Warnerade

Members-

Posts

184 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Warnerade

-

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

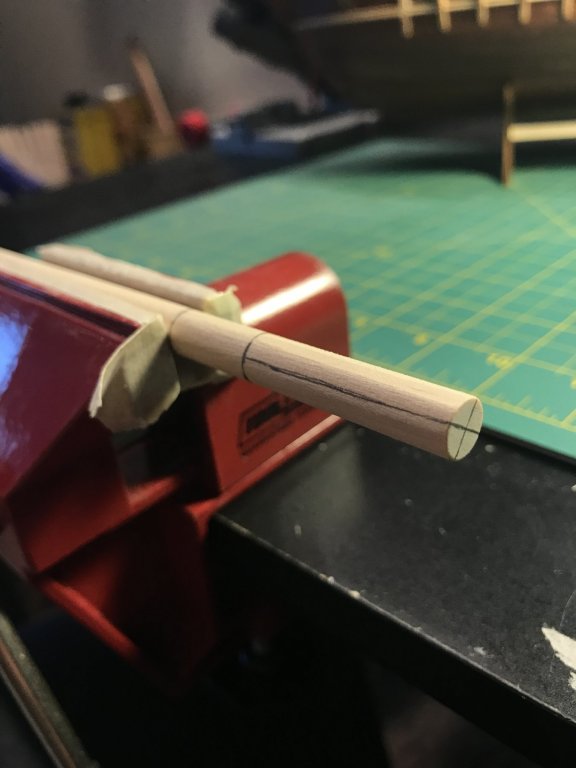

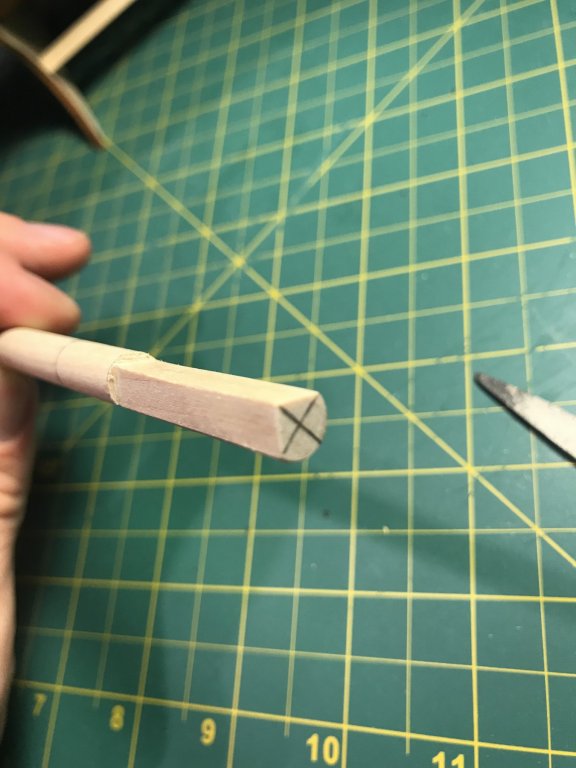

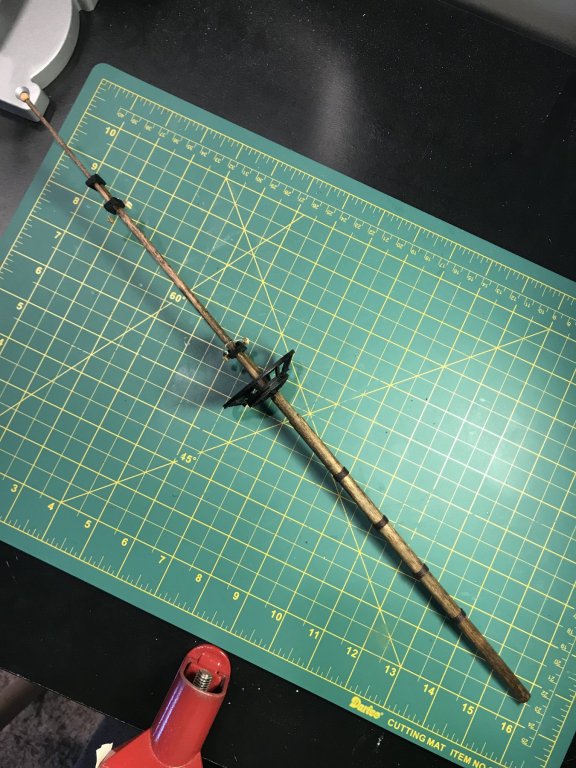

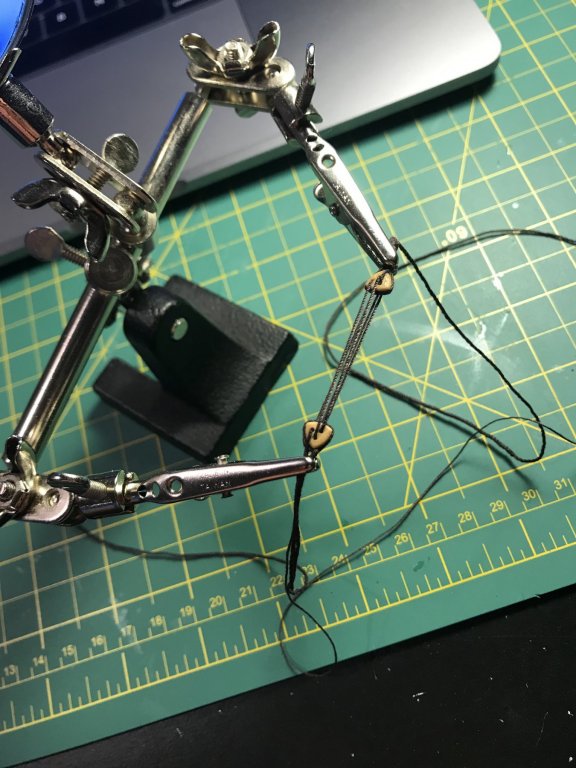

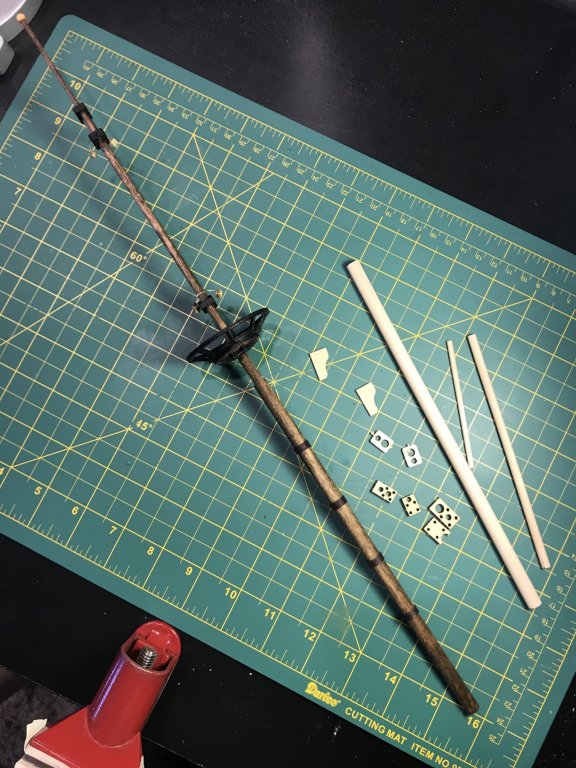

The deck is fully assembled and I am now working on the masts. With my first build I just used super glue and square knots, this time I am at least attempting to tie the proper knots, started off strong with whipping on the main mast. I also recently made a live edge table, it will not be part of the final display of the ship but I am planning on making a display case for it and I would like to implement a live edge component similar to this. Considered even making a recess in the “river” for the ship to sit in, like it is actually floating down a river. Who knows

