-

Posts

177 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ron Burns

-

Brilliant time lapse and a beautiful job on your Surprise! I can hear Aubrey and Maturin pounding away on their instruments as it comes through the skylight. Thanks for that I think I will read the books again as they are like old friends. Perhaps I will find a kit down the road after Winchelsea

-

Chuck, as usual your work is astounding. I'm so glad I went this route instead of anything else. I have a question...what size treenails do you suggest for the deck and hull? I'm going to have a bit of time killing off the chemo so I figured I could spend it making treenails (mindless and almost soothing I hope)

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi everyone First things first...Chuck, thank you for the very speedy delivery of my Chapter 4 parts and especially for the replacements you sent. When I messed up the first time I was heart broken. Well, second time around worked out OK I think. Between daily radiation and a dose of chemo, I finally got the keel together and the bulkheads glued in place. As per your suggestion I used a couple coats of satin wipe-on poly and it really makes the cedar pop. It's a beautiful color. Got a few bits of ply left to glue and then I get to fair the beast! Btw...anyone think we can stitch sail like this in 1/4 scale? (just kidding, thought this was amazing though)

-

Bench Top 5" Disk Sander

Ron Burns replied to DocBlake's topic in Modeling tools and Workshop Equipment

I know this topic is a bit dated but still wanted to say 'Thank-you'. I grabbed one after reading your recommendation and need to say it's perfect! It did come with a clamp, vac connection, variable speed and 3 grades of peel and stick paper. It's already helped me on my Winchelsea and while building my thickness sander. What I couldn't believe was how quiet it was with very little or no wobble, No buyer's remorse for this one! Doc Blake, are you the Ship builder that left a comment on Amazon? -

I don't know if this helps but I recently put in an order for some 'Black Hornbeam'. I've seen it used by many older European modelers mainly eastern bloc in place of ebony. It's a stable, dyed hornbeam that is pure black through and through and can be finished as sweetly as ebony and easy to work with. This gent here was good enough to send me a piece (still waiting, just ordered) from Moscow. 35cm x 4 x 4 was $8:00 Shipping was double! He uses it for beautiful decorative carvings, jewelry, knife handles etc. https://www.livemaster.com/search.php?searchtype=1&search=black hornbeam My plan is to use it for my Winchelsea's wales

-

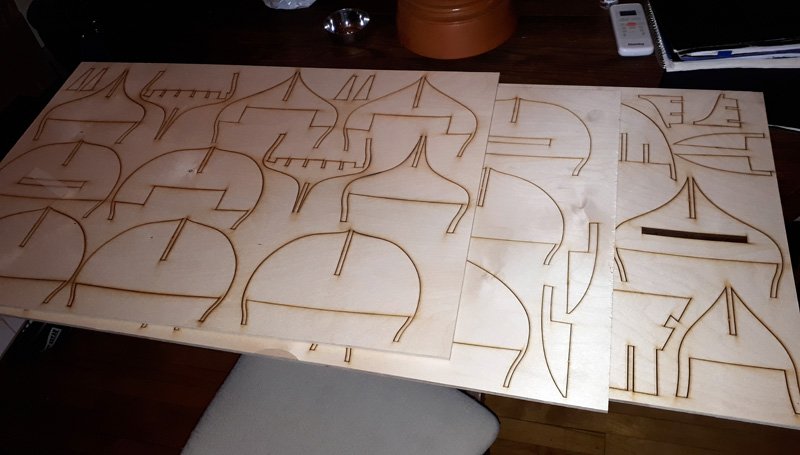

Thank you kind folks for the likes. Just getting started seems to have taken forever! Here is a small bit of wisdom I will pass on to you...when importing from a pdf and creating tool paths for lasers, cnc routers etc...'Check the darn slot widths before you cut!!!' For some reason when I brought these into Corel, every corner was open so I had to close all the open segments. I printed out the bulkheads straight from the pdf and used the small scale included to make sure everything was good. I didn't check the slots!! every 6mm slot was off by a hair or 2 to the small side. I know...better looking at it than for it right? Anyways..finally freed from their sheet bondage and filed and sanded to fit, we can get on with trimming the beard and building!! I still can't believe how this thing is designed. The entire ship balances on a 6mm spine! Thank you all for going before me as I can clearly learn from your experiences and wonderful craftsmanship

