-

Posts

572 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mrcc

-

Finally finished the deck planking on all the deck levels... With three coats of wipe on poly. I made the mistake of sanding the green lath on the rear deck wall... not sure why I even did it... I have now lost the lustre and brightness of the green stain and will likely have to do a new wash or stain on it.

-

Upper deck complete but also working on the very top rear deck... Instructions are not clear... Nothing fits properly - and finding myself shimming this or that corner at every step. I had to add a ledge for the rear deck lip to sit on - not in the manual. I also had to shift the hole (in the deck prior to planking) for the mast by 3 mm and then braced the hole from underneath. I will later refine with a file. I might just take a break here as I am starting to get frustrated with this vintage kit!

-

Now dealing with a dilemma, I followed the side profile on the plans in adding the top line of gun ports and thought they were accurate but in the first picture (once placing the top deck), the deck does not extend far enough. I referenced a couple other build logs on MSW and it seems I am the only one that placed them as forward as I did but yet I seem to have taken an accurate approach to the plans. As evident in the following pictures, I extended the deck, having felt that there would be no subsequent problems in the future by doing so. Aesthetically, I extended it by 11 mm and should have only done 5-6 mm. There is some bulwark details (under the deck lip) that need to be added and they only needed that 5-6 mm extension.

-

Quick check to make sure the holes for the masts (on the upper deck) line up catching the second hole below. All good there but did have to file 1 mm one side or the other, prior to planking, in order to get that direct line. Planked tight to the revised hole and filing with a round file in order to get a tight friction fit of the dowel.

-

Working through the instructions, basically following the outline as dictated by Mamoli on their plans. I find them easy to follow and there is always pictorials to guide you. I find that is how I learn best and it seems my log follows the "a picture tells a 1000 words" principle. But you have to watch as you need to think 2-3 steps ahead and the instructions are not always clear or comprehensive. It also helps with MSW and the 3 specific logs that I follow... lots of guidance there as well! Anyways... working through the second deck planking and preparing the last 4 ports, 2 to port and 2 to starboard. Cheers,

