-

Posts

83 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Sunsanvil

-

-

- CaptainSteve, mtaylor, Elijah and 1 other

-

4

4

-

Maybe you got a bad batch of glue. I use Lepages Pro Carpenter's Glue and I love it.

Can you do a quick experiment for me: put a blob of it on something like a paint pallet or peice of tin foil. Next morning, whats it like?

Mine seems to be very "brittle". As I recall (which I grant is imperfect) other PV type glues I've used in the past all dried to a somewhat supple/resilient blob.

-

Everything is pre-shaped. The shear broke away at the stern while I was bending/fitting the next plank: just pushing the next plank against it was apparently too much for it, which seems absurd.

And in any event, the temp tabs which I mentioned at the onset were flat pieces of wood glued to flat wood. When I took those off I expected the tiny strip of wood to break, not pop off cleanly.

This is turning into quite a mystery.

-

Now I'm getting nervous: while fitting the next plank on my hull, the sheer plank let go in two places...

-

Thanks all for your thoughts.

If I read this correctly: you are concerned about PVA-yellow having too weak a bond based on a temporary

bond being reversed too easily?

Well, now that you put it that way...

But seriously, those temp-tabs were put on the same way I've done everything else: apply glue, clamp, let dry. The concern which hit me this morning was that if all 8 of those popped off with such relative ease, what does that say about all the other assemblies I've done to date? I wonder if I need to take more care in terms of surface preparation or something.

B

-

That takes me back. I spent many years in East Africa some time ago and recall visiting the Dhow builders in Lamu. Fascinating old-world craftsmanship!

B

- WackoWolf, mtaylor, thibaultron and 1 other

-

4

4

-

So far on my little build I've been using carpenter's glue, specifically this brand:

http://www.lepage.ca/en/lepage-products/pva-glue-wood-glue/carpenters-glue.html

I thought things were going well until it came time to take off the temporary keel guides/holders which were spot glued to the building frame: they popped right off with I think far too little effort! The wood itself was not damaged at all: the separation was cleanly at the glue interface. This doesn't seem right for a glue which is supposed to have tonnes (literally) of holding strength.

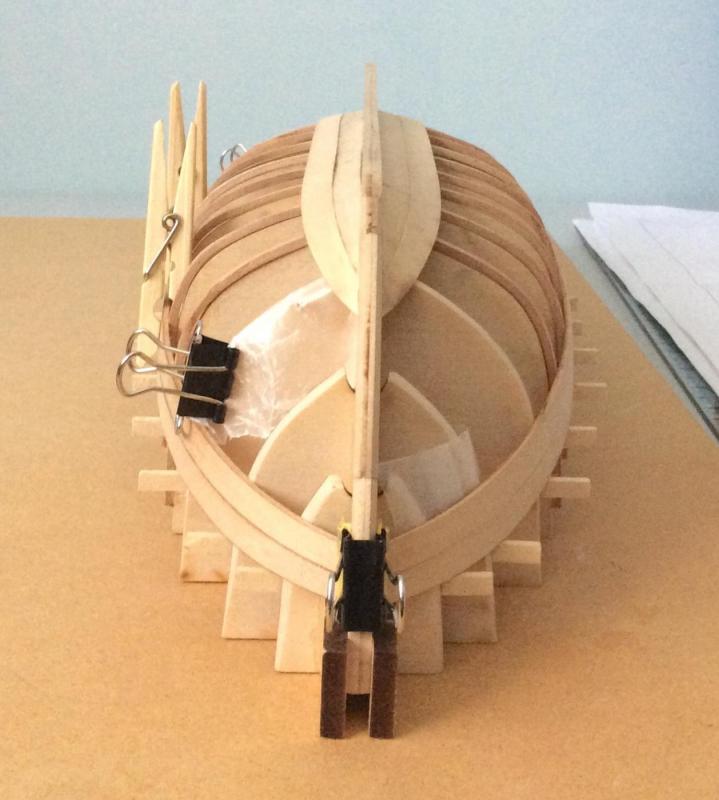

The only thing I can figure (and this is just a guess) is that the margin of error on the clamping force is too narrow. The fine print says to use "50 to 150 psi" and "Avoid excessive pressure,which will result in starved glue joints." How on earth am I supposed to gauge what my array of clothes, binder, and dollar store clamps are doing?!?

