-

Posts

2,611 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JSGerson

-

I chose instead to construct the headers and sills slightly different. Instead of installing the posts first, I decided to install the headers and sills as one piece each, guaranteeing the horizontal lines are true. Since the verticals don’t have to line up with each other, any slight error with those will be unnoticeable, at least that’s the plan. To make the sills and headers, I initially tried to bend the wood with disastrous results, so I cut them out as blanks. Then they were carved to their final shape by trial fitting, filing, and sanding. As it turns out, I was a little short in my lengths, so I had to fill the gaps with additional wood (color change).

-

Quarter Gallery Windows The key to Quarter Galleries as I see it, are the windows whose sides aren’t necessarily parallel, nor perpendicular to the sill, and are different shapes from each other. Get those dimensions right, and everything else will fall into place, get them wrong, well…. To make matter a bit more challenging, the kit plans do not show true dimensions of the windows and nor could I find a US Navy plan that showed them either. The kit does supply laser cut windows, but their dimensions don’t consider the side view distortions resulting from curved surfaces of the galleries printed on a flat piece of paper. Additionally, the practicum states: “they are much too thick. If you do use them, you will need to sand them down to about 1/16" to 1/32" thickness” If anyone plans to use the kit’s laser windows, I just can’t see how they would fit properly. Every build log I have looked at has the galleries built slightly different from each other and the plans, some better, some worse. I’m pretty sure my gallery dimensions are different from everyone’s else’s as well including the practicum and the US Navy’s so. as an initial crack at figuring out the dimensions, I’ll use the practicum and the US Navy plans only as guides not gospel. The 1926 US Navy side view plan of the galleries has cross sections from which I hope will help me figure out the approximate dimensions. I will let my model dictate the final dimensions. My first attempt, hopefully not my first of many attempts, was to make a card stock template of the surface of the gallery window area. What makes this this a bit tricky is the template is three dimensional as it curves around. Base on the US Navy plans, the windows have a slight vertical bow although the plans did not show a view to indicate whether there was a horizontal bow. The vertical bow was so slight, I don’t think it would be discernable at model scale. My template does not capture that bow. It will be used mainly to get the overall window positions and dimensions.

-

When scratch building my pump handles, I had to decide whether to show them in the stored state or action state. I chose the full configuration action state because I thought that the layman would not understand what they were if they were all folded up and stored. You obviously didn't have a choice because even if you wanted to, the kit parts weren't designed to be assembled. I think however, the stacked pump arms are backwards (not that a layman would know). According to the photos from the actual ship, the wooden handle are stored above the axis of the pivot bar. And you are right, the kit's pumps are out of scale. If you look at my scratch pumps (which are no way perfect), mine look way more delicate because I tried to get the scale right. How successful I was is questionable. Still, your model is looking great. Jon

- 163 replies

-

- Model Shipways

- Constitution

-

(and 2 more)

Tagged with:

-

I have been collecting the photos since 2013, about when I decided that I was going to build the Constitution. Almost all the images came from Google searches, and other build logs. The one thing I learned about Google searches is, if I look for “A,” I’ll find some “A” as well as “B,” “C,” and “D.” If they are good images, I’ll keep them even though I wasn’t looking for them at that time. If I tried later to find those same images, I wouldn’t find them again, so I grab what ever looks like it might help me at some later date. I now have about 3,500 images all neatly set in identified folders so I can find most anything I want to look at. So if you need anything, let me know, I might have what you are looking for. I’m a visual person, I need to see what I’m making. I’m from the Boston area. I left in 1977. I made a few visits since then but never got to really explore the city. I did get to visit the ship Thanksgiving 2014 just before it went into restoration, but the yardarms were already dismantled, and a lot of other detail was either covered or removed. I really miss the place but not it’s winter weather and muggy summers. If you ever get to visit, DON’T drive in the city, walk or talk public transportation (MBTA) it’s well worth it. Jon

- 163 replies

-

- Model Shipways

- Constitution

-

(and 2 more)

Tagged with:

