-

Posts

1,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

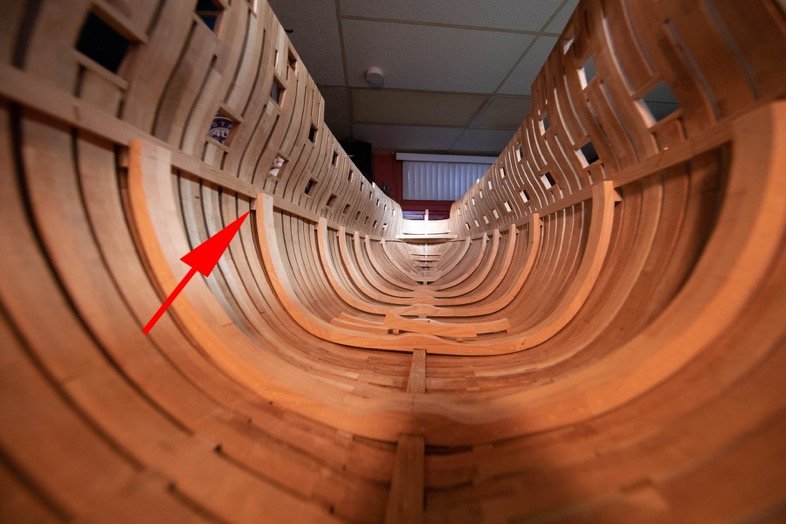

Glued most parts except the rail where the deck beams will rest. These rails must be still removable to be able to cut notches for the deck beams from the first deck later. Half frames rest on these rails and to glue the half frames , a spacer is added under the rails so that the half frame can be glued somewhere. Also the setup to take photos is now completed with a new tv. This way, it is very easy to observe very closely construction details photos

