-

Posts

572 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mrcc

-

Very poor service indeed... I had some problems with Cornwall Model Boats as well with regards to unanswered emails on a special order of a part. They are both hit and miss.

-

My advice is to keep pestering John at Jotika… He will eventually get back to you but it often takes a while.

-

More progress this weekend... Finished nailing the copper nails into the strakes. Created a little template and ran it along the strake with a quick touch with my archimedes pin drill and then came back to fully open the hole for the pin. Quick dab of yellow PVA glue and pushed it in in large sections at a time.

-

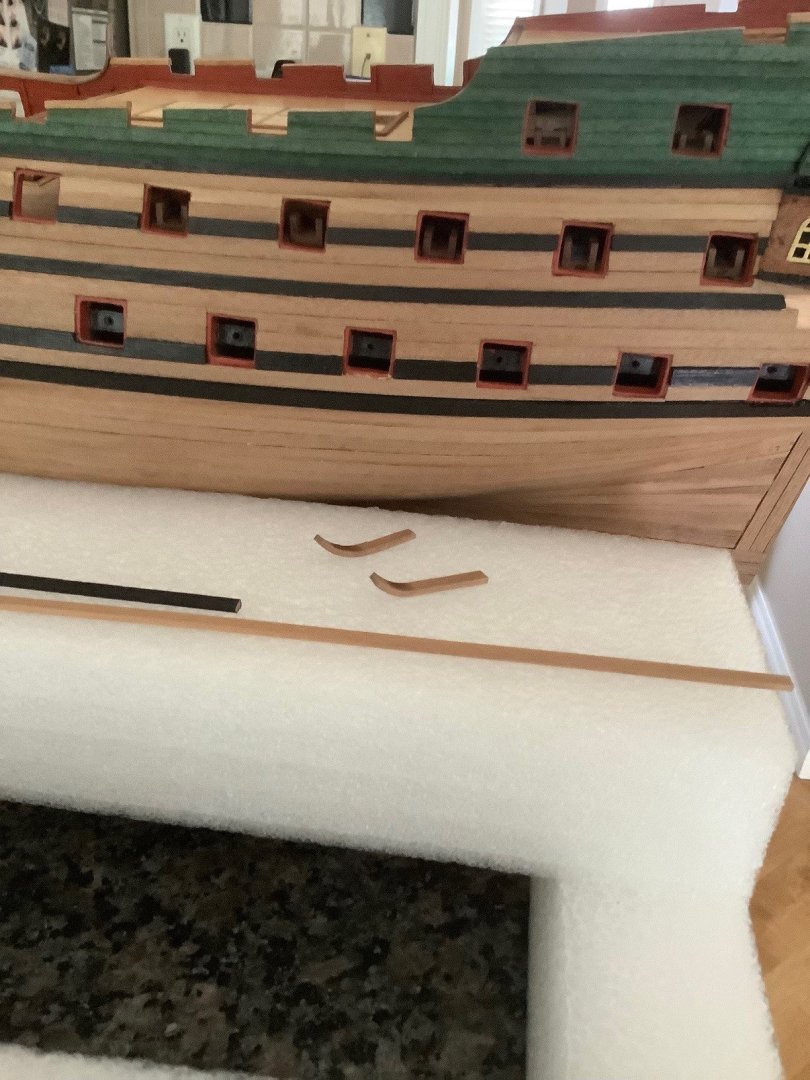

The cap railings are 2x4mm but at the curved profiles, found it absolutely impossible to soak and heat bend the planks. I ended up bending a couple of 1x5mm planks and then once I got the correct curved profile, was able to laminate the two 1x5s to get closer to the rest of the spec'd 2x4mm railing. Sanded them back a bit, sanded a bit of the heat scorch marks and very happy with the results. Thanks to everyone for checking out my build log!

-

Lots of work getting the upper deck gun ports at the correct heights from the deck, relative to each other and from side to side, also making sure to get a flat run for when the deck railing caps go on. Also getting the correct profiles for the deck railings, with the specific challenge at the points of curved profiles, especially matching to the opposite side. Took lots of measurements from the plan, transferring, changing, and remeasuring, having to add and sand back in some cases from the initial hull planking that I did. Luckily the gun ports were initially located correctly from side to side to each other from my measurements from an earlier stage of the build when first rough cutting them out. Once satisfied, I started the upper side wall planking with the stained planks.