-

I’ve been following your build quietly since you started. The model is coming along quiet nicely. Your trials and tribulations with the pumps brought back some recent memories of my attempt with them. I was/am building the full ship with the addition of scratch build detail on the gun deck. Unlike you where you had to construct the full length of the pumps, I only had to show the parts seen on the gun deck. You had the kit parts, I had to scratch build mine (Post 456). I did have the advantage of an open deck to work with. I don’t know if your cross-section kit was available back in October 2020 as I might have tried to purchase the applicable parts for my model and saved myself a lot of trouble. Either way, the pumps are a challenge. Jon

- 163 replies

-

- Model Shipways

- Constitution

-

(and 2 more)

Tagged with:

-

Constructing the bench seat was straight forward. Using the Starboard image with the privy revealed, I eyeballed the shape and height of the bench. The base was scored to give the impression of vertical boards. Also, the image revealed that the floor had to be repainted as I had initially painted interior completely white. This meant scraping the white paint off with an X-acto blade and staining the wood. By the time the windows are installed, I doubt any fine details will be visible, but the viewer will know something is in there. Again, my philosophy, the closer you look, the more you see. It keeps the viewer engaged.

-

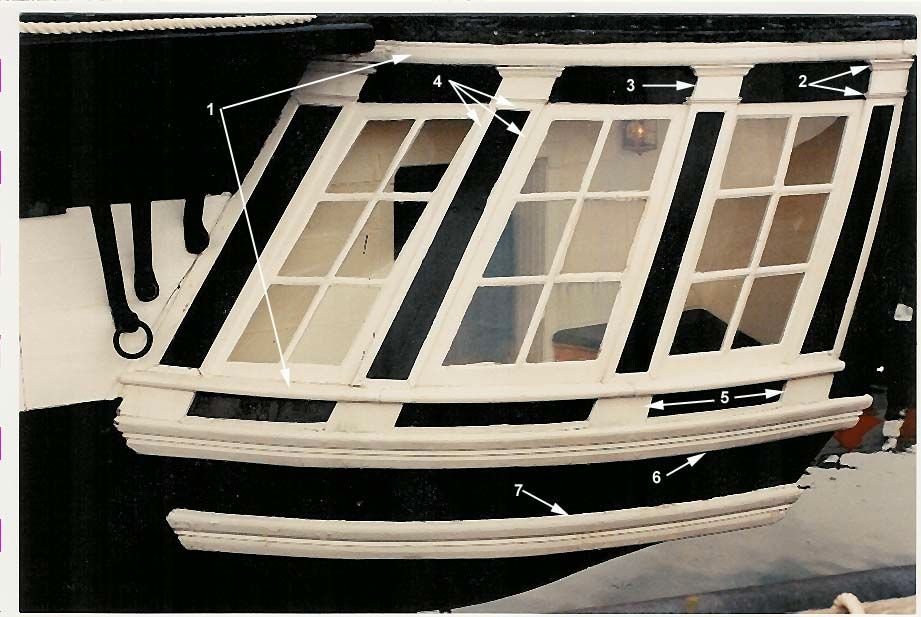

Quarter Gallery Interior Nobody, as far as I know has attempted to place anything inside the quarter galleries. So here I go again. In the practicum there is a photo (HP7.2.5.-1) of the port quarter gallery annotated with numbers for the instructions of the practicum. It also shows that the interior of the quarter gallery can be seen by an outside viewer. What can be viewed is a bench seat, which on the starboard side lifts to reveal a privy, and a wall sconce light. The bench seat is easy to make, the sconce is not. If I was adding interior lighting, I might have considered it, but since I have no electrical skills, the light is out (pun intended).

-

Glad I was a bit of inspiration for you. My biggest problem is seeing that close. I physically have to get my nose within a few inches of a spinning disc that could explode due an in-opportune hand movement. I need to wear head mounted magnifiers and lights to see that close which provide eye protection, but those cutting discs are very fragile to tiny lateral forces. I broke one already just moving my work piece into position and just touched the disc. Luckily it wasn't spinning at the time. An X-Y table gives you a lot more precision. Mine just doesn't have the expanse of movement I need. I hope you can work it out. When you get your X-Y table set-up working, please post it.

