-

Posts

628 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Worldway

-

Steve, very nice. I love the detail you have put into this. Great job.

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

More tools - Luthier, jeweler, fly-tying

Worldway replied to vossiewulf's topic in Modeling tools and Workshop Equipment

My dad worked on Canadian military jets during his career in the RCAF. With jets, most if not all nuts/bolts had a securing wire twisted on to them to ensure they don't unscrew similar to the picture below. This tool was made to do just that. The pliers clamp on to the wire and by pulling the screw thread, they turned the pliers thereby twisting the wire. I figure they will be invaluable when I make my own eye bolts. I haven't figured out yet but I'm sure they will have a lot more uses in the model building world. -

I must have overlooked that particular post because I referred to your build log constantly. I made it like the picture on the box. I wish I hadn't now because it looks a bit off but it will be our little secret. Just like the beds that will never be seen

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

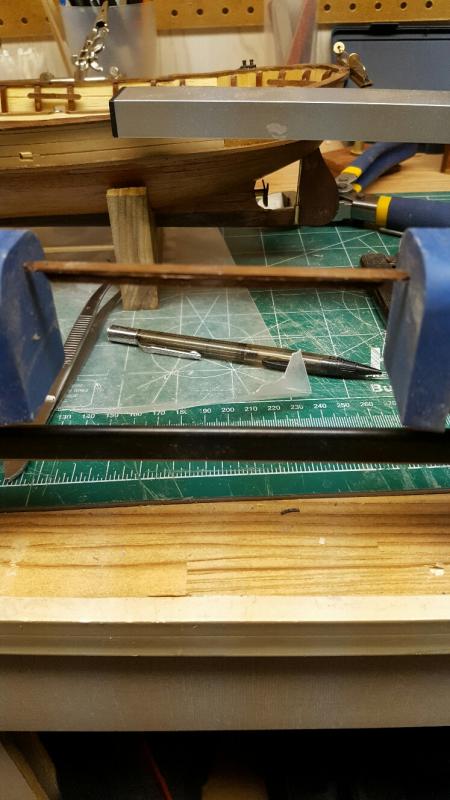

I went down to my shop tonight to grab something really quick, and well, one thing led to another....... So, from reading other logs I knew that the aft section of the false keel was delicate. I still managed to break it. Luckily it didn't snap off, it was just a fracture, so I applied a bit of CA and was back in the game again. After that, I figured it was safer to sand the laser char with the keel on edge. While sanding the middle keel, I guess I got too aggressive and, once again, I fractured the part More CA and everything was fine. I think I was lucky that nothing completely broke off. I wan't happy with the fit between the aft and middle bulkheads so did additional sanding (carefully) to get them better in line. I then used a generous amount of carpenters glue to attach the three sections and added some weights. I'll let them cook over night.

-

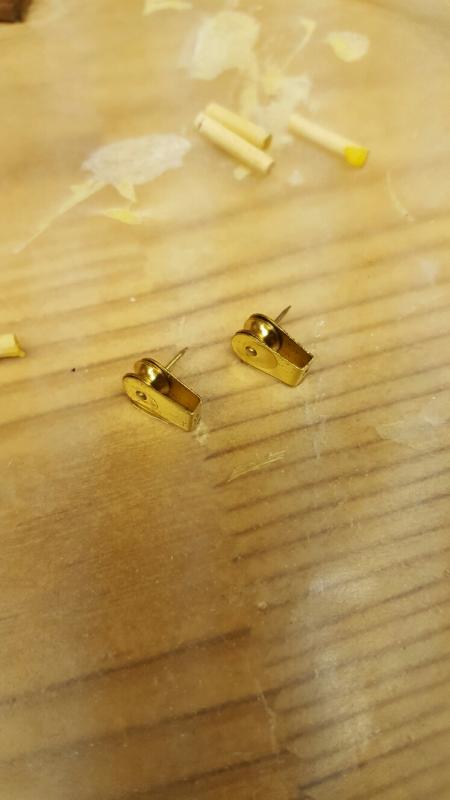

Steve, I noticed on my kit that the little pulley frame that the sliding doors sits on is mounted one way in the instructions and another way on the box cover. Did you have the same problem, and if so, which way did you mount them. Looking great by the way.