-

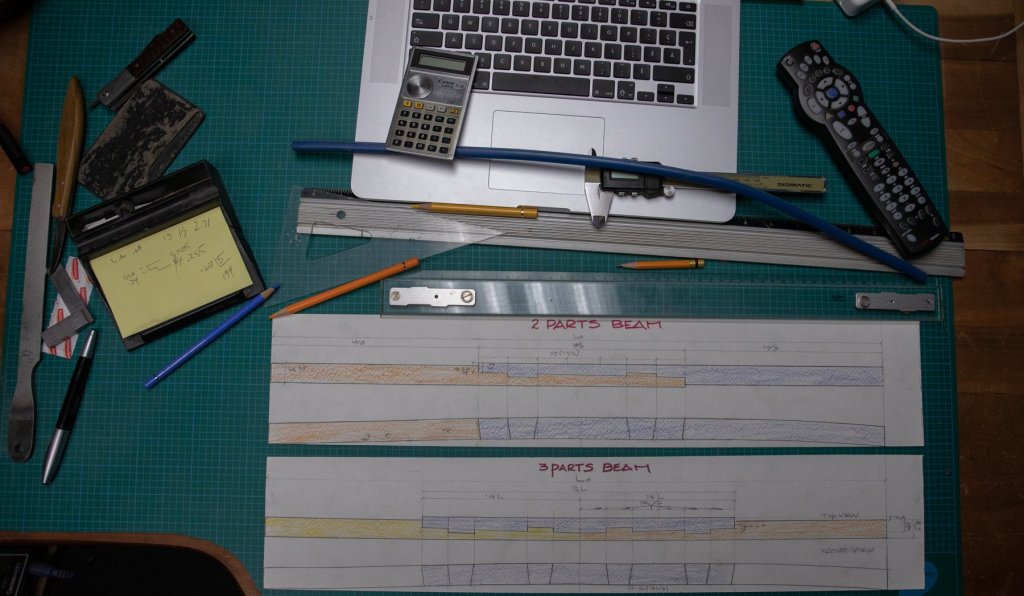

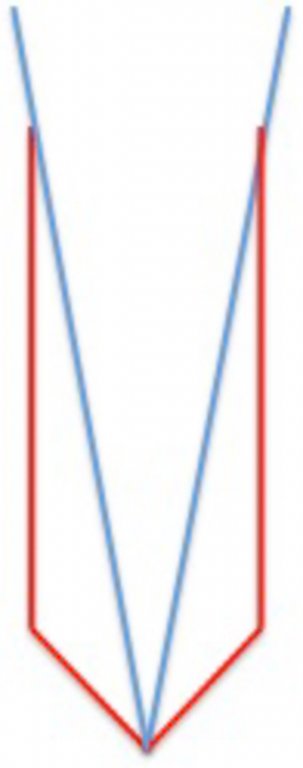

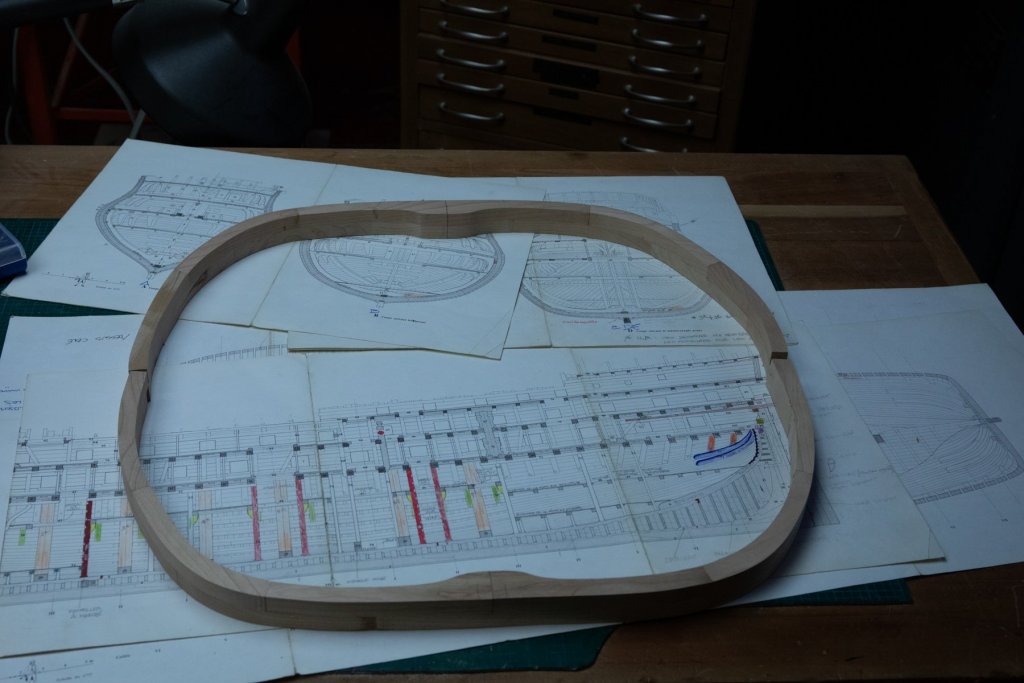

Installation of reinforcement pieces. The easy way to assure parallelism between each one is to set a spacer. 2 of these have a double use: they will also receive the planking of the false and first deck. Deck beams of the first deck will rest on a large plank on each side of the boat. Each frame will have 1 notch each side to sit them. The first deck is the one withe the greater span. For this reason, some of the frames will be made in 3 parts with taper notches. This is a great method to assemble beams. Probably with the weight of the parts only, it would be enough to fix the parts of the beam. I remember the first time I tried it, I was surprise how strong locking this mechanism is able to perform; the same way as a taper sleeve but because the parts are assembled in an arc additional lateral strengths comes to lock even in a stronger way the assembly. Depending also from the needs, there will be beams from 1 part, example the first 2 in front. beams made from 2 parts will also be include in the first deck depending of the needs. With the fabrication of the camera studio stand, it will be easy to insert a full frame camera inside. One of the advantage is that it is easy to set the camera parallel to the model. I will try to give access as much as possible inside. For this reason, deck and wall planking will be install only in essential circumstances. In a way there will be as less as possible longitudinal planks but more perpendicularly to the keel. Parts are temporary fix until all the notches to receive the beams of the first deck are done. I got an answer from Lee Valley and Veritas for the detail knife. Here is a part of the last paragraph: ''We also have some other design we are working on. In order to avoid any conflict your product submission will not be reviewed by our designers. SO, I can only hope they can produce a sharp knife with their wood plane blade. While this time, when I will want to have a sharper knife, I will regrind one of those blade in a V shape or may be I could do a knife blade from a half wood plane blade.

