-

Posts

599 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Cabbie

-

- 241 replies

-

- mermaid

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Hi James, if you put your plank in place while it is still a bit wet you can move it around into position, doesn't need much glue. Just keep an eye on it in case it moves. I use a very small art brush to apply glue. Use some leftover bits and practice on something else. When it is stuck it is done, push it flat and move on to the next. I sometimes do 2 or 4 in one go. Hooroo Chris

- 241 replies

-

- mermaid

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Looks very nice James I have been using contact glue on mine , might pay for it later on when it comes to cleaning up. I diluted mine with a bit of turps so that it was more runny and easier to clean as i go. If you can, look for a cabinetmakers brushable grade. I would pass you some over but it is a bit far! Cheers Chris

- 241 replies

-

- mermaid

- modellers shipyard

-

(and 1 more)

Tagged with:

-

In one of the sections in link, depending on whether you are scratch or kit. But please read the topic on naming your log makes ti easier for others to find later on. https://modelshipworld.com/forum/9-members-build-logs/

-

Welcome Peter? sounds very interesting. Please start a build log and show us what you are doing. Hooroo Chris

-

CAD help needed

Cabbie replied to Cabbie's topic in CAD and 3D Modelling/Drafting Plans with Software

Morning or evening for you Phil and thanks for replying. Definitely a windows user and it exports DXF or DWG, so that should be ok. Sounds very good about the ease of use help forums, though i might go for the 3d version just in case. thanks Chris -

CAD help needed

Cabbie replied to Cabbie's topic in CAD and 3D Modelling/Drafting Plans with Software

Thanks Tony and Vaddoc I used to own a copy of turbocad a long time ago and had forgotten about turbocad. I don't mind paying a little bit for it. The TC 2018 2d/3d might be the one. then i will need to work out how to get the data out of the kitchen program into TC. Thanks Chris -

CAD help needed

Cabbie replied to Cabbie's topic in CAD and 3D Modelling/Drafting Plans with Software

Thanks Lou But I don't need the imaging part i can produce images as per below, just need a simple cad program for 2d plans etc. thanks Chris -

Hello Forum Apologies if topic not suitable here please shift I am a cabinetmaker by trade but terrible at cad. Can anyone suggest a simple to use (lol for me) cad program that i can import? plans from my kitchen design program and do basic adjustments, measurements etc. Currently my kitchen program outputs to bto cad , but i am finding that too complicated to use, don't have the time to learn it. All i want to achieve is a plan like pic attached but that i can add measurements too. My design programs produces some very nice 3d rendered images but the they go to bto cad and i get lost. Thanks Chris

-

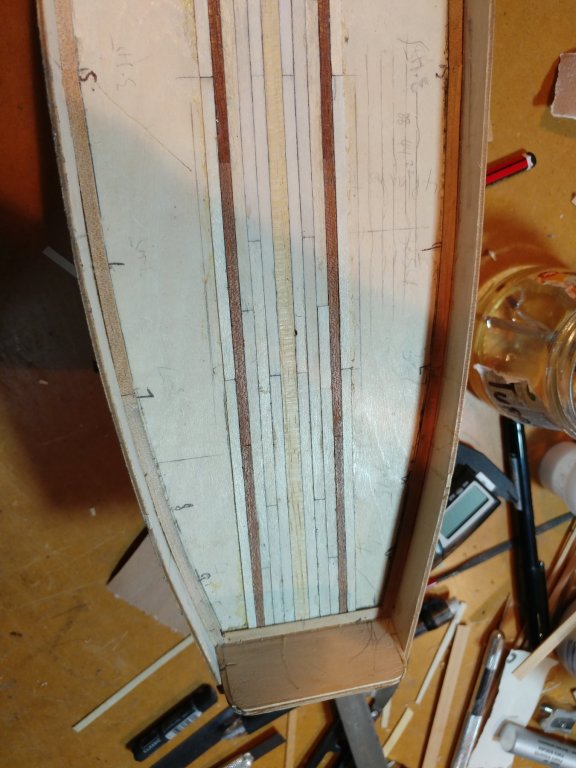

Minor update and look what happens when I turn my back for 5 minutes. The boys thought it would look good with "racing stripes". Who would have heard of such a preposterous idea. However i really don't mid the look, a bit unconventional, but what the heck. Lets hope that is all they have in mind!! Cheers Chris

