mog

Members-

Posts

196 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mog

-

1st stage of shroud and rat work, really glad I made the extra space under the platform, it gets really tight fitting the lower shrouds, ratline work a little rusty, however coating all with thinned white glue helps pull them into shape

- 57 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Fore yards rigged, a little different than rigging yards on a schooner, so two more sets to improve my technique

- 57 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

The build is looking really good, don’t you just love the sweep gun ports, kind of makes the rattler look tame, will be following the progress.

- 467 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

Spanker & Gaff booms, in the big scheme of the build rigging the booms is relatively simple, however in saying that I still snapped the cleat, and had a tough time threading the double block with the right slack. ( ok simple is never simple) Can only guess trying to rig once set in place, far too many lines and fragile parts All has confirmed why I’ll be sticking with the plan to rig everything I can off ship

- 57 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Attempting another start my last return to the workbench was short lived the 3 month set back turned into a year, had to go back to my notes to find the right starting sequence. however it's the enjoyment of the build not the pace Masts dry fitted, ready for 1st stages of upper and lower shroud work. Will complete as much off ship rigging as possible. Stop cleats and aft platform stanchions will be added later to minimize damage while working in the tight spaces around the platforms.

- 57 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Looking at the pic of the deck, whats wrong with it ? You can see the planking, the lines look good. A deck is a well worn area, about the only place you will see one look like new is maybe a yacht. My spin is it will be just fine with some stain or oil, the lines will standout and different shades of planks will come out. Your first description made it sound like the deck looked like plywood, again like Tulok said once you put something on it you will see a major difference. Just don’t try to over think this into an over fixed mess, go with what the natural wood gives you and you will be fine MOG

-

Harbm Agree with Hornet, not much you can do with over sanding, refitting might be your best choice, on deck planks. or anything in the .05mm range I very light sand just to smooth, stain or varnish will bring out the grain . Mark being an old hand is right about always testing on scrap first . I tend to stay away from paint as much as possible, so I use different types of wood, using stain & oil on the build. All will effect different types of woods, in allot of different ways. If your building style is no paint then trial and error on test pieces is a must. I would also highly recommend keeping a log on what works when you test, down to how many coats it took to get the right shade. So far on my Rattlesnake I have used several different stains, and mixed several to get the right shades and tones There’s no way to keep it all in your head, plus keeping a log not only tells you how you got that right shade, you will at some point have to go back and redo or touch up an item or area , you want it to look the same . So I log what I used on hulls, rails, decks ect. Again we all have our own styles; the site is a great place to get advice and good ideas while finding out what works for you and your build MOG

-

Sorted out the correct placement of the blocks on the maintop platform,, a small task, But my thanks to all who helped decipher the different RS plans that are floating around. Know that I have started again, and being able to stay longer at the bench I hope to make some steady progress

- 57 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Scott, your advise and help as always is much appreciated MOG

- 264 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

paint or stain

mog replied to lionfish's topic in Painting, finishing and weathering products and techniques

Agree with everything that has been said, it’s all a pens- on, it depends on the ship, the type of wood, the effect your looking for. Some say historical accuracy drives all, which is great if that’s the desired end. Using the Rattlesnake as an example if everyone went for the same historical colour scheme we would have allot of builds that mostly look alike. For me it’s all about the look and feel I want to achieve, when I do paint which is very little it’s for detail, I don’t like hiding the natural wood tones so I stain and oil, using different types of wood, letting the colour, tones and shades take their own course, but that’s just the way I build. Everyone is different on how they get to their final result. I guess that’s what I enjoy about this hobby you can see the same ship in so many different ways each with its own style and feel. Just my thoughts. MOG -

Martin, Don't know much about the NRG, except of course this site is conected, is it a good group to belong to ? also you know you love the world of planking gunports all the best MOG also while I have you here going back a little on yourt Ratt main/fore plattforms did most of the blocks go under know about the bunt line blocks fore and aft, but what about the reef line ect...

- 467 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

Scott, Are there buntline blocks on the AFT side of the platform ? Some folks say to put 6 on the front and 6 on the aft, however not sure what the aft side would be used for as the plans don’t really show them, your thoughts MOG

- 264 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Martin, You just can’t get away from the Ratt crowd, the new build looks great, will be following along MOG

- 467 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

Jon, Your build is coming along very nice, , working thru problems and learning new techniques is what the hobby is all about, but the main goal is to enjoy the experience, I have said more than once you build for the builder, for most of us a build will never be perfect, but do it your way, overcoming the unknown is a great feeling. I have been working on my Rattlesnake for several years, the enjoyment never fades, most of the RS builds on the site are unique in their own way , I don’t like to cover up the wood so I stay away from paint, as much as possible, I try to make all my own parts, not a fan of the kit supplied metal ones, Ok sometimes my scratch built parts are not 100% like the drawings , but it’s all learning, In my log Rattlesnake by MOG you will see I have went down my own path looking for a natural old school feel. Your planking looks really good, small flaws are part of the planking process, I made allot of errors but sanding and filler helped me get over it. And I like to double hull so I buy very thin ,5mm strips for a second planking , I found double hulling not only covers some small flaws but gives a good look. On the ships long boat I spent three weeks getting the right shape and look, The site has helped me over many problem areas, some great builders JPett, Scott larkins and JSGerson to name a few are first class builders seek there help you will not go wrong. Again it’s your build do it your way , take your time and you’re your will end up with something you will look at with pride for many years. look forward to seeing your progress, MOG

