-

Posts

3,030 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bruce d

-

Hello Igor and welcome to MSW from the UK. Perhaps you would like to post some pictures of your models? Bruce

-

Hello again Tim, I was about to offer sympathy and suggest an aspirin sandwich but it looks like you are on top of it. However, I still have one comment. If, and I will not try to guess, if the bulkheads you have ended up with reconcile with the original plans of Lapwing, then you have the ability to add more bulkheads easily. The Danish plans are hi-res and G5757 has around 17 or 18 stations. Ignore if I am telling Granny about eggs. Bruce

-

Hello Ships Carpenter and welcome to MSW. Those two projects sound impressive, may I suggest telling us a bit about yourself and starting a build log (or two)? Regards, Bruce

-

Hello Herby and welcome to MSW from the UK.

-

Welcome to MSW from the UK.

-

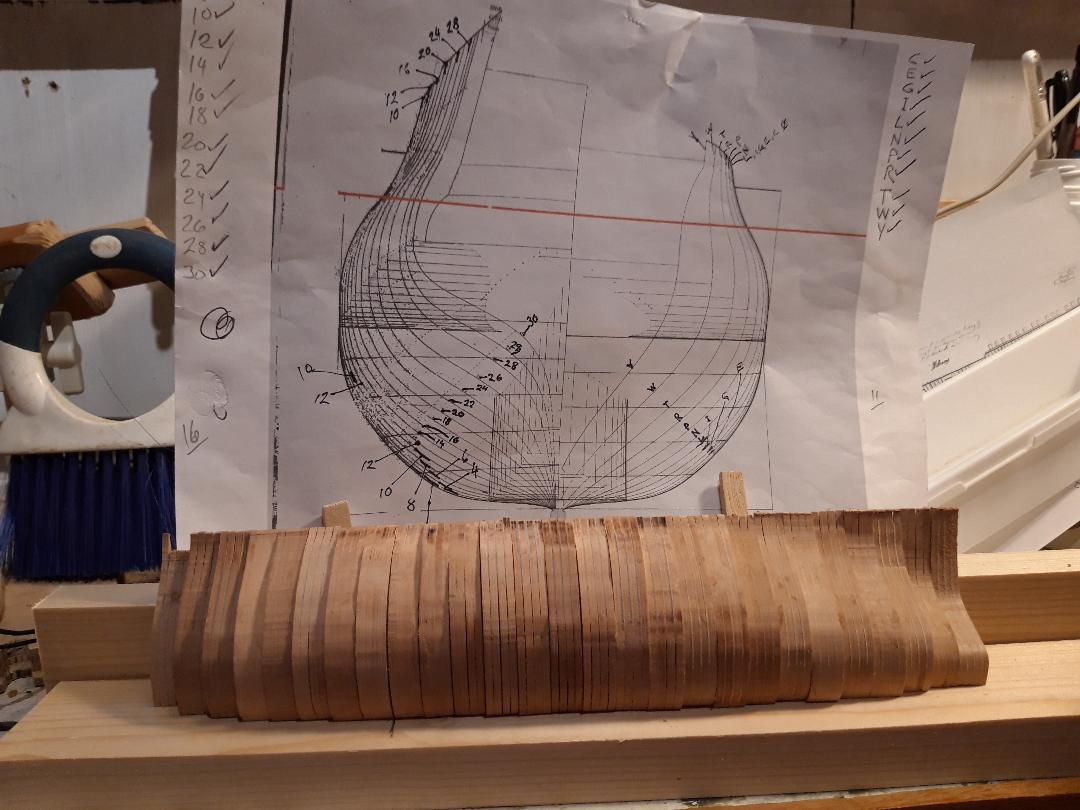

Thanks for the input. As for which method I am using, well, that is part of the attraction of the Reed/McNarry style. It can be seen in the third photo in my first post. In it, all the hull assembled so far consist of pieces that started out being a solid shape representing a portion of the hull and then, in the best manner of a sculptor, you chop away everything that doesn't look like framing. In the photo you can see some as yet unfinished pieces behind the partly finished hull. The centres have not yet been removed. Mine will look similar but instead of each frame being from one piece of wood it will be of two butt-jointed on the centre line and re-enforced by the next frame which is made of three pieces, one of which is glued across the bottom. The cross grain problems you offered advice on are (so far) not cropping up. Things got better when I settled on alternating solid pieces with smaller strips of the same thickness at right angles across the lower section. I hope you follow that jumbled description: if not, I should be bringing the first sets of parts together soon so watch this space.

