-

Posts

60 -

Joined

-

Last visited

About norm1116

- Birthday 11/16/1954

Profile Information

-

Gender

Male

-

Location

Baltimore

Recent Profile Visitors

-

Ryland Craze reacted to a post in a topic:

Portland by Rick Abramson - FINISHED - BlueJacket Shipcrafters

Ryland Craze reacted to a post in a topic:

Portland by Rick Abramson - FINISHED - BlueJacket Shipcrafters

-

As tough as it is, once completed, the Portland is a beautiful ship to display! Great job John and Rick!

- 14 replies

-

- portland

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

GrandpaPhil reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

GrandpaPhil reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

-

Hello all! After a lot of time, I have decided to abandon the Portland project. I lost all motivation and desire to complete it. I gave away the Portland to someone who may complete the ship. They have visited this log before and are familiar with the status of the boat. It's been great! Thanks for all of the support and I apologize for not seeing this through.

-

Kurt Bainum reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

Kurt Bainum reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

-

Racer31h reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

Racer31h reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

-

Racer31h reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

Racer31h reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

-

GrandpaPhil reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

GrandpaPhil reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

-

popeye the sailor reacted to a post in a topic:

Esmeralda by Chborgm - Billing Boats No 730 - Naval Training Ship

popeye the sailor reacted to a post in a topic:

