mog

Members-

Posts

196 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mog

-

For flags ,numbers & lettering I use BECC model accessories . There flags are cloth & very good quality the flag in question is 48 star Naval Jack length C 38 mm , but 20-25 mm would work just fine. The jack was posted when a ship is docked or in port I have two US flags same measurements , for the numbering I use US/international pennant style 6mm , the best fit for 1/30 scale

-

Most of the work is caught up, now awaiting materials to proceed so I have posted the Jack while docked Wishing all a hearty thank for all your help & advise , Please have a Merry Xmas & Happy New Year, hopefully we will see calm seas ahead.

-

Ok guys thanks for the comments. The kit is the same as Kevin's, # 1233 I don't like using kit supplied castings & yes I modify the kit heavily , the 50 cal's at this scale standout & give the boat a good look , the casting parts just didn't do it ,but that's just me anyway, I went with 3D for the 50's & mounts , then modified them following ELCO plans from 1942 yes 3D is expensive, then me being a bonehead I end up using little of the original 3D part, however it get the look I want, I don't use many 3D parts, but again at this scale there is a time& place for them. Mike

-

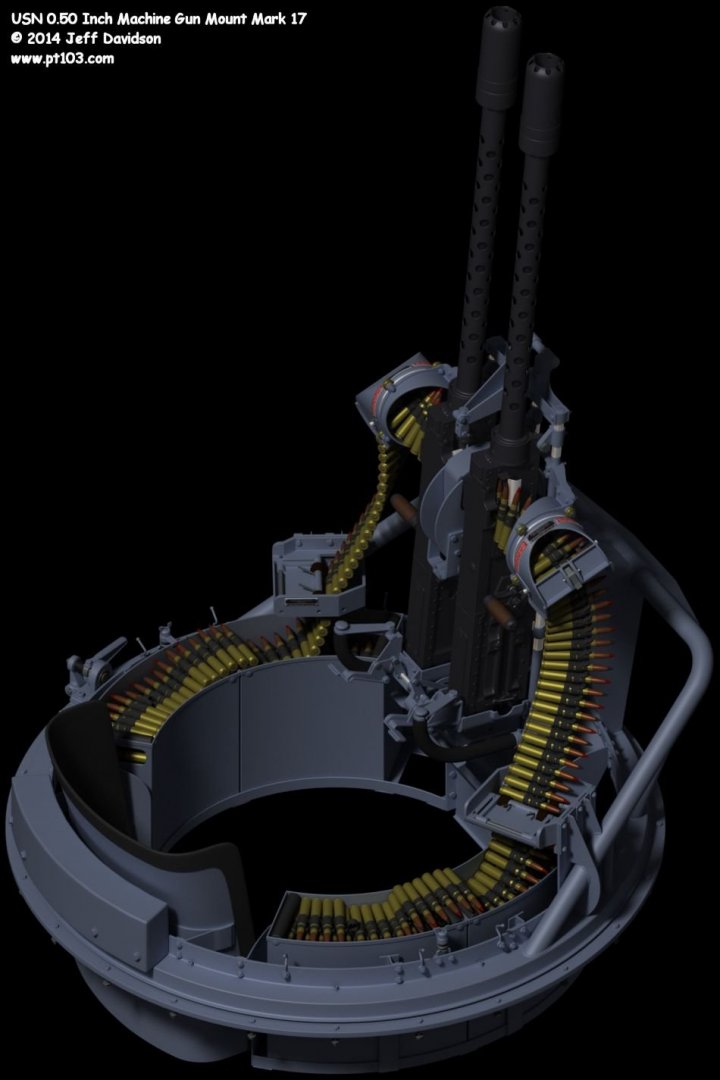

looking really good, we talked about thinking out of the box in some areas in the cockpit I reshaped the control panel area to fit my needs as I found the instruction book misleading ,anyway your getting there , photo from Jeff Ds site pt103.com highly recommended for anyone doing a PT , I use it daily for my build. Mike

-

Twin 50 Cals with mounts ready to prime. As master model builder Gene Berger is always telling me “anything worth doing is worth redoing “ I did not like the first trigger assembly So did it again, Sometimes you have to use a few 3D parts , however working around 3D printed parts at this scale is very fragile, so I combined scratch built with 3D one a better look & 2 I really broke up the original parts.

-

50 Cal machine gun mount with scratch built trigger assembly. And parts to assemble the second trigger group. At this scale detailing has its limits, the working space in tiny, & you can only do so much fabricating parts. Following the weapons blueprints I got it as close as I could.

-

Forward & Aft 50 Cal stops and 50 Cal spent cartridge hopper not sure if I will use the hopper yet? Still being very much a metal fabrication novice , doing the stops rate the toughest project yet with every piece having to conform with the turret ring , plus bends, shaping & getting the heights right , much reworking & a few choice words for something that might look simple , which I quickly found out was not.

-

torpedo caps are being worked , it will take a little time as the have to shaped just right to get the inside the tube look, also the caps will be a different shade than the rest of the boat, so fitted after the finial spray of the tubes. Plus the tubes will not attached to boat until the last

-

Finished fabricating the torpedo mounts suspension. I don’t like using aluminium because it doesn’t solder with getting into a painful process, so it has to be glued, which it equally does not like, anyway it got there in the end,

-

Thanks guys, I do use some 3D parts mainly for smaller things, & yes its expensive , however done with Shapeways , 1 the cost & 2 they print what is sent to them not matter how good the design is the quality is on them and lately there has been far to many question about there work so now if I need anything printed, like custom figures , helmets, life jackets , gun mounts etc.....I have a supplier in Spain who prints his own items from resin at a fraction of the cost, high quality & he will custom it to exactly what you want. The Virus has slowed it down but quality made to my needs for a great price works for me, I already have a good chunk of money in this build so any good deal helps . I try to make as many of the parts as I can, ok they don't look a clean as pre made , but its my work so its in my hands however sometimes there are parts that are way way above my skill level , on the current torpedo tube section which I have over a month of time invested the breech door assembly will be 3D , its the only tube part that is too detailed & to small for me to do properly. anyway its all getting there if it was easy everyone would do it. Mike

-

The early stages of fabrication on the AFT torpedo turntable cradle mounts still 5 more parts to add to each, more work to do. AFT turntable base complete ready to prime

-

First stage building the components for the torpedo tubes, ready to be cleaned up. These components fit on the top surface of the tubes. Still have to build the Aft holding cradles , undercarriage, and another set of training gears. Overall when the tubes are completed I think I will have fabricated about 150 individual parts, every thing has to be built times 4 which makes slow, hair pulling progress trying to get each set to match, which is almost impossible , so I idea is get them close , with so many handmade repetitive parts you would go nuts getting perfect exact matches. Pressing on

-

Starting to show a little progress , attempting to scratch build the torpedo tubes, learning from plans & pictures . its fun but trying to get it right is slow work. fit tested parts of the of the superstructure, and cleaned up the control panel

-

Torpedo tube training gear, rope locker hatch Torpedo tube training gear permits the tubes to be trained inboard so that no part of the tube structure extends over the rail. When action is expected, the tubes are trained outboard, by hand.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.