-

Posts

1,484 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

- 1,127 replies

-

- 1,127 replies

-

The Foredom is a totally different tool. It runs at around 20,000 rpm and is full of power. The Turbo carves runs at 400,000 rpm and has no power what so ever. You paint with the turbo while you cut with the Foredom. You will have to use one to understand what i mean. I have long had a compressor so that cost is not of concern for me. The hand piece is around $200.

- 1,127 replies

-

- 1,127 replies

-

Just saw this post. Sorry Bruce. No there is no record of her playing a role of any kind during the war.

-

- 1,127 replies

-

I have included some of these changes in the video and replaced it with a new version.

- 1,127 replies

-

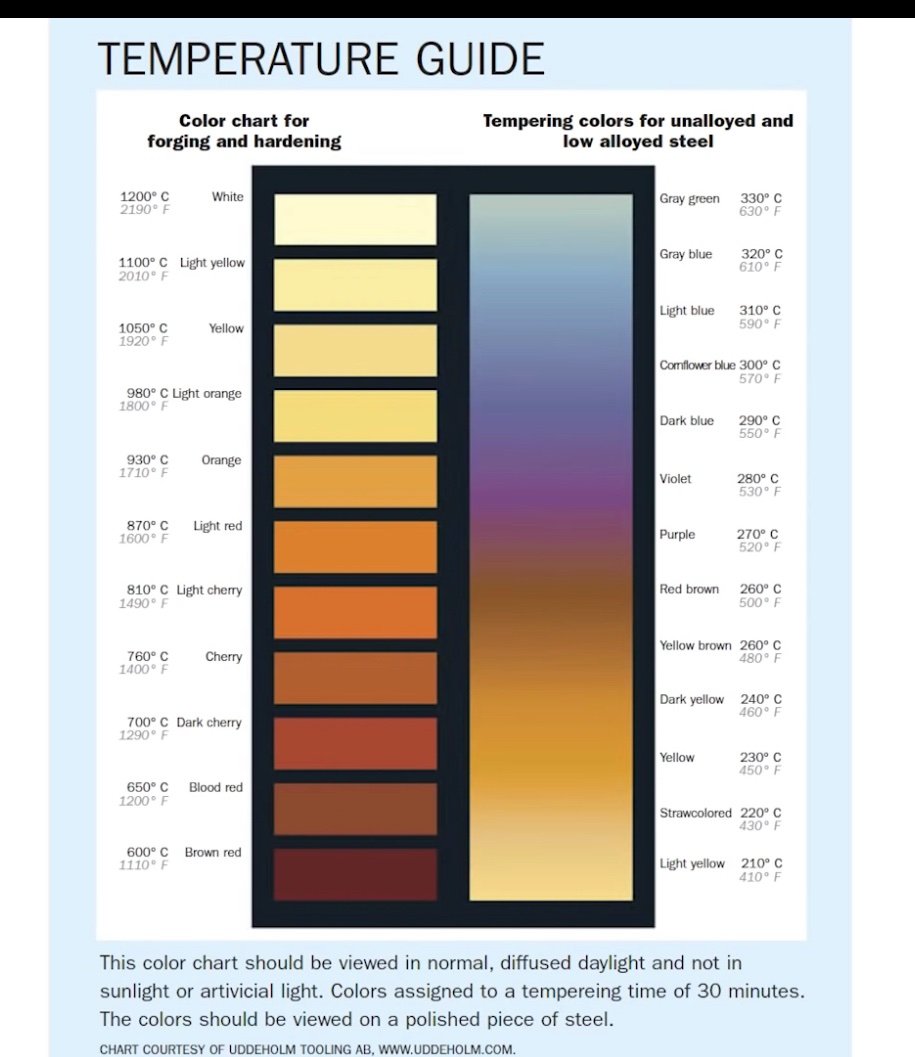

Thank you Alan. Ill have to read it about 5 times to understand in layman's terms. What was interesting in the videos on YouTube is that the test to achieve the correct heat was arrived at by testing the magnetic properties of the red hot steel. They claim its only when the steel has lost its magnetic properties that it has achieved the correct temperature to be made soft, and they just let the piece cool at normal room temperature on the work table. Going back to my colour chart above thats between 1300-1400 degrees F.

- 1,127 replies

-

- 1,127 replies

-

Good to know, but in any case thats why the fire extinguisher is always close at hand. In case.

- 1,127 replies

-

Just looked TTT up and this is getting far to technical for a simple mind like mine. Having read it i have no way of knowing what type of steel the hacksaw blade is made up of so no way of knowing how long it should be heated to and the exact temperature. But i am always will to learn. Thats the purpose of my videos.

- 1,127 replies

-

Lots of very good questions, let me say that the process was based on my research. I do not pretend to be an expert in this field, quenching to soften. It was particularly mentioned that steel that is brought up to a slow heat should not be quenched as it will become brittle. They specifically suggest that it should be left to cool at room temperature. Apparently this is different for gold and silver and specific only for steel. tempering. There are different opinions about the temperature and the time it should stay at that temperature. The objective here is again to slowly bring the piece up to a low red heat. This temperature is supposed to be around 250 to 300. when this happens and to check that the correct temperature has been reached and you have a magnet check the steel to see if it has lost all its magnetic properties. This is the critical temperature. At this point it is dunked in the oil. The type of oil does not seem to be important except for environmental issues. At 300 degrees there is little chance of fire. Some use cooking oil some use old discarded motor oil. Water is not recommended as it will again make the metal brittle. The time spent in the oven is just to get to temperature slowly back to the 250 to 300 degrees. Once achieved You simply turn off the over and let it cool naturally providing your wife does not come around and want to know what you are doing in her oven. This was my big problem as we were renovating her kitchen at the time hence the use of the toaster oven. The swishing of the steel in the oil is an old holdback from my drinking days as i was a rum salesman.

- 1,127 replies

-

Thanks for all the great advice. We are not there yet but close with the tools we have. That power point presentation from Toni was invaluable as you will see when the video is done covering this part of the build.

- 1,127 replies

-

I am doing all that Alan, its the scale that is giving me the challenge. Also on the Mill its difficult to see the depth of the cuts. Ive made some 10 scrapers so far but not happy with the results. Today i am going to see of i can hook up one of my cameras and blow it up on a monitor to get a better feel for the depth of cut. My Turbo carver is small enough to cut the curved surfaces on the hacksaw blades but my smallest files are useless.

- 1,127 replies

-

Working on making the moldings. Having a hard time with the scale. Most of my tools , blades, files are too large, but i will get it done but it will take a few attempts. So there will not be another video until I get it right.

- 1,127 replies

-

This blade was not good. Too few teeth, made a lot of noise. Wasted my $5.00

- 1,127 replies

-

Harbor Freight 4” saw blade. I forgot to say i purchased a 4” saw blade with a 1/2” arbor for the Jim Byrnes saw and it works great. Its a bit noisy but i can now make 7/8th cuts when making bulk stock. It is a bit noisy but works great. At $5.00 how can you go wrong. In the past i used my Proxxon to do this work but it would struggle when making large amounts of stock.

- 1,127 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.