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

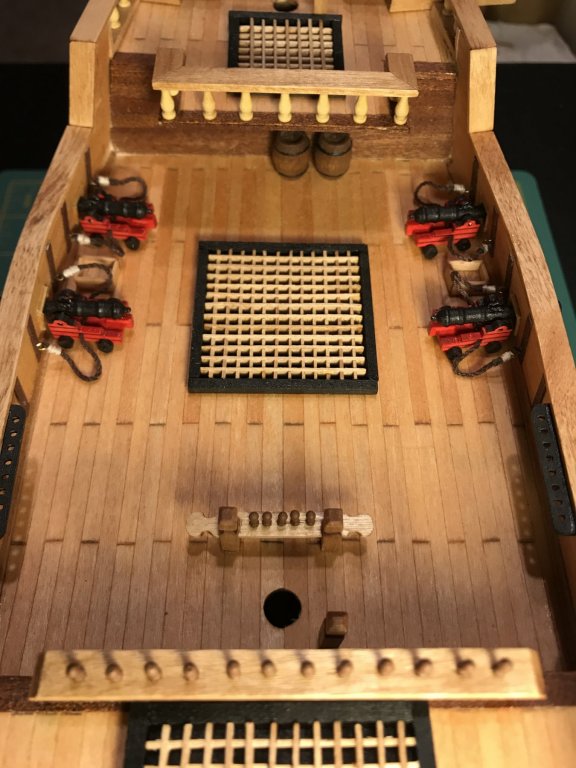

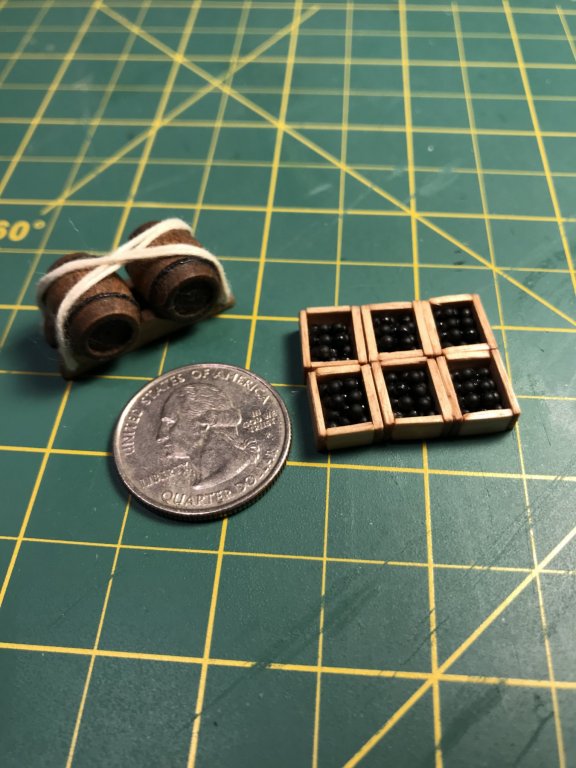

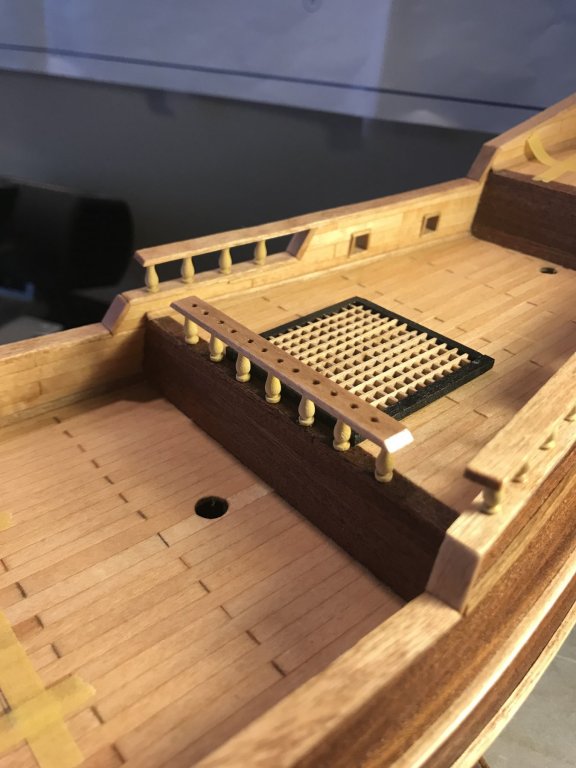

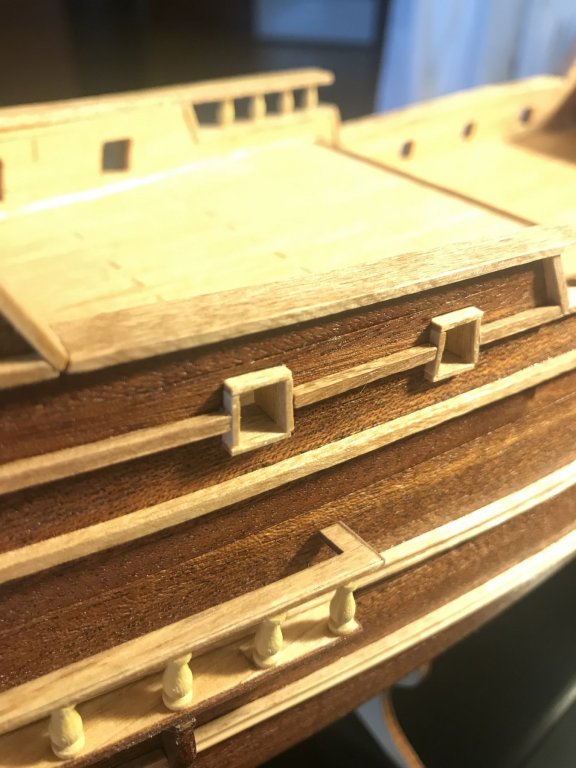

And the deck is essentially done! I remade a few more of the laser cut pieces supplied with the cut. They were shaped fine, just didn’t hold varnish and I prefer the wood look to paint (I painted a lot of things early on while waiting for glue to dry with planking...before I got too far in planning) so other than that not much customization has gone into it. The directions are pretty much spot on with plenty of detailed pictures. Time to start working on the masts and putting the dead eyes on the channels.

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

This is a fantastic piece, and definitely is now on my “todo” list, sorry to hear about the wife.

- 121 replies

-

- bounty

- constructo

-

(and 1 more)

Tagged with:

-

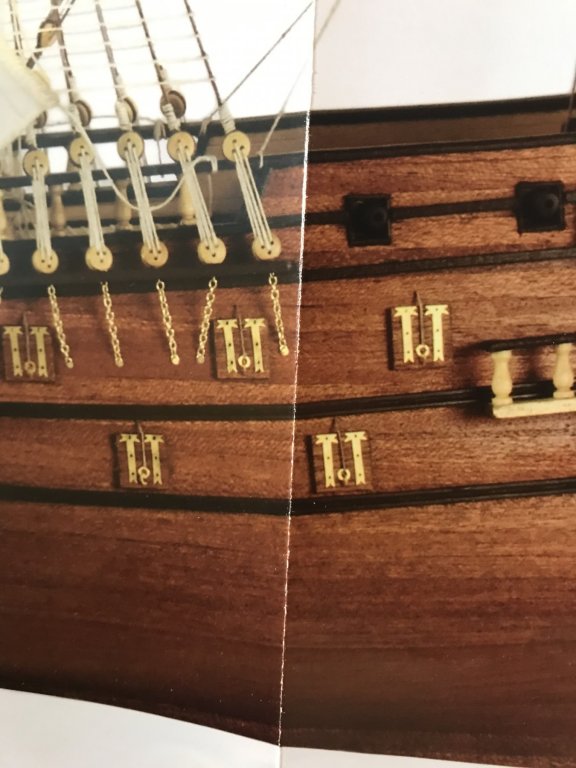

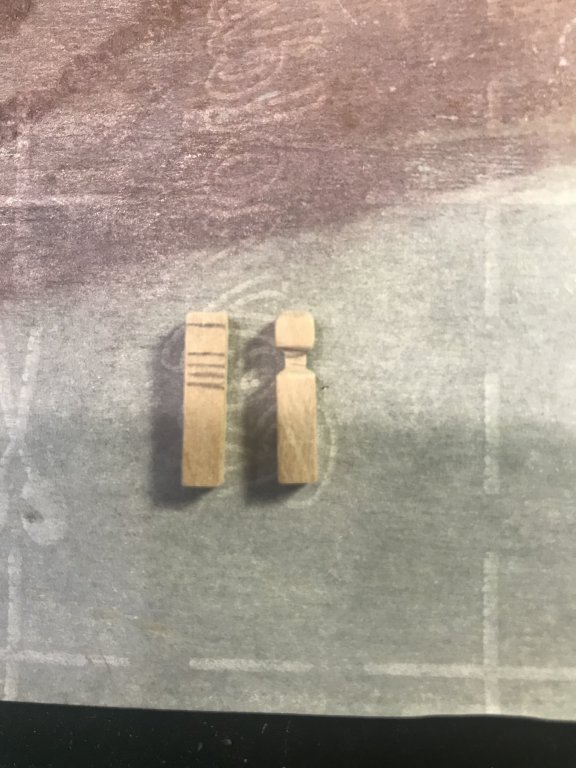

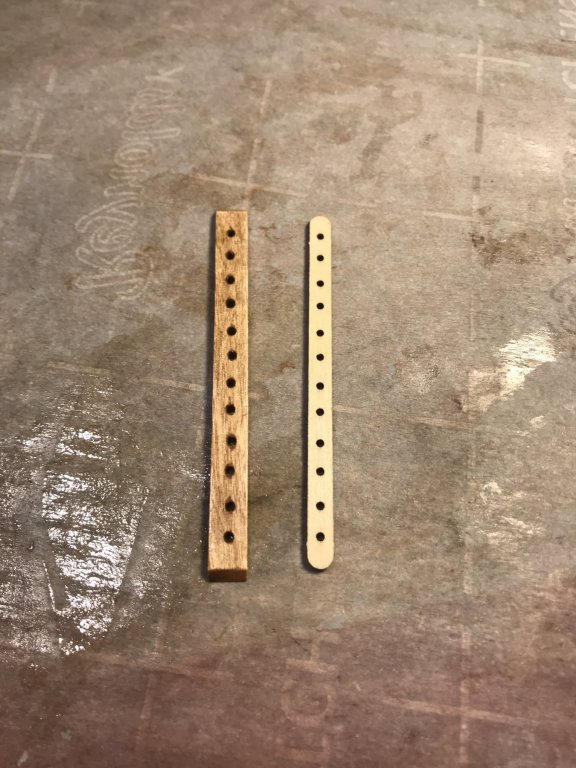

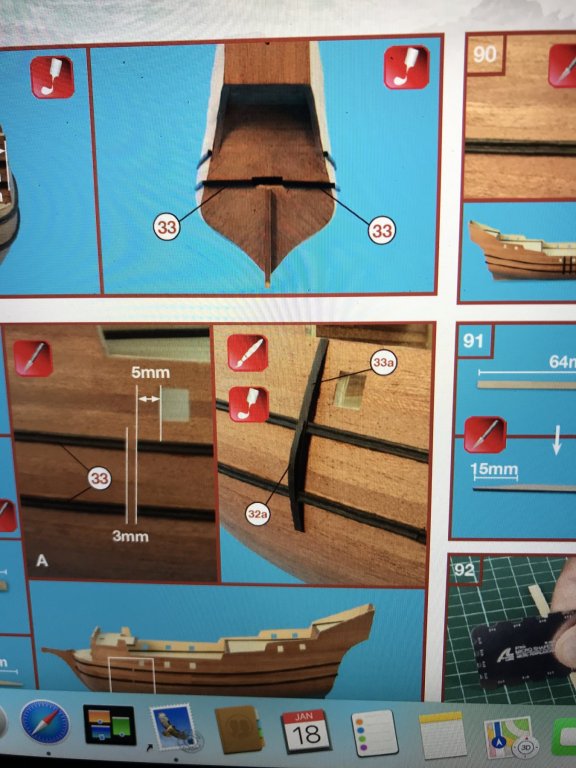

Got to work on the gun ports. The directions say to leave the pre-cut brass pieces as is and paint small black dots to mimic a nail or bolt holding the brackets on but I decided to go the other route. I think they turned out really good. The plank cutting job i made made made this process so simple. For anyone reading, I highly recommend some sort of device like this.

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

Animated video of useful model rigging knots

Warnerade replied to Bob Cleek's topic in Masting, rigging and sails

This is fabulous, thank you for posting this -

I decided to apply the same reinforcing technique to the channels for the dead eyes, I have 3 brass pins inserted in each one. I forgot which log I got that idea from (one of the many San Francisco’s I’ve browsed) but if you’re reading this, thank you. The holder for the belaying pins came with a laser cut piece, but as with the railings it was rather flimsy and didn’t hold varnish at all so I made my own using a small dremel bit. It is really coming along, I cannot wait to start rigging.

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

My goal is to finish this by the end of May before I start up a new residency. I am moving right along now so I think that should be doable. Just starting to poece the deck together, like the railings, anything that is glued to the deck and will have rigging tied to it/under tension will be getting reinforced with a small brass nail and extra glue.