-

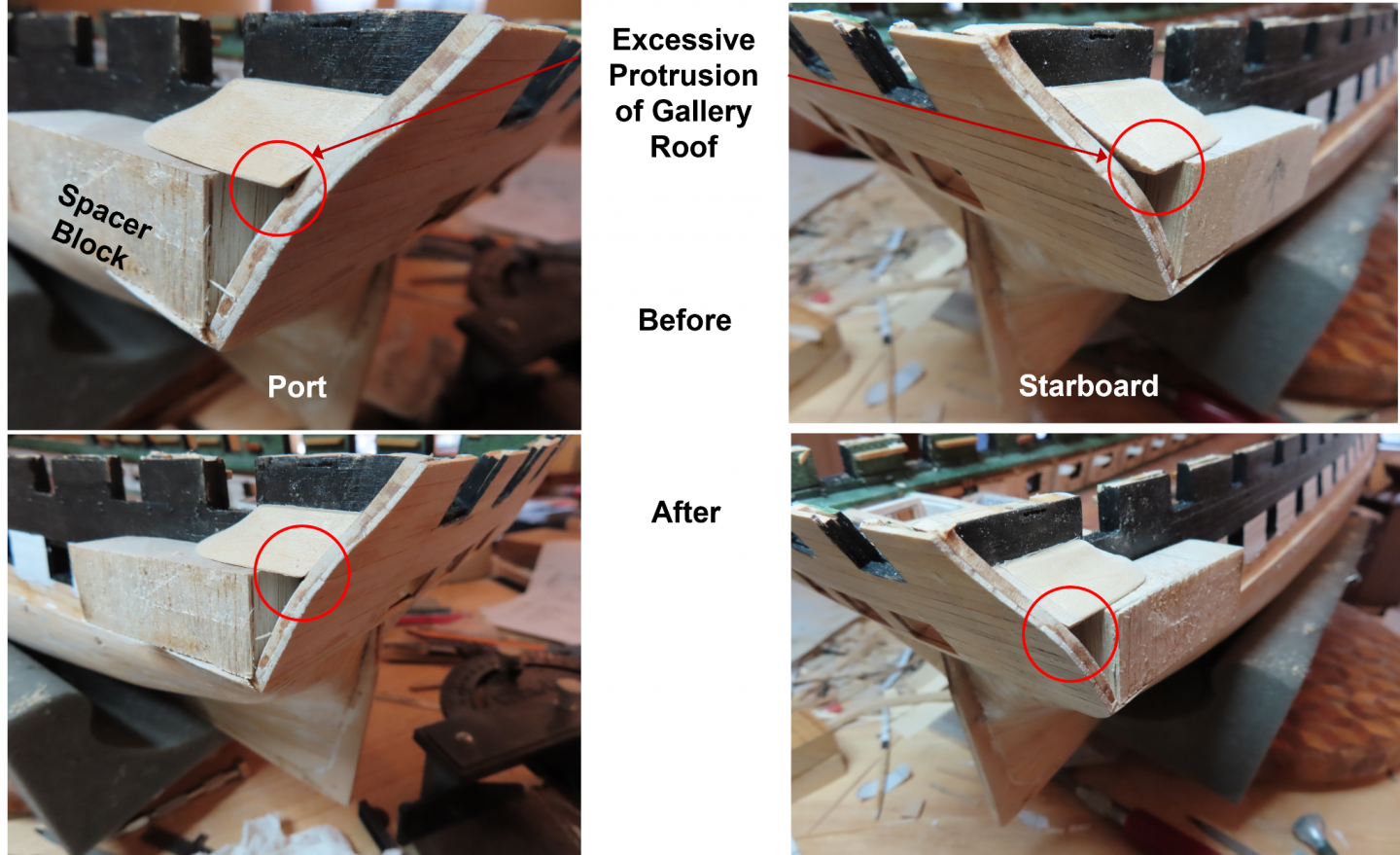

Once I made the molding, I had all my parts for the quarter galleries’ roof. The roof molding was cut and painted first. Using the gallery spacer block, the roof pieces were glued into place level with the gallery floor. Touch up painted was added to the remaining exposed transom wall. Finally, the roof molding was added to the roof. So far, so good.