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

This is my second build. I received the Bluenose kit just before Christmas. The Admiral "suggested" I put it under the Christmas tree. So on Boxing Day I did an inventory. All parts were present and accounted for. However, one problem I had was that one of the dowels was badly warped. I emailed Model Shpways and had two replacement dowels in about 2 weeks. Excellent customer service. All the wood was sorted, organized and stored in cardboard tubes. I laid the plans out flat to try to get the folds out of them. I plan on following Bob Hunt's practicum from Lauck Street Shipyards for the most part but will also be using the MS instructions manual plus other build logs on this forum. I also purchased the book Bluenose by Brian and Phil Backman. Toronto: McClelland and Stewart, 1965. According to MS it was a major reference for the kit. Right now I am cleaning up my workspace and getting everything prepared to start this build. I will be pre-occupied over the next few days but hope to get started later this weekend.

-

Thanks Doug, looking forward to my next adventure. By the way, I've noticed you haven't posted any build logs for a bit. Everything progressing OK?

- 134 replies

-

- artesania latina

- mare nostrum

-

(and 1 more)

Tagged with:

-

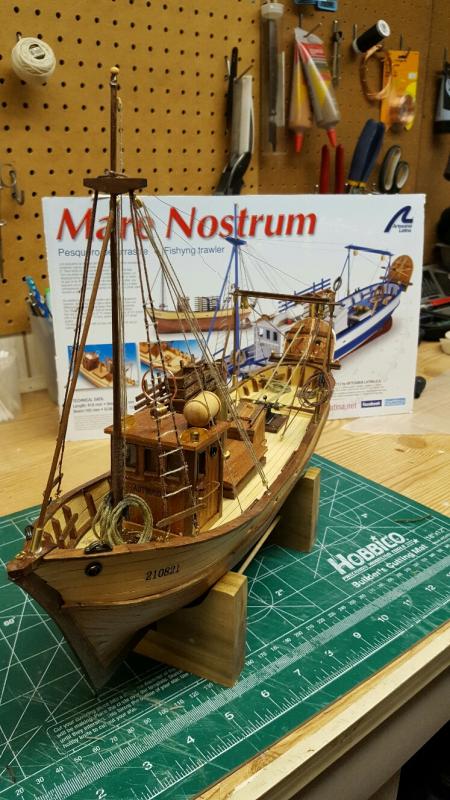

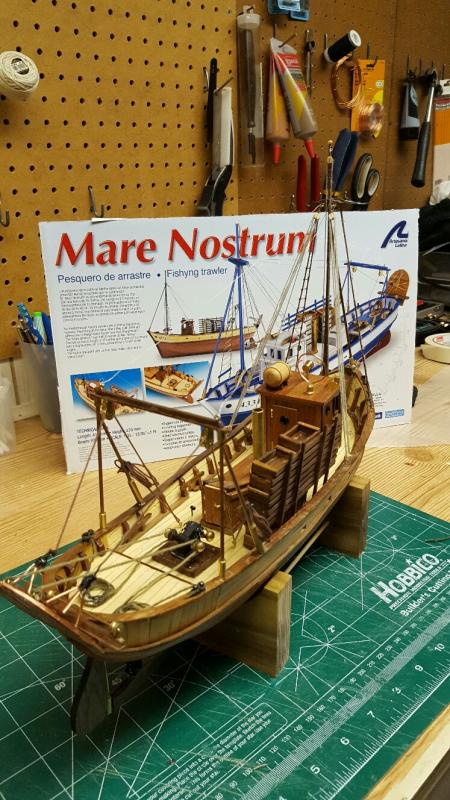

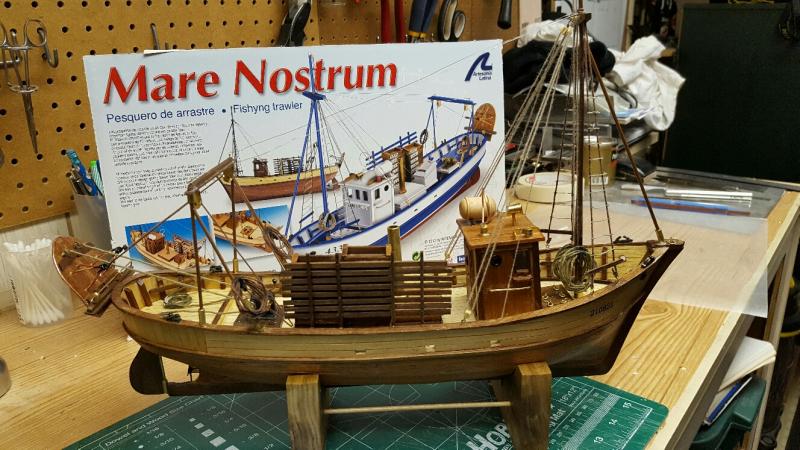

So here it is. The final pictures of my Mare Nostrum. I finished tonight. However, there is one addition I want to make but the part hasn't come in yet so I won't close off the build quite yet. But for the most part, it's finished. It's not as detailed as it should have been but to me it's a good model. There were some discrepancies between the plans and the picture on the box. But I did what I thought was correct. The bench is now empty, waiting for the next build.

- 134 replies

-

- artesania latina

- mare nostrum

-

(and 1 more)

Tagged with:

-

Hey Hof, the Bluenose is the Model Shipways 1:64. Starting soon.

- 134 replies

-

- artesania latina

- mare nostrum

-

(and 1 more)

Tagged with:

-

Pinky Pilot Schooner "Dove" - right pilot's flag of 1875?

Worldway replied to Small Stuff's topic in Nautical/Naval History

It is the red Canadian ensign. The other example in the link posted is a flag that is flown when there is a pilot aboard the vessel. -

Yeah you right. Sitting back right now and enjoying a cold pint.

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Very impressive. I stand in awe. However, I think I'm ahead in the build and might just beat you

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Your tool boxes are amazing. Did you make them?

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

I'm close to finishing my first build and although my sorted wood worked well, I found out later that my company uses a lot of paper (for the CAD machine). And lo and behold they have perfect 24" x 2" tubes that holds the roll of paper. So they gave me a bunch and I find this is perfect. I've since repurposed my first idea.

-

After you tied them did you add a little glue to keep them secure?

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Continuing the final details. I started some rigging. I know it's not "proper" but it is as per the instructions. I did a little more sanding to the plinth and added a second coat of varnish I had a small accident and knocked the model over. Because of that one of the frames broke off. Not a big deal, just re-glued it. I'm hoping to have this finished this weekend. I spent a half hour re-jigging my work area in anticipation of the Bluenose. Hopefully I will start the build log very soon. Although the Mare Nostrum has given me a lot of grief, and although I have seen a lot of much better examples in other build logs, I'm still happy and proud what I have done with this little kit. I will display this proudly.

- 134 replies

-

- artesania latina

- mare nostrum

-

(and 1 more)

Tagged with:

-

Steve, would you mind telling me how you did your rat lines. I'm at that stage right now and haven't figured out how to tackle them.

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

- 134 replies

-

- artesania latina

- mare nostrum

-

(and 1 more)

Tagged with:

-

Well I'm on the finishing stages. Tonight I worked on the upper structures and mounted the deck furniture permanently.

- 134 replies

-

- artesania latina

- mare nostrum

-

(and 1 more)

Tagged with:

-

Your not wasting any time with this build. Very nice work.

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

I used the sheet that the bulkheads were cut out from. From the drawing I got with the model, I determined that bulkheads 6 and 10 were the best positions. I traced the opening from the sheets onto a piece of wood and cut them out with my scroll saw. I hope you understand what i'm trying to describe.

- 134 replies

-

- artesania latina

- mare nostrum

-

(and 1 more)

Tagged with:

-

- 134 replies

-

- artesania latina

- mare nostrum

-

(and 1 more)

Tagged with:

-

Yes it does, thanks. Would be very curious to see your looming in progression. Please post pics if you do.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.4b9546914df2c235b4fe82d7c03670bd.jpg)