Esmeralda by Chborgm - Billing Boats No 730 - Naval Training Ship

-

coxswain reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

coxswain reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

-

coxswain reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

coxswain reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

-

Nunnehi (Don) reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

Nunnehi (Don) reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

-

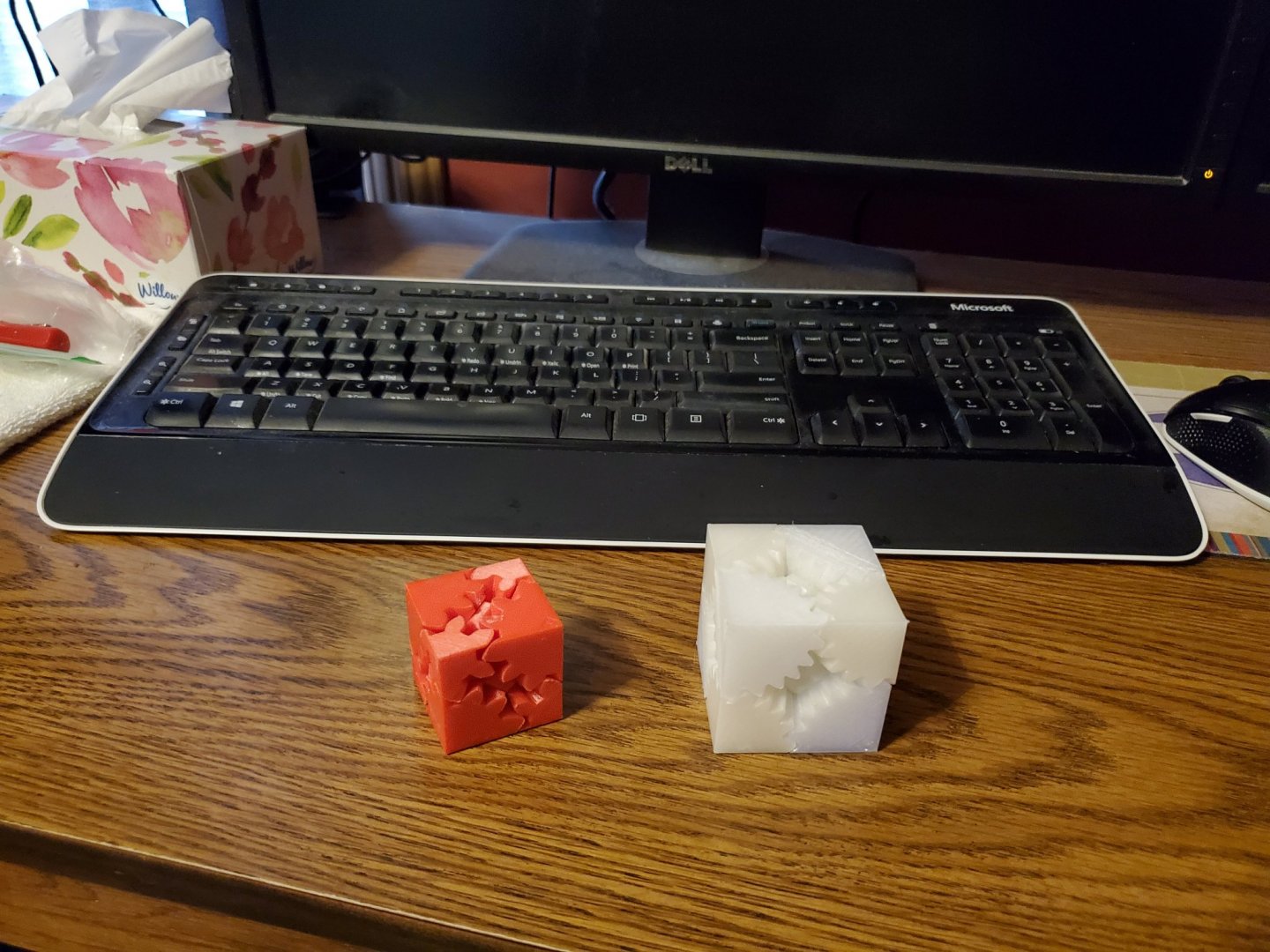

Walking Beam While reading the manual, I was thinking how I was going to handle this piece. I decided to incorporate 3D printed parts to simplify a couple of parts, so here's what I have so far. I printed the triangular piece where the 2 beams meet and glued them in place. I printed the cross beams and supports and glued all of that together. I think the two outer segments came out fairly well. I set one of the parts on the plans. The manual says that a lot of the engine is below the main deck level, which we do not have access to because of the solid hull. I thought about removing some of the material, but with my luck, I'd have to buy another kit to fix a major error. So, my engine will be my representation of whatever is above that line. I'm currently a bit confused by the cross bars on the end views, and will have something figured out in a few days. I'd love any thoughts/ideas you might have. I'm also going to take another look at Dan's engine. He did a nice job with his.

-

Main deck to saloon deck Sorry I was gone so long. 2020 was a drag. I hope everyone made it through the year successfully! I installed the main deck back in this post. I followed the directions to paint the outer edge of the main deck aft grey, then install the Ladies Saloon Profile, Lower. So, the first thing I did getting back to the model... I missed the center mark by a 16th or so. Glued it down off center and all. I will (hopefully) be able to make corrections if needed, so no big deal. I checked/read the manual for the 1000th time, and it said "Other structures that you may want to build at this time are..." So, I decided to take care of the 3 or 4 smaller sub assemblies then return to the decks. These decks are scaring me a bit I guess. Will return soon!

-

All, I have truly slacked this year. I let the Portland intimidate me. Every time I looked at it, I thought of how many ways I could screw it up. Everything has been on the table all year, and is getting packed up again tomorrow. I promise to get back to it in 2021 (Thanks VTHokiEE for noticing that error!). Have a great AND SAFE holiday season!

-

norm1116 reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

norm1116 reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

-

John, I'm looking at your window trim work. It's incredible! I hope mine comes out that clean. You are right about the Portland, but it is one of the best looking paddlewheelers I've ever seen. I'm going to be one proud dad when this one is completed! Maybe this log will attract others to the Portland and BlueJacket.

