-

Posts

1,222 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by jbshan

-

Roughly, yes. It's been through the camera, to my computer, through the internet and now your computer and your monitor, but yes. That's why I try to use a description you can find an example of instead of relying on the picture. Another way is to use Crayolas, because you can buy a box and use that for a color match.

- 143 replies

-

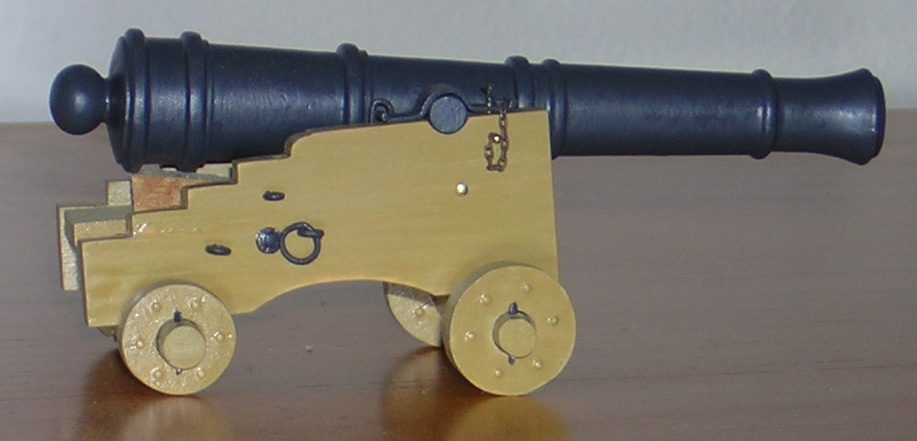

Mike, you could use the Constitution (from your Niagara thread) photos for a painting guide for the gun carriages. Sometimes they're red, sometimes yellow ochre/buff. Painted wood work, black iron work, my take.

- 143 replies

-

A larger work table may be in order, for keeping away from the edge of.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

I used a couple of Lil Pins, in one of the parts bags, to reinforce the stern davits to the rail. They're in a good place to get bumped. After they're in, just paint the heads black.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

Good examples, Dave, thanks. Treenails have always seemed to me to be an example of doing a thing because you can, but if they are out of scale or, on hull planking, only used where the kit bulkheads happen to come instead of every foot or two, they're done mostly for the 'coo factor' ('coo, woodja look a' that'). Look at Chuck's work or TFFM series by David Antscherl for properly done, subtle work.

-

I've found several images showing a couple of chains (?) between the forward fairlead and jack staff leading down and a bit aft, both anchored and underway. They may have intended to hook up the paravane, use it, then, upon recovery, restow the chain. I still don't think they would have let her anywhere near enemy-mined waters, at least without an escort more suitable for that work.

-

Cool photos, Darrell. The farmer on whose land this transpired, Wilmer McLean (thanks, Yahoo Search) decided he didn't like the neighborhood and moved to a nice quiet spot at Appomattox Court House.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

Keep in mind what you are seeing is not trunnels but rather wooden plugs covering either nail or screw heads. On the quarterdeck, supposedly, instead of a plug with wedge (as you can see in some of the pics) they would use a diamond shape with the grain running parallel with the grain of the plank. I doubt you could see those, to scale. I would say any of these would be max of 3/4" so be very careful of scale. I have read of these being done with broom straws which are pretty small, but between 1" and 2" in 1:64 scale. I've been working on a 1/2" scale model and have had good luck using the tip of a drafting pencil to make a deep mark. This model I don't think had plugs, just the bare nails, but you can judge the appearance for yourself.

-

Perhaps this was something they provided for, but never actually used. I can't imagine letting one of these get anywhere near anyplace they even suspected had mines. Likewise, some had submerged torpedo tubes. Torpedo range, 5 miles. Main armament range 15 + miles. They'd be more likely to hit one of their own. Looking forward to more progress pics. This is a type of vessel and model I'm not likely to be involved with, so I'm participating vicariously.

-

Going back a little, I'm wondering how they worked the paravanes from that fitting low on the bow. Were there chains or cables permanently affixed? I can't imagine sending even a seaman apprentice (from another thread) down to hook things up when required.

-

Tackle would be used to keep the gun tight to the bulwark. Mike's frapping would be involved. Chocks under the wheels would also keep it from coming loose. There are some illustrations in the literature.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

Bob, try some thin wire and twist it up in a drill, like an egg beater drill so it goes slow. Jud, it is the Seaman Apprentices that fish out easily and drip dry well, yes? :-)

-

Mike, some people make up a coil off the model, then place it on deck with the fall of the tackle disappearing under the coil, as if it were all one line. If frapping works for you, frap away, it looks good, too.

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

There might even be less inhaul tackles than guns. They would share with each other. Considering a 'gun crew of 10' might serve two guns (P&S), each needing 7, those two guns might share one inhaul tackle, though I haven't seen this anywhere in print. They would be needed only to withdraw the weapon upon first loading. Once fired, the weapon would recoil into loading position.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

I put the ringbolts in the deck, but didn't rig inhaul tackles.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

That's the type of burr I was thinking of, Mike. Use it like a countersink, just to knock the roughness off. That'll help with whatever else you do around the hole, too.

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

Careful, Mike. It may be addictive. Yes, if you cut a cylinder on an angle, you get an oval hole. Here you have compound angles. Make 'em long and trim to fit. Mine look a little rough, too. I probably would try to chamfer the edges with a bit or other grinding thingy turned backwards in my pinvise. Just be careful about it grabbing the paint and pulling.

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

The inboard end of the anchor cable goes through a hole in the corner of a hatch and is coiled in the cable tier. The end is belayed to the foot of the foremast so it doesn't run out.

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

The tube may be your charlie noble. I just drilled holes. As I'm going to leave cables in, you won't be able to see whether it's lined or not, and who's to say they were lined originally, anyway.

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

I used a smaller drill and pin vise and off set it to be on the center of the hole, not, for example, on the waterway or the bolster outboard. Drill partway from each side, using the plans for a rough angle, then when the holes meet, go up in size and adjust the angles to meet. If you can get a set of reamers, sort of hand-powered square drill bits, you can finish up with those and avoid tearing the wood. Hawse holes were sometimes lined with sheet lead, made into a tube and extra left on the ends which was then slit and the ends folded back and nailed. This is to protect from chafing and water getting inside the planking. Think of lead flashing used on a roof, around a chimney or dormer.

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

And the corollary to Mike's post: With a thicker deck watch out for the clearance for the carronade barrels. Put one together and check that the ports are high enough.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.