-

Posts

5,504 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rwiederrich

-

Cutty Sark by NenadM

rwiederrich replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Frankie......I admit...I'm not a purist in the greater sense of the word...but I do want accuracy and scale. However, if wood, plastic, paper, medal, wax, clay, etc. can be skillfully used to achieve my goals...i will surely employ them. I paint and weather my models so.....a multitude of sins will be covered up...shall we say. Once complete..I feel the final goal has been closely achieved.....getting there is part of the fun...and if I used a kitchen pressure cook pot as part of the process so be it. Thanks for your fine comments and encouragements. Rob

-

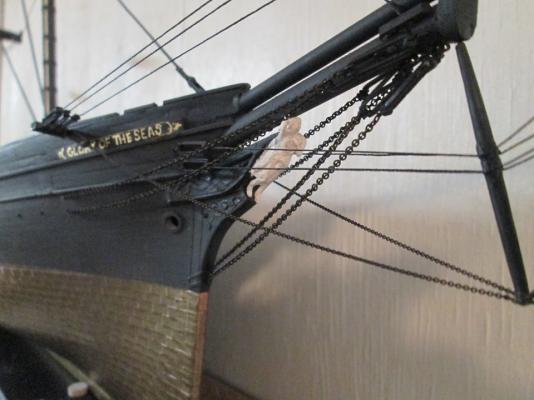

Thanks Ed...I appreciate that coming from you. Yes I alter the hull shape as far as I correct the shape of the bow and stern to replicate the model I am building. As far as the Glory is concerned...her cutwater was much steeper and her deadrise was shallower then the CS. I didn't go into details as to how I corrected that but so far is to say..I re-engineered a hull to my liking and specs. The more noticeable items such as deck houses...height of bullworks...forecastle and poop deck design and mast composition are all modeled after the prototype and scaled line drawings and deck/rigging drawings were utilized. Such as is your manner of building. Just not as profoundly accurate in actual structural detail of the hull construction. A knowledgeable inspector would easily know my model was the Glory of the Seas..based upon her above water details. Thanks for commenting Rob

-

- 3,618 replies

-

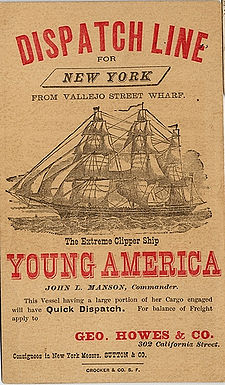

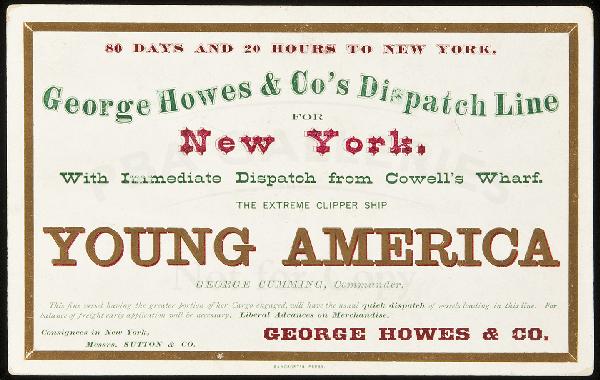

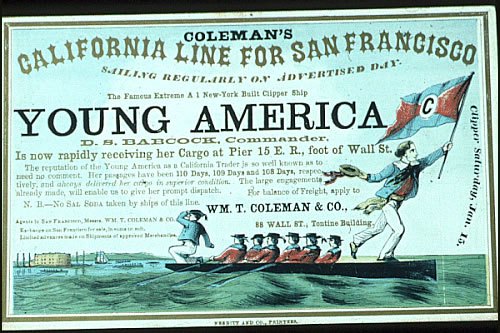

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Ed does the YA have a 3 tier keel and a shoe as well? And if the outside planking engages the rabbet in the upper tier.....who's gonna see all that fancy stopwater plug work? Rob(So impressed I'm not sure what question to ask first)

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Awesome...build. Can't wait for her to sail. Rob

- 79 replies

-

- pride of baltimore

- privateer

-

(and 3 more)

Tagged with:

-

Good analysis and description.....grain was carried in large bags and items like tea and dried goods needed to be dry. I recall reading that the Clipper Dreadnought lost nearly a quarter of a grain shipment due to a sprung keel seal. Many clippers suffered with dry rot in their old age. Rob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Fantastic...purist approach.....no detail is over looked. Rob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

rwiederrich replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Thanks Lou.....Static models are not my thing. I prefer to build an historical ship..then place them in an historical scene. It causes not only the appreciation of the ship build...but draws the viewer into the history of the ship...making your display far more impactual..and might even entise the viewer to build a model for themselves. Self promotion of a great hobbie. Plus you have a fine model to view and the scene it's in. Thanks for your fine comments and posts. Rob(I'm building the Ferriera the Cutty Sark when owned by the Portugues...set in a dirty backwater mouring)- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

rwiederrich replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Here are some older but nice images of the bulworks and many other details. http://groups.yahoo.com/neo/groups/cuttysark/photos/albums/2076722189/lightbox/643145068#- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Daniel..thanks....carving a small woman figurehead was daunting to say the least...but I think I captured the idea. The scroll work on the cheeks was also carved and was fun. Since there are no models of this particular clipper...everything was scratch built from line drawings and lots of study. When I finish her...I'll begin the work on another Donald McKay creation...the Donald McKay. She had some of the first gangways installed on clippers to give better axcess to the seamen. My modles are not as detailed or skillfully executed as some are on these pages...but I enjoy them and I'm having fun. Again...thanks. Rob

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.