-

Posts

1,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

I use walnut stain made from walnut shell https://ardec.ca/en/p/62/walnut-stain The color has to be fix with alchool. I also do some other mix with beewax and other components depending of the results I want I am not sure you use a good method to turn ropes, look like some turns are missing to hold every thing together.

-

It is a good thing to know where is the blade without necessarily seeing it. I like to watch on Historia channel a program called Fire and steel, a competition to make and test a knife: blade and handle. Every time they test durability by hitting the knife on hard objects when the handle is round, the handle slips in the hand and reduce the performance of the blade: the judge does not like that. I think that the size of the handle is also important. Just like it is easier to build at 1/48 scale than 1/184, because the part is easier to hold. I think that the same rule can apply here. I knew that I have more control with a bigger handle and I think that this one reason.

-

One last element to add at this level a double wall filled with sand. Before it is too heavy to turn upside down, 1 coat of tung oil is applied below first deck outside, it gives a complete different look to the cherry wood. I did a photo of a word program text. Before I was able to copy text from outside MSW, but now when I copy text, it is included as a photo in small definition!!! My search for knives continue. I ordered new blades to try, assembly require.

-

Today's photos. Yesterday, I got a Sashimi knife. I did regrind it in a V shape. This way, this knife, can be use with both hands; left or right. To give an idea how it performs, I easily got few millimeters thick slices in a very mature tomato. I did try the last knives I got, and it is clear that scalpels are out of the game. As the doctor said scalpels are made to cut skin. I said many times that scalpels works fine, and it is not false, but a knife with a stronger blade can be as sharp as a scalpel blade and greater strength can be use, a better control with a heavier knife is also possible. I tried the knife from Vossiewulf and it works better than a scalpel also. You just need to add a handle. Just like there are many shapes for carving knives, there are also many shapes for a hobby knife depending of what we are cutting. May be, another avenue, to buy a ready to use knife, I also got, yesterday a knife from Flexcut carving tools. I already have one from this company which is OK. The new one is Wittlin jack with 2 blades. I will try it to compare...

-

New to table saw

Gaetan Bordeleau replied to niwotwill's topic in Modeling tools and Workshop Equipment

At the opposite, if the blade is too high, the blade will be touching the wood at the front and back. If the wood is not parallel when the blade touch the wood in the back... it will cut again, and this we do not want. -

New to table saw

Gaetan Bordeleau replied to niwotwill's topic in Modeling tools and Workshop Equipment

I agree with Jaager Also if a blade is too thin, it is going to wave in the wood. Personally, I do not use these metal blades. I rarely cut thinner than .100". I always use carbide blades, for all the thickness, last for months and makes almost perfect cut. If I want a true regular thickness, I finish with the thickness sander. Additionally, I will also use the thickness sander on the 2 by 4 after each cut to start with a straight finish. Probably starting from a 2 by 4 going to small planks means you are going to loose over 60 % of the wood, that is a lot: the smaller the planks, the greater the lost of wood. -

LED Lighting https://www.bhphotovideo.com/c/buy/LED-Light-Sources/ci/12248 Actually, LED lights are the best type we have on the market. By example BH photo sells all kinds. With this lighting, you take photo as if you were outside in the sun. If you take a photo, you will get the real color and you will not need to ''white balance'' the photo and the white will be white not yellow. Now the bonus side, these LED lamps can also be use for regular lighting in your work. LED lights are very powerful, in fact you must not look directly. By comparison, if you compare an ordinary lighting with it, you will realize it is like day and night. As we can see at the photography store, there are many prices. If you buy one, buy the best you can and you will not regret it. This morning, I took one of my Matthews stand which is usually fitted on a base and I inverted the post and screwed it in the ceiling, so I can add a LED lighting. Before the Led lights, with other types of lights, surgical light were much more effective than home lighting. This type of lighting used in photography, especially for video, is less expensive than a surgical light of today and it is as much effective.