- 131 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Kenny One last thought on your new build, do have a reference collection started yet ? I have two books that are must for me, “ Neophyte Ship modellers Jackstay” by George Campbell and “Ship Modeling Simplified “ by Frank Mastini Allot of reference, detailed pictures on just about every step in a build. a great need to have tool section. I go to them over and over. really could not work without them. I follow Mastini's style of building , which centers on natural wood and stain , very little paint. Just a thought that might help you along the way. MOG

-

Welcome the world of the rattlesnake build, there are a few builds going on with a wealth of ideas and information, JPetts log is one of the best sources to follow he does excellent work, As he said the bulkheads have a few issues, on most of the Rattlesnake kits they are flimsy at best and care must be taken during this important phase. In my log “ Rattlesnake by MOG” I removed the thin deck frames, because I got tired of them snapping, I did not replace them until I was ready to do deck work. Enjoy your build and please feel free to share ideas and ask any questions you might have

-

HMS Victory by JPett - Corel - 1:98

mog replied to JPett's topic in - Kit build logs for subjects built from 1751 - 1800

Nothing wrong with over thinking, how many times do we find ourselfs just setting in front of the build ,your mind going in all directions, visualizing all the different ways a piece is going fit, finding the best way, only to look at it from a different direction and find a better way, guess this is why we love this hobby. You know I have all the high speed tools for quick sanding, but like you I spend hours hand sanding and filing, something about getting the feel for the part your working on. After 6 months away I have had to rethink my entire build sequence, hoping to find some flow in the building, anyway will be following both your builds MOG -

Injury recovery took a minor setback 3 extra months away from the build, gladly was able to spend some time at the workbench today, nothing big added deadeyes to the topmast platform, allot of rust to shake off, but glad to be back in the boatyard. Photography is a bit rusty also.

- 57 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

After a lengthy recovery from surgery, I’m about ready to return to the shipyard, really looking forward getting restarted. As always I will be looking to the members for advise as I shake off some rust. MOG Mike the keel clamp is from model shipways , picked it up several years back it works well in the early stages, before to ship gets to heavy but when the hull planking starts to take shape I move to a shop made cradle. For better support

- 57 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

When to stain wood?

mog replied to Keith_W's topic in Painting, finishing and weathering products and techniques

Bart 430, The finish on my builds are 99% stain and oil ( reference my build log rattlesnake by MOG) water based or regular oil does not really matter to as long as I get the effect I want. I use allot of sanding seal and varnish, as with most builds you finish and seal the hull before attaching items to it. Plus I don’t know a builder who has not broken something that required gluing back on at some point. I have never had a problem gluing over any of it. The only thing is if you use seal or varnish always get a good coat stain down first , like it says seal is a seal and the stain will not penetrate fully. MOG -

Paint and Tung Oil

mog replied to tinyellie's topic in Painting, finishing and weathering products and techniques

Agree with Brain C Tung oil and most paint don’t mix well, however it sometimes depends on the type of wood, environment, brand of paint or oil. But I see it as paint is for paint and oil or stain is well oil or stain I try to stay away from paint going more for a stain and natural wood look. Of course this is just my spin on what works for me on my Rattlesnake by MOG At the end of the day it’s your build . your desired effect., As with any finishing it’s all trial and error on scrap wood to get the effect you like. -

Sanding sealer works very well , clear smooth, very hard finish, fills in minor defects, however you want to stain, put at least one good well rubbed in coat first, then seal. Light sand and stain again if desired. I often rub stain over the seal, attempting to gain a different effect. As with any finishing it’s all trial and error on scrap wood to get the effect you like. MOG

-

Brian The shape looks good, If you want to practice , you might try planking the hull, I always double hull , really gives a nice effect , and will cover any flaws on the sold hull , have a look at my longboat in my log rattlesnake by mog, the longboat is a standout feature of the build, take your time with it as you want it to be special. Also you want it to keep to the overall style you want to present for the whole ship. The Dremel is good for rough shaping but the high speed can get away from you really fast, I use it Sparingly to get shapes started, then is allot of hand sanding , for me building is a slow thing, never a race, anyway these are just my thoughts, as I've said many times on the site it's your build do it your way, build to please the builder.

-

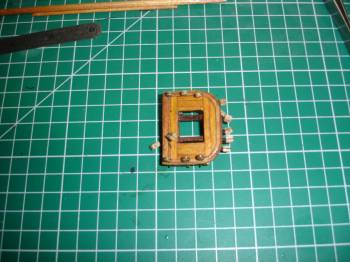

First stages of the main mast Trestle, cross trees , cleats and main top platform , will have to do some filing and sanding to make space for the shrouds, allot of blocks and rigging have to fit into this small space, will set up all blocks ect.. before attaching to the mast.

- 57 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.