-

Posts

496 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by twintrow

-

What do you use your mill for ?

twintrow replied to captainbob's topic in Modeling tools and Workshop Equipment

Thanks again Janos. Now to try my own ;o) Tom -

What do you use your mill for ?

twintrow replied to captainbob's topic in Modeling tools and Workshop Equipment

Thanks Janos for the samples. I assume you flattened nails, then grind them to shape with a grinding wheel (dremel?). Do the bits need to be tempered? Heat to cherry red then immerse in oil?? Or are they sufficiently hard left alone? Are the edges sharpened? thanks again Tom -

What do you use your mill for ?

twintrow replied to captainbob's topic in Modeling tools and Workshop Equipment

Mark thanks for the links. While they are for the Mini-Mill, some are useful for my purposes as well. Especially the "products" section. Tom -

What do you use your mill for ?

twintrow replied to captainbob's topic in Modeling tools and Workshop Equipment

Thanks Janos much appreciated Tom -

What do you use your mill for ?

twintrow replied to captainbob's topic in Modeling tools and Workshop Equipment

And David I live in a retirement community and we have both a metal shop and wood working shop, so I intend to join them and get the training I need. No doubt faster than trying to learn by doing by myself. -

What do you use your mill for ?

twintrow replied to captainbob's topic in Modeling tools and Workshop Equipment

Thanks Janos I remember reading about making the mill bits from a drill bit and it just didn't seem practical. I'm glad I asked. I would like to hear more about this statement though "What you can do though is making your mill bits from broken drill bits, piano wire, silver steel, etc. I am doing this quite often and with those I can make nice moulding profiles." Would a little explanation of how be possible. Or if you know of a site where it is demonstrated? No ,more than I think I'll be using the mill bits, I think I'm better off buying them from a professional source. I'm thinking 4 or 5 different sizes is all I'll ever use, and overwhelmingly on wood. But I will be making a lot of moulding. thanks Tom -

What do you use your mill for ?

twintrow replied to captainbob's topic in Modeling tools and Workshop Equipment

Ian Since you ave some experience with a mill, I read that one can make a milling bit by just flattening the end of most any drill bit on a grinder. Does that make sense?? thanks Tom -

What do you use your mill for ?

twintrow replied to captainbob's topic in Modeling tools and Workshop Equipment

Bob thanks for posting the question. I just ordered an x-y- table for my drill press and was wondering what all I can do with it. My primary intent was for making blocks (ala Chuckie blocks) and decorative moldings. then I saw the windlass on another post, and a couple masts being made on a mill. So, I'm hopeful it will be as versatile as I think it will be. Tom -

Atta boy Floyd, I don't have anything from the Harvey, but lots of left overs from other builds, be glad to send you some too Jesse. Where are you located?? Maybe one of us is close enough to drop off some extra wood. Tom

-

OK Jesse but I would still go on line and try to identify which particular strain of mold it is before handling or touching it. I had a small patch of mold in one of my clinics after a rain storm.....OSHA made us tear out the entire wall and seal off the exam room while doing so. The they identified the mold after tearing everything out, turns out it was harmless AFTER THE FACT! So check it out THEN decide what if anything needs to be done. Tom

-

Get new wood for the kit comes to mind first. If that is not an option for some reason, try adding small amount of vinegar to the soaking water. And when dry sand the area. Unless the mold is black it usually isn't harmful. Look up mold on Google for the different kinds and try and identify it. If the "bad" kind, discard the wood (all of it) and start with fresh wood. Shouldn't be much of an expense. Tom

-

There are a couple Aciera on ebay now. $4,000 and up. Too rich for me.

-

Question on false seizing / zip seizing

twintrow replied to slagoon's topic in Masting, rigging and sails

Sarah Are you waxing the shaft before wrapping it?? Must rub on some beeswax, then wrap, then a drop of thin CA. And wax every other seize, if not every one. Tom -

Harbor Freight Workbench

twintrow replied to Landlubber Mike's topic in Modeling tools and Workshop Equipment

Mike don't forget the old "standbys". A blank door on two or three hand made saw horses works well for a working surface. If you are near one or two of the big box DYI centers they sell damaged doors, or ones pre-drilled (in error) pretty cheap. Also used furniture stores (like Goodwill) sometimes have desks that will work well in a pinch. And there are the Habitat for Humanity stores where they sell used doors too.My Dad always said "build it, find it, or get it from scrap, don't buy it new." He meant when building around the house of course. Tom -