-

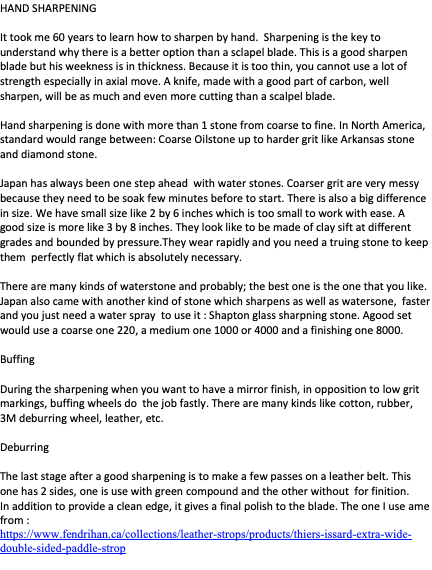

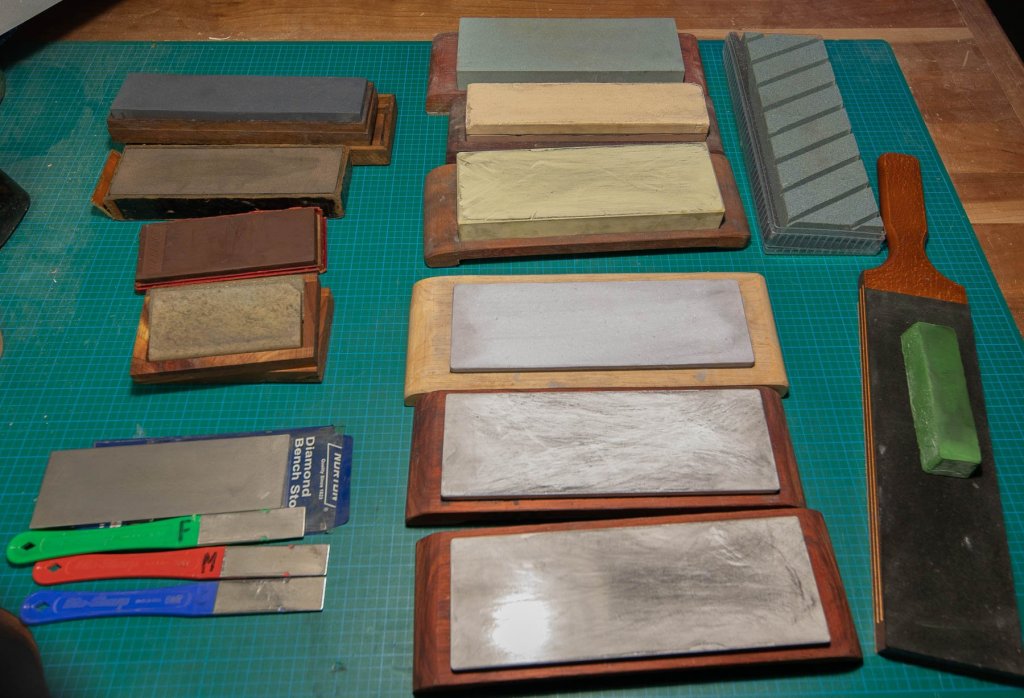

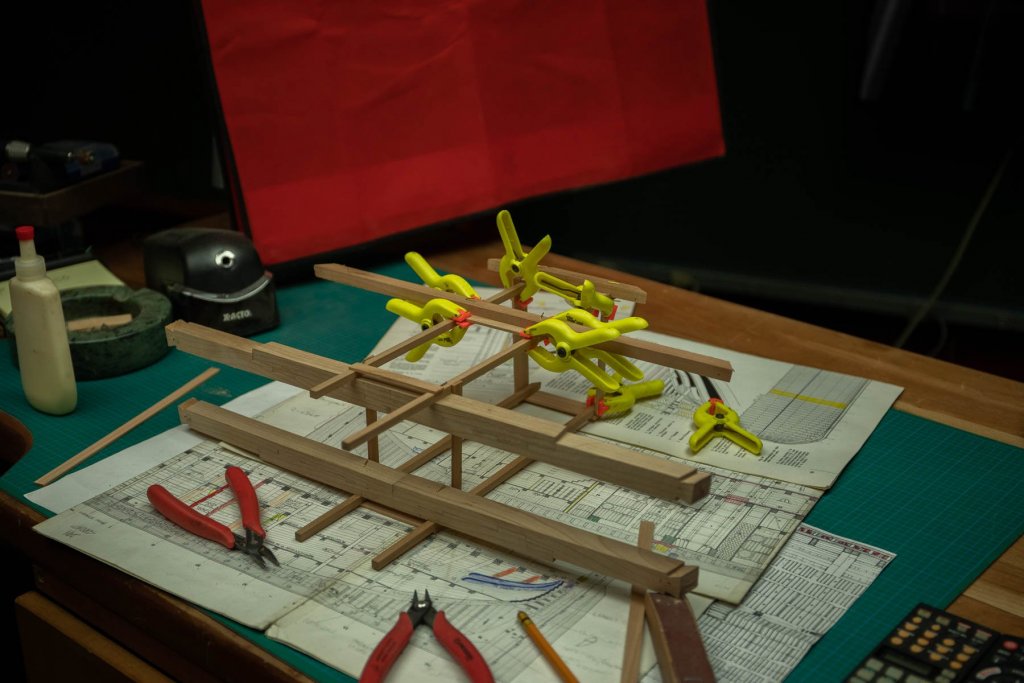

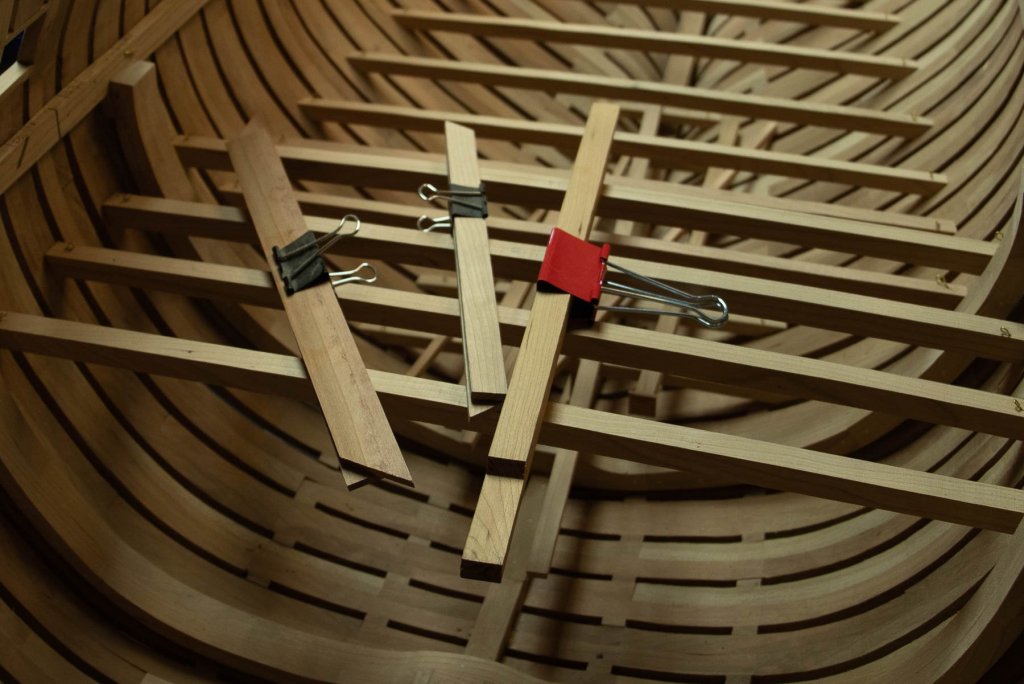

Thank you Amalio, I am sure you will enjoy it. It is a perfect size to sharpen knife. One of the nice aspect of these stones size is the flatness, very effective to straighten a blade profile. photo 1,2: Just finished t to shape another 100 parts: deck beams for the first deck 32beams made of 3 parts each and 3 beams, already made of 1 piece. photo 3, 4: I found a perfect application for my new knives, the fourth one shows how effective it is. Third picture show how the beam rest on a block. It is easier to make the notch if I do not have to hold the part so I can concentrate on holding the knife with 2 hands. photo6,7: gages to measure the width of the deck beams. photo 6 the gage was also use to locate the notches on the frames.

-

There is no Musée de la Marine in Québec, but we have an old french Arsenal in Montréal. Around 30 years ago, I was authorized to manipulate with gloves a copy of Duhamel de Monceau, Traité de construction... If I remember well, this book had many owners and the clergy has been one of them. I like your idea to try other wood than boxwood for carving. I liked to try a lot of exotic hardwood, one of the first reason for color, but I stopped, too much expensive. Last week, I got a piece of cocobolo about 1 by 5 inches by 4 feet; $175, expensive, for all the colors of this plank. Now, I use almost 100% cherry wood. I also tried it for carving, was not so bad but these were not extremely detailed.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.