-

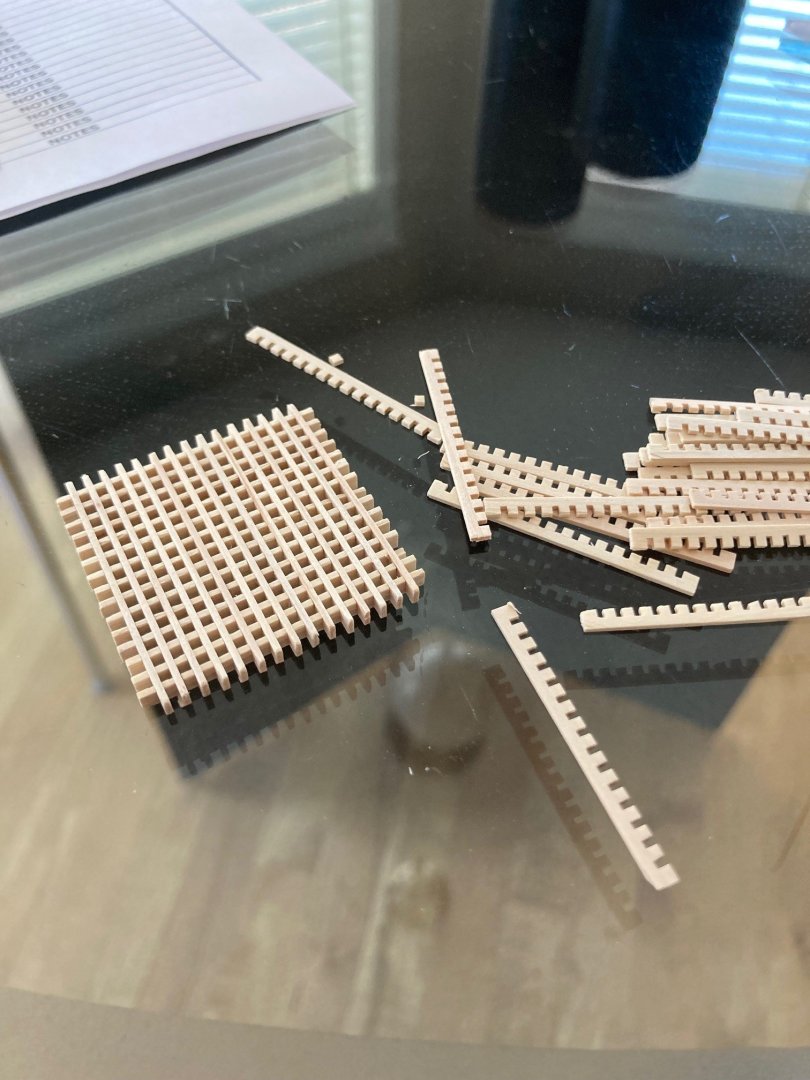

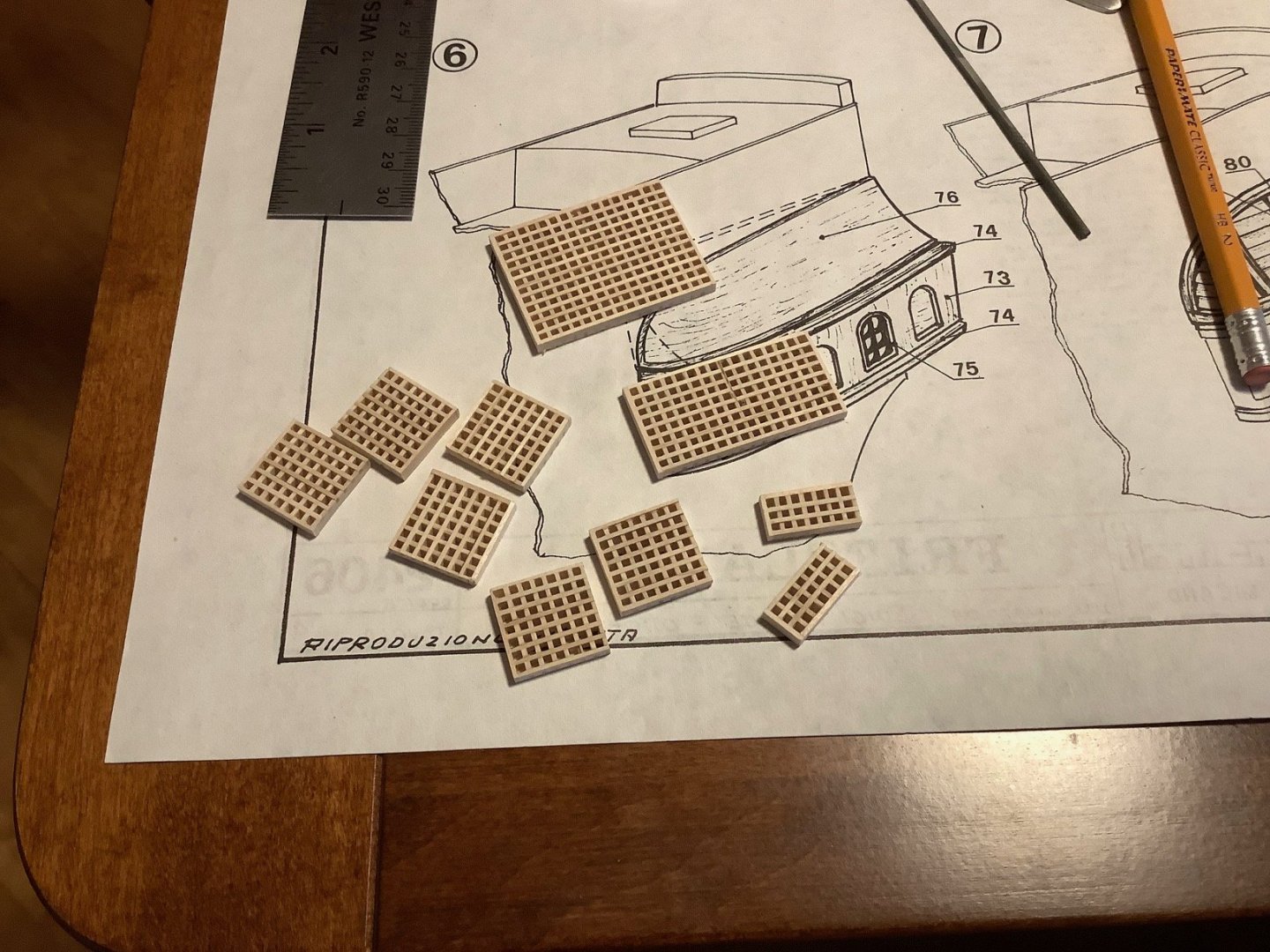

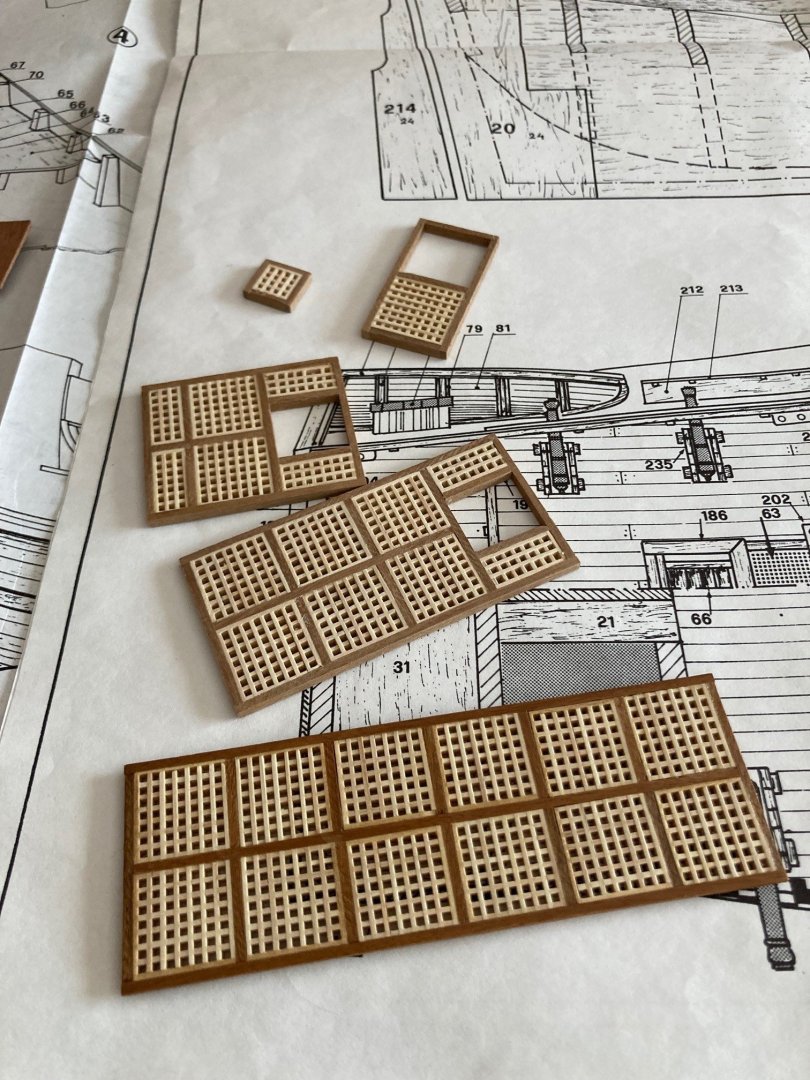

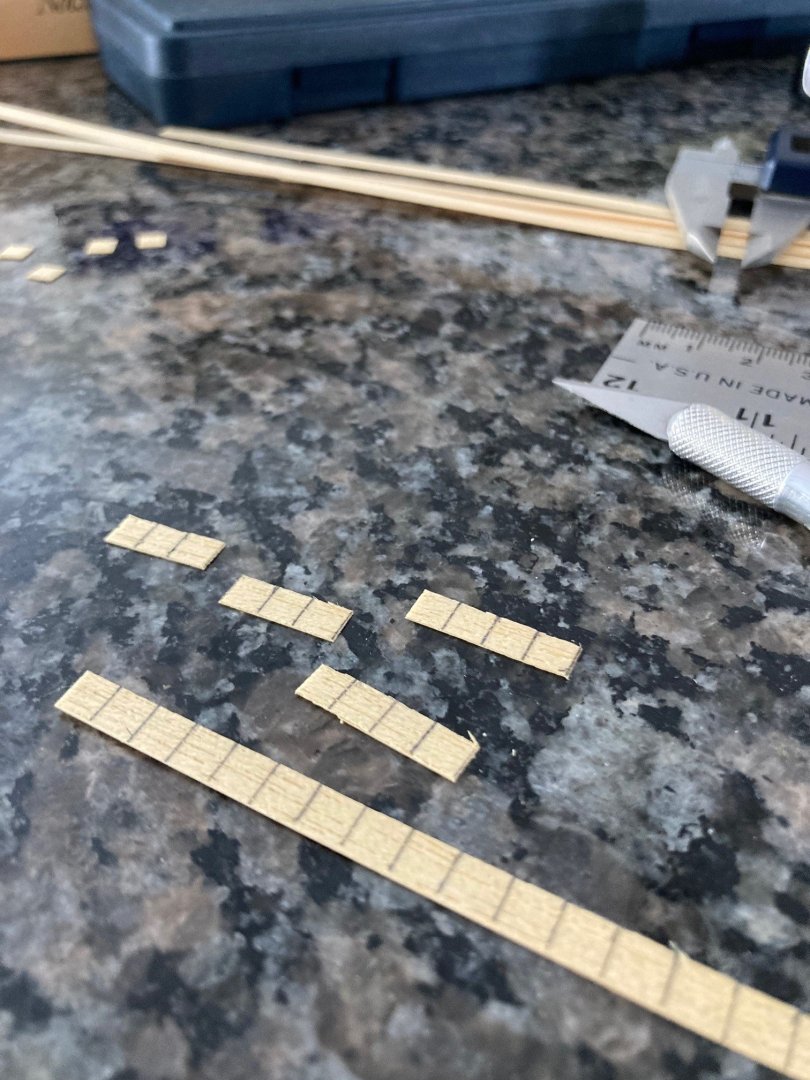

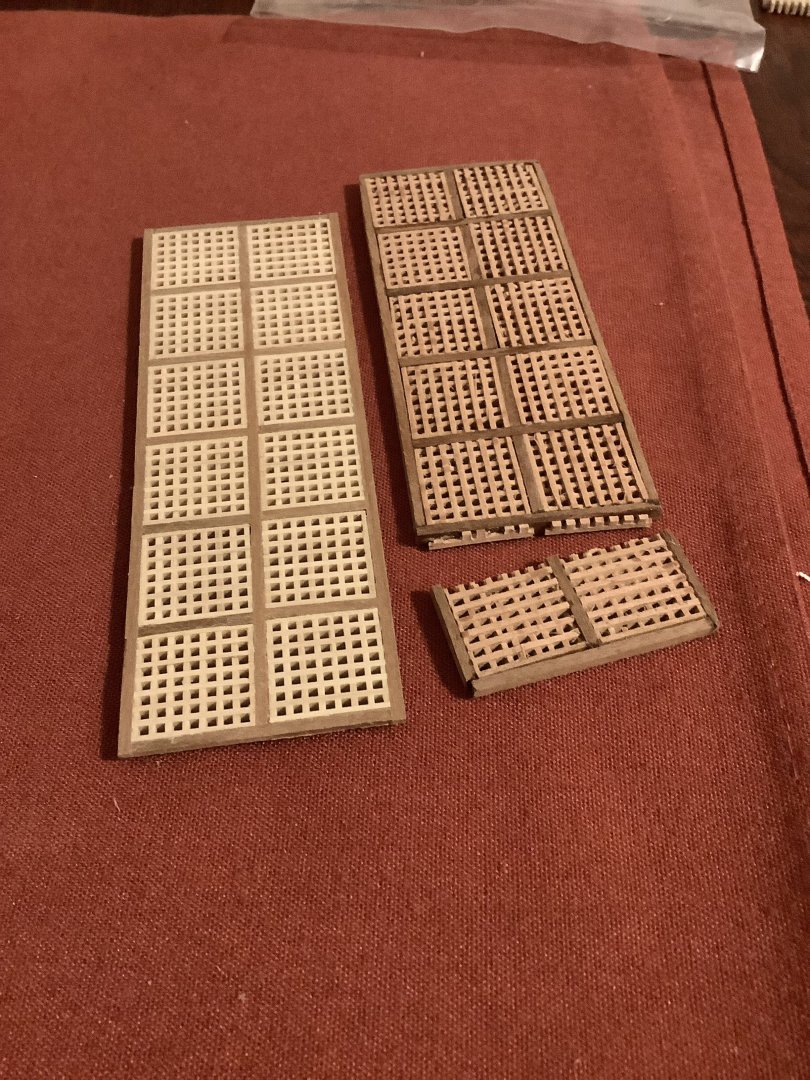

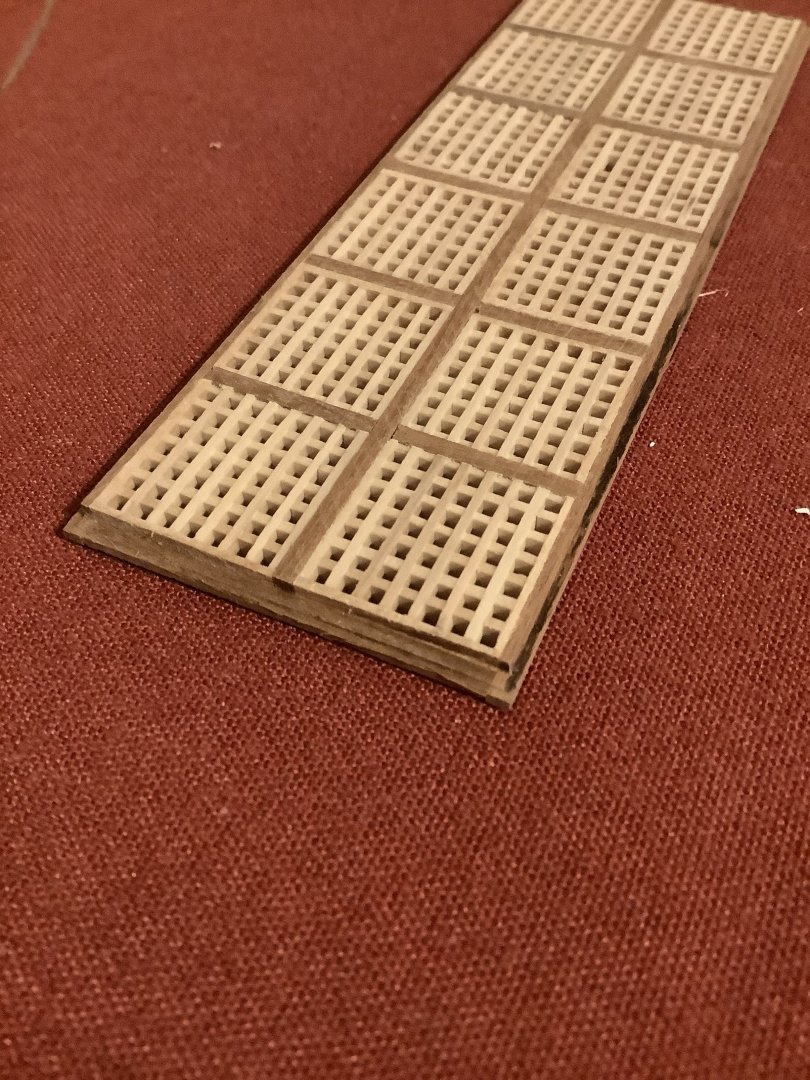

Just doing my best Bob... thanks! Some photos of the grating kits and their assembly. The original wooden gratings that came with this vintage kit were extremely soft and crumbly and I just had to source them from elsewhere - Jotika, but unfortunately one package was short 10 out of the 30 laths and fortunately for me, I was able to use that last grating and the remnants of such to make the tiny grating in the last photo.

-

An update following some weekend work. I put three coats of wipe on poly on the main deck with just a very slight sanding with a grey 3M pad just after the second coat and prior to the third and last. I think it looks great! The beams were installed with some fiddling of the beam and the ledge it sits on in order to get that perfect level aspect of the deck from side to side. Just a few 1 mm shims here and there... and I have a nice sweep of the upper deck upwards as the deck approaches the stern.

