-

Posts

600 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by vossy

-

-

g'day Duke, good to see another Bounty, albeit a different kit to mine. you are lucky that there is a great build log on this site for your particular model. me, i have no such reference i'm afraid. anyway onto your keel problem - i reckon you could probably fix that by using filler blocks or rods between problem bulkheads until the alignment is right. i don't know how many models you have built but i have done a few and i can assure you that the keel and bulkhead definitely need to be 100% correct alignment and perpendicular before you attempt to do the first planking. in fact i reckon this somewhat boring and seemingly easy part of the build is imo perhaps the most critical part of the build for if you get this wrong pretty much everything afterward will also be wrong and out of alignment. anyway happy building over there in canada

cheers chris

-

g'day brian, thanks for that. so i'm figuring its going ok at this stage?

-

all i want is some guidance on the first planking of my Bounty

- Landlubber Mike, mtaylor and hornet

-

3

3

-

ok need a bit of advice here

hope someone can help

hope someone can help  it appears there are zero build logs on the beginning of this model

it appears there are zero build logs on the beginning of this model

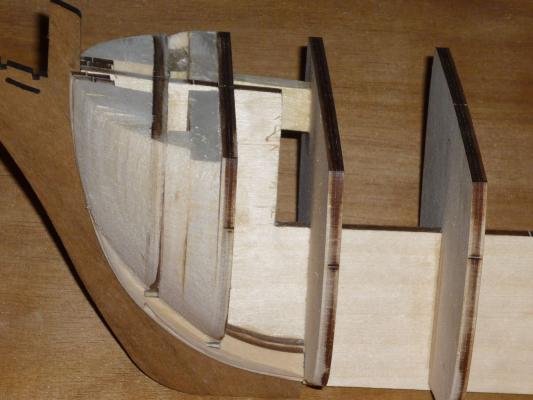

in case I muck up the uploading of files again!!!! I will ask the question and just hope the pics come through. Do I need to add any more horizontal first planks to Bounty's stern area? Or should I now just keep going with the first planking layer on the sides and sweep them up to meet the stern area as it currently is?

cheers chris

Hopefully that worked

-

g'day brian, we didn't have it during gulf war 1. but then again we were stationed behind nearly all the US Fleet

so probably didn't need it that much

so probably didn't need it that much

-

HMAS Torrens camo was grey. i know - i personally put a lot of it on

-

g'day all have progressed but work in the wineries takes up much of my time

will post updated pics tomorrow hopefully. just began first planking on stern

will post updated pics tomorrow hopefully. just began first planking on stern -

g'day all, this is probably a dumb question but what exactly does a serving machine do? do i need one? and if so any recommendations on units out there?

cheers chris

-

can't find it on a google search but my computer skills are as refined as a ballet dancer in football boots

but at any rate i've never heard of them.

but at any rate i've never heard of them.cheers chris

-

g'day mate,

apart from the brisbane lions afl website this is the only place to be seen on the net. anything and everything Bounty will surely be appreciated by many here. welcome

-

-

I'm sorry but I'm finding it harder to create the log than to actually build the model!!!

-

ok so that sorta worked

will try to post more pics... standby incoming... ummm how do I post more pics in my log???

will try to post more pics... standby incoming... ummm how do I post more pics in my log???  :(

:(  I'm no bill gates either!

I'm no bill gates either! -

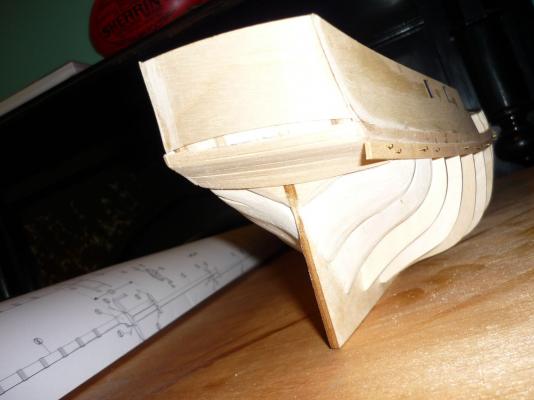

:piratebo5:ok so I thought I would begin a log on the Bounty as their are very few around. I have viewed david's and roman's build of this great vessel a zillion times and hope to do them justice with this effort. due to my interstate work commitments updates maybe somewhat spasmodic but I will do my best. please be forewarned I'm no Damien Parer with a camera though!

am going to bypass the usual pics of box contents etc and get into the nitty gritty. here goes.....

am going to bypass the usual pics of box contents etc and get into the nitty gritty. here goes.....