-

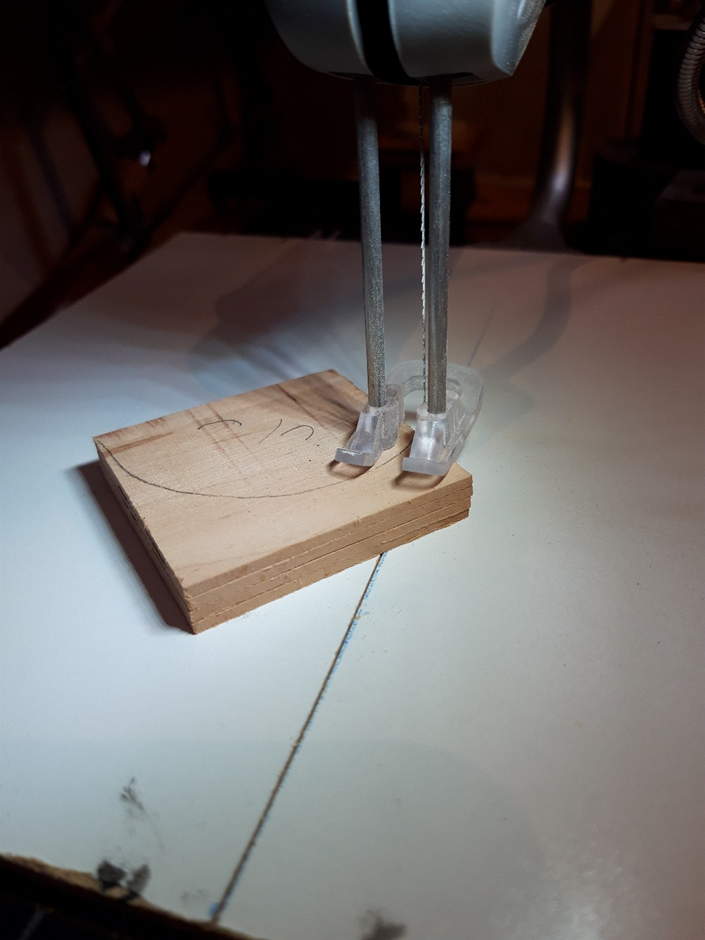

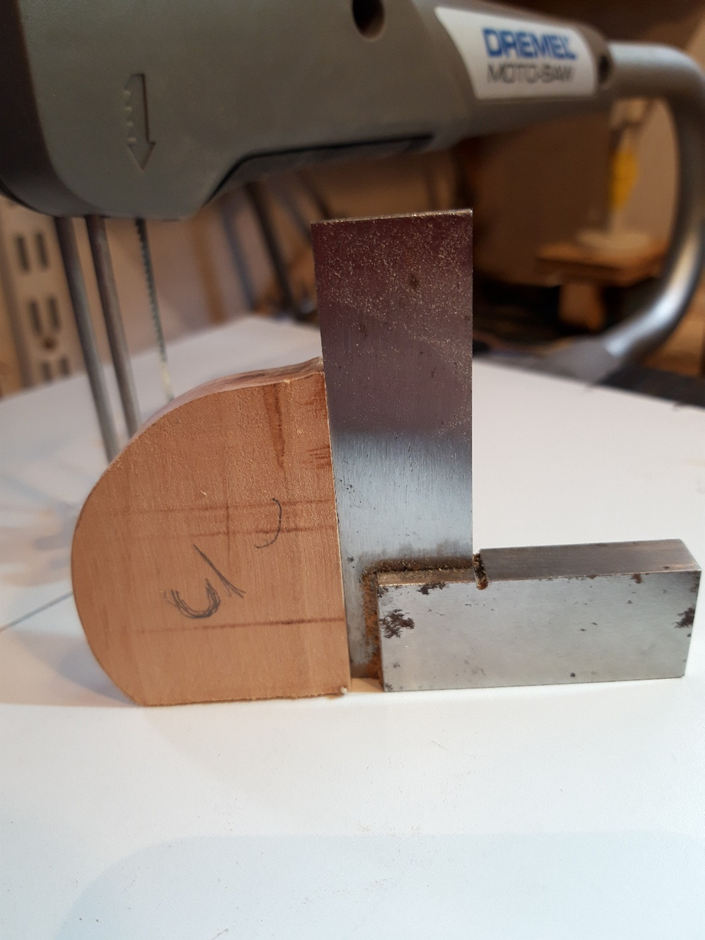

The four are now cut to shape in one operation on the scroll saw and set aside still attached to each other. The final shaping is done with a small drum sander. ... and checked. … and immediately put away before I can do any harm. By the way, this is my new favourite tool. Seriously, it makes me giggle it is so good. Tool review to follow. ____ Next is the building board. Bruce