So, topics for conversation:

- What am I doing wrong

- What should I be using instead.

Thanks in advance for any thoughts and advice. Sadly I've already got the shear and garbords in place using this stuff and am now terrified.

-

-

-

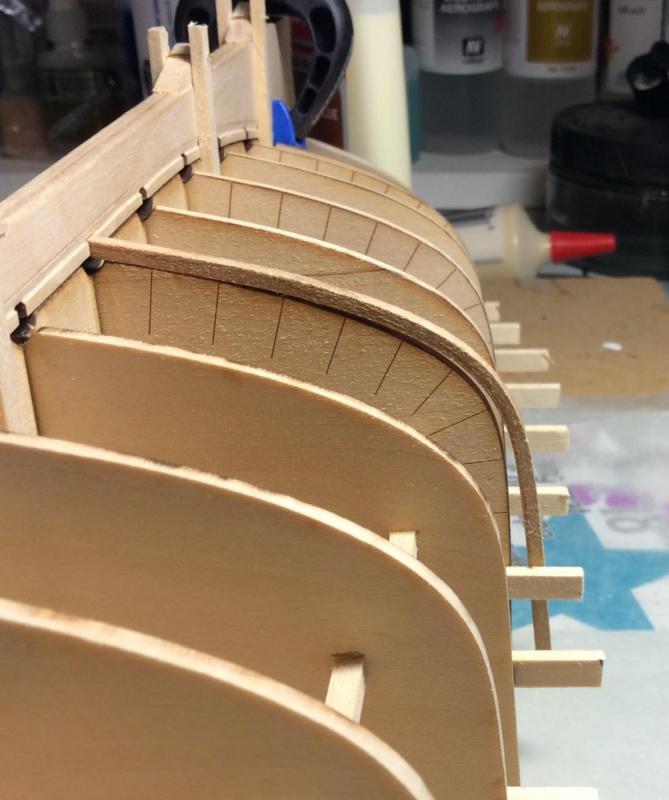

Here is where we stand...

The last of the ribs are glued in place. I now need to fair the rib-less forms (1,2,&3) as well as the transom. Actually looks like I need to touch up the fairing on the ribs themselves. I know I had those forms near perfect, and I made sure every rib was bent and twisted to conform but I guess that's just the vaguery of wood for you.

I have to say, my first foray into bending did not go as well as I hoped. I was off to a good start using the soak and then shape over the curling iron method. A couple broken ones and I was on a streak of 6 good bends... then it really became hit and miss. In the end I overall broke 1 in 3. Then for the last 2 I tried boiling them for 15 minutes...and they went on like butter! Maybe that was just luck, I don't know but I now wish I tried that at the start. I'll be using that method for the tween frames for sure. I'm just super scared now I will run out of the cherry wood stock.

The real question now is, how to approach bending the planks? I don't have a pot big enough to boil them.

- mtaylor, Elijah, Mirabell61 and 1 other

-

4

4

-

I'm not crazy about solvents but I don't think the water-cleanup wood stains are going to provide the finish I want. What would I need to cleanup brushes and whatnot when using Minwax stains (the yellow can ones)? Hopefully something which doesn't only come in a giant 2l bottle.

Everything on my extensive (plastic) modeling rack is acrylic/water base. I think I have every product that Vallejo has ever made.

-

I have what I am sure is a really really stupid question: why is the kit's lower deck only 2/3 width? Is that purely to let more light down to the level/rooms below or something?

Also, where oh where can I get a couple of those nice heavy steel right angles you have? No, seriously!

-

Was looking for a build of this kit to inspire me.

Wow.... Just.... Wow.

-

Thanks much for that Keith.

I did a couple more, broke both, decided it was a combination of going too fast and possibly bending in the wrong orientation. I looked carefully at the stock and its seems fairly clear that the ribs are rip-cut from a board (two sides are smooth, the other two rough). Putting the smooth side to the outside and inside (the rough sides fore and aft), I did 6 more successfully.

I also experimented with my first (test) rib by dipping it in water and working it on the (hair) curling iron to see if subsequent bending or twisting is possible and indeed it is. That will surely come in handy as I get away from amidship and on to the ribs which need convoluted twisting to properly follow the fairing.

It really is a revelation to learn just how pliable a material like wood can be.

- Elijah, mtaylor and CaptainSteve

-

3

3

-

That looks good. The plans, as I recall, mention spot-gluing the frame pieces just above the sheer-tabs.

Thanks. Indeed they will be spot glued. I just didn't know if that much spring-back is "normal" or if I would want to reheat one like that and try to get it a little closer to perfection before forcing it the last couple mm into place.

- Elijah and CaptainSteve

-

2

2

-

-

Is there a visual cue to use?

I read that a gentle plying of the part will give an indication of the best orientation to bend it in (the one which is most yielding).

- Elijah and CaptainSteve

-

2

2

-

I don't believe so. With one method the steam itself is the heat source, with the other the water is simply a barrier against scorching from a dry heat source (air or an iron).Wouldn't that be equivalent to just soaking in hot water? Or perhaps steaming?

Admittedly I'm only just getting acquainted with wood in my modelng journey, but I imagine one should use whatever method works best for a fairytale giant building a tiny ship...and those methods may be different from that of a 1:1 man. After all we don't have 1:16, 1:48, 1:350 size men on our desks helping us.

.

.- mtaylor, thibaultron and Canute

-

3

3

-

- CaptainSteve, Elijah and Ryland Craze

-

3

3

-

Thanks for this! I just did my first bend on my wife's iron and it worked remarkably well. I didn't even use the clamp but rather ran the piece back and forth against the barrel of the iron and worked it into shape. I did soak the part for about 20 minutes first as well for good measure.Pete. This is similar to the one that I have ...

... it has a thumb-operated clip to hold the hair/wood. You'll need to apply pressure to the clip once the piece of wood is placed inside, in order to form the bend. Hence, the tea towel to avoid burning your fingers.

We'll see tomorrow when I pop it off the frame how well it holds shape.

- mtaylor, CaptainSteve, Canute and 2 others

-

5

5

-

-

Real yacht builders, back in the days when the yachts had to be planked rather than coated with resin, used to use steam boxes. That was how they made the planks conform to the needs of the hull.

Indeed... because it was, and still is, impossible to apply dry heat to such large real-world piece of wood. But if it WERE possible, they probably would have done so centuries ago since, as has been well documented now, water and steam are only carriers of the heat which is what does the actual work of softening the lingnin.

- Canute, michael mott, mtaylor and 2 others

-

5

5

-

I'm approaching the point in my build where I'm going to be doing my first bending of wood. I'm in Canada, the house is sealed up tight for the coming winter, and as such a kettle or pot of perpetually boiling water is a big no-no (mold and mildew).

I read that the microwave might be a vaible option for me. Does anyone have any experience they can share? Soak the wood first? Wrap it in wet paper towel? Roughly how many seconds/minutes to start with?

Thanks.

- Canute, thibaultron and mtaylor

-

3

3

-

HMS Bounty Launch by Sunsanvil - Model Shipways - Scale 1:16 - First wooden ship build

in - Kit build logs for subjects built from 1751 - 1800

Posted

Yea I though there was enough overcast light coming in the window but clearly the iPad didnt think so and knocked the shutter speed down on me. I really need to replace my stolen camera soon. Maybe a boxing week sale.