-

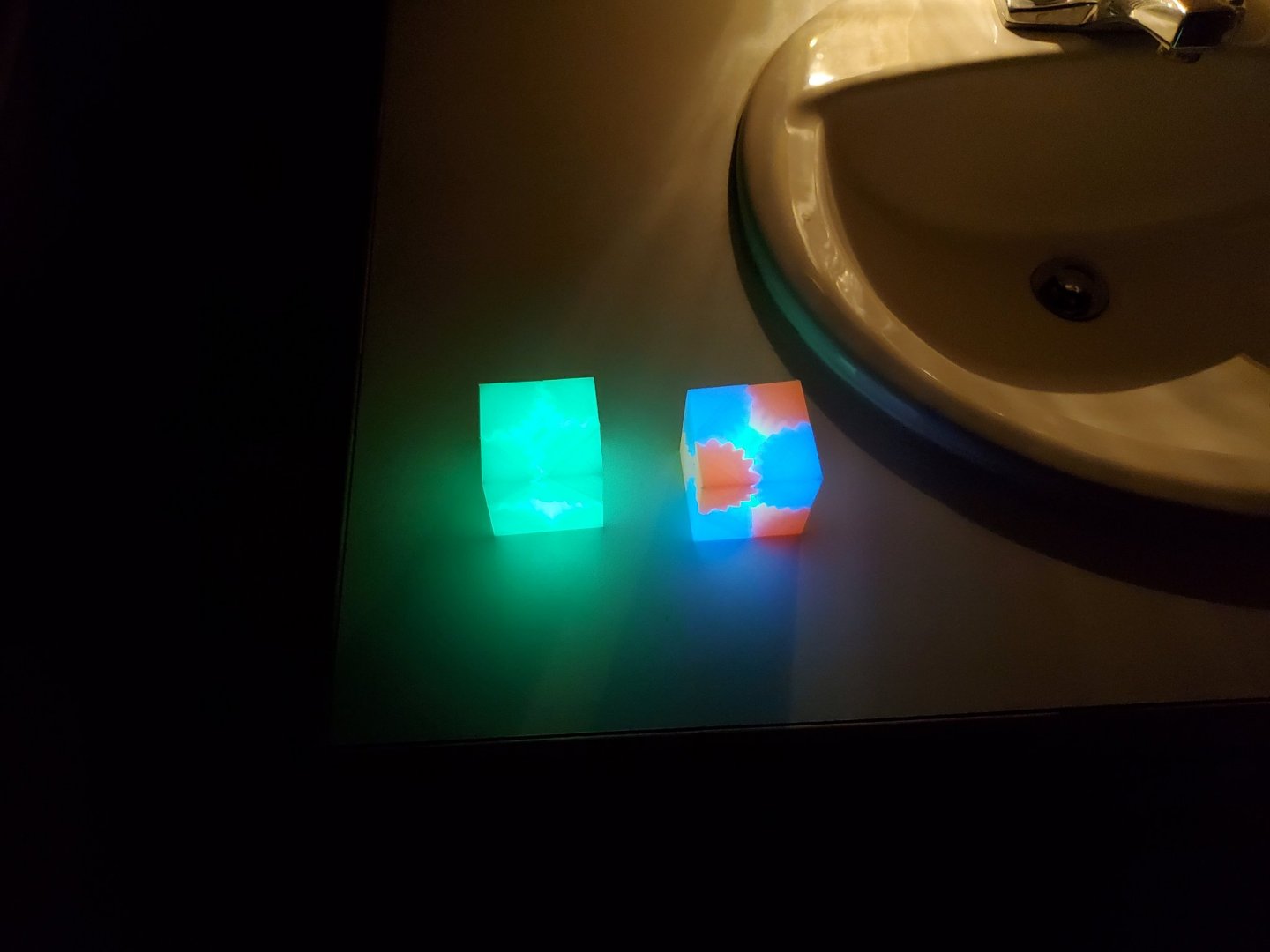

John, The skylight looks great! I've been reading the manual that came with the new model, but after reading your post, I'm going to check out the manual from the original kit. I set out all of my stuff to get back to building, but needed to be sure I wouldn't have to put it away for any Easter family gatherings. I plan on starting up again next week! I have been tying up a lot of time with a 3d printer I bought for my birthday last November! Way too much fun! I may use this printer to produce some parts for the engine.

-

norm1116 reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

norm1116 reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

-

norm1116 reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

norm1116 reacted to a post in a topic:

Portland by jbelwood and norm1116 - BlueJacket Shipcrafters - abandoned

-

Rudder - I followed the directions for the rudder. I did have to trim things more than I expected to get it to fit, but it looks fair. I'm reading up to see what the next step is, plus I'm going to start the walking beam, so I hope to have more posts soon. There is a steering arm that will be added to the rudder at a later date. I'll put that here when I get to it.

