-

Posts

314 -

Joined

-

Last visited

About Moxis

- Birthday 12/16/1947

Profile Information

-

Gender

Male

-

Location

Lahti, Finland

Recent Profile Visitors

-

Archi reacted to a post in a topic:

Proxxon Mini Lathe DB-250 - Opinions/assessments/recommendations?

Archi reacted to a post in a topic:

Proxxon Mini Lathe DB-250 - Opinions/assessments/recommendations?

-

mrtaylor57 reacted to a post in a topic:

Ratlines

mrtaylor57 reacted to a post in a topic:

Ratlines

-

Captain Phil reacted to a post in a topic:

Clara May by Moxis - FINISHED - 1/48 scale - ketch - after David McGregor plans

Captain Phil reacted to a post in a topic:

Clara May by Moxis - FINISHED - 1/48 scale - ketch - after David McGregor plans

-

catopower reacted to a post in a topic:

Laserboard, what material and where to get?

catopower reacted to a post in a topic:

Laserboard, what material and where to get?

-

ccoyle reacted to a post in a topic:

Le Cerf by Moxis - FINISHED - 1/48 scale - French cutter

ccoyle reacted to a post in a topic:

Le Cerf by Moxis - FINISHED - 1/48 scale - French cutter

-

smtm2013 reacted to a post in a topic:

How to fix copper/brass strips and fittings to hull or other surfaces?

smtm2013 reacted to a post in a topic:

How to fix copper/brass strips and fittings to hull or other surfaces?

-

DaveBaxt reacted to a post in a topic:

Proxxon Mini Lathe DB-250 - Opinions/assessments/recommendations?

DaveBaxt reacted to a post in a topic:

Proxxon Mini Lathe DB-250 - Opinions/assessments/recommendations?

-

Rudolf reacted to a post in a topic:

19th Century French portable binnacle

Rudolf reacted to a post in a topic:

19th Century French portable binnacle

-

3d printing crew figures

Moxis replied to highlanderburial's topic in 3D-Printing and Laser-Cutting.

This is exactly what I would like to do too. The quality of prints made with resin printers is way better than ones produced with machines using filaments. Also the cost of these printers begins to be acceptable. But what is still prohibiting me to step on this path is the problem to learn to use a 3D design software so brilliantly that I could be able to produce something that I could be happy with. I have a hobbyist's free version of Fusion 360 software which I have tried to learn, but still after a few month's practize I am still far from being able to design parts for ship models I would like to print. So my question is, which software you guys are using to design your parts or crew members, and how have you learned to use it properly so that the quality of prints is acceptable? -

Moxis reacted to a post in a topic:

3d printing crew figures

Moxis reacted to a post in a topic:

3d printing crew figures

-

Moxis reacted to a post in a topic:

3d printing crew figures

Moxis reacted to a post in a topic:

3d printing crew figures

-

Moxis reacted to a post in a topic:

3d printing crew figures

Moxis reacted to a post in a topic:

3d printing crew figures

-

Moxis reacted to a post in a topic:

3d printing crew figures

Moxis reacted to a post in a topic:

3d printing crew figures

-

Moxis reacted to a post in a topic:

3d printing crew figures

Moxis reacted to a post in a topic:

3d printing crew figures

-

Ripping Planks - what I've learned from others

Moxis replied to glbarlow's topic in Modeling tools and Workshop Equipment

Usually I scratch build models of 45...47" of length, therefore needing planks of 50" to be able to use one plank from bow to stern. -

Ripping Planks - what I've learned from others

Moxis replied to glbarlow's topic in Modeling tools and Workshop Equipment

Quite often I am cutting planks of 50" length or more with my Proxxon, and have no problems at all to do that. I am supporting the stock sideways against fence with a block of wood as described here, and with another hand pushing the stock through. My blade is a Proxxon one with carbide tipped teeth and 1,6 mm kerf. After a little practice everything goes quite smoothly. -

Moxis reacted to a post in a topic:

Lower cost (?) shiny metal parts

Moxis reacted to a post in a topic:

Lower cost (?) shiny metal parts

-

Lower cost (?) shiny metal parts

Moxis replied to Patrick Matthews's topic in Metal Work, Soldering and Metal Fittings

Very interesting. It begins to be clear that you can electroform or electroplate items relatively easily at home with copper, but us ship model builders would need parts made of, or at least look like made of brass. So I think it is not possible to apply brass surface directly on conductive paint, but you need first to electroplate the part with copper. But how about gold plating, can it be applied directly on conductive paint? Gold plating could be perfect on small items, it will look like polished brass, never oxidize and very thin layer of gold doesn't cost very much more than plating the parts first with copper and after that with brass. -

Lower cost (?) shiny metal parts

Moxis replied to Patrick Matthews's topic in Metal Work, Soldering and Metal Fittings

Very clever indeed. Could it be possible to brush plate brass directly on the conductive paint? And which products he was using for brush plating? -

Moxis reacted to a post in a topic:

Show me yours tools !

Moxis reacted to a post in a topic:

Show me yours tools !

-

Moxis reacted to a post in a topic:

Show me yours tools !

Moxis reacted to a post in a topic:

Show me yours tools !

-

Hello Agamemnon9, could you explain how you make those wonderful carvings? And if you consider new tools, how about a small CNC router or 3D printer and a good 3D design program?

-

Moxis reacted to a post in a topic:

Show me yours tools !

Moxis reacted to a post in a topic:

Show me yours tools !

-

When I was making a round compass cowl for my Maaninka steamer, I first made a suitable sized ovalish ball out of plasticine. On the ball I applied a thin coat of a gel of milled fiberglass and epoxy, but left the underside open. When the epoxy was cured I removed the plasticine so I had a thin ballform coating which was sanded smooth and painted with brass colored Alclad. When weathered with black pigments the result looked quite realistic, although was not shiny polished unit as normal with these things. Thin celluloid plate was glued inside the cowl as a glass and nice compass rose found in Internet was scaled and printed & attached under glass. Then the cowl was glued on top of a wooden pinnacle.

-

Epoxy over PVA

Moxis replied to dkuzminov's topic in Building, Framing, Planking and plating a ships hull and deck

I have used milled fiberglass mixed with epoxy to a gel like stuff and applied it inside the hull. When cured it strengthens the hull considerably and makes it watertight. https://www.amazon.com/Great-Planes-Milled-Fiberglass-Ounces/dp/B001BHEGRO -

Thanks Per and Jaager. My Corel version was many years old, I think it was #7 or near. No key or anything left, so I think it is not possible to restart it any more. GIMP might be nice. I have to study it more carefully. I don't need this software very often, so don't want to invest hard earned money for it.

-

From time to time I need some flags or other graphic drawings for my projects. Earlier I was using Corel Draw which is a vector based program and very useful for these tasks. Unfortunately a few months ago my old computer crashed together with Corel Draw. I was immediately downloading a free trial version but that is accessible only for 30 days. Buying new version is out of question because of high price. Does anybody know any other free or affordable graphic design software which would have nearly same features as Corel has? I was already testing Inkscape but results are not very promising, even after learning and reading through numerous tutorials available.