-

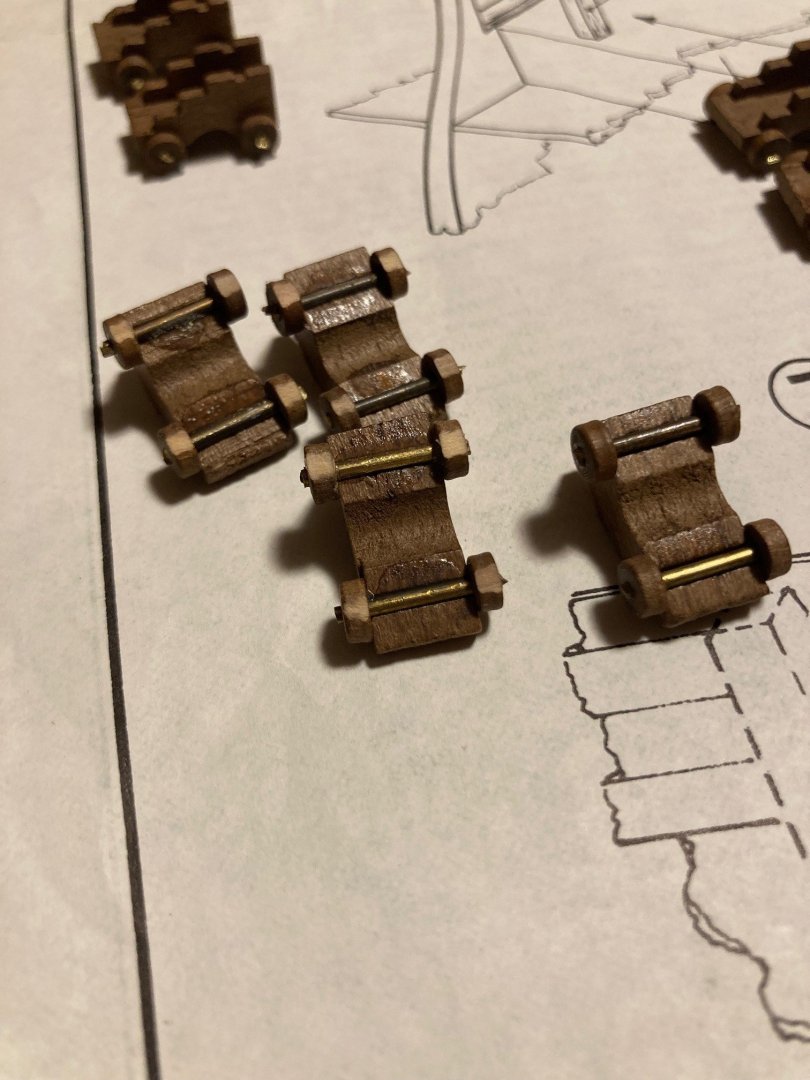

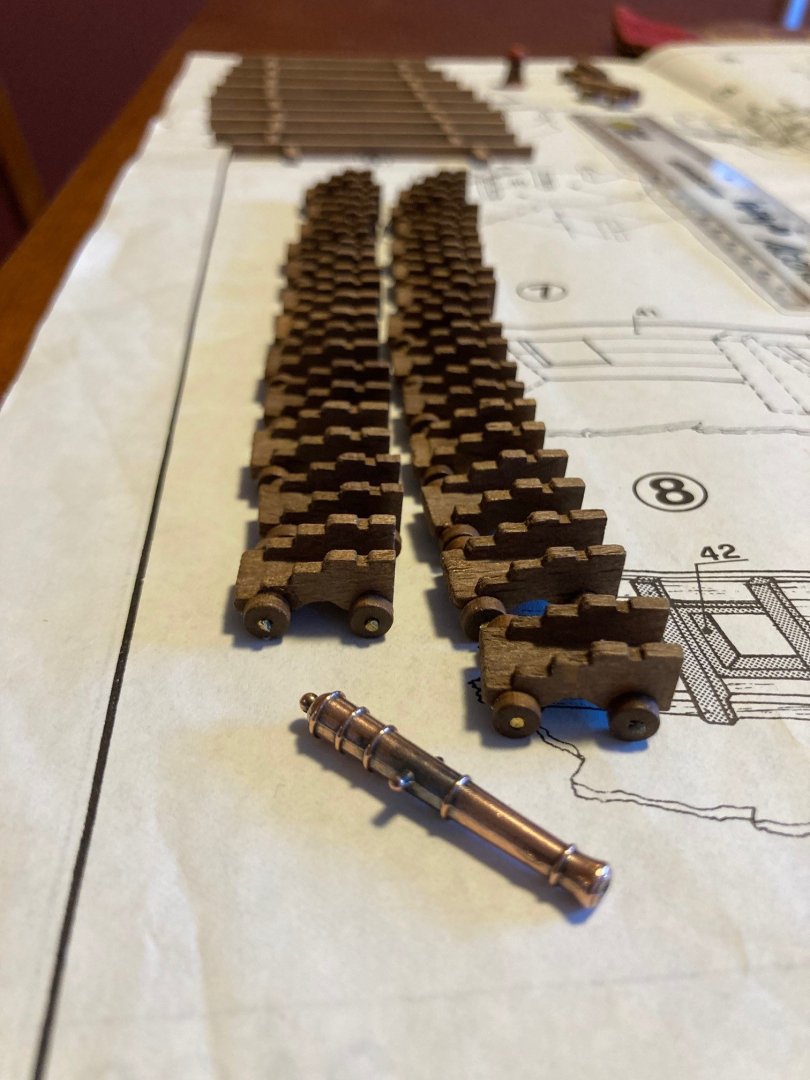

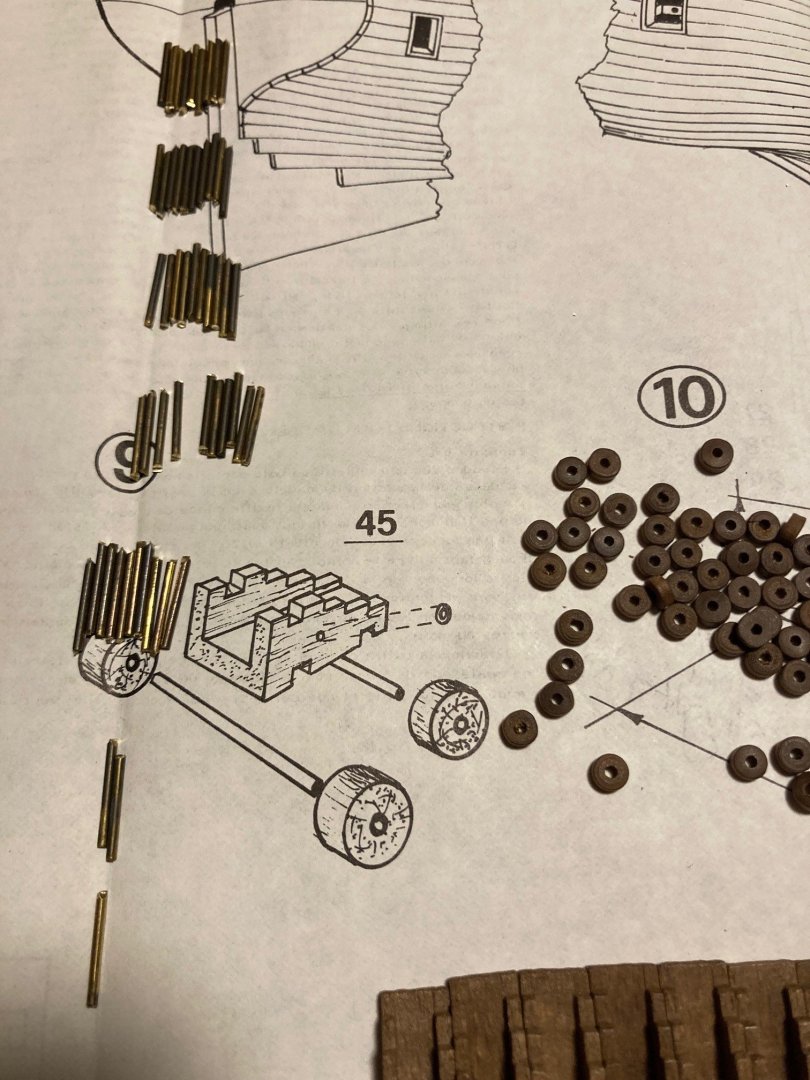

More details done this week... I sanded down the wheels on the gun carriages in order to get a firm contact for gluing the carriages down prior to them getting hidden from the deck above. I have to now varnish the deck and put the beams in in order to lay down the upper decks... going to use wipe on poly. All fun so far!