-

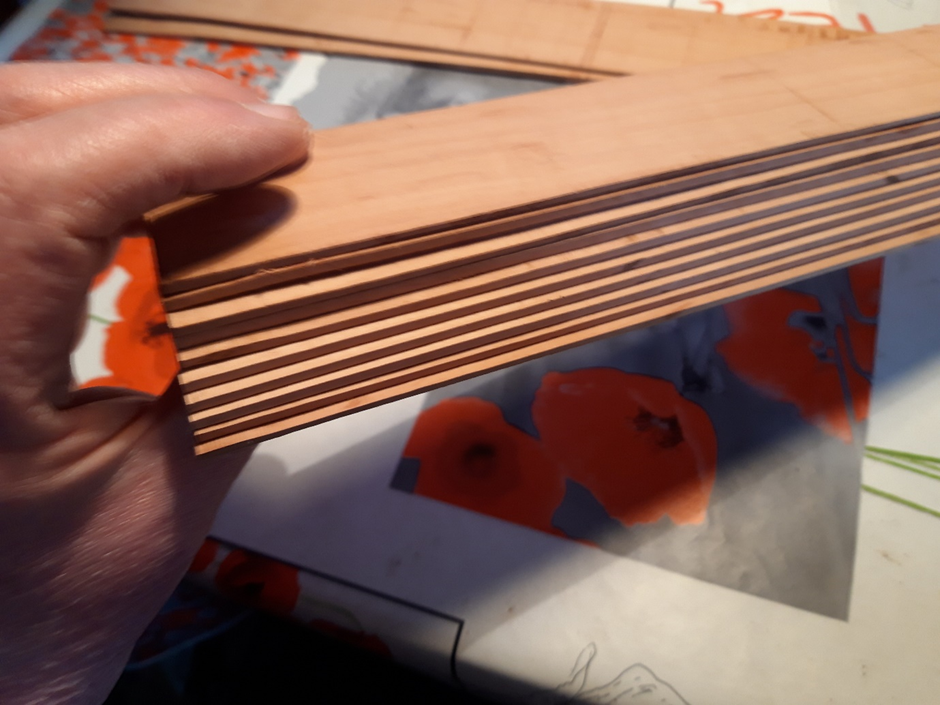

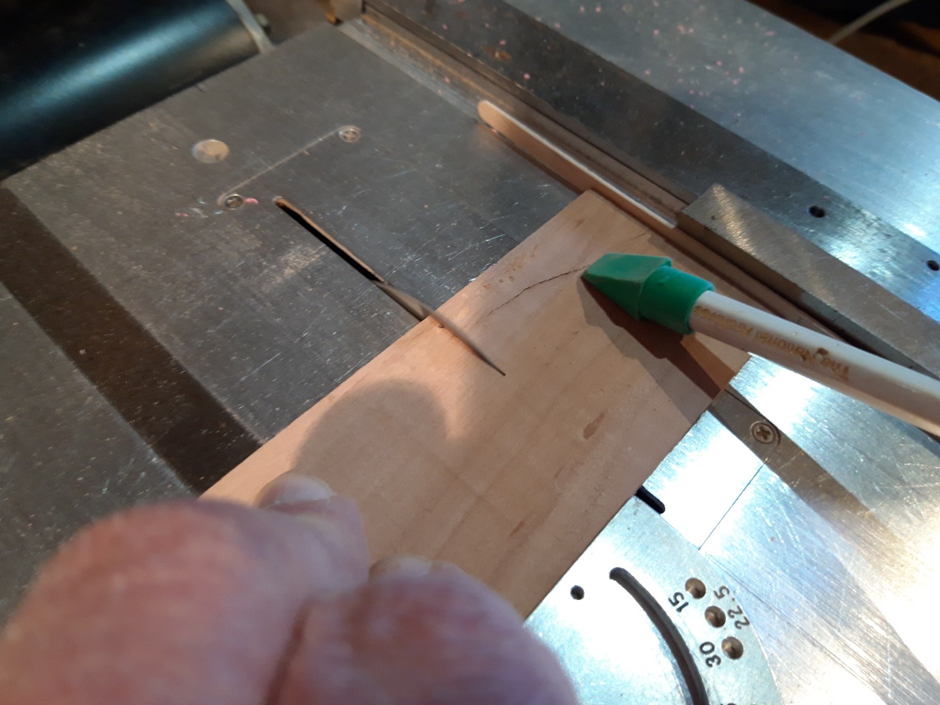

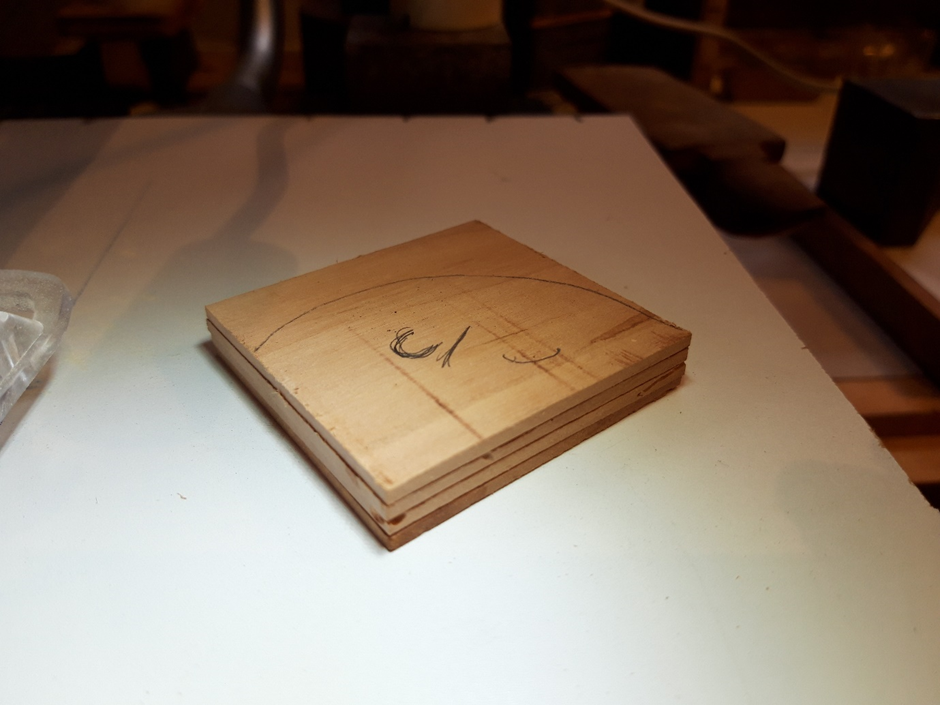

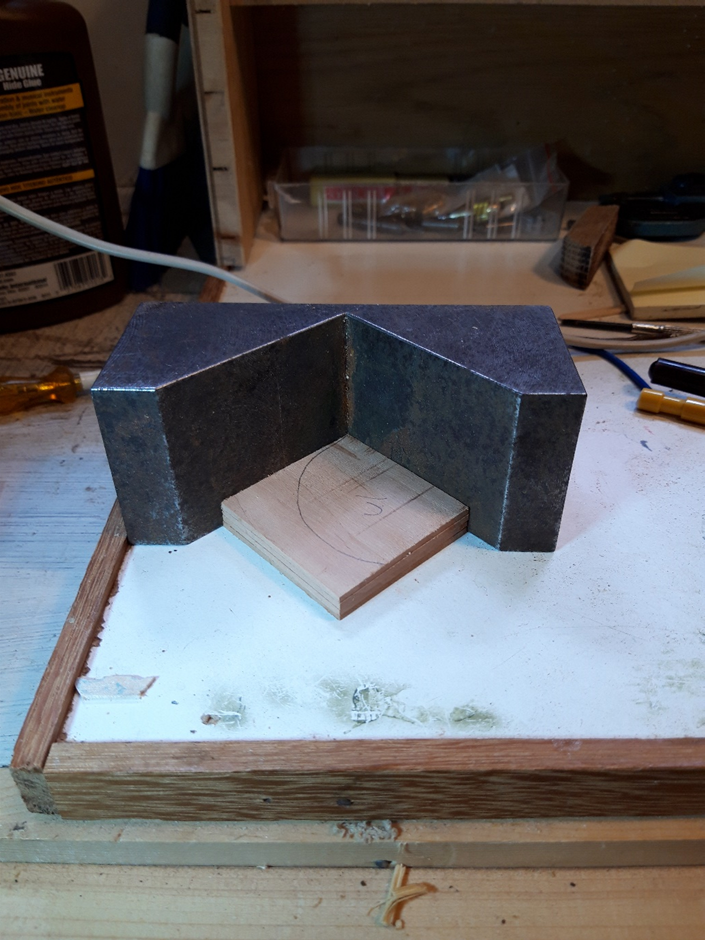

I am using Swiss Pear for the hull. There are 27 hull sections and four frames in each. From my available stock I could produce rectangles 50 x 44 mm which means the majority of the frames will be made from two of these blanks side by side. First steps in milling from blocks of Swiss Pear: Rough cut: they were then put through my shop-made thicknesser. Ready to cut to size on the Byrnes saw. … and then the blanks are sorted. ______ There are twenty-seven hull sections: Each hull section was printed on card and cut carefully to shape. The red line on the card is lined up with the top (short) edge of a blank and the centre-line aligned with the long edge. The importance of a perfect 90 degree corner here will be evident soon. Using the card as a guide the shape is transferred to the pear blank with a mechanical pencil. Note the grain runs vertically. The blank is immediately marked with the profile name to avoid mistakes. This marked blank is now used as the top in a stack of four blanks, held together with blue painter’s tape/CA glue. This avoids getting any glue on the wood. If you don’t know the tape/CA trick, here’s how it works: Put blue painter’s tape on the two surfaces opposite each other. Put a few small dabs of CA on one of the tape surfaces and bring the two together, aligning carefully. I make a stack of four with the middle two having tape on both sides and the result is perfectly stable for scroll sawing. The painter’s tape leaves no residue when removed. I don’t bother with a CA accelerator since I want a moment to ensure things are lined up before the CA grabs. Clamp or use weights as in pic below. I may have gone a little over the top with the weights. (Since these photos were taken I now glue-up two stacks of four at once with no problems.) Once the CA has cured you can handle the assembly like it was one piece and as long as you can avoid lateral pressures they will stay in line. Bruce