-

Lighting the Work Area

Gaetan Bordeleau replied to Richmond's topic in Modeling tools and Workshop Equipment

https://www.homedepot.ca/en/home/p.100w-equivalent-daylight-5000k-a19-led-light-bulb-2-pack.1001006062.html your best bet is probably to go to a big home store and choose some kind of LED light bulb Lumen and are written on the box. In this example 1500 lumens and 5000K -

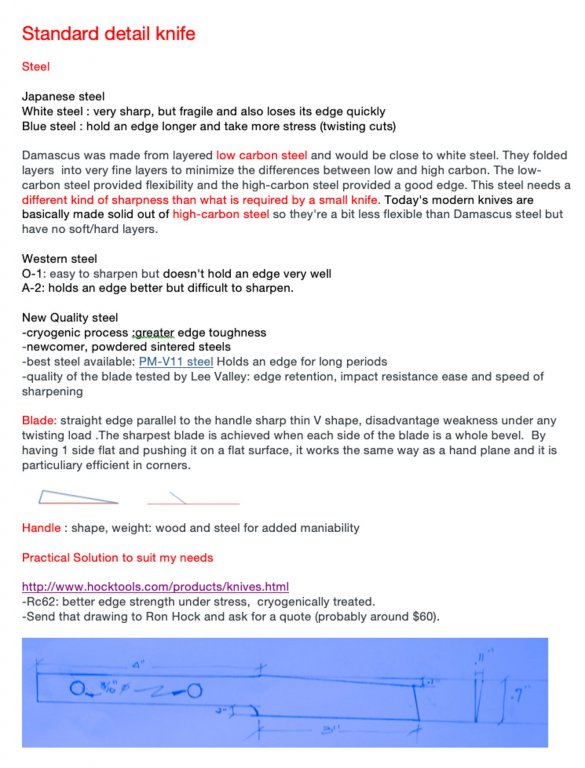

3 things: Unfortunately, here is what Ron said: "I hate to disappoint but we don't have a good way to make this for you. Sorry, no quote.'' Vossiewulf, I am sure you will agree: there are sharp knives but there is also extremely sharp knives May be after Christmas I will write to a company to see if they would like to produce a good Standard Detail Knife which would be extremely sharp. Actually they do not really have any. I think that PM V11 steel would be a very good choice!

-

micro drill adapter for mill

Gaetan Bordeleau replied to michael mott's topic in Modeling tools and Workshop Equipment

Higher the speed, the smoother surface, a router bit acts the same as a milling cutter. Same idea with my wood planer; 2 speeds: the higher for finishing. At the opposite if you go too low, the knives will not cut as well; they will want to tear in the wood, especially at the edges Proxxon has a small mill that runs 20,000 rpm which is perfectly fine. Some model maker prefers to use a mill for wood at 5000 rpm... the only good reason I can see is because of the many accessories of other brands. When I can, I prefer to use aluminium where the cutters plunge like in butter. When strength is not a factor, I prefer to use high density plastic, very easy to turn and high degrees of accuracy can be reach. -

Yes Carl, in fact I did it for the microscope. I took the idea from a Microscope arm support like in the photo. This is my actual set up. I did try about 10 setup before with many camera tripods but I wanted to simplify so everything fits on the table. In macrophotography, stability is a must. In the future, I would like to get a studio camera stand, something like this old model from Cambo. Very nice model but I doubt I could find one like this!!!

