-

Posts

7,760 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CDW

-

Didn't mean to infer it was. Simply that the old saying, to the victor go the spoils of war, is now, was then and will ever be true. Look back at history as far back as we know...the artisans, experts, and "scientists" have always been kept as spoils of war. ordinary men and women are expendable. That's the cold hard truth. There is no reason whatsoever for me to believe it would be any different today.

-

Ready to test and touch up a few places if needed, then lay down a smooth coat of primer over the whole model. The S.2D I’m building has a detonation cord in the canopy. Other aircraft I’ve seen have white/light gray colored cords. I’m guessing it’s the same for the Buccaneer. Suggestions? Don't waste any money on aftermarket wheels or antennae for this model. The kit parts are as good and the wheels maybe better than the aftermarket ones. Perhaps they were intended for the old 90’s Airfix kit cause this kit doesn’t need them at all. I do recommend the cockpit set. It’s amazing.

-

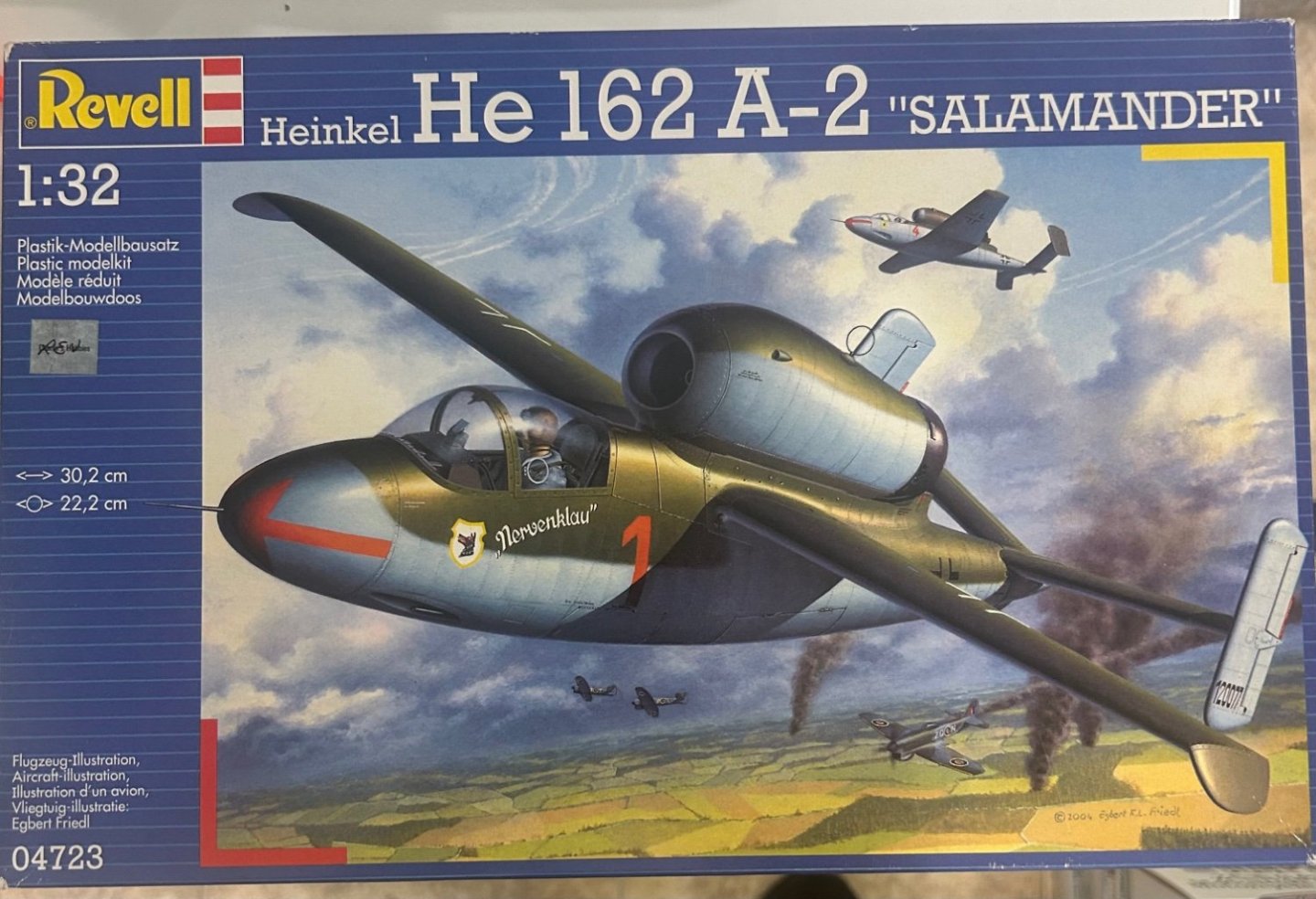

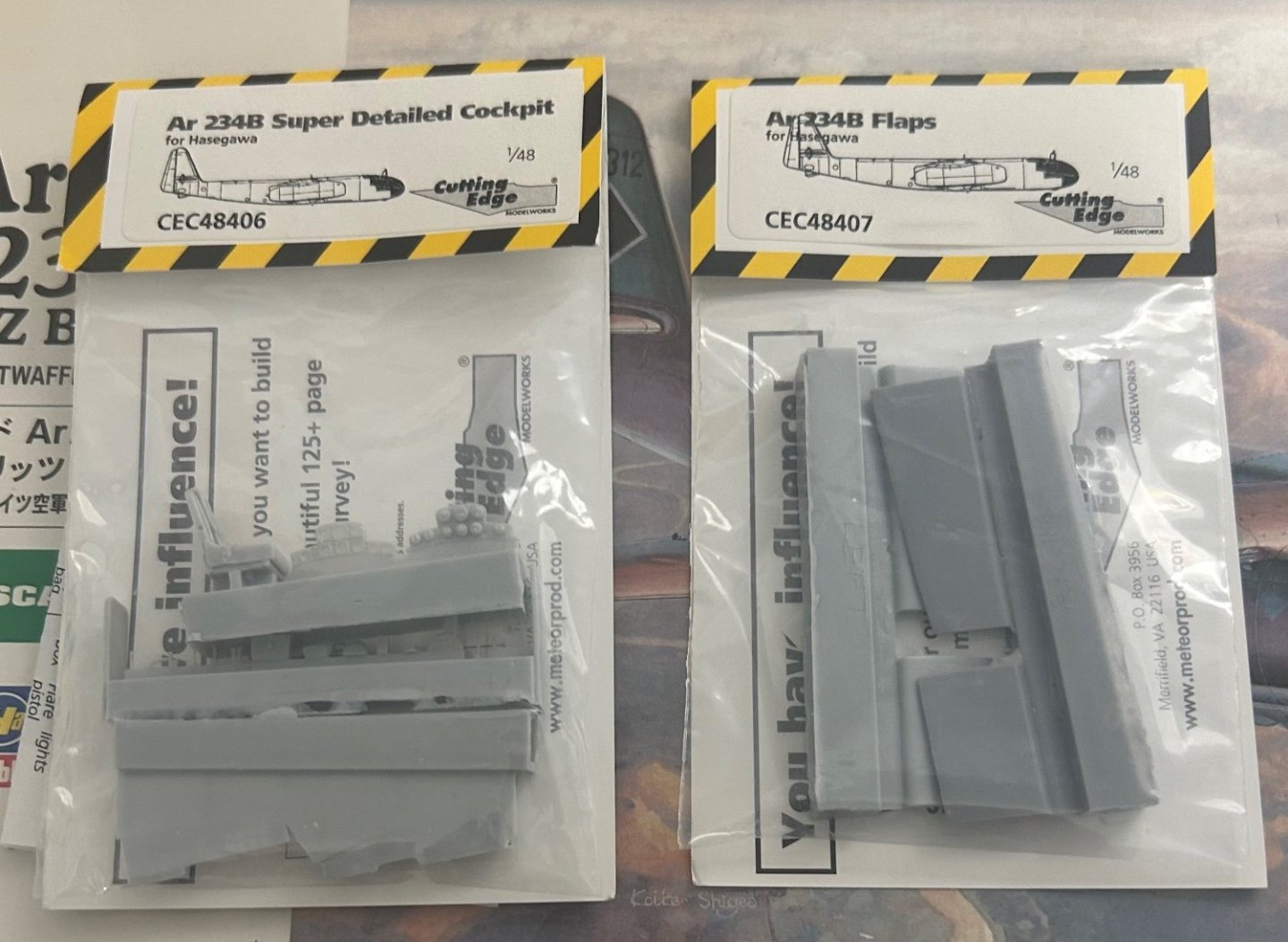

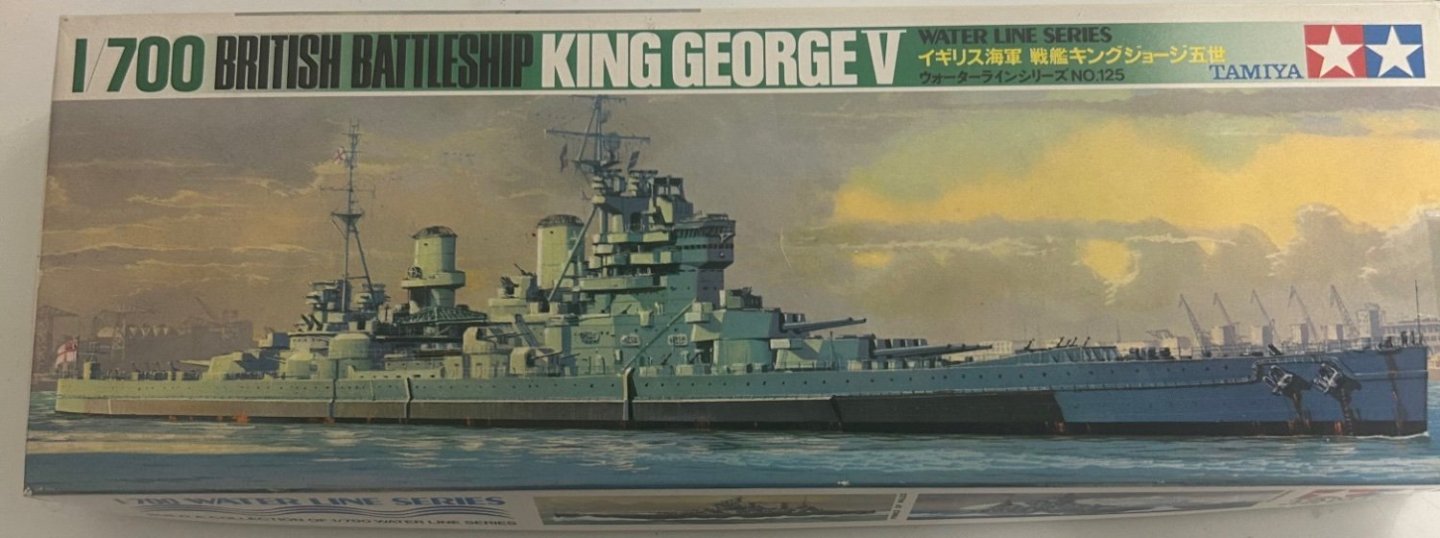

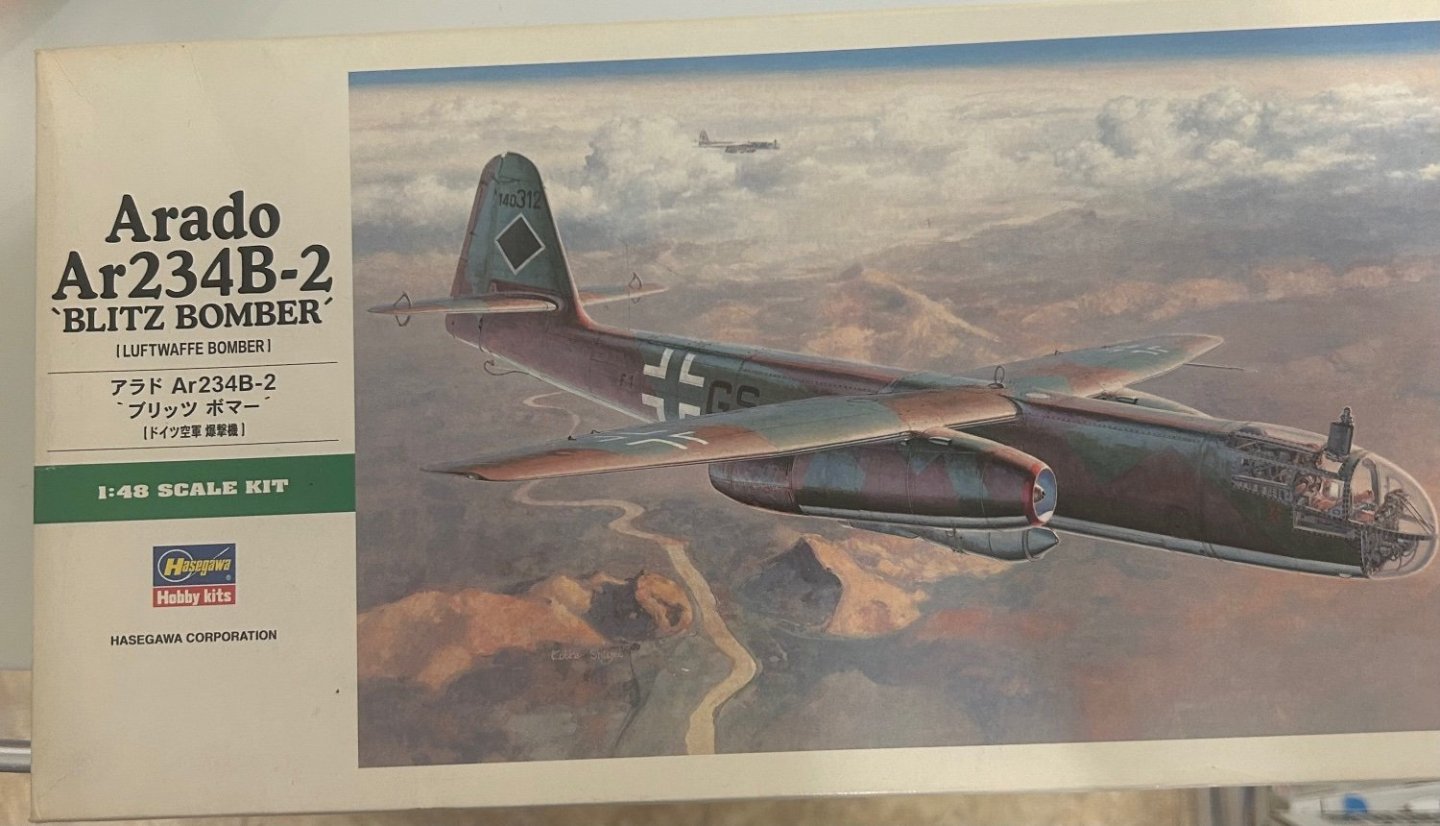

At the model show two weeks ago, they sold raffle tickets to raise money to help pay expenses. Tickets were a dollar each or thirty tickets for twenty dollars. I bought thirty tickets. There were multiple jars where the tickets could be placed with each jar representing a particular prize group. I put my tickets in a 1:32 aircraft jar, a 1:48 aircraft jar, a ship jar, and a paint & accessory jar. Multiple drawings were pulled each hour of the show and one grand prize drawing at the end. I hit one drawing in each of the four categories I entered. It was a lucky day I guess.

-