-

Thanks for sharing your build log... Excellent result!

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Reached a milestone in that the hull planking is complete. I bought some walnut filler and will at a later time fill some of the wider spaces between some of the planks at the bow but overall happy with how the planking turned out. Also started to transfer the measurements from the plans to the hull, preparing the upper profiles, for gunports on the upper decks.

-

Mistake on Sternpost Planking

mrcc replied to mrcc's topic in Building, Framing, Planking and plating a ships hull and deck

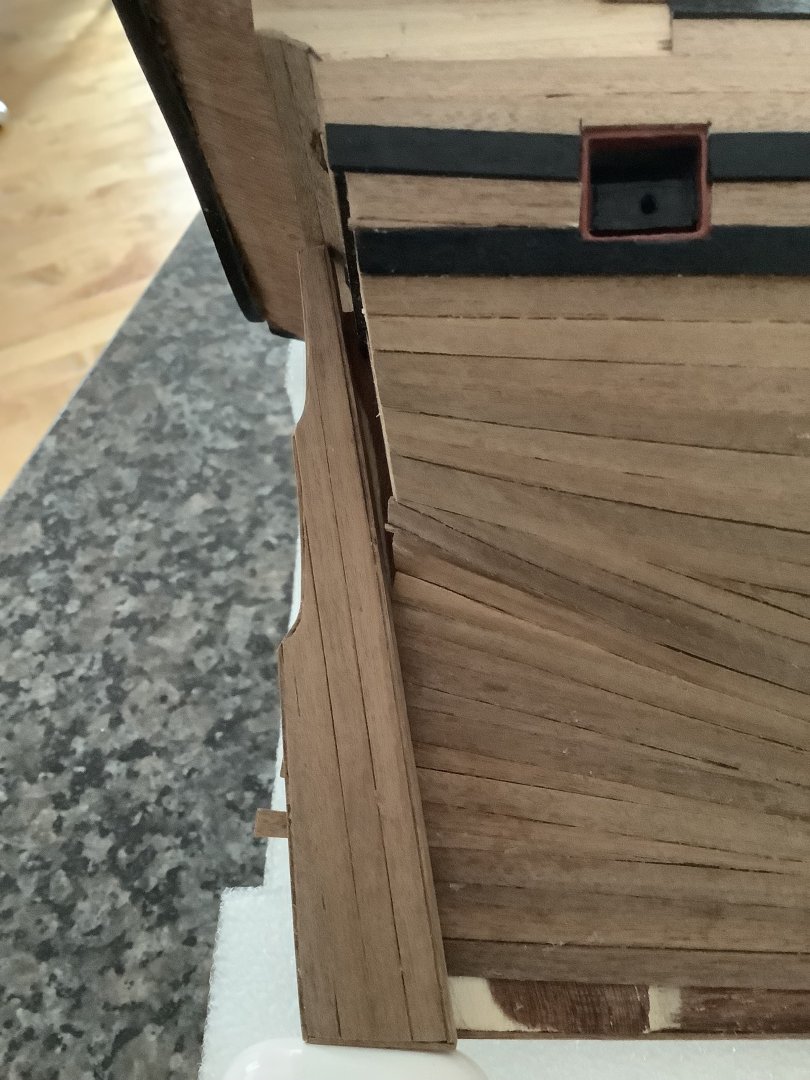

Much easier that I thought... marked the forward edge of the sternpost line, scored a line with a blade, heated up the plank portion in order to release from the glue, and the plank end lifted up effortlessly. -