-

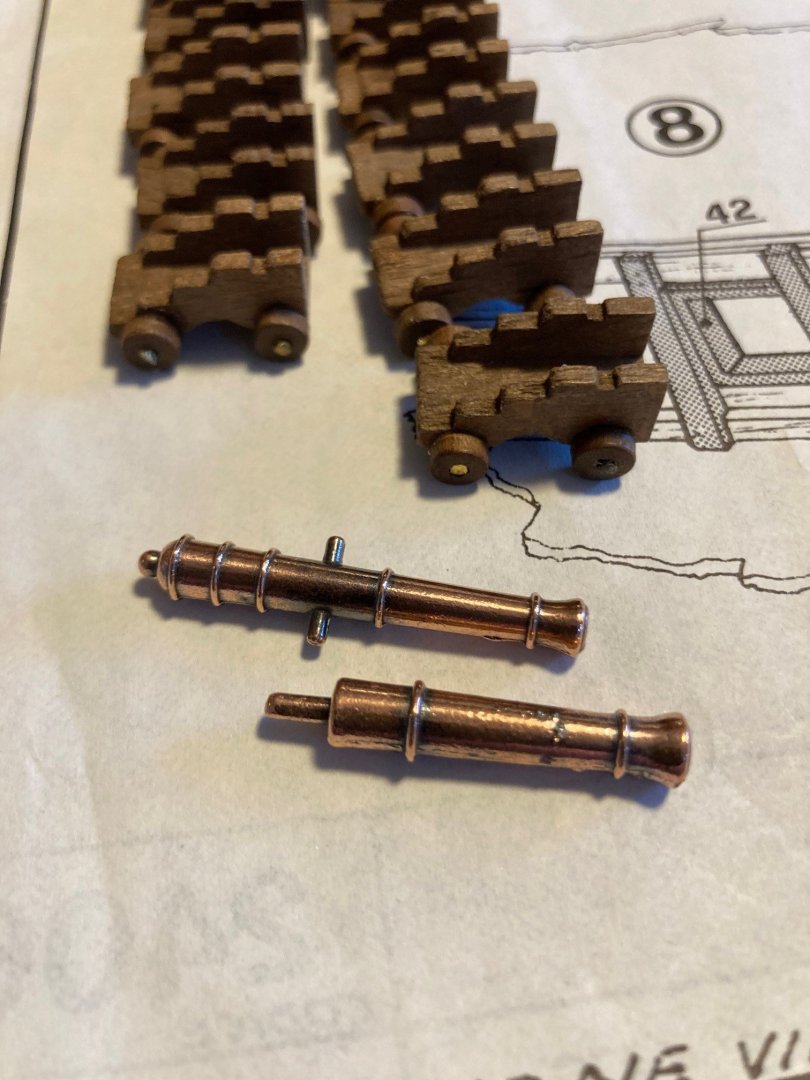

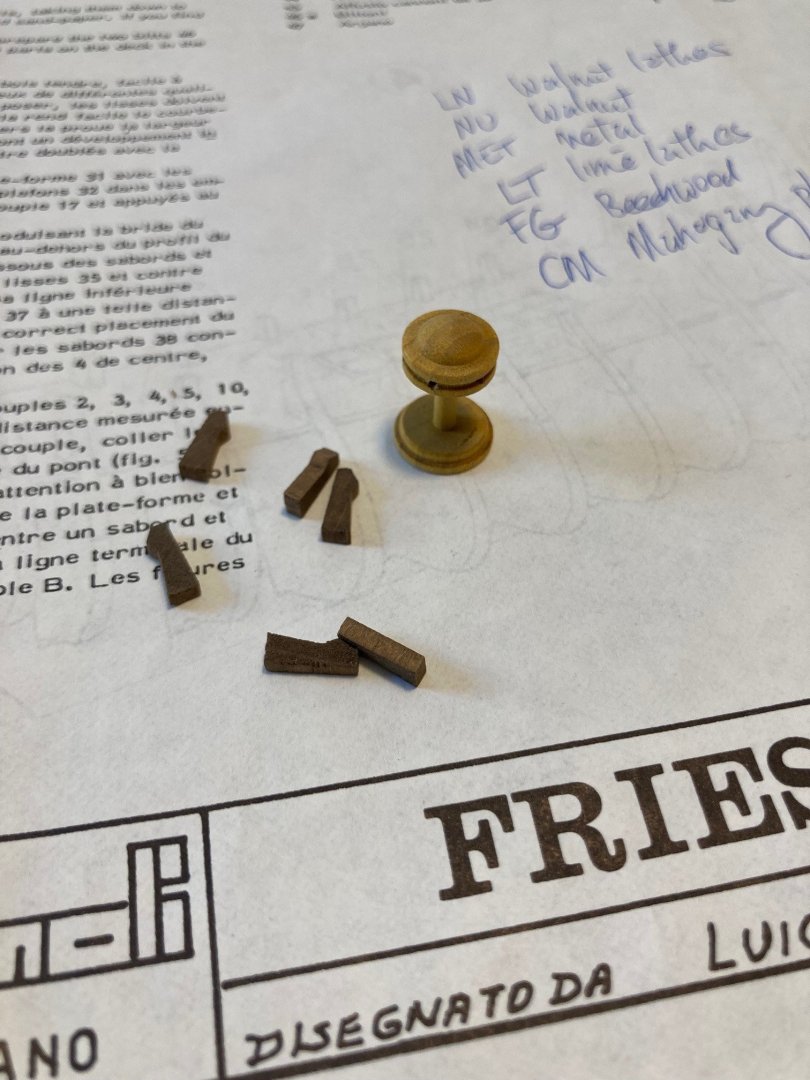

Should have provided a picture of the built gun carriages. The second picture roughly portrays the difference in the cannon extension from the port referencing the top cannon to be placed inboard and recessed a bit on its carriage and the bottom picture, referencing the dummy cannon and its placement in the lower row of gun ports.