-

Continuing with trying to make a decent scraper, I had marked the blanks (initially used old X-acto blades till I ran out, then switch to single edge razor blades) with a Sharpie to indicate where to cut. The sharpie markings were in turn scratched with a pin showing the planned profile. I have a limited number of ultra-thin, and very fragile Dedeco International cutting discs. What I lack is a steady hand and good eyesight. The spinning cutting disc cuts extremely quickly; one twitch and you've over cut or cut the wrong area and at worst, the disc shatters. In an ideal world, the scraper blank would be held fast to an X-Y table for precise cuts. My tools don't have that capability, so I'm forced to move the scraper blank by hand. It took some practice and luck, but I managed to make a reasonable scraper. Creating the molding with the scraper should be the easy part.

-

Except that it didn’t work. There is no micro adjustment for the vertical position of the Dremel tool mount. Getting it to the proper height was a pain. Once I finally got that set, the boxwood was put in the slot, and it slid beautifully. However, there was a smidge (that’s a technical term) of space between the wall of the slot and the boxwood. Although the space was just less than the width of a piece of copier paper.it was enough to allowed lateral movement as the boxwood slid along the slot making the cut groove meander. If the slot was any tighter, the boxwood would not slide easily. Then there was the Dremel drill press mount itself; it had a minute wobble to it that it also contributed to the wandering groove. My idea was fine, my tools however lacked the necessary stability and tolerance to make it work. Back to the cutting disc. In addition to fine cutting discs, I also had a Dremel diamond cutting disc which I tried first. After removing the X-Y table and remounting the drill press stand to horizontal mode, I just stuck a hunka-chunka (another technical term) piece of wood on the drill press base. I couldn’t use the X-Y table because the tip of the Dremel tool was now outside its area of operation and my piece of wood was too big. On top of the large piece of wood I stacked two smaller pieces (stuck together with double sided tape) to raise the work area as the Dremel tool would not go any lower. Using old X-acto blades for my blank scrapers I tried cutting my first profile for the quarter gallery roof top molding. The molding is only 1/16” wide and I wanted to get two grooves. Using the Dremel cutting disc didn’t work as it was just a bit too thick. I practically had to put my face within inches of the high-speed cutting discs just to see what I was doing. The depth of field of my optic head band is just fractions of an inch, not to mention the visual magnification distortion. I got a working scraper, just not the one I was trying to get.

-

As us Conny builders know, there are several moldings on the quarterly galleries and elsewhere. One of my nemeses (among many) is making the scrapers to form the moldings. I have yet to produce one to the proper width and profile. I have fine cutting-discs that I bought when making the Rattlesnake as it was part of the instructions, but they are very fragile and not cheap. You twitch, and they shatter; not good if your face is just inches away. So, I tried a new method. I cut a slot into a length of wood just wide enough so that a strip of 1/16” wide boxwood would slide along its length. The slotted piece of wood was then mounted with a drill press vise on an X-Y Table on my Dremel drill press so that the sliding boxwood would move just below a diamond cutter on the Dremel tool. As you push the boxwood through the slot, the cutter would cut a groove. Easy, peasy.

-

Mr. Hunt addressed the issue of detail: There is nothing wrong with what he states, but I’m not building my model based on what others will see or not see. I’m building it for me and if only I and the “man upstairs” can see it, so be it. Of course, I must balance that stance with practicality. How much satisfaction am I attaining if the detailed is buried with how much trouble is it to construct it’ That’s why I didn’t add some detail on the stove for example. I may be crazy, but I’m not that crazy (am I?). So, all that said, I decided to make the gallery roof look like it has a copper roof by giving it a copper roof, then paint it black. All that will remain (hopefully) are the subtle copper seams. Because the practicum warned that the copper tape supplied with the kit may not be enough to fully plate the hull, I had purchased an extra roll sometime back. That is why, the coppering of the roof is not bright and shiny because I used the top layer which was exposed. It gave the roof a nice patina, but unfortunately I had to cover it with paint. I did a painting test to determine which type of black paint to use on the copper, enamel, or the kit’s acrylic paint. As it turns out, both covered the copper about the same, but the enamel was more scratch resistant, so enamel it was.

