this time... First though a closeup of the kit supplied stern lanterns before they were attached to the stern... very nice in my opinion. Shame about the different color of the panes on the large centre lantern. I told my wife I was going to take a big break at this stage of the build but last night I could not help but turn a few of the masts with the used Proxxon lathe that I bought roughly two years ago for this very purpose. It was fun!

-

An update as I have now officially finished the hull. All the gun port lids are now attached and with the exception of all the cannons being installed onto their gun cradles, I am now ready for the masts. I am going to place the cannons at the very end of the build... There are additional fittings such as eyelets and ring bolts to attach to the deck and hull but their placement is more associated with the rigging stage of the build. I will likely pre-drill some of these holes for the eyelets and ring bolts at this time, before the decks get too cluttered.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.