-

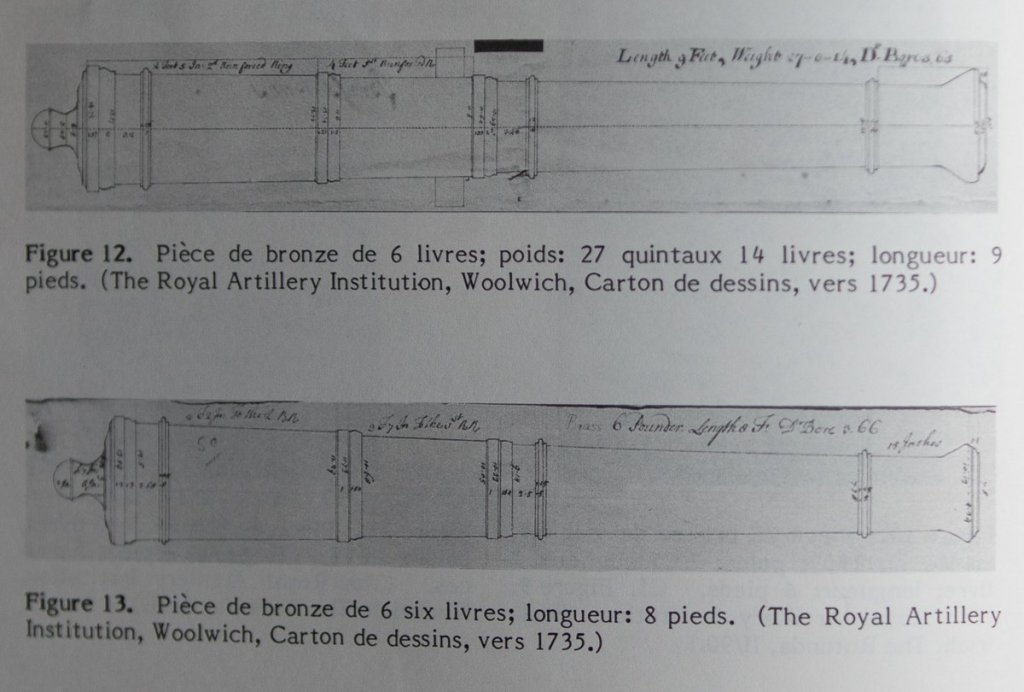

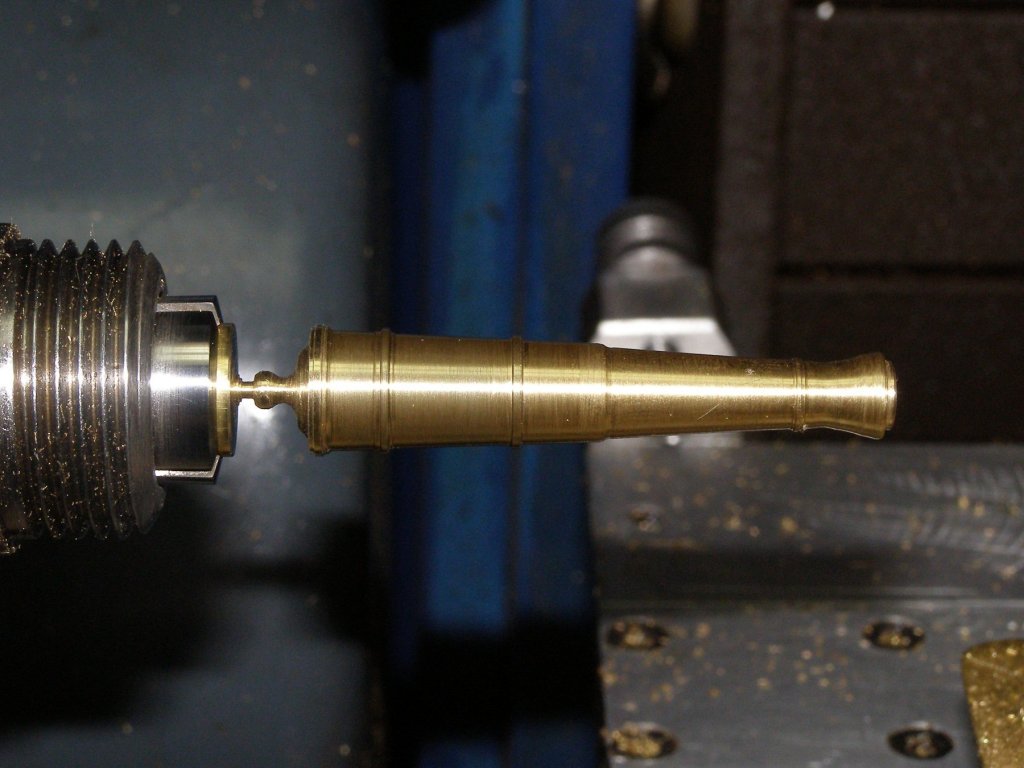

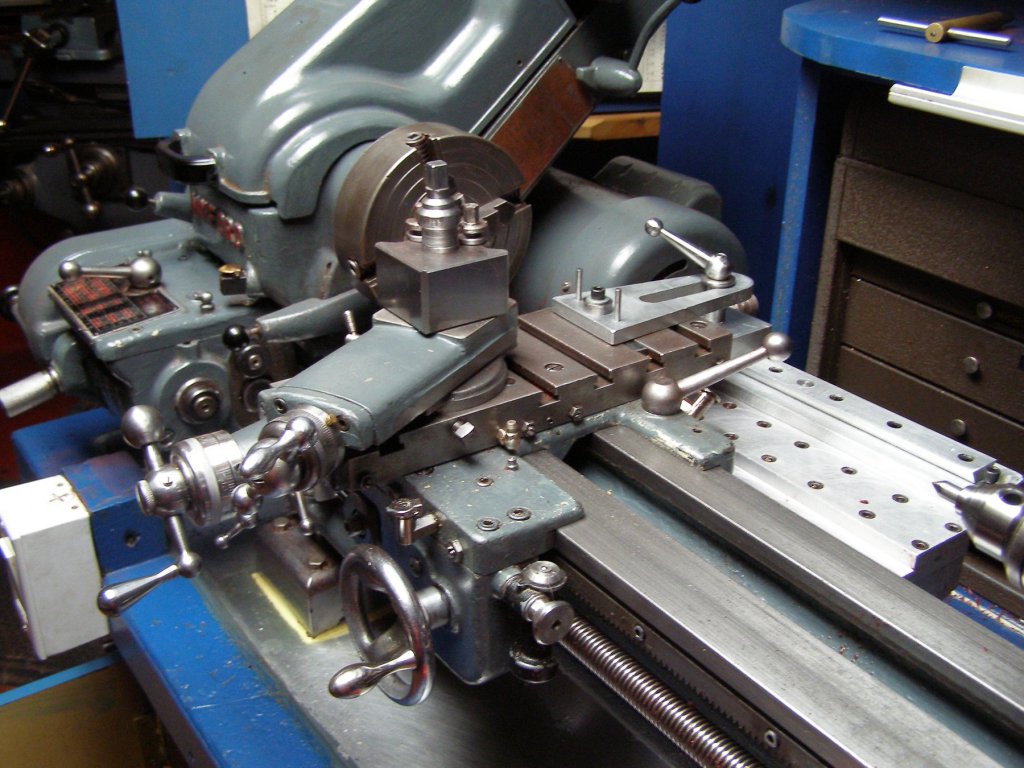

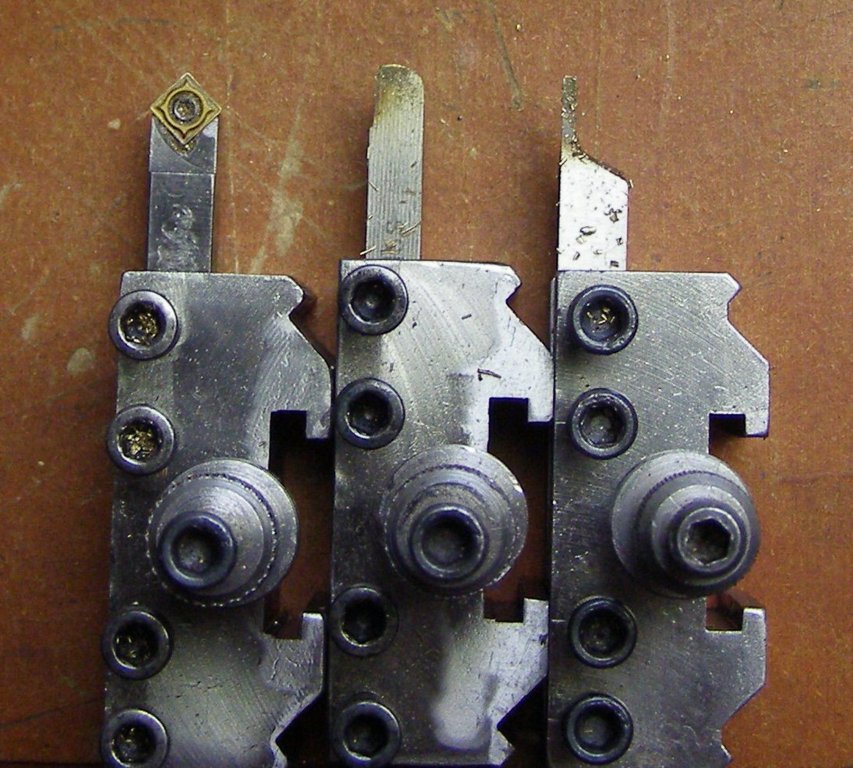

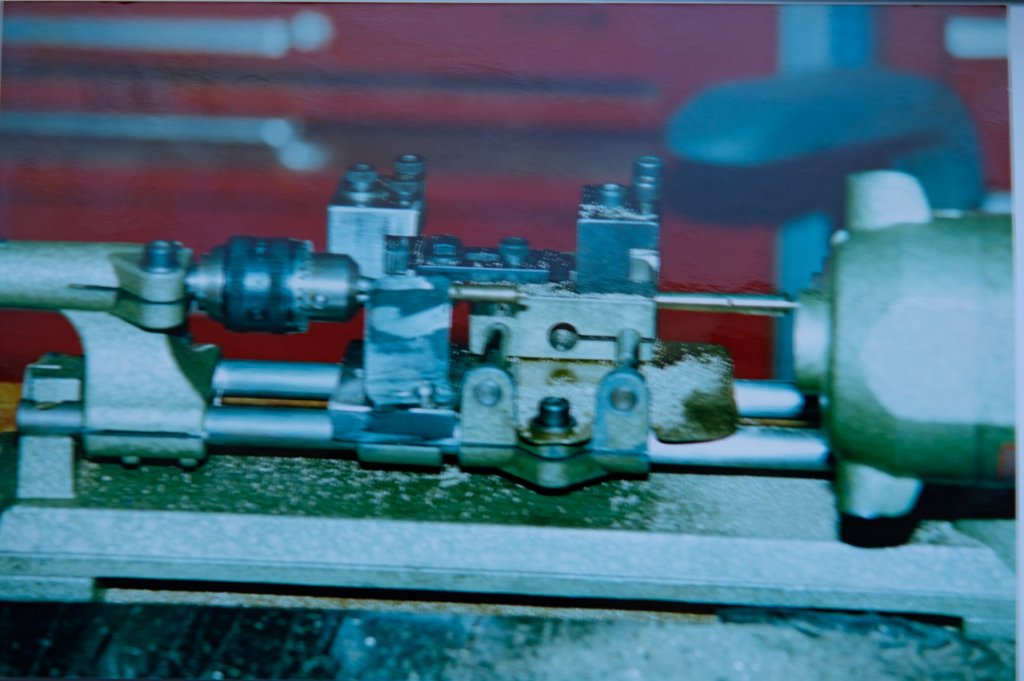

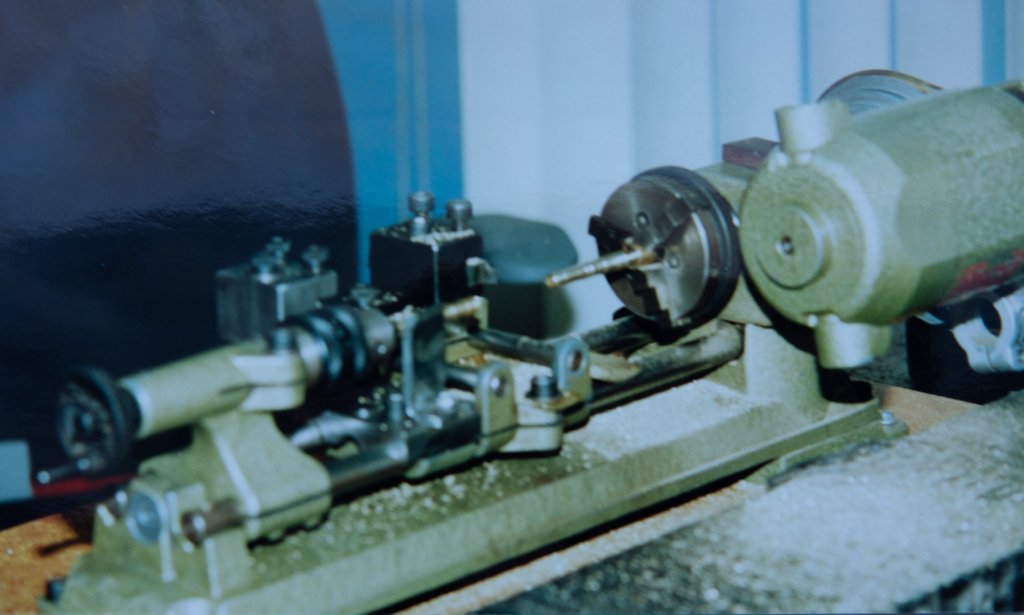

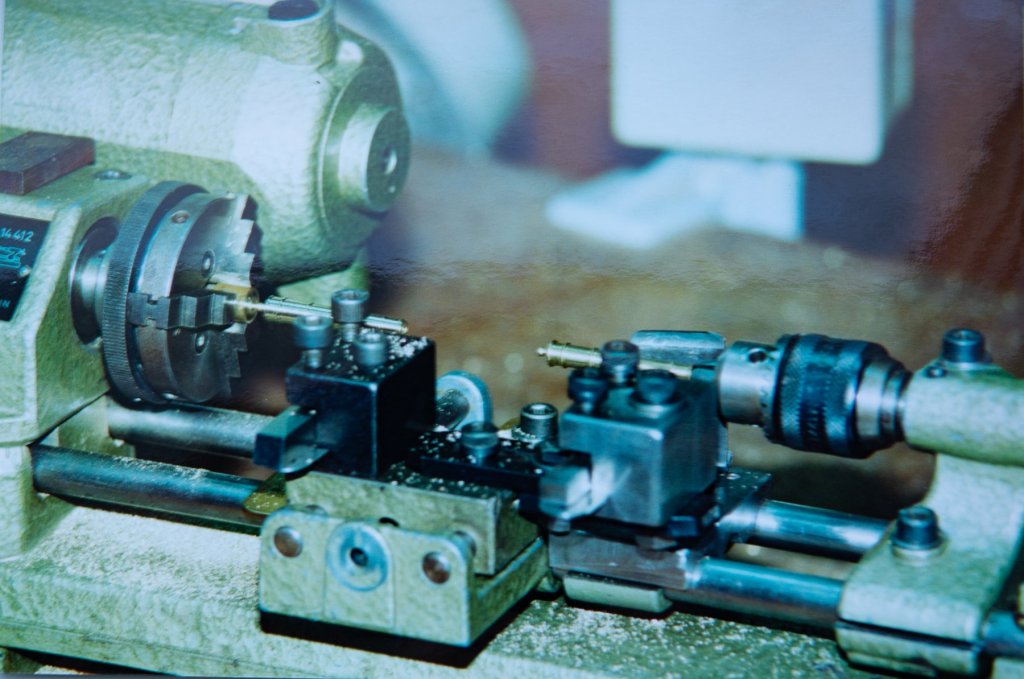

None of the above. The first times I used a duplicator for Unimat. Now I use a taper attachment, a guide to set a precise angle for the taper. I work by steps which is at the end a faster method but collets are required to reposition blanks more precisely Example first deck cannons, same step for each ones, then second step for each one and so on

-

USING A FLASH OR NOT? Last week, a man, in an exhibition, was saying that he was always using a flash in manual mode, never in TTL (true the lens). Many years ago, it was true. Todays flash are much more performing. Here is another common belief : a studio flash is much more performing than a flash on a camera. With the development of the electronic technology; you can buy a flash which fits on the camera hot shoe and it can perform in TTL as good as in manual. This week, I got a new on camera flash and I am very please by his performance. On the last 2 photos, untouched, show the result of this morning test : The first one : with a flash in TTL mode, 100% automatic. The last one : no flash, neon lighting. The color are not as much appealing!

-

That would be a nice cover page for Lee Valley. I could not do better.

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.