-

Posts

177 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ron Burns

-

Those are some pretty sexy cheeks! I can't wait until it all gets released. Thanks for an immaculate job Chuck.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Tom, I think I should check my birth certificate 'cause we might have the same middle name I just have a IV or V after my name! I ended up ripping that entire side off yesterday as it was a bit wonky. The first strake didn't sit right and and when being pried off decided to take some of it's brothers with it. I can't imagine trying to remove so much on a solid hull! The surface area being bonded to would make that a supreme PITA!

-

WOW! Those are many more options than I realized possible. This will prove to be a great learning experience and I think I will give the dye a shot along with the steel wool and vinegar just to have options in the future. Experimenting is *always* fun and any method that keeps me away from a paint brush will keep me *and* the model very happy! Thank you very much

-

Thank you Jim, Tom and Jaager (I apologize, I don't know your name). The piece in question looks wedge-like in the photo. It's actually relatively square but the macro function and the angle of the photo really made it look off. Unfortunately, Ottawa doesn't have too many places to provide the re-sawing service. I have used the advice and sent out a few feelers and hope to get a note back. Black Hornbeam is actually just hornbeam that is impregnated with a black resin through and through. Hornbeam, from what I understand is not very useful except for firewood until it's been stabilized with the resin. It can be cut through and through and will be black. It can be polished up and look quite beautiful. If interested, a quick search on Etsy will give you an idea of what can be done with it. In regard to the Winnie's wales, yes, they are meant to be painted if one uses the Alaskan Yellow Cedar or Cherry or whatnot. I am not the best painter and to paint something of that length, I would be sure to mess it up. If it comes down to it, I will paint but would rather not. From what I can see, the black hornbeam used by modelers for that purpose by many eastern bloc countries looks amazing without a drop of paint :). I will follow your advice Jaager and do some practice runs. If it proves too problematic with my crappy bandsaw, I will save for when I can do it justice. Thanks again guys!

-

Hi everyone, I'm sorry if this has been gone over before but I am looking for some re-sawing advice. I have a small piece of Black Hornbeam that is roughly 4cm x 4 cm x 35cm. I am looking to create some planking for the wales of my Winchelsea. Unfortunately I am only in possession of a 9" porter cable band saw. With the proper fence set up and the correct tension, do you think it is possible with my bandsaw with the stock blade? I'm willing to try it if you guys think its possible. The other question I had was which way to cut? Here's a pic of the hornbeam on end showing the grain. Thanks ever so much! Ron

-

Wow! I can actually see the shape of the hull quite clearly now. You must be nearing 30 lbs or more before you start trimming off the 'fat'. Thank you Tom for those great explanations as you go along. It does a soul good to think along different lines of construction once in awhile and I am really enjoying it (think I mentioned the enjoying part before)

-

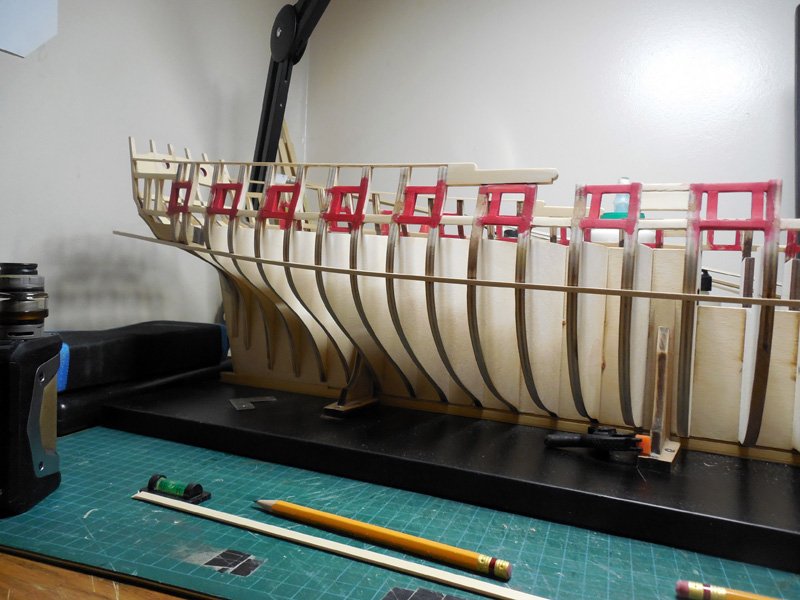

OK, I lied. I had to show this. 1 wale down, 3/4 wale to go. I'm really glad this is a first layer planking and that i will be adding more. Its definitely a learning process and I'm positive there will be more than a few do-overs after this. JJ, thanks for those pics. They made a world of difference. One thing I learned, wait until all strakes are installed, then sand. I had installed 2, sanded a bit and then the other 2. My sanding is never perfect and it took just a wee bit more to level out all 4 strakes in the end. I also like the idea of giving those planks a bit of extra meat on their bones just to enable a bit more sanding without getting too thin.