-

OK, here is where I go off the deep end. Most everybody who copper plates the hull (as opposed to painting) tries to provide detail for the copper nails. Some are done well, others not so much. I figure if you are going to so much trouble to simulate the dimpled surface of the copper hull, why is nobody trying to simulate the copper seams on the quarter galleries’ roof? Maybe nobody was aware there was a copper roof on top of the roof rafters and wood sheathing. You can see the roof coppering seams below.

-

I noticed that the practicum, for what ever reason, skipped fabricating a roof element. These were the 1/16” bases of the roof blocks which sits directly on the quarter gallery cabin. Because there is fine detailing that will be added to the gallery, I am using boxwood in lieu of basswood wherever fine detailing is required. Boxwood is harder than basswood so it will hold fine edges better. Using my disc sander and a Dremel tool with a drum sander, two pieces for each gallery were cut and carved to shape. There are two long narrow 1/16” thick roof caps that I have yet to fabricate.

-

Basically, what this boils down to, is positioning the roof to the to the most aft gun deck gun port landmarks and then extending the roof dimension aft to the transom. The kit plan’s roof is just too short. In effect, this is what Mr. Hunt did. In fact he had to add additional wood to the roof block after he fabrication because it was based strictly on the kit plans. Because I now know this beforehand thanks to the practicum, I cut my roof pieces extra long so that it may eventually be trimmed to the proper size based on my model.