-

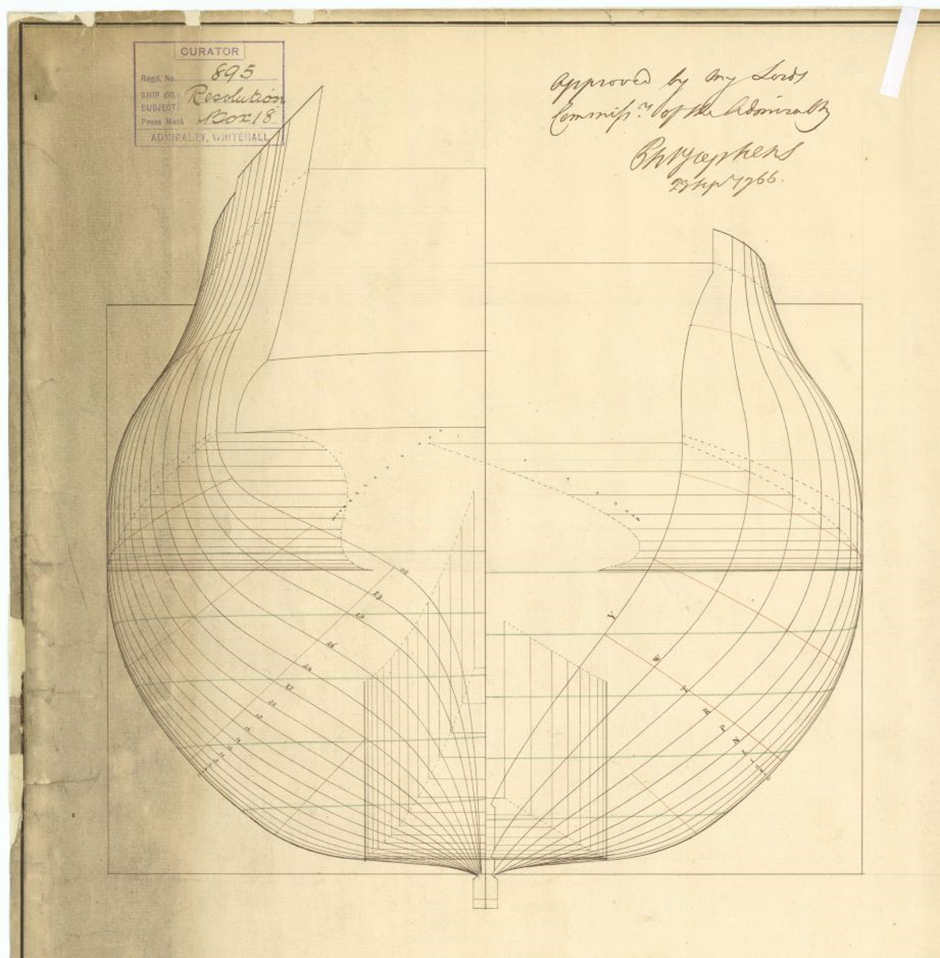

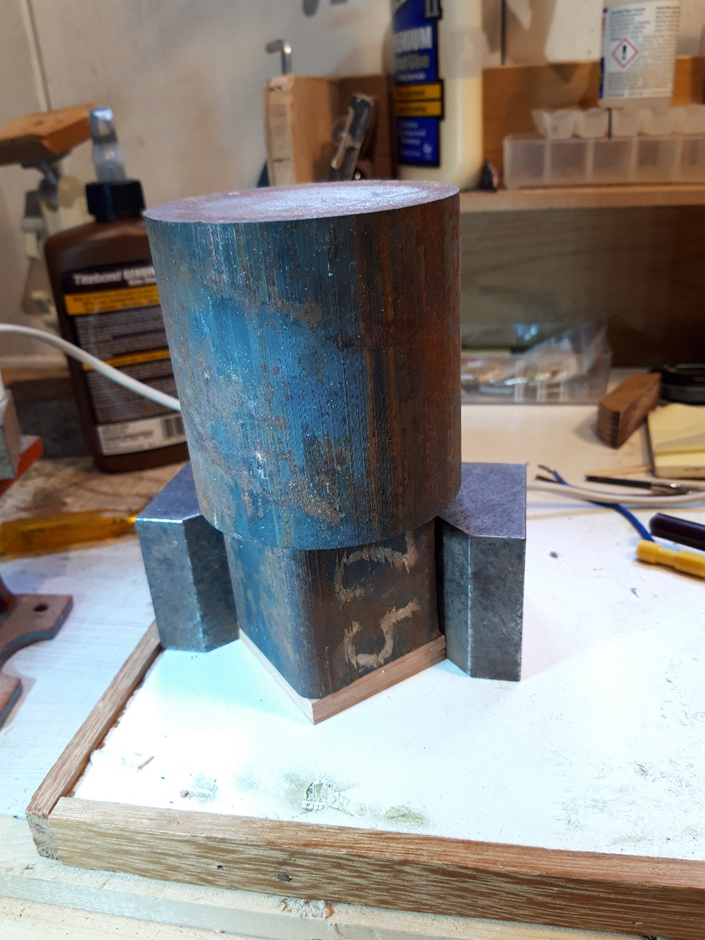

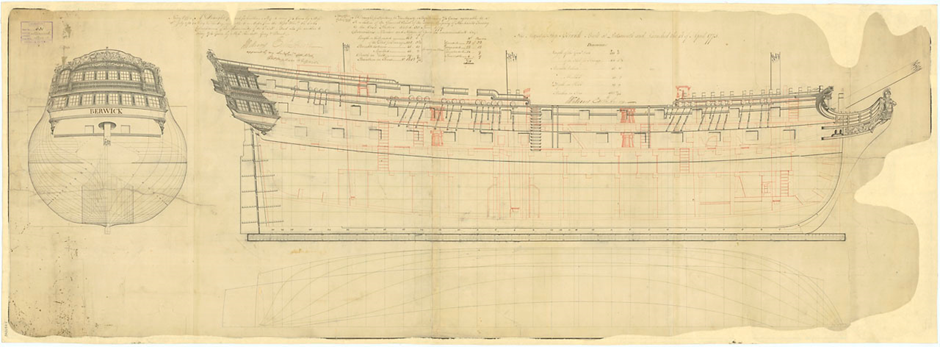

Many people look upon the Navy Board style models of Donald McNarry and Philip Reed as works of art. I am one of those people. Here is an example of the ‘Philip Reed Navy Board style’ in 1/192nd scale: In his book ‘Building a Miniature Navy Board Model’ he tells what is necessary and shows the often counter-intuitive steps in a logical order. It was only when I considered building one that I recognized his skill as a modeler is matched by his ability to describe and demonstrate his methods. After I read, re-read and generally immersed myself in his process I was impressed with his brevity in explaining an intricate process. For better or worse, I decided to attempt building a model in this style. - Subject: HMS Berwick 1775, an English 74 gun third rate of the Elizabeth class designed by Slade and built at Portsmouth. She fought at Ushant and Dogger Bank, was captured by the French in 1795 and served them under the name Berwick. She was re-captured by the Royal Navy at Trafalgar and three days later foundered in a storm while being returned to England. J2632, one of the HMS Berwick NMM plans: Length on gundeck: 168’ 6” (51.36m) Beam: 47’ (14.3m) Scale: 1/192, which is 1/16th inch to the foot. This gives a length on gundeck of 268mm and beam of 75mm, a.k.a. 10.55 inches and 2.95 inches. Material: Hull main components are Swiss Pear, upperworks will be lime, contrasting woods where appropriate. Plans: There are several plans of Elizabeth class ships in the NMM collections, including Berwick, and there is also the contract for sister ship Bombay Castle. I used the hi-res plans for the framing of her sister-ship HMS Resolution in the Wikimedia.commons site (Category:Ship plans of the Royal Museums Greenwich - Wikimedia Commons) as the basis for the hull. The Danish Archives also have an alternate view of the same ship in hi-res and the two agree. I am indebted to MSW member Martes for generously sharing his digital renderings of an Elizabeth class ship. Digital tweaking was carried out with PhotoSuite on