-

Posts

343 -

Joined

-

Last visited

About Pete Jaquith

- Birthday 07/04/1943

Profile Information

-

Gender

Male

-

Location

Indio, CA

-

Interests

Family and friends, full size shipbuilding, marine history, scale ship models, and woodworking

Recent Profile Visitors

-

schooner reacted to a post in a topic:

Lucia A Simpson 1875 by cdrusn89 - AJ Fisher - 1/64

schooner reacted to a post in a topic:

Lucia A Simpson 1875 by cdrusn89 - AJ Fisher - 1/64

-

Gary, The scale is 3/16" to the foot (1/64). The hatch coamings are 3/16" above the deck planking. Timberheads are 3/32" sq., bulwark planking is 1/32" and upper hull planking above the copper sheathing is 3/64". The attached picture shows the ledge in hull planking at the top of the covering board.

-

cdrusn89 reacted to a post in a topic:

Lucia A Simpson 1875 by cdrusn89 - AJ Fisher - 1/64

cdrusn89 reacted to a post in a topic:

Lucia A Simpson 1875 by cdrusn89 - AJ Fisher - 1/64

-

No Idea reacted to a post in a topic:

Buying Filler Blocks

No Idea reacted to a post in a topic:

Buying Filler Blocks

-

catopower reacted to a post in a topic:

Buying Filler Blocks

catopower reacted to a post in a topic:

Buying Filler Blocks

-

Landlubber Mike reacted to a post in a topic:

Buying Filler Blocks

Landlubber Mike reacted to a post in a topic:

Buying Filler Blocks

-

thibaultron reacted to a post in a topic:

Buying Filler Blocks

thibaultron reacted to a post in a topic:

Buying Filler Blocks

-

Buying Filler Blocks

Pete Jaquith replied to mikiek's topic in Building, Framing, Planking and plating a ships hull and deck

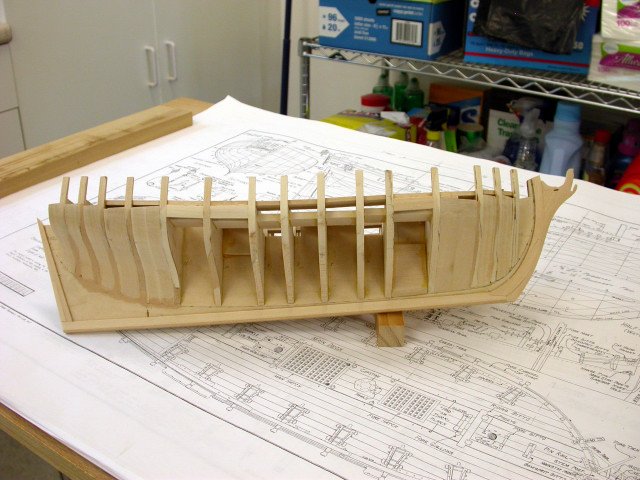

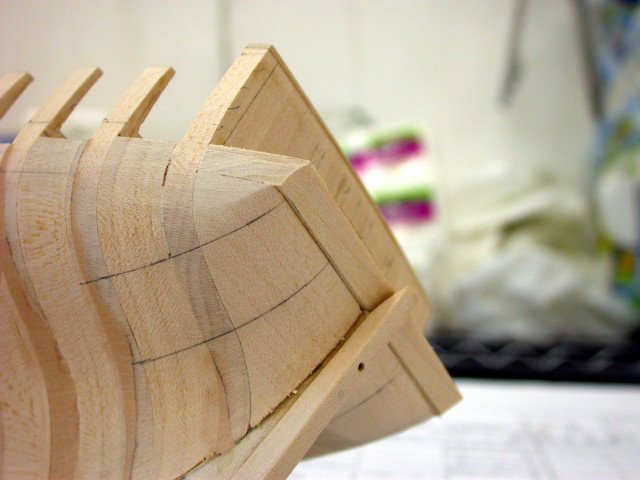

I used 1/8", 1/4" 1/2" and 3/4" basswood sheet laminated for the bulkhead spacing for filler blocks. If basswood is not available, I would use pine or popular. Shaping was done with #80 grit paper wrapped around 1" and 1.5" dowels. They turned out to be very effective fairing tools rapidly removing unneeded material. This was followed by #120 and #150 grit paper using the same large dowels. After initial shaping with gouges and chisels, I use the same large dowels for fairing laminated solid hulls. -

Ryland Craze reacted to a post in a topic:

Buying Filler Blocks

Ryland Craze reacted to a post in a topic:

Buying Filler Blocks

-

Snug Harbor Johnny reacted to a post in a topic:

Buying Filler Blocks

Snug Harbor Johnny reacted to a post in a topic:

Buying Filler Blocks

-

thibaultron reacted to a post in a topic:

Buying Filler Blocks

thibaultron reacted to a post in a topic:

Buying Filler Blocks

-

mikiek reacted to a post in a topic:

Buying Filler Blocks

mikiek reacted to a post in a topic:

Buying Filler Blocks

-

Buying Filler Blocks

Pete Jaquith replied to mikiek's topic in Building, Framing, Planking and plating a ships hull and deck

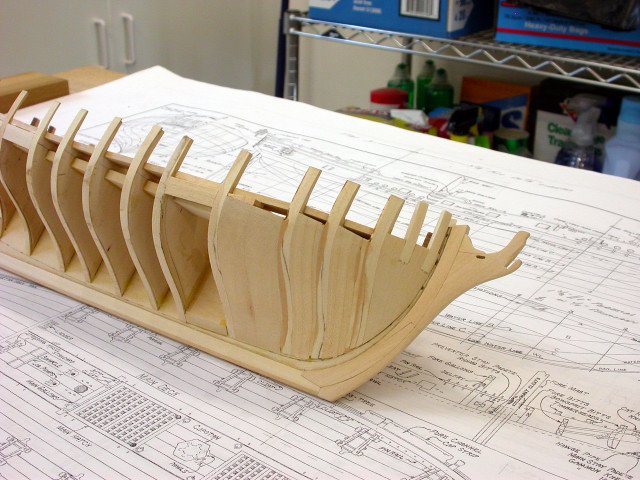

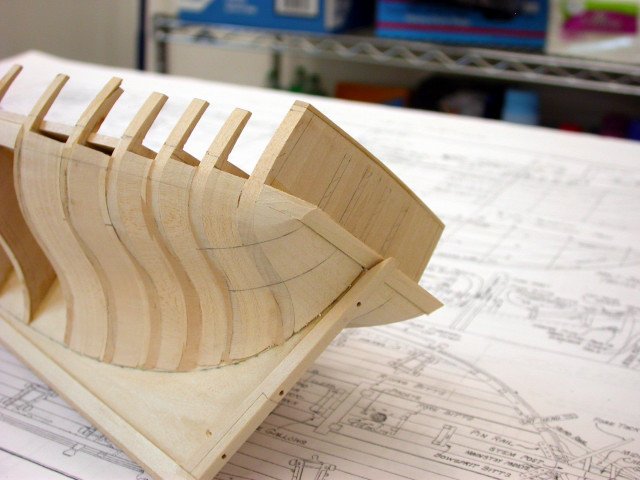

Mikiek, I have used pine or basswood for filler blocks. Easy to work with but firm enough to provide excellent planking support. Attached are pictures from my Fair American build. -

Pete Jaquith reacted to a post in a topic:

USCG Harriet Lane by _SalD_ - FINISHED - Model Shipways - 1:96

Pete Jaquith reacted to a post in a topic:

USCG Harriet Lane by _SalD_ - FINISHED - Model Shipways - 1:96

-

Adding Bulkheads

Pete Jaquith replied to acaron41120's topic in Building, Framing, Planking and plating a ships hull and deck

Here is how I solved the problem in my 14 Gun Brig Fair American kit. The fillers were either bass wood or sugar pine. -

Lofting article

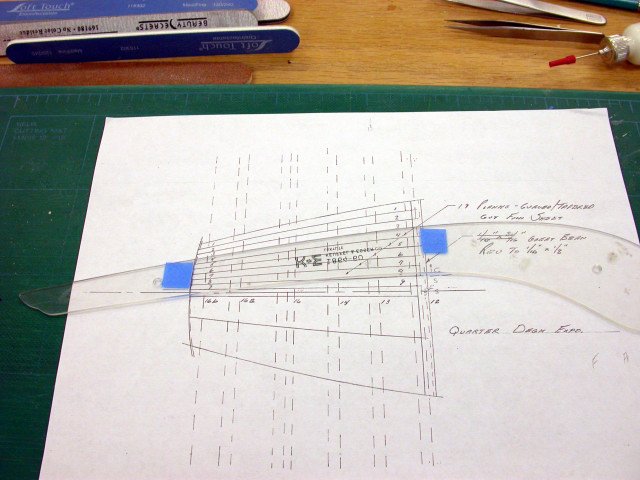

Pete Jaquith replied to a topic in Building, Framing, Planking and plating a ships hull and deck

After graduating from Webb Institute of Naval Architecture and Marine Engineering, I joined Bath Iron Works in Bath, ME. My 1st year included an apprenticeship in the "full scale" and "1/10th scale" mold lofts. Very enjoyable time and I learned a lot re structural design, material routing, and design for production. Later in my career, I ran the mold loft at BIW and oversaw the transition to 3D CAD. Today, most of the traditional loft functions are preformed near automatically using artificial intelligence (AI) and the 3D CAD design product model. Recently I have assisted the US Navy and warship builders with recommendations re modern 3D CAD Product Model design systems. For model building, I prefer to draw my own lines using ship's curves, a tapered pine batten, and lead batten weights from my four years at Webb. -

a drafting tool or paper weight

Pete Jaquith replied to garyshipwright's topic in Modeling tools and Workshop Equipment

As shown in the 1st picture they are great weights for ship modeling. I cast mine at Webb Institute in 1961. Shipbuilder, Pete -

Pete Jaquith reacted to a post in a topic:

Ship paintings

Pete Jaquith reacted to a post in a topic:

Ship paintings

-

Pete Jaquith reacted to a post in a topic:

Flying Fish by campbewj - Model Shipways - 1:96

Pete Jaquith reacted to a post in a topic:

Flying Fish by campbewj - Model Shipways - 1:96

-

Pete Jaquith reacted to a post in a topic:

Flying Fish by campbewj - Model Shipways - 1:96

Pete Jaquith reacted to a post in a topic:

Flying Fish by campbewj - Model Shipways - 1:96

-

Pete Jaquith reacted to a post in a topic:

Smuggler by juhu - FINISHED - BlueJacket Shipcrafters- 1:48

Pete Jaquith reacted to a post in a topic:

Smuggler by juhu - FINISHED - BlueJacket Shipcrafters- 1:48

-

Pete Jaquith reacted to a post in a topic:

Phantom by SkiBee - Model Shipways - 1:96 Scale - New York Pilot Boat

Pete Jaquith reacted to a post in a topic:

Phantom by SkiBee - Model Shipways - 1:96 Scale - New York Pilot Boat

-

Pete Jaquith reacted to a post in a topic:

Flying Fish by Jared - Model Shipways - 1:96

Pete Jaquith reacted to a post in a topic:

Flying Fish by Jared - Model Shipways - 1:96

-

Shipbuilders, My ship modeling has been limited in recent months due to: Preparation of a major Technical Paper on "Warship Design and Acquisition" to be published in the Naval Engineers Journal Sept. `21 issue, an American Society of Naval Engineers (ASNE) publication. Incredibly hot weather which prevents work in my garage shop. With the paper complete and weather improving, I look forward to getting back to the shop. Regards, Pete

-

Pete Jaquith reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

Pete Jaquith reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

-

Pete Jaquith reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

Pete Jaquith reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

-

Pete Jaquith reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

Pete Jaquith reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.