Harbor Freight Workbench

twintrow replied to Landlubber Mike's topic in Modeling tools and Workshop Equipment

Wait for it to go on sale....AND....if you get their newsletter on-line, often they send a 20% off any single item coupon. Even better! Tom -

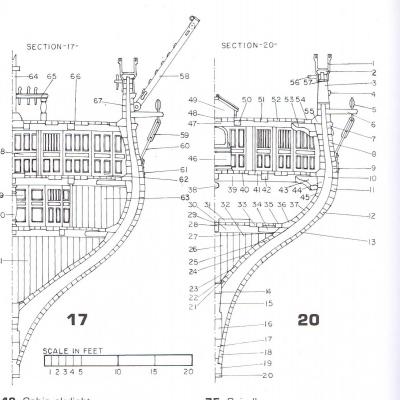

Alan I base my opinion on what I see in the AOS drawings. For example. below are two scans of drawings showing the chainplates, the two drawings (on the left) are of the Constitution and the single from the Endeavour. They show the channel at a 90 degree angle from the ship center. And assuming the ship to be level in the water that would also be horizontal to the sea. The tumblehome the two ships is slightly different, so my assumption is regardless of the tumble home they would be mounted at 90 degrees. If I am incorrect in my assessment please let me know because, I mount them always this way. thanks Tom.

-

Allen and Wayne. 90 Degrees from the hull would also be parallel to the water, assuming the hull was sitting level. Brian, I just took a look at 4 different AOS ( I have 8) and all had some form of support to the channel. I have one that shows only the chains as being the support. It is your ship, build her the way that satisfied you. I'm not positive given the recent events, but I'm not aware yet of thee being someone who checks our builds for details ;o) Tom

-

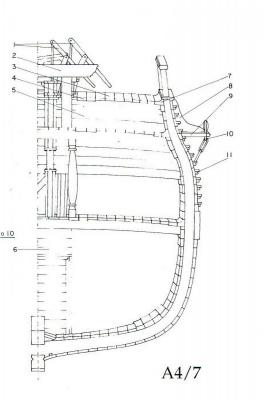

Sam the channel should remain 90 degrees from the hull. And you are correct the channel should be braced, but not with a knee from the bottom, from on top of the channel. The purpose of the channel is to anchor the masts using the shrouds. And since the tensioning of the shrouds would necessarily place a great deal of strain on the channel in an upward motion, the channel needs to be braced either with block supports as shown in the picture (picture from Pettersson's Rigging book), or with metal braces, from the top side. And after nailing or pinning the chainplate in place at the bottom hole, insert nails or pins in the other two holes as well. Also you will want to run the chainplates as an extension of the shroud following the same angle down from it's attachment to the mast. I take a piece of line and before starting the shroud set up, pull the line down to the channel as the shroud will set, past the channel to show the angle of the chain plate. Using the first hole to mark the angle. You can see the angle of the chainplates in the picture. Hope that makes sense. Tom

-

Pulley sheaves out of plastic hangers

twintrow replied to Walter Biles's topic in Masting, rigging and sails

Walt A good alternative to real sheaves is to use brass cannon truck wheels. Several of the kit makers sell them. I took some out of an old kit I had (don't recall now what it was) using for parts. I've used them in catheads a couple times. Tom -

-

I solved this by running the rope through both blocks (each end), apply the needed tension for the fit you want, then see how she sits before tying off. If it wants to twist, I rotate the block at the bottom until the rope is untangled, then tie off. Tom

-

octagon portion of a yard/mast

twintrow replied to Juan Carlos's topic in Masting, rigging and sails

At many hardware and some auto parts stores you can buy octagon nuts in many sizes. I put one at each end of the dowel and file a perfect octagon each time. If unable to get a nut with a large enough dia to fit the dowel, I reduce the dowel to the smaller dia for about a 1/4 length of the dowel then put on the nut. Seems to work for me. Tom -

gulfmedic1 You can get a bunch of small clamps at Harbor Freight if you have one nearby. Very cheap. Or in a pinch you can use clothespins, or the black and slver paper clamps too. Tom

-

qwerty2008 You can buy micro bits from Model Expo for $1.79 for a pack of 10 bits, plus shipping of course. I can't imagine buying needles much cheaper?? Tom

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.