various plans to incorporate features needed for the model. The side view is too large for my home printer so two sets incorporating the full hull were produced to scale at a local reprographic company; the 27 hull stations and everything else were produced on my printer. If you have Philip Reed’s book, please refer to it. If not, here is a bare-bones explanation: the idea is to carve the hull out of slices of wood glued face to face. These ‘slices’ from which the model is made are cut to the appropriate profile for the hull station before assembly. Once the collection of slices is glued together the basic shape of the hull is revealed. Each slice then becomes an individual frame/futtock by a process of assembly, un-gluing and reworking, re-gluing and fairing and so on. During one of the stages, while the shaped frame sections are disassembled, the inside line of the futtock shape is drawn on each piece and the waste wood in the centre is removed. After this step is complete and the pieces re-assembled, the beginning of the ‘navy board’ look begins to emerge. The keel, deadwood and deck beams all have equally oblique paths to completion but that comes later. One more look at his work before I get onto my build. Here is a glimpse from midway through the construction of Philip Reed’s Mordaunt: The first hurdle quickly becomes obvious. The ‘slices’ which started as solid pieces of wood became futtocks after they are first assembled. The thickness of the slices is crucial to the outcome because their size must exactly match the scale thickness of the timber on the original. If too thin, the model will be short; too thick and the model will be too long. To amplify, if the model requires for example 100 timbers then you need 100 vertical pieces of wood (let’s stop calling them slices now). When glued face to face, if the pieces are 0.1mm too thick then 0.1 x 100 = 10mm too long. That’s nearly a ½ inch to my friends in North America. Whether metric or Imperial a 10mm/ ½ inch error is a bad thing at 1/192 scale. So, as Philip Reed says in ‘the book’, you have to establish this dimension by trial and error. It is simply not an option to rely