-

Priming, Hull Paint, Waterline, Keel, Stem Post, Stern Post I learned a lot about painting. Actually I remembered most of it from the past, but it came rushing back while painting the hull. I suck at painting. Spray, brush, you name it, I am no good at it. So here goes... I felt that I did an OK job getting the hull ready to paint. I figured after a coat of primer I'd notice a few spots to fix. Let me tell you, painting the hull showed me how wrong I was. My hull has many more imperfections than I would like to admit to. I'm letting many of them go since they will not be visible on display, but they are there! I did a couple of primer coats using a white spray primer. You may have noticed that I forgot a step. I need to refer to that manual more often. I should have installed the keel, stem post, and stern post first. To get there, I needed to take care of my display needs. I purchased the optional stanchions and display board. Both are exceptional. I knew the keel would need to be removed where the stanchions are located. They recommend and send 3 stanchions for the Portland, but I want to try only 2. My thought is I could set it up for 2 and add the third later if needed. I pulled out the display board and decided how I wanted the boat to sit on it. I drilled holes for the stanchions. I used my string to find the center of the hull. I set the boat on the stanchions where I wanted it to sit, lining up the center as close as possible. I then pushed a screw up through the stanchion to mark where the hole would need to be drilled in the hull. I drilled that 1 hole on the center line, and mounted it to the base. I aligned the 2nd hole, and marked it with the tip of a screw through the stanchion. I unscrewed the hull, adjusted the 2nd mark to the center line, and drilled the 2nd hole. I remounted it all to see the results. Check out that display board. It is really top notch. I'm sorry I didn't take any photos bending the wood around the bow, but I followed the manual and here's what I ended up with. Using the plans, I tried to have this part meet the keel where the thickness changes. I don't remember the exact measurements, but the keel is the same thickness until it approaches the bow, where it thins out a bit. I knew the keel would need to be cut out for the stanchions, so I added the first piece. I added the keel between the 2 stanchion holes, and the keel post. Using a sanding block, I sanded this area so the keel smoothly rounded the bow. I left the bow part thicker than the plans show. I may need to resand it later, but I wanted a bit if insurance just in case. You can see the final product below: I used calipers to measure where the waterline is on both ends of the boat and marked the hull at those locations. I needed a flat area to do this work, so I used the kitchen island. I liked John's use of a large mirror, but if you saw me you would understand why there are no large mirrors at my house. Using my highly professional Norm-O-Matic waterline marker, version 2.0, I lined my pencil to the mark on the bow. The pencil did not align at the stern. I added the necessary shim to raise the stern to the correct height. That did it. The next step was to make sure the port and starboard heights were the same. I used the square and made necessary adjustments. I went by the deck height. It worked out alright. I drew the line around the hull. Be careful around the sponsons. It felt tricky. If I took a photo of both sides of the boat, the waterline looks "off" a bit. But I think it's because of how I built the sponsons. Not really noticeable, but it's there. I think the first place I heard about Tamiya tape was on Dan's Portland page. Then John mentioned it also. So, I decided to buy some from Amazon. Worth every penny! I don't know how others do the waterline thing, but my thought was to use the tape to cover the line I drew, then mark the line again for cutting. It turns out that the Tamiya tape is kind of see through! So, using a fresh X-Acto blade, I carefully trimmed the tape at the marked waterline. I do not have a photo, but I added a 2nd layer of tape below the first so I wouldn't have any slip ups. So here's the first coat of red, hand painted with the paint I got from BlueJacket. Another plug for them. It is really nice paint. A bit of sanding and a 2nd coat. More sanding, a third coat, and remove the tape! I have a touch up or two to take care of, but in display mode, I'm accepting my work as it appears. Thanks as always!

-

All, Sorry things are going slowly! I got a part time job stocking shelves at my local Walmart. I could walk there if I had to. I'm working 3 days a week 4 a.m. to 1 p.m. After 21 years behind a desk and never exercising, this has been good getting me back into exercise, and I'm getting paid for it! Of course, cleaning up 21 years of sedentary fatness is a bit painful. I painted the hull, so I will post those photos today.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.