-

Then of course, getting the cannons built and placed before the upper decks are fixed down. The carriages are glued down first on to the deck and later are the cannons placed through the port onto the carriage for display purposes. Much talk in the other Friesland build logs about the length of the dummy cannons that are to be placed in the deck below the main deck. Some kits of a particular era had cannons that were way out of scale with regards to length and... alas, I have one of those kits that are at least 5-7 mm too long compared to the cannons on the deck above.

-

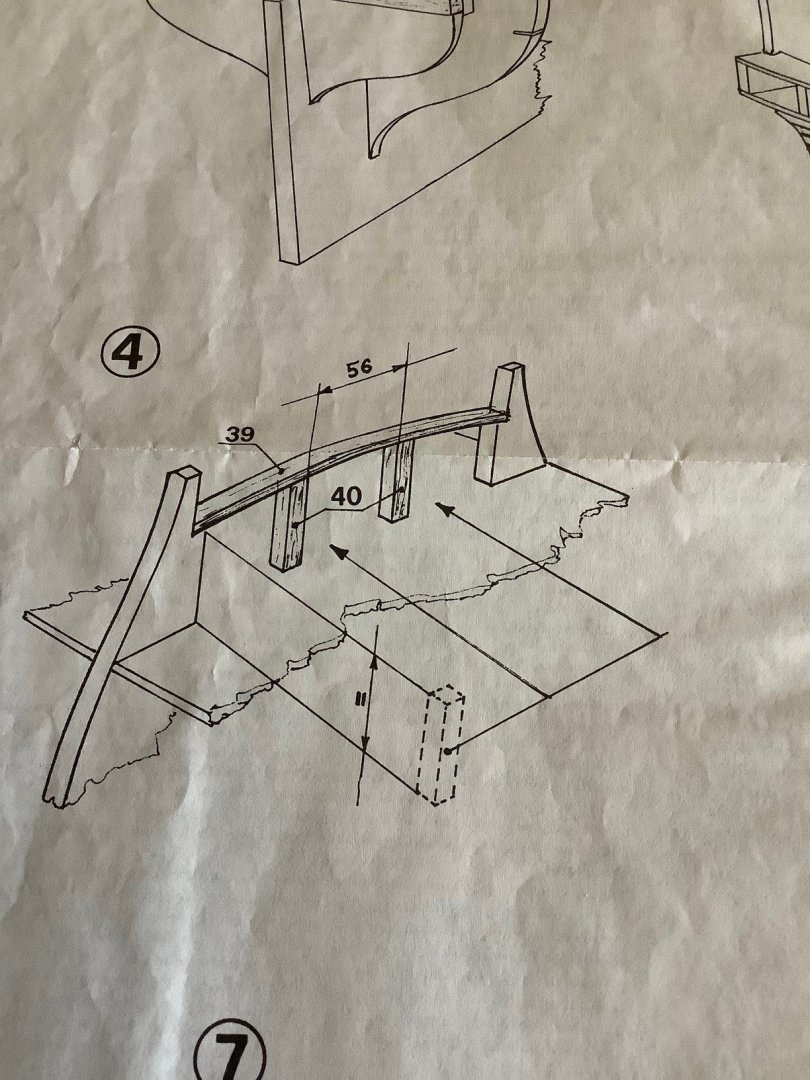

Got some work done on the Friesland this past weekend. Every step requires double checking and shimming where necessary. These vintage kits (pre laser cut) require lots of double checking as nothing is ideal with regards to fitment and further with regards to level and square. The bulkhead frames in the kit were not ideal and thus the builder always has to be thinking about future steps and how things will look. I leveled the hull and then worked forward in terms of shimming the deck support beams in order to make sure they are all level relevant to the hull and each other as evident in the pictures below.

-

Lastly, spent a few hours this past weekend in sanding the hull, and it is now pretty close to being ready for the second (finish) planking layer. I added some fill at the bow and even less at the stern, but through the majority of the hull, added 0.5 mm to 1.0 mm strips to fill slight hollows (especially on the margins of the gun ports) and then sanded back to flush, and though it make not look great, this hull is very nice and smooth (at this time).

