-

Posts

599 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Cabbie

-

HI Ian and Dave thanks for looking in and the likes. You really want me to suffer don't you, Dave At this stage I am all chicken and not treenailing, a lot of those planks are only 3.5mm wide and less and i don,t know if I will do it well enough, but will take another look at it later. Next i am marking all the ports, channels and other bits before 2nd planking. Its a kink I have I have to plan it out before I start and I want to make the spaces for ports as I go. Though how the little ones that are only 3.2mm X 6.4mm will look I don't know. Cheers Chris

-

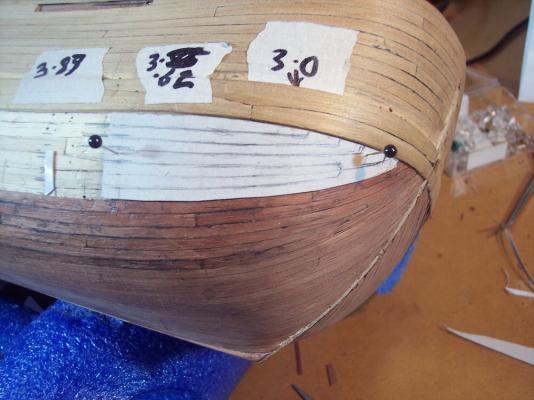

Good Morning all Update time again, I have finally finished planking under the wales. it has been given a fairly good sand, but will need a lot better. I think i will leave it, at this stage and move up above the wales, because as in my usual style I will probably knock it around during more work One thing I do know in doing what I have done is, that I have a deep appreciation for the work that the masters are doing. it involves so much concentration and workmanship to keep the work up to the standard that they do. Anyway a few pics, it is a bit nqr, but i am happy with it.

-

Thanks for the likes and looks folks. But there is going to be a little delay while I remove one of the planks in the top photo and replace it. it is going to keep bugging me if i don't, It won't take too long I have already had a bit of practice doing this. These close up photos just show too much some times. And yes, Slog can't wait to have a good sand and put some poly on. Cheers Chris

-

Good Morning Don she is looking like a fun build and you are doing a top job as usual. Perhaps you should save on glue by setting up a webcam, it would be far better than whats on tv these days. Or at least record what you are doing and we can download and watch. Cheers Chris

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Good afternoon all Getting closer now, only 10 planks to go to finish under the wales. And it will be pleasing to move on even though I have enjoyed it so far First a couple of pics of bent planks before fixing And some photos of her as of Saturday arvo. This is one of the clamping method I used to hold the plank whilst drying. And one of the stern, it looks a bit ugly like this The sanding will make a big improvement. Hooroo Chris

-

Well I am just extremely jealous of the kit, the quality of the plans, and that you are doing it, But do enjoy and i will force myself to watch. Cheers Chris

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Hi rusty Jumping on board to watch your build, I have a Syren waiting on shelf for me after I finish my Endeavour. From what I have seen so far your build will be a good one to get some tips and ideas from and to see how it should be done. cheers Chris

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Good morning Mike Yes you will need wider planks, I don't know enough yet myself to help you with what you need to do. But this topic was going earlier http://modelshipworld.com/index.php/topic/12582-to-spile-or-not-to-spile/ I think in the past they looked for the trees with right bend in them. Cheers Chris

-

Good Morning Ian and thanks I have seen the scratch idea and didn't get around to trying it. One thing I did for spiling was to get the shape first by trial and fit, and the once the plank is made, fit a piece of card on the ship next to the existing fixed plank, and then place spiled plank on top of the card and mark the top edge on the card, which is then the bottom edge of the next plank. Make sense?? Any way, done with spiling wasn't too bad only 4 spiled planks each side. Hooroo Chris

-

Good Morning to all. Still planking, but getting closer. the plank under to one that is being held by the pins had to be spiled, but after making the card template it wasn't too hard. I am hoping to finish under the wales by the end of next weekend. err maybe! Now off to do a bit of planking, before some house chores. Cheers Chris PS Hi Mark can't wait to sand and put some poly on it.