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

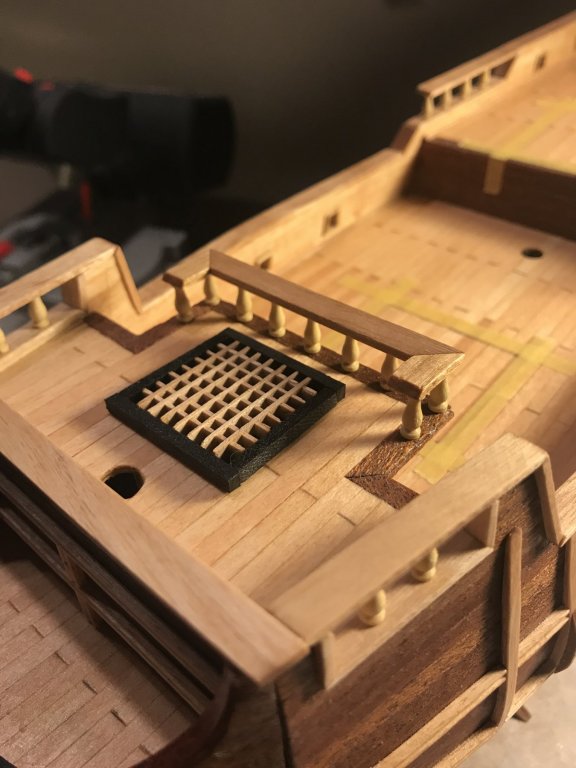

Welcome newbee, After painting one of the floors black under the grating, I definitely wish I had taken the time to plan and cut out the floor first. I still considered it, but voted against it given that I am already so far along and figured I would probably mess things up with my dremel and I would regret it. Next build though I am planning on that. Leaving the floors painted black and gluing the grates over leaves a lot to be desired in my opinion.

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

The kit itself came with laser cut pieces for the deck railing along the balconies of the ship, but they were very flimsy and weren’t even size appropriately for the deck. On top of that the supplied plywood did not look the same at the outer railings once it was varnished so I decided to make my own. They turned out very nice I think

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

So if I have this understood correctly, the helmsman would stand inside the little cabin, and thus the whip staff would be in there as well? It would not be visible on the actual deck? Man, should have did my research before I ordered a few things...there goes 5 bucks wasted on a ship wheel haha Thanks for the feedback gentlemen

-

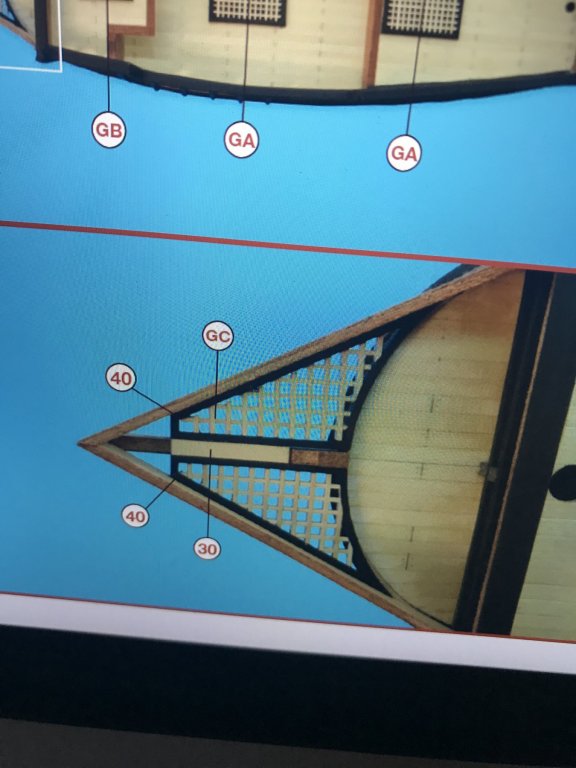

I am getting to the point in my build where I am starting to plan the deck. Looking at the plans, there is no capstan and no captain’s wheel, but there are four grates along the deck. This seems a little excessive to me, and I’m considering leaving 2 of them off and putting other things on deck (like a capstan and wheel)...below are a few pics of which grates I am thinking of leaving off. I was considering putting the captain wheel on the stern most upper deck and leaving that grate off. Putting the capstan on the middle deck in front of the cabin, and then leaving off the grating on the bow deck just because it seems like once the railing is installed all of the rