-

Posts

3,034 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bruce d

-

Hello Robert and welcome to MSW from Sussex.

-

Welcome to MSW from the UK.

-

Welcome to MSW from the UK.

-

Hello Jölle and a warm welcome from the UK.

-

I'm wondering if the mystery items are for a specific task. I have read of a carpenter preparing a ship's boats used for anchor work or artillery transport and assumed it was fitting the needed items rather than making any permanent modifications. Having fruitlessly spent some time trying to find details of any of these modifications I concluded the shipwrights and carpenters were directed in some way that was not recorded. The one area where I know very specific arrangements were made was in preparing boats for launching Congreve rockets but alas, they do not appear to have survived. FWIW, I will dig out a drawing I found showing the proposed method of outfitting a boat of that period with a slide for mounting an artillery piece. If memory serves it used rollers ... who knows if it fits but we'll see? HTH, Bruce

-

Rolltop Desk by kgstakes - 1/4 scale

bruce d replied to kgstakes's topic in Completed non-ship models

Very cool, Kurt. I can instantly think of a dozen questions about this desk so, yes please, I would like to see a log and get a look at your processes. Bruce -

Kinsale played a big role in the 17th and 18th centuries and built at least one RN frigate, HMS Kinsale. Kinsale Dockyard - Wikipedia According to this page HMS Kinsale was the only ship built there for the RN: List of frigate classes of the Royal Navy - Wikipedia Nothing I have found in The National Archives catalogue contradicts this. There was a lot of activity but it was almost exclusively maintenance and repairs. Ireland produced a lot of shipwrights for HM shipyards but I speculate that this was due to a healthy trade in merchant craft. HTH, Bruce

-

It looks like Apollo has landed on his feet. He's a cutie!

- 443 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Update: I'm chipping away at the frames as time allows, will post photos when I reach a natural break. Also, work has begun on the fixture to hold work in progress for stern decorations. The Society of Model Shipwrights is linked with MSW as a chapter club. A talk on building Berwick is now on their channel: Bruce

-

FM, good advice (as usual) from Allan, and another book by Philip Reed is close to your stated needs: PERIOD SHIP MODELMAKING An Illustrated Masterclass It's on Ebay, AbeBooks and other places as well. In iit he walks us through building Prince de Neufchatel in 1/192 scale. McNarry and his wife were superb modelmakers and won quite a few pots at early Model Engineer Exhibitions in London. HTH, Bruce

-

Size of a printer needed

bruce d replied to Frank Burroughs's topic in Modeling tools and Workshop Equipment

What Allan said, plus check the lines with a straightedge and measure the diagonals (corner to corner) for skew. -

Hello Paul and welcome to MSW from the UK.

-

Ships at Trafalgar - what kits are available?

bruce d replied to bruce d's topic in Wood ship model kits

Update: AL have just announced a whole new Santisma Trinidad: Also, JoTika are promising a 74 with an interesting history. My bet is it will be HMS Defiance, a Trafalgar veteran, but we will have to wait and see. -

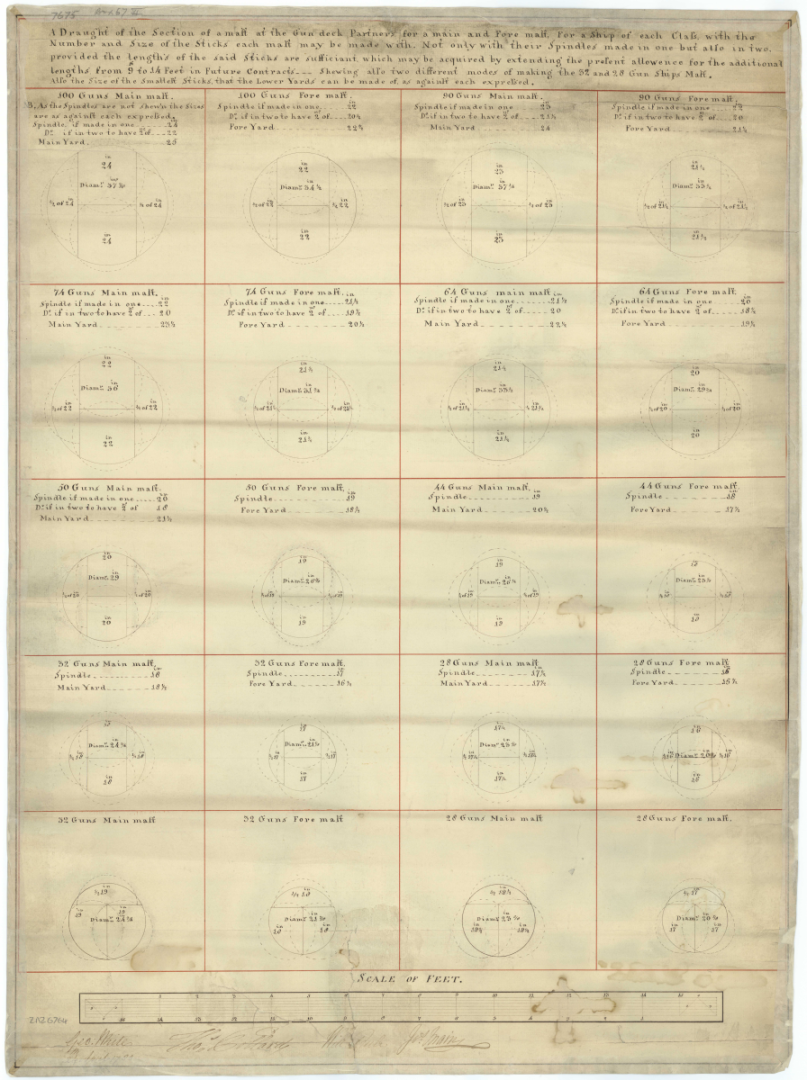

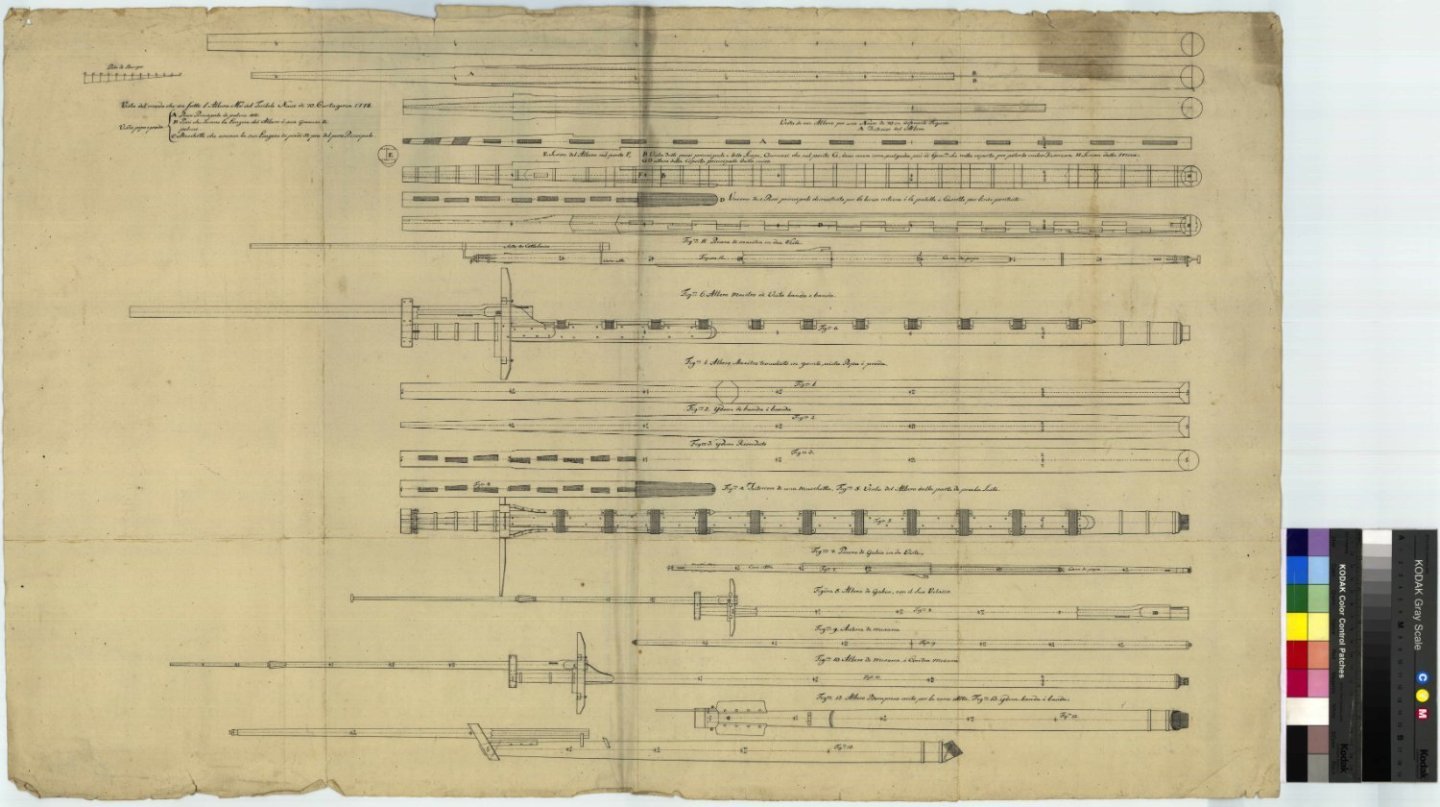

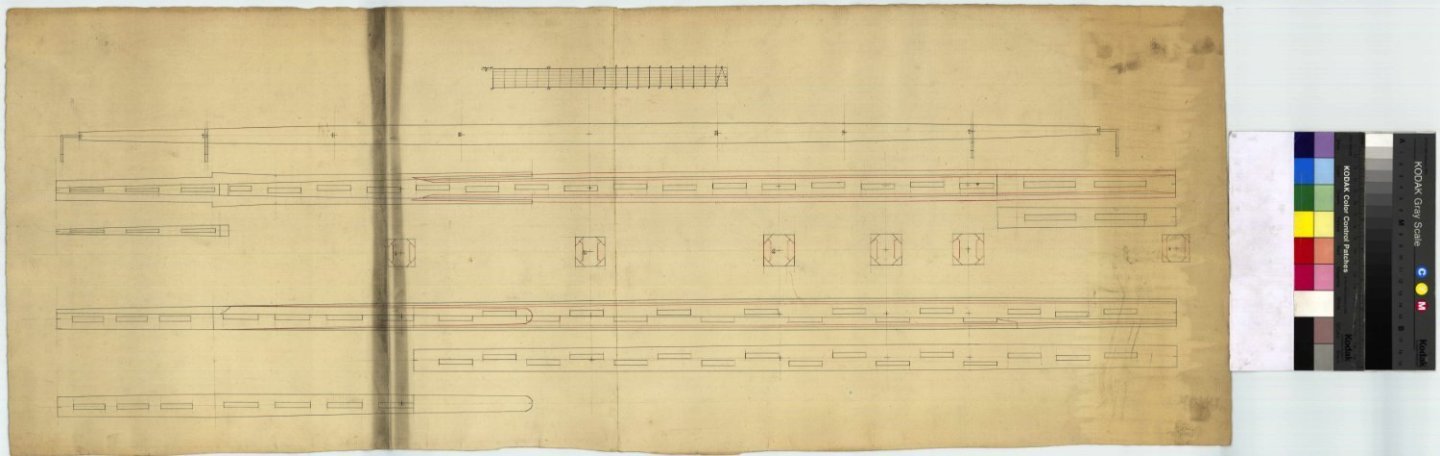

Construction of Masts for 18th Century 'Ships of the Line'

bruce d replied to tmj's topic in Nautical/Naval History

-

-

Fascinating. My only potential contribution is to look at the word FULMINANT when translated into English. The modern translations all steer us to 'angry', 'furious' or 'quick like lightning' but the older translations included 'splendid'. The magnificent drawings have a theme of bundled lightning and flaming spheres. They follow military decorations and emblems of grenadiers of the period so closely that it cannot be a co-incidence. These decorations would have suited a bomb vessel.

-

Fix uneven paint area

bruce d replied to DMM's topic in Painting, finishing and weathering products and techniques

Bummer. It would help a lot to know a some more such as what paint, was it brushed or sprayed? It looks like a plastic model so hopefully it will stand a bit of handling during the repairs. Bruce -

Kevin, just watched your newest video online. Nice work, enjoy your break.

- 1,104 replies

-

Construction of Masts for 18th Century 'Ships of the Line'

bruce d replied to tmj's topic in Nautical/Naval History

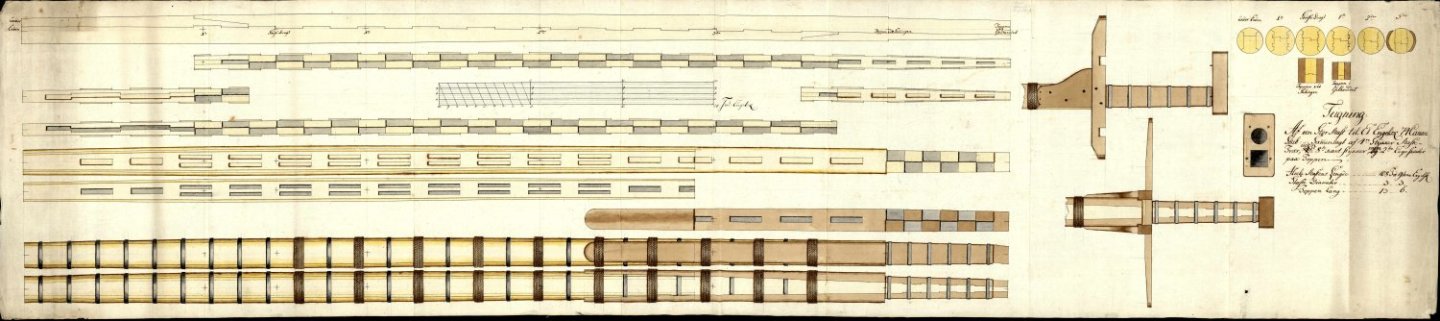

These drawings from the Danish archives may be of help. D206 is for English ships '80 and 100 guns', undated but from late 18th century: D201, as above but for 74 gun ships: G4728, more 74 gun ship masts: You can download hi-res copies free from their website: Arkivalieronline (sa.dk) HTH Bruce -

Lovely model, Richard, and I like her just the way she is.

- 104 replies

-

- pegasus

- victory models

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.