-

Very creative work, Ian This ship is going to look amazing when finished, with the different timbers and the patterns on the deck and the quality work you are doing. Hooroo Chris

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Good Morning Hof Just checking to see how things are going. The lower planking is certainly time consuming and fiddly to do. How is it going? Have you given much thought to the various, portholes, openings, hinges? What are they properly called? I am waiting to see what you do with yours . I haven't got a clue. Except I don't like the metal ones supplied with the kit. Cheers Chris

-

Yes, definitely top class work work, Ron Very neat and tidy. Cheers Chris PS Do we get to see a pic of Ron bouncing on the trampoline. Maybe when you are finished as a celebration.

-

Thanks for the tips Pat and David, though I'm not sure about using the CA glue. Will it stay there and show through the poly later on? I tried to work out the next plank and couldn't, so I decide to shape some card to fit in the remaining space and mark the planks on it. That made it a lot easier to mark out, and I realized rhat I can cut each plank off as i go and use to make them. So now its off to file some finger nails, and skin off me. Cheers Chris

-

Beautifully done Mark, The windows are well spaced and have even symmetrical shape to them, and with the glazing it is going to finish very well done. Chris

-

Good Afternoon all 35c outside here this afternoon, so that's it for the outside work. So I thought might as well do a little update, any excuse to think ship modelling, will do. The bottom photo is of the first 2 hooked planks for the bow. it took 4 goes to make the first one. The Jarrah is brittle and breaks little bits off. I will be only posting a limited number photos until I finish planking below the wales. Its too hard to take a good photo to show the details without doing a proper sanding and putting a finish on the planks. Specially of the bow. Any way planking is proceeding at usual pace, so won't take too long. For those that haven't seen this pic I am trying to plank the bow as per scan 38 on this page http://modelshipworld.com/index.php/topic/1207-endeavour-replica-construction-pics-moved-by-moderator/ On a different note I just noticed that I have followers, very flattering, thanks to all. BUT, Being a follower here doesn't mean that you sit back for an easy ride. You will need to put in at some stage, I will need it later. Some have already offered advice and I always say "the more the better" So chip in especially, if you see me about to do something wrong. Hooroo Chris

-

Good Morning Gonzz0 On my swift I made them run parallel with the top of the sides, from memory i think they had to be side bent to some degree, But i don't think they needed much persuading. Here is a link to some photos I put in my new member intro. http://modelshipworld.com/index.php/topic/10630-new-member-from-victoria-australia/?hl=cabbie#entry320598 I still plank by the rule of "If i can bend it and make it sit flat, i do it" Probably not correct ship building technique, but a man has to do, what he has to do. I sill haven't learnt what exactly is the correct method for something like this, perhaps someone else will chip in. Keep modelling Chris

- 38 replies

-

- artesania latina

- Virginia

-

(and 1 more)

Tagged with:

-

Good Morning Hof AOTS has them down in actual mm's with its 1 to 96 scale going from the bow 25.5, 23, 30, 33 mms at the stern. The middle measurements taken at the step in the gunwales. On their plan they have a little curve up at the stern to be 30mm. On our scale mine ended up being close to parallel, 40mm at the front half and 54 at the rear. Hope all this makes sense. cheers Chris

-

Good Morning everyone Thanks to all for the looks, likes and comments. I nearly have the first pair of drop planks done, will post some pics soon. Tricky little devils to keep in the right line. Hi Don, yes I cant wait to finish below the wales and get some poly on it. A lot of planning and in my case, some copying of the replica, but i still had to make it fit on my ship, and it needs constant checking to see that I am keeping spaces right and planks in line. It is a very busy site, MSW these days. Logs disappear down the list quick, and its a lot of time spent looking to keep up. Hooroo Chris

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.