-

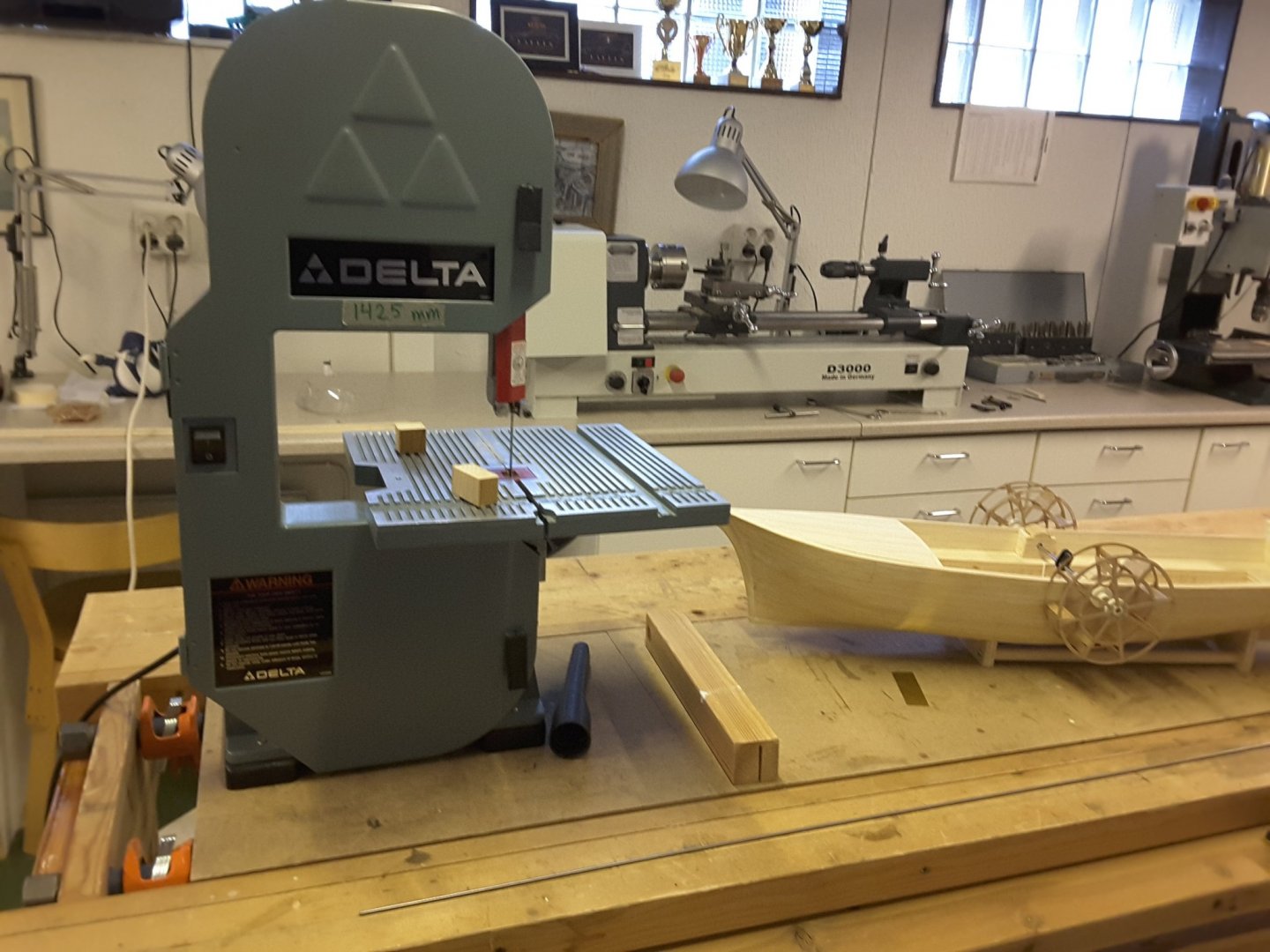

Thank you guys, now I know I have a 7,8" bandsaw (wheel diameter 200 mm), a nice old Delta which could be bigger and more accurate. But with it I have built a lot of models and it fullfills my needs satisfactorily. I had a Delta scroll saw too, but never learned how to use it properly. Or maybe it just was not the perfect tool, so I let it free to recirculation for somebody else's frustration. A Hegner would be my dream, but too expensive for a retired person. So old school manual jeweler's saw is what I am using to produce small accurate parts. Time I have enough!

-

I have always wondered what means 9", 12", 14", with bandsaws? Is it the diameter of the wheels, throat distance or what?

-

Mini Table Saw recommendations

Moxis replied to captainscott's topic in Modeling tools and Workshop Equipment

I have same question, I wouldn't like to order blades from US, they must be available in Europe too. -

Mini Table Saw recommendations

Moxis replied to captainscott's topic in Modeling tools and Workshop Equipment

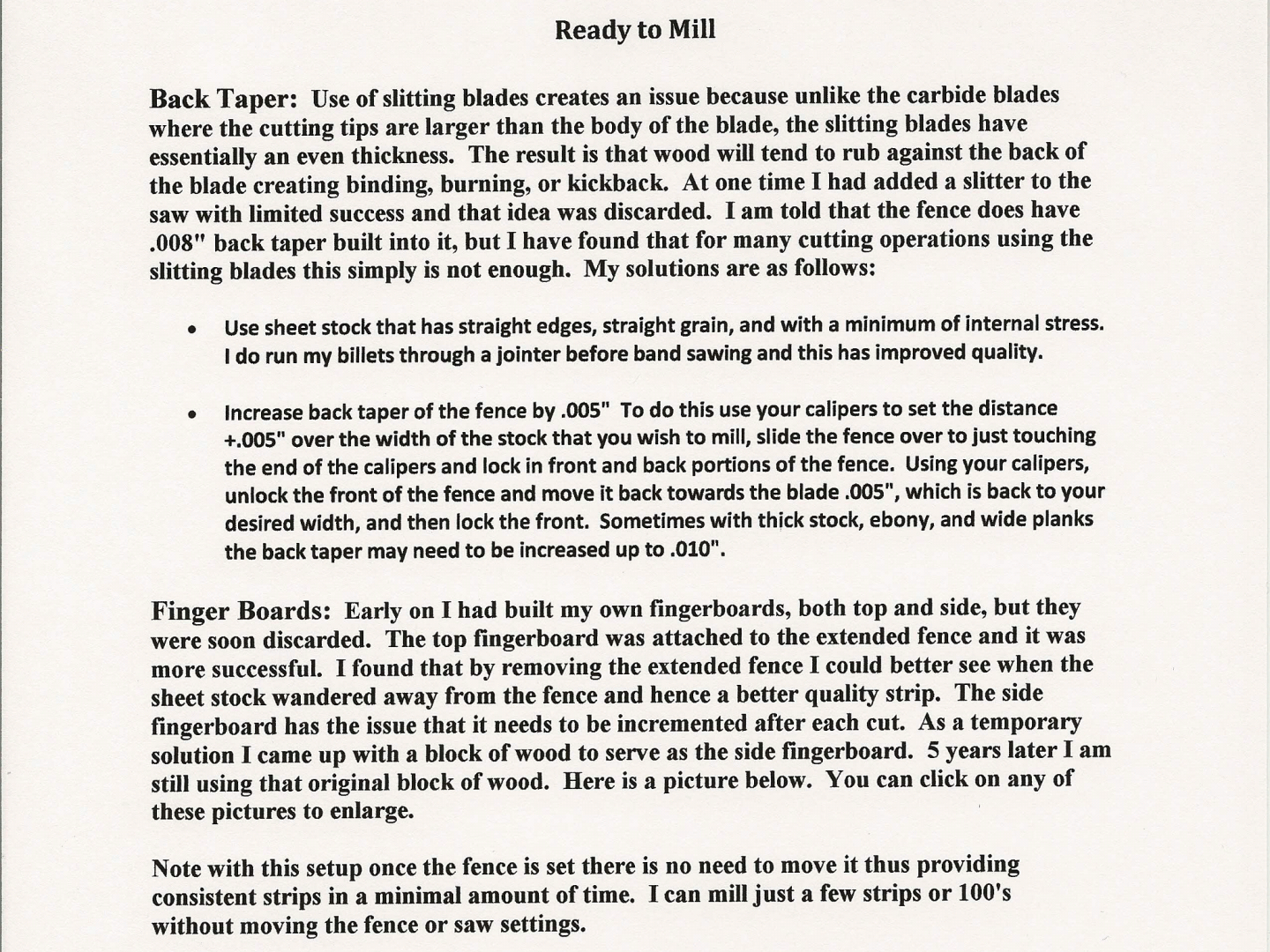

I was reading through the instructions .pdf but didn't quite understand the chapter "back taper". Is it really so that the fence of Byrnes saw is divided in two, the part before blade and the one after blade? And this gentleman is adjusting the part after blade a bit (0.005") differently than the forward part? Or is there something that I just don't understand?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.