Here's what I have learned from my own puny research efforts: The first operational Buccaneer aircraft was the S.1 assigned to the RN The S.2 received upgraded, more fuel efficient Rolls Royce engines S,2A's had modified airframes and improved avionics, and transferred to the RAF S.2B's were modified S.2A's with a bulged bomb bay designed to carry an extra fuel tank as well as improved targeting systems carrying the Martel anti-shipping missiles and anti-radiation missile. Used by the RAF during the Gulf War. S.2D's (my model version) were RN S.2's upgraded to "full S.2B standards". Now, what I also know is that the S.2D does not have a bulged bomb bay. So this leads me to believe the "full S.2B standards" did not include the extra fuel tank or if it did, it was a smaller one as there are no bulged bomb bay doors. It does have the equal/same avionics and targeting systems of the S.2B

-

The weapons this aircraft version is modeled to carry are two TV Martel anti-shipping missiles and a single Martel AS.37 anti-radiation missile, The fourth pylon carries a Martel TV-guidance data link pod. So is this aircraft more like a Royal Navy version of a Wild Weasel? Seems like it to me. This is why I'm not sure if the bomb bay doors would remain operational. It's conceivable to me a fuel tank may possibly be added there as the slipper tanks don't appear on this version. Mind you, this is all wild speculation on my part.

-

Oh wow...I did not know the kit supplied the instructions and materials (and jig?) for creating the spokes. Very nice but tedious for sure. If you don't mind me saying so, I would consider using your molded seat to create a silicon replica mold and then cast the seat from resin. Cover the resin seat with leather. It will be difficult to cover that seat because its probably too flexible. Resin opens up the possibility to use a contact cement which will not harm the resin but adhere leather to it.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.7e80607770d9078b2f0b470e8c9c33ac.jpg)