-

Hi everyone Just a few words and a few images to show that things are progressing very slowly! Found out I have the 'Big C' and docs have me jumping through hoops preparing to be irradiated. As it turns out, that sweet little band saw will sit for a bit longer. I didn't have the gumption to cut out all the pieces so I imported all of the bulkhead file into Corel, created some dxf files and used a laser. I really wanted to stay away from the char but it wasn't so bad after all. As many of you have mentioned in your wonderful build postings, this ship is HUGE! I'm doing all of this in my dining room and I must say my wife has been very tolerant of my mess! I sourced out a Canadian company for the cedar to cut all of my planking. Can't be fighting with a certain Republican over softwood lumber now Since I need to cut planking, of course I need a thickness sander and got it into my head I want to build one. So far I've got the power supply, speed controller, bearings, belts, drum, 1:2 timing pulley and motor. Just have to get my butt in gear and finish it. I only hope I can produce lumber of the quality Syren provides Excuse the bad images. I will bring out the real camera when I get things going. Chuck, perfect advice to use the glass to ensure flatness. That entire false keel stood on its own! So far I've only freed 5 of the larger bulkheads and made the mistake of under-sizing the slots so I need to sand a fair but. Sanding is good for the soul but a tad dull after a bit. Ok then....back at it!

-

Chuck, Reg, thanks! Weird you mentioned the label paper Reg. While looking through that 'all encompassing online store' for spray adhesive, a bundle of 100 8.5 x 11 sheets of inkjet sticker paper came up. Thanks!! I hate glue sticks with a passion from my old days of card modeling. The spray always worked a charm but these sheets are less cost than a can and they won't leave residue. Onward!!

-

Thank you for the welcome Chuck! Here we go! It took forever for my band-saw to arrive but it's here! Word of advice to all of you other novices around...before you cut a single thing, check out your saw completely and don't trust the factory setup. The blade guides were way off on mine. For a little saw I couldn't be happier. I'm usually so poor I can't afford to pay attention and this was a great deal. Anyways, silly question 1 and 2.. I have printed off the bulkheads on 20lb copier paper. Should I use a heavier paper or cover stock? What do you recommend for glue to bond the patterns to the ply? I was thinking spray adhesive but really want to be able to remove the paper after the cuts.

-

After drooling over many many kits and model builds all over the place, a magical force directed me over to the Syren Ship Model Company. Chuck Passaro's frigate hit me almost as hard as when I first laid eyes on my beautiful wife. I have to build it! So far I have built a lot of card models and built 2 ship hulls from wood, based on Shipyard designs. This will be a learning experience for me and a great joy. For you guys looking in on this it might be a lesson in 'how not to do things' but I'm hoping you will point in the right direction or administer a virtual swift kick For tools, I am building a mini table saw with bits and pieces starting to arrive daily. I received my baltic birch ply a couple days back and I also ordered a small bandsaw as my father's day gift. My order for the 3 chapters worth of goodies and the castings went in to Syren this afternoon. I look forward to meeting you all when I finally get started. Thank you Chuck for a beautiful model and for our past conversations. It all struck a chord!

-

Hi everyone! After lurking for a few days and combing through many of your exquisite builds and build logs, I believe I might have come to the right place. I found this site by doing a search for 'best wooden ship model' and couldn't wait for my registration to go through to see the results of the ongoing poll. I'm an old card modeler that mainly built Great War flying stuff and had always sat back watching other folks create wonderful ships from the Shipyard line. Of course, being the bonehead that I tend to be, I grabbed the Shipyard HMS Bellona as my starting point and introduction to ship building. I reached the point of almost completing the hull and was starting to contemplate masts, rigging, etc. when my wife (of 25 years at that time ) took ill and everything got put on hold for the past 3 years. She has recovered wonderfully and I thought it was time to start building again. I look forward to meeting all of you, learning and sharing. Best Regards! Ron

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.