-

Posts

5,520 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rwiederrich

-

Rick. I wanted to tell you, that I think your representation of this model is fantastic. You've represented yourself as a very good model maker and detailer. However, I have issues with this tye and lift design the manufacturer has chosen to represent on this model. It is clearly a plethora of engineering and design application....with a yard truss coupled with a gin block on the yard head...leading to two more bilateral gin blocks craned beneath the topgallant cross trees. But looking at the overall lift characteristics and actual lift extension...when fully raised the topsail yard will just barely pass the mid point on the top mast. The yard can never reach its full lift...due to the impedance of the exaggerated lengths of the entire lifting design. You'll just plain run out of lift room due to, too many components of the lift system. I noticed this same situation on other builders versions of this kit as well. If the yard gin block was fixed directly to the yard, and the upper double gin blocks were fixed with less crane strapping. Maybe it might be possible to lift that yard as far up against the futtock shroud band, as it should be. This is only an observation of the kit...NOT your exemplary fabrication of it. Sorry for any perceived malicious remarks. I just always evaluate rigging designs that model manufacturers use and improve them for my own models if I can....to follow more traditionally functioning designs....of real sailing vessels. Rob

- 359 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Riiight. I forgot. They are very nice...revisiting them again. You went all out on those sheet blocks. Mine are a bit simpler in design Rob