I always use filler blocks

its a little known fact that God created Balsa wood to specifically stop model ship builders from abandoning the project at this stage

its a little known fact that God created Balsa wood to specifically stop model ship builders from abandoning the project at this stage

and on the stern

ok heaps more to come just need to see if this worked before posting more.

cheers vossy

-

g'day mate,

my advise, buy the kit and bash the living daylights out of it! doubt you will find many (other than very top end i.e.. price) that don't need a little tweaking here and there. our hobby isn't an exact science

but thats what makes it fun.

but thats what makes it fun. -

g'day mate,

i score each of my deck planks with a 2b grey lead pencil on either side and end before laying them. i find even after a good, albeit light sanding with 240 grit the caulking effect is just right for me (i am captain after all). i tend to use lime wood 0.5mm strips for my planking (wether supplied with the kit or not - amati bounty supplied walnut strips which i considered too dark so i bought replacements from my favourite shop - hello float-a-boat - for 8 bucks). this timber is quite pale so i reckon i might stain with a light oakish type of colour. i do recommend however to do test patches on scrap timber before committing the final colour to your build.

cheers chris

- CaptainSteve, harbm and HIPEXEC

-

3

3

-

-

i reckon half the fun and the challenge is to research, learn and bash as you go. i have bought five kits - billings oseberg (in hibernation), amati santa maria (completed), mamoli golden hind (about to step the masts), amati bounty (just begun), corel victory (first planking nearly complete). all these vessels were actual boats in their day and i'm pretty happy with what i will be building (apart from the insistence of these manufacturers to include metal lifeboats on vessels built in the 15th century etc). at the end of the day who cares if 'your' model was a real ship or not? i bet most of your family and friends who admire and stare enviously at your finished ship wouldn't know endeavour from bounty, cutty sark from thermopylae etc. i say more effort on the manufactures part should go into the supply of more authentic materials to build such things as boats, gun carriages, incidental deck furniture etc and let the builder recreate it as best he/she can. i say we start up a movement to abolish fake metal lifeboats. my hero columbus would turn in his grave!

cheers chris

-

umm, glowing? sorry michael not sure anymore?

cheers chris

-

g'day brian,

nothing wrong with the product, just wouldn't recommend it for a final

coat on a model

cheers chris

-

g'day brian,

linseed oil would be one of the worst oils to use as it penetrates extremely well.

its why back in the day all the cricketers used to oil there bats with it. it soaks in toughens

the wood and gives a more flexible timber. downside; nothing much sticks to it. hence the

reason cricket bat manufacturers made polymer bats so their logo's would adhere to the wood

for longer.

bottom line: linseed oil is a highly efficient/effective penetrating wood conditioning oil. once

applied its pretty much there to stay.

cheers chris

-

g'day mate.

do you mean you have to GLUE other items to the hull that you have oiled?

2 pac or other oil based adhesives will bond to oiled surfaces but to be sure i concur

with brian about sanding both surfaces to be bonded together.

another more foolproof, albeit tedious, time consuming, slightly expensive method would

be: sand the second (oiled) planking to within a nano millimetre of its life and relay a

3rd layer over it. given the original second layer is only .5 of a mill thick i reckon if you

spend an hour or two with a bit of 120 then 180 then 240 grit paper you can probably get

the hull back to an even better stage to apply your new final planking sans oil.

might sound daunting but i bet this will give you your best outcome. don't know what part

of the world you are from but i reckon 20 odd dollars would cover the cost of the new strips

cheers chris

-

g'day michael,

need to know what type of oil you used, where you put it, and what you want to

put over it? i'm a professional painter by trade so i may well be able to assist you. there are a

few options available to fix your problem.

cheers chris

-

personal choice plays a big part i reckon, but for me on my golden hind painting

below the waterline was a godsend. i reckon the kit was missing (among many other

things) at least 16 second layer planking strips. luckily i had many of the same dimension

left over from amati santa maria and although a different colour because i painted

below the waterline nobody (ok, except you guys) knows any different. staining

or more to the point clear coating looks fabulous on a well planked hull though.

sort of like looking at the admiral in a swimsuit as opposed to a trench coat

...

...cheers chris

HMS Bounty by vossy - Amati - scale 1:60

in - Kit build logs for subjects built from 1751 - 1800

Posted

well this is where I'm at. stuck! no-one seems to either know or want to offer advice bar roman who lives in Russia and takes an eternity to communicate with because of the distance and time zone issues (not his fault btw). will give it till the end of the weekend then just like Indiana jones take the great leap of faithand hope for the best.

no-one seems to either know or want to offer advice bar roman who lives in Russia and takes an eternity to communicate with because of the distance and time zone issues (not his fault btw). will give it till the end of the weekend then just like Indiana jones take the great leap of faithand hope for the best.