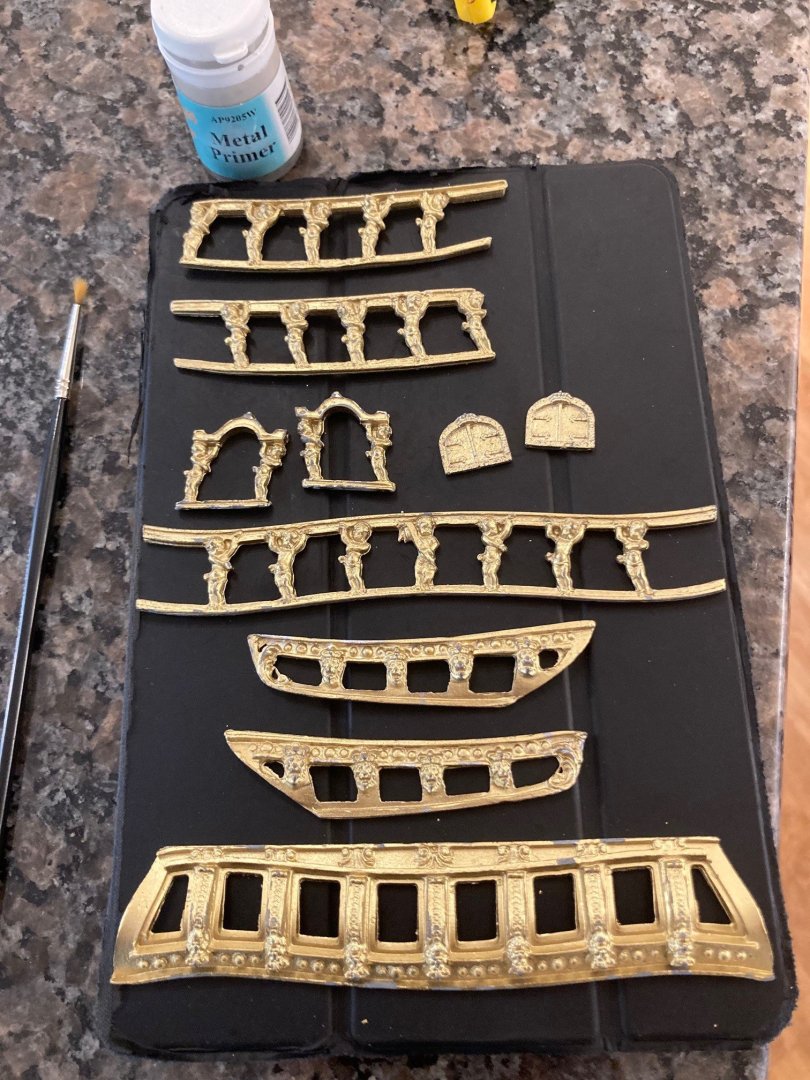

Still some small plank pieces to lay at the bow and along the keel, but almost done! Little diversion though with the castings at the stern; applied the metal primer and getting ready to paint... I am very unsure of the painting scheme at the stern as all sorts of different options on Google images. My preference at the moment may not be historically accurate??? PS These casting are probably 40 years old and given the molds were relatively "young" at the time of casting, I have to say the primed stern decorations look very good to me.

-

Wonderful build log Clare… I love how the Mamoli kits build out. Thanks for sharing!

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Mistake on Sternpost Planking

mrcc replied to mrcc's topic in Building, Framing, Planking and plating a ships hull and deck

I know… strange! -

Mistake on Sternpost Planking

mrcc replied to mrcc's topic in Building, Framing, Planking and plating a ships hull and deck

Thanks TMJ for your advice… yes I used PVA glue on the planks and I will take your advice of heating the planks after scoring a line where the stern post should be, and then trying to lift off the ends. PS strange that I received your advice via email but yet your reply/post will not show on the MSW web log - even after, what 10 hours. -

Mistake on Sternpost Planking

mrcc replied to mrcc's topic in Building, Framing, Planking and plating a ships hull and deck

Thanks TMJ... good advice and I may end up doing that but I think I will first try and delicately cut back those flared planks with a razor blade and fine chisel. -

Mistake on Sternpost Planking

mrcc replied to mrcc's topic in Building, Framing, Planking and plating a ships hull and deck

Thanks Bob... Even if painting, sometimes you can see trace planking outlines and if painted, still need to tie into the stern post above the waterline... -

Thanks Zappto... I really appreciate you checking in on my build log! Some progress on planking but it has been a slow go as busy with work and then away on holidays for 2 weeks in Greece. Anyways here is some progress... I did have to taper the rear stem post as I decided to completely plank the post and rudder and you need to taper back down to account for the thickness of the planks otherwise the pintles won't fit. Nothing noted in the instructions but do know this from my previous Mamoli Santa Maria build. Same for the rudder... Definitely need some fill between some planks in some areas of the hull. I think I did a better job of planking on my previous Santa Maria build.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.