- 359 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

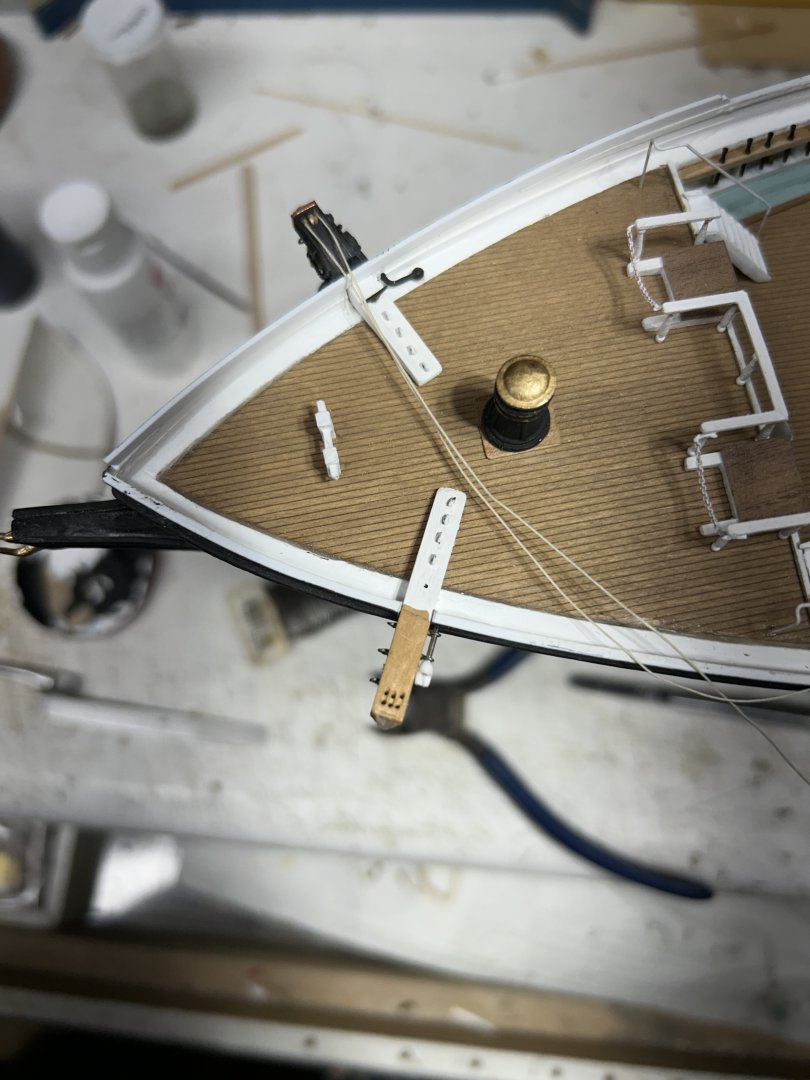

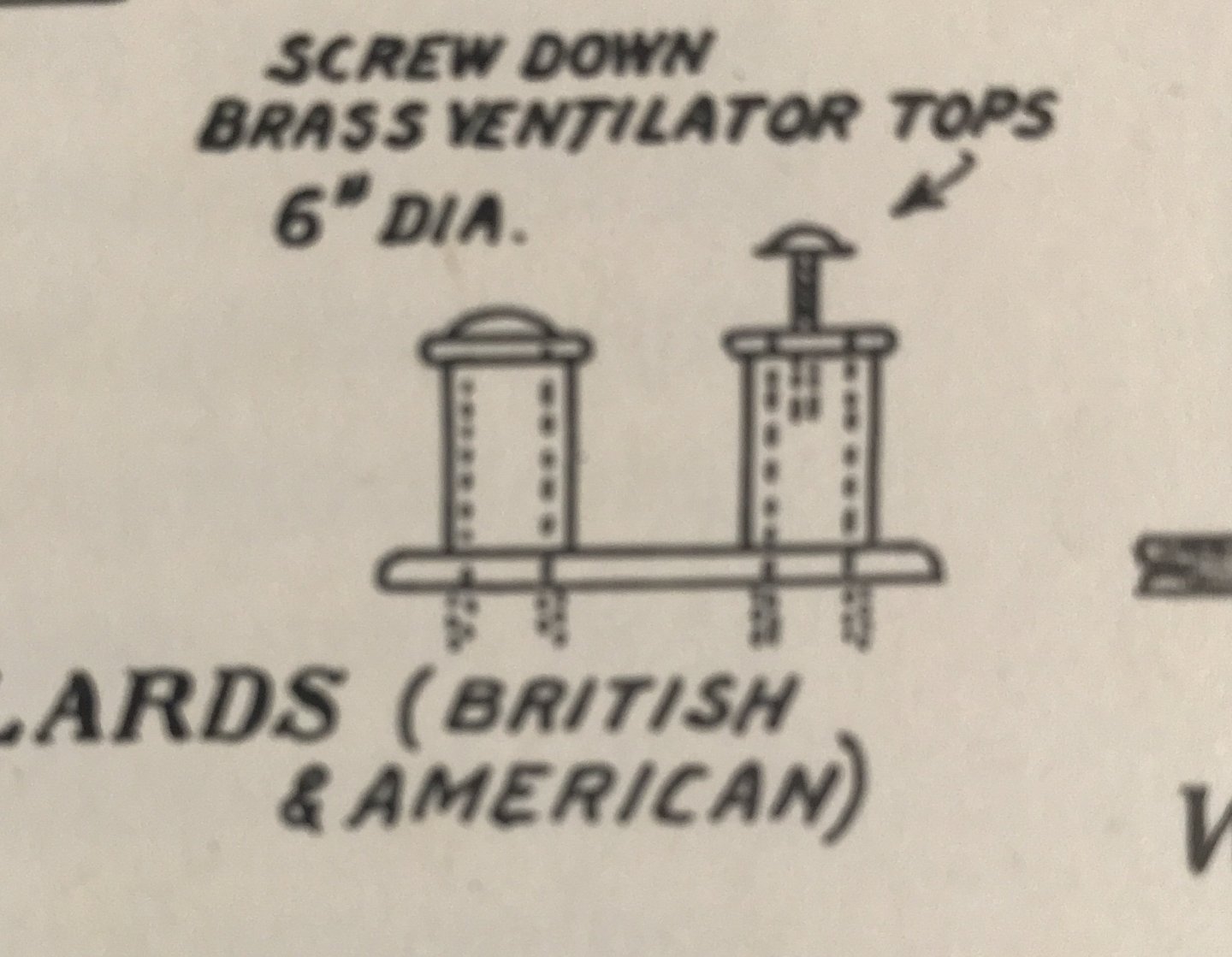

Really, apart from those Buttersworth paintings, all we have to go on is what was typical of clippers of the time. McLean clearly describes her deck features in general, but the finer details are left up to the modelers creativity. And, as you put it, up to their, *powers of observation*. Knowing, from the gate,.......that McKay was given the most extreme levity of design and fashion. We can conclude the most discrete furnishings were employed. I still have to determine, where the iron (vented) bitts are to be placed. 2 On the forecastle and 2 aft on the poop deck? Rob

-

Everything is just stunning...absolutely stunning.... I just might consider taking up another hobby.......... Rob (Maybe whale or bird watching)

-

Hey Rick. Just wondering.....what is your process for making Gin and Sheet blocks? I have not seen it. Rob

- 359 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks Rich. Yes it's true.....most onlookers are truly unaware of the actual functionality of many aspects and components of a large sea going clipper ship. Or how many builders of these wonderful ships, actually are interested, or have the desire to fully compliment their models with accurate and complete components? EDT comes to mind, of one who is an extreme accuracy modeler. But he also built his model in a scale able to accommodate such precise detailing. Us modelers down here in the smaller scales, have to modify, simulate or just completely illuminate some details....because the fabrication to do so...is just too microscopic for even the most discriminating critic. If a magnifying glass is required to properly inspect your models details.....then, you've become a magician. Rob (Just doing the best that I can)

-

Footropes, Flemish Horses and Stirrups

rwiederrich replied to hof00's topic in Masting, rigging and sails

I’ve always reminded builders to keep their stirrups/foot ropes very short. I made sure they were on my Glory of the Seas. The men working the sails are able to do so. Rob -

Good move. Looks convincing. Fine work in such a small scale. Rob

- 165 replies

-

- Red Jacket

- Marine Model Company

-

(and 2 more)

Tagged with:

-

Bill, I watched both videos. It was truly amazing what these men accomplished, with what they had. ...... Freezing rain, dangerous pitching heights, cruel *Bully boys*, scurvy, sleep depravation, and the cruel list goes on. All we can do now, is, enjoy a romanticized version....of *Wooden ships and Iron men*. Rob

-

Rick, I wondered how you did your release. I went back and forth....from the latch, like device on the Flying fish to EDT's Young America twist release. I went with the latter. It had to drill an exact hole through the Rail, aligning exactly with the release bar. It was a booger to install and then paint. Rob

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.