-

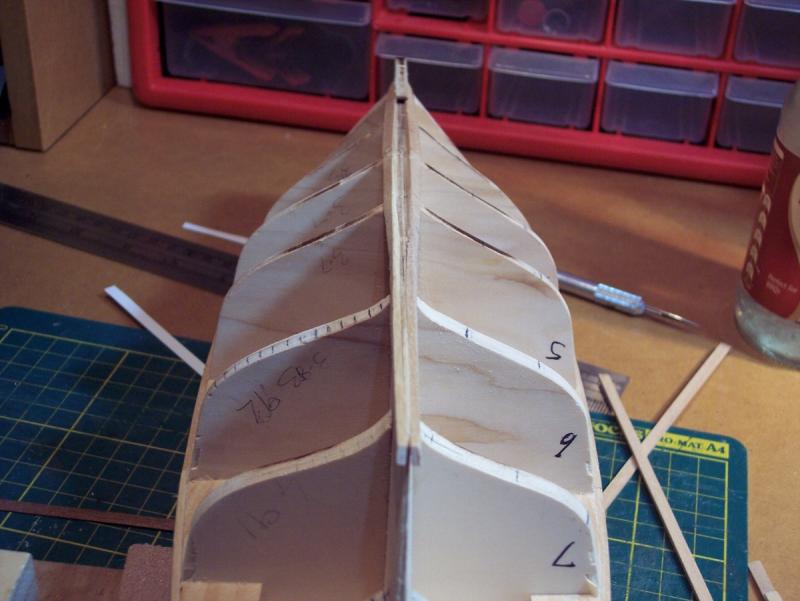

Wonders will never cease, I am back to model building and staying this time, though progress will be slow. A few pics are attached to show that the first planking is finished with a little bit of filler and the bulwarks have been glued on. Time to plank the deck next I think, should read instructions I suppose. I am planning on using hooked, tapered and bent planking if I can with the material provided in kit. Hooroo chris

-

Good Morning Capt'n Al Difficult job planking these sorts of ships and I was lucky that I had a full size replica to copy. https://www.flickr.com/photos/endeavourvoyages/albums/72157634081735926/with/9022926874/ Be careful with what I say I am not, by any means an expert on old sailing ships. more like an eggspurt. I think your 1st paragraph is close to the mark, but planks should not be reduced to less than half the original size. The planking rules did still apply, the joins still needed to run in the right line. I tended to to whatever I needed to do to make the plank fit, without doing anything too drastic. Have a look at how my endeavour planking finished.I haven't had any comments about whether it is strictly within rules. http://modelshipworld.com/index.php/topic/11341-hmb-endeavour-1768-by-cabbie-artesania-latina-160-kit-fiddle/page-6 I didn't use steelers at the stern. I started out with wider planks at the keel which when tapered gave a natural curve upwards. Planks were dropped under the wales as per the replica. I Hope some of this helps Cheers Chris