-

Anyone using electric plank bender?

Ron Burns replied to MESSIS's topic in Modeling tools and Workshop Equipment

Looks like a great device but us in N America would require single phase 120V 60hz. Our 208 (240) is actually using 2 phases and is used for stoves and dryers on a dual breaker rated from 20-30 amperes. It looks like a good 30 watt soldering iron with a great looking head on it for shaping planks. I have a butane iron I use that would be the cat's meow with that head on it! Come to think of it, it looks like it will fit your average soldering iron... -

Tom, JJ, Vlad et all, Thanks for the encouragement! Well, here it is. My first wale strake. I promise, no more posts here until I actually *really* get something done Chuck, thanks for your planking videos. Made myself a little planking board, swiped my wife's iron and learned how to edge bend. Took me 3 planks bent the wrong way to realize what I was doing at the bow. Once figured out, she lay flat and happy. Gonna work out how to re-saw on my little bandsaw and make some black hornbeam planks for the 2nd layer. Thanks for the patience everyone! Ron

-

Why do some manufacturers make single plank kits?

Ron Burns replied to Meriadoc Brandybuck's topic in Wood ship model kits

See? The voices of experience can always make sense of things! I never even thought of many of the reasons for double planking and it does make sense for many circumstances now that you guys have laid it out. I've seen the magic that certain people have done with single planking and I can't see wanting to do it any other way (especially with that AYC :)) -

Why do some manufacturers make single plank kits?

Ron Burns replied to Meriadoc Brandybuck's topic in Wood ship model kits

Not that I am in the know what so ever, I think there are a few reasons for this. Using a single layer is basically the way a real ship was built. Using 2 layers allows for a much cheaper wood to be used as a base. The 2nd layer of better quality wood is thinner and less expensive than if used as a single layer. The 2nd layer also allows for the mistakes of the first to be covered up. Using a single layer leaves less room for mistakes but I think will teach the correct way to plank right from the start. There are many tutorials for planking here and if followed, the builder will learn a wonderful skill. To me it's scarier but well worth it -

Thanks JJ, weird how I kinda latched onto you as my mentor I appreciate it more than you can imagine. I skipped the nail part and even tried using those T-type pins. I started splitting the crappy basswood so I marked and pre-drilled holes for the pins. That didn't work well either so I ended up tacking a batten with cyano every few bulkheads. The joints were easy to pop off and re-tack. For Shi*s and giggles I took random measurements along the waist to compare to the other side and they seem to be close. Close enough only counts for horseshoes, handgrenades and crap fights so maybe I'll be lucky and pull this off!

-

Frank, welcome to the group! In case you're still looking for a building board, I ended up using a pre-made laminated shelf from a local hardware store. It was cheap, really flat and straight and the lamination made it easy to clean off glue, paint and dust. Love the cigar boxes! They seem to be harder to get here these days. Ron

-

Thanks guys for the encouragement! JJ, I did what you suggested and it was well worth it! That poly sure does nice things to Alaskan cedar. I'm at the point where my inexperience is driving me nuts. I'm not used to 2nd guessing myself so much but I'm sure in time it will get better. I found some cheapo basswood sticks for battens at a hobby store miles away. It was a tossup...hardware store or just pay 60 cents and get them cut already. Figures I find the wood but small brass nails are on back order forever. Anyways, I mapped out my starboard wale and I *think* it looks ok. What do you folks think? PS. since posting these pics, I saw that it needed to come down just a wee bit at the bow. It's fixed I spend too much time here..good night1

-

Tossed on the WOP and man, it pops! It's a great place to experiment a bit being able to cover it up should it go south a bit. I can only imagine what a second or third coat will do after some 600 grit sanding or better. Just trying to figure out where I can grab some 1/8th strips long enough to map out my wales..

-

New To Building Ships Help and advice needed

Ron Burns replied to Richard O's topic in New member Introductions

My real first ship model is Chuck's HMS Winchelsea. It slides right into the size you are looking for and the support is second to none. The materials are first rate if you choose to pick up the parts for each of the published 'chapters'. The other thing that really got my attention were the many build logs of the other members here along with Chuck's as he continues to develop the Winnie. As it stands, to me, this is one of the most beautiful frigate models I've seen. I come from modeling in card for years and slid right into this. You will have no problems coming from RC. -

Vlad, I can't believe how quickly you have gotten this far! And well done too! It's great to see the confidence. As I get older, I hesitate and procrastinate more and still make mistakes! Now I will follow in your footsteps friend I'm really relieved to hear that all worked out with the scale of your model. Happy New Year to you as well Ron

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.