on a calculation and procure wood based on that figure but you can’t check without wood to perform the test so … clearly the final milling of the wood to the finished dimension can’t go ahead until the trial and error test is successful (photos below show the test process). This complicates matters if ordering wood from a supplier and I had no practical solution other than to mill the wood myself. To test, mill a piece of wood to the desired thickness according to your best guess. Ten small sections of this wood are glued together face-to-face and lightly clamped in a vice. When cured, the combined thickness is compared to the scale plans of the framing. It is either right or wrong, no half measures. After four attempts, it turns out that the correct thickness for my purposes is 2.2mm (.087”). I was able to achieve this +/- .1mm consistently so I felt confident but took one extra step to keep things within spec: all blanks were graded and the thick, the thin and the spot-ons were sorted. More on this later. The actual milling of the wood is a major part of this build but it feels right to keep the two subjects apart so I will start a separate thread on my milling adventures. For now, I will skim through the milling and get to the model-making. Warning: sawdust ahead. Bruce

-

https://www.kentonline.co.uk/medway/news/girl-8-finds-what-could-be-100-year-old-letter-in-a-bottle-288063/?utm_source=newsshowcase&utm_medium=discover&utm_campaign=CCwqMwgwKioIACIQRJjtI_FXZlsdOcT1rBcrRSoUCAoiEESY7SPxV2ZbHTnE9awXK0Uw77DYATDcje0B&utm_content=bullets

-

Hello Sam and welcome to MSW from Sussex. Bruce

-

As this thread has become an interesting sounding board for observations, here's something I found about colours. Almost all early powerboat racers were green below the waterline. I am referring to around 1900 to the 1930s. It was a convention, not a rule, and other colours were available but shunned. Several manufacturers made 'hull green' paints, especially in the USA. So, at least in the early 20th century, superstition did not keep green off of these boats. Perhaps quite the opposite.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.