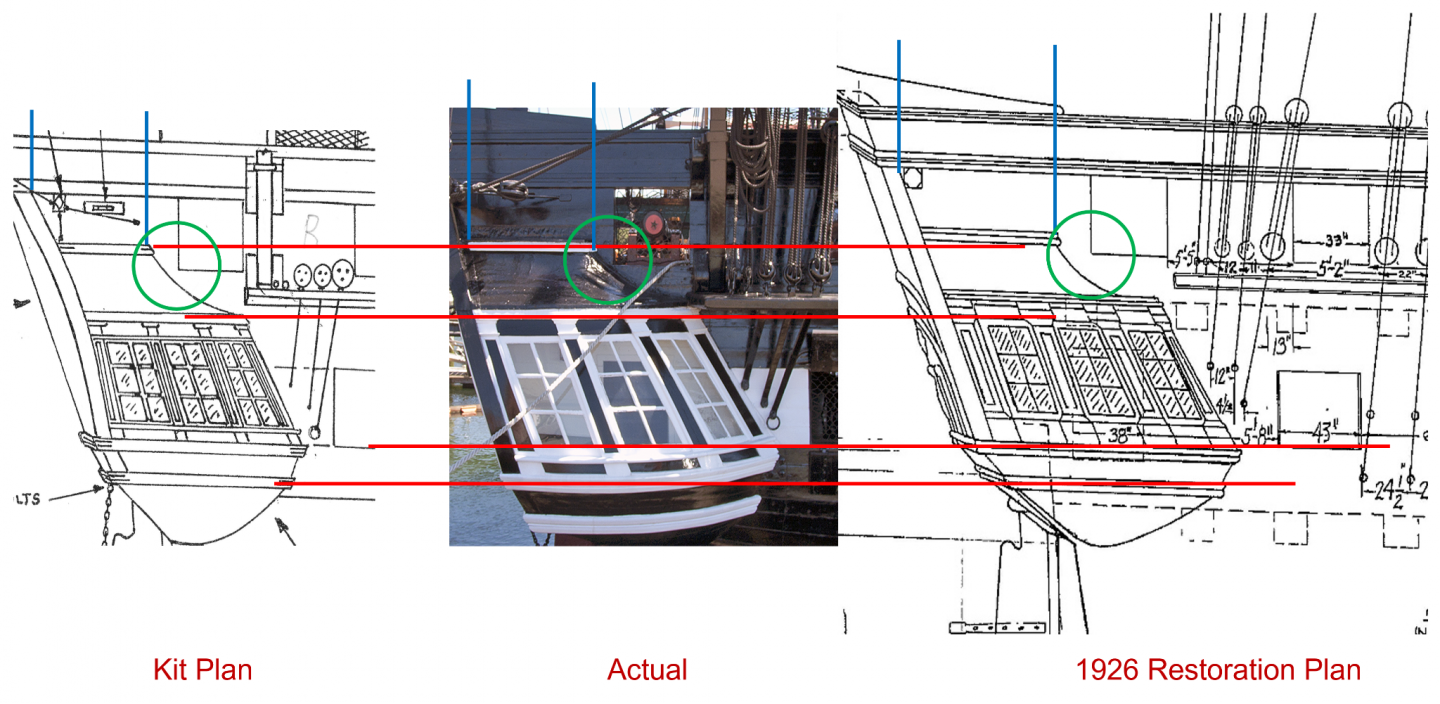

-

For those of you interested in whether I wasted my time applying the faux bolt heads, if the light is right and if the moon is in the Seventh House and Jupiter aligns with Mars, you can just see them if you squint your eyes and look at it sideways. So yeah, it was worth it. Quarter Galleries Right off the bat, the practicum identifies a problem with the galleries – the plans don’t match the actual ship. Bob Hunt was concerned when he saw that the most aft gun deck gun port, bottom aft corner almost touched the roof the gallery. However, the plans showed a larger gap. So I checked and compared the kit plan, against the 1926 restoration plan (which the kit is based on), and the best photo of the gallery I could find. The problem is compounded by the fact everything is perspective distorted either by the camera or the draftsman’s line projections. In the image below, the red lines line up the horizontal lines of the gallery. The blue vertical lines show the horizontal distortion. The kit plan shows the gallery compressed horizontally compared to the photo and 1926 plan. The green circle is Bob’s original concern with the gun port. The answer is to build so it “looks like” the plans but not necessarily exactly like the plan. And by “plan”, take your pick.

-

¼” wide auto pin striping tape was applied to the hull lining up exactly to the tops of the gun deck gun ports. A thin coat of white paint was applied along the top edge of the tape to seal off any potential bleed points. If there were any, it would bleed white on white. Then three coats of black paint were applied to the hull. Once the third coat dried to the touch, the tape was carefully peeled away. I have not done very much detail painting of this manner, so I had some minor touch-up work. Now for the interesting part, the quarter galleys.

-

First step per the chapter is painting the interior frame walls of the gun ports black. The next step was to apply the white paint between the gun deck gun ports. I used a thin coat of white primer and then two coats of white paint, both supplied by the paint supplement package offered by Model Expo. The instructions specifically indicated to over paint the white areas between the gun deck gun ports to ensure full white paint coverage. The black paint to follow is supposed to cover the excess.

-

Change of Plan – Painting the Upper Hull While waiting for my drill bits to arrive, I decided to look ahead at the infamous quarter galleys that has been the bane of so many builders by reading Robert Hunt’s practicum’s Chapter 7, “Outer Hull Details.” I realized then that I was once more in sync with the practicum …for the most part. Among other things, the practicum directs the builder to install the port lights and scuppers after the quarter galleys are constructed. Once the quarter galleys are done, the hull details port lights, scuppers, the stem and transom decorations installation are next. All that work will free up any restrictions to competing the gun deck interior which has a lot of work. Based on that thought process, I’m postponing the port light and scupper installation and will proceed to following Chapter 7. Since I have already marked the port lights and scuttle locations, I went ahead and drilled pilot holes with the new drill bits, so their locations wouldn’t be lost when this portion of the hull is painted black and covers up my position marks.

-

Using a 5/32” dia. brass tube (chosen by trial and error), short pieces are cut off and squeezed just enough to create an 0.0960” oblong cross section tube. A piece 0.010” sheet brass, was cut into a rectangle with one end rounded to represent the scuttle door. Filing the edge of the formed tube leaving the corner edge proud creates the lip flange. In order to drill a couple of holes to create the oblong shape, requires a 7/64” ( 0.1094”) bit. Another drill bit I needed (I actual purchased a set of 16 bits) The door was attached with CA glue. These will be inserted into the wide hole in the hull almost flush leaving the door and flange lip protruding from the hull. This will provide some detail even when painted black.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.