-

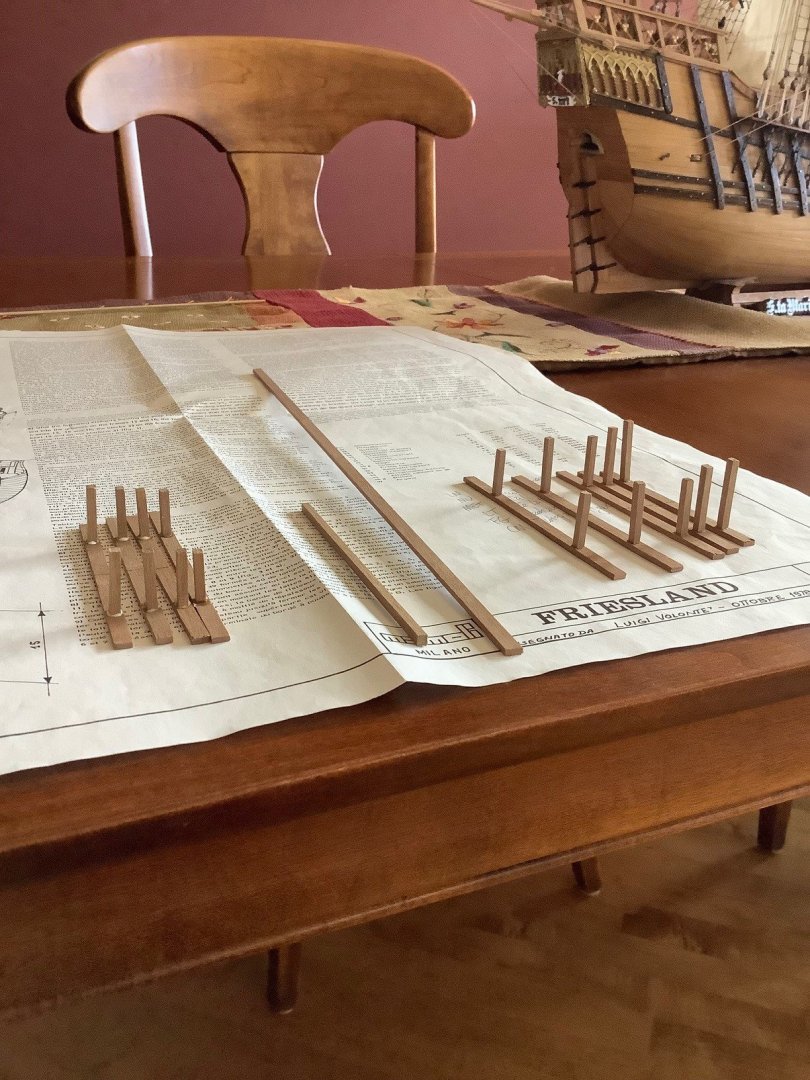

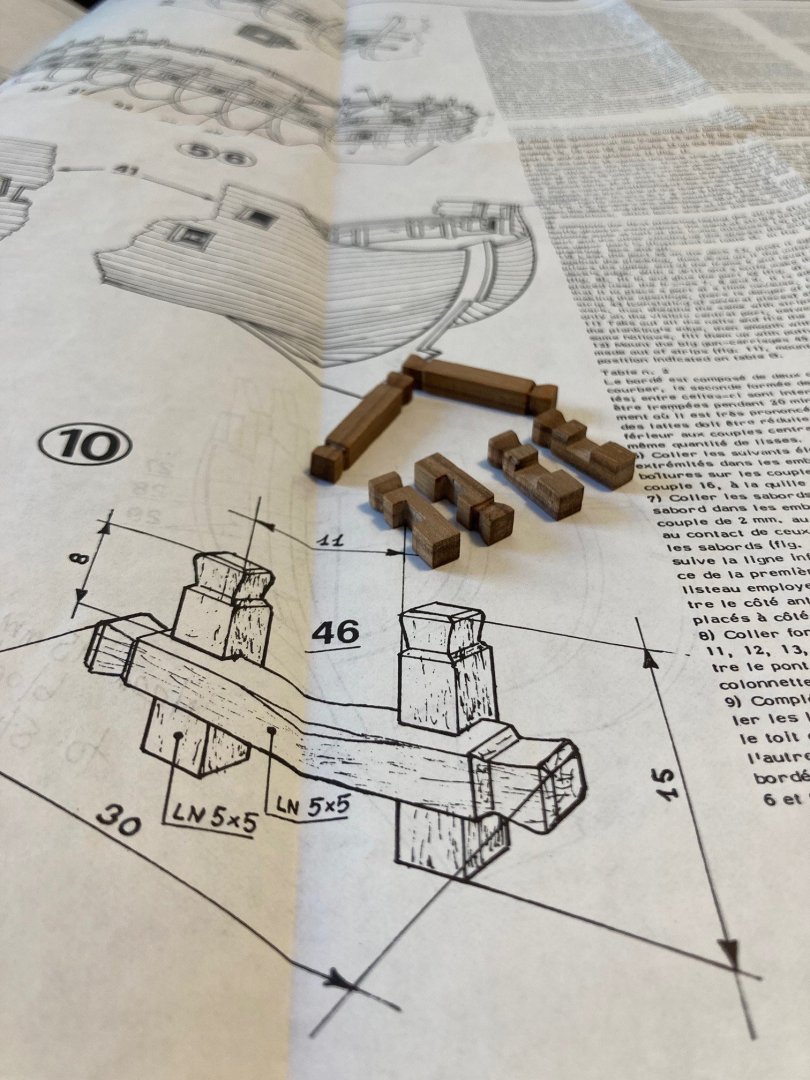

Started to work on the deck fittings... per the plans. Happy with my cuts on the bitts... used the table saw to cut slits in 3 passes half way through the material to 5 mm width in the uprights to accommodate the horizontal bit. Used the saw at an angle of 40 degrees and ever so slightly scored the tops of the bits on all 4 sides of the end and fine tuned with a file for a satisfactory result. The capstan is as pictured and easy enough to figure out but absolutely no guidance in the instruction manual. The instructions only say "glue to the deck". Not sure if I should research a color scheme that is period specific and may do some research on this tonight.

-

The Mamoli plans do not call for this step in the instructions but thought I would add this detail should anyone wish to peek through the gunports. The edge of the bulwark is a simple strip of 5 mm with lines drawn through them (to simulate ends of the sides) and the side strips are regular strips that are 5 mm in width.

-

Long time since posting an update as was working on another kit... now finished. One of the disappointments with this old vintage kit was the gratings, they are extremely brittle and fragile as you can see in the picture below. I could not live with the result and as such ordered a number of grating packages from Jotika/Caldercraft (made from beechwood). Happy with the result... I cut a recess in the outer margins in the underside perimeter of the grating with my Proxxon saw, also creating a nice margin on the deck, and was lucky enough to have a nice tight friction fit to hide the LED light switch.

-

By the way... I could not even find the kit on Corel's own website. Strange!

- 32 replies

-

- Sperwer

- Billing Boats

-

(and 1 more)

Tagged with:

-

Hi Jan... Yes I am sure 😊... take a peek at the screen capture and the attached image from modelexpo's website in the US. I was not aware of this kit until just recently myself... it looks beautiful! Merry Christmas!

- 32 replies

-

- Sperwer

- Billing Boats

-

(and 1 more)

Tagged with:

-

Thanks Peter… yes it is a nice break from the big builds but this kit had some frustrating elements to its construction. All good though… I know Corel has a Dutch Royal river boat that looks really interesting as well.. should someone be interested in this specific subject matter. Yes, Merry Christmas to you as well!

- 32 replies

-

- Sperwer

- Billing Boats

-

(and 1 more)

Tagged with:

-

- 32 replies

-

- Sperwer

- Billing Boats

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.