-

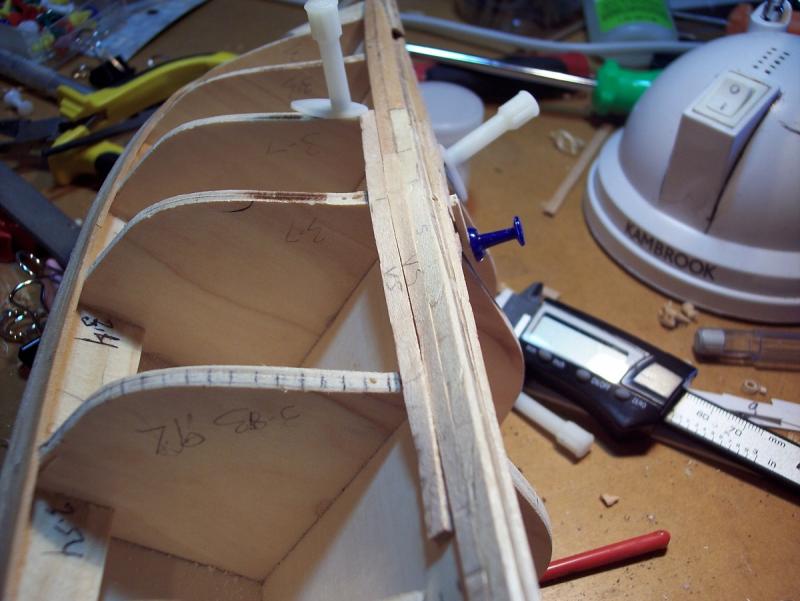

Hi Rick, unfortunately not in the Whitsundays. Had a bit of time off over Christmas but haven't got much done. Other things keep intruding, went back to work last Monday. Too many customers at the moment and its not going to get any better. I have managed to get a few planks on, and have been experimenting with different methods of holding them in place I have given up on the chart pins and now will just use the planking screws. The plank with the 90 degree twist is a pain in the butt to make fit. It did glue in better than what the photo shows. I have started steaming only those planks in a container in the microwave and it softens them enough to allow them to twist. And then use the planking screws to hold them in place until they dry. Then I take them off and do a final fit and glue in place. Yeah I know doing it the hard way, each plank is tapered, fitted and glued in place. I think that now is the best time to practice planking and work out methods. Thanks for the tip about the cannons, but the are still a while off yet. LOL Cheers Chris

-

Finally garbords are on, and rebate has been cut into the stem. Now its time to plank. It is a bit unconventional leaving the false keel off, but that will make it easier to get the thickness right. It will be fixed on before 2nd planking I will probably make it a bit higher, as it is now there is not much showing under the planking. hooroo Chris

-

Hi Rick haven't got started today yet, the Admiral is at work and will be home soon. Then we will get stuck into it. i left the false keel of at this stage so that i can sand to the right thickness before the 2nd planking. I am very conscious of the planks fitting up to it, and will glue on before 2nd planking.

-

Thanks Rick, yes air con is on and the modelling room is a great place to sit under it. Might add the blocks, will see if I can do without. It is a bit hot and dust today, but 36C is ok if you don't have to go out in it. Hi Dupree thanks for looking in, BUT, be careful following me, you don't know where you might end up. Cheers Chris

-

Good afternoon mi Lords and Ladies And merry Christmas, or a happy whatever you like to celebrate. A little bit has been happening on the Mermaid, 2 blocks added in the bow to give the planks something to finish on. The top planks under the gunwales are on, and part of the Garbords are on. First some pics And now a question, or is that 3? or more How should the garbord plank finish up to the stem post? I believe that they shouldn't finish in a point? Is it correct in what I am doing? Should it be done as a hooked plank, with the next cut from a wider plank to allow that. yes i am a fussy bloke, this is only the first planking, but I figure that this is the best time to get the technique right. Cheers Chris

-

Thanks Rick, Steve and Hof For the pictures and advice. I have decided to glue half the amount on as Hof suggested, I found the off cut of ply sheet that the transom was in, and have glued it in place. One reason for doing so is that I will be able to have a large round on the bottom of the transom to plank around. I will probably take off the 2 downward points, of the transom at the keel. They are right behind the rudder hole and at this stage I don't see any need of them, but will leave that until I need to do. Just another little question, What would have been the width of a hull plank on a full size boat like this,150mm, 200mm? Thanks again, Gents

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.fecd4818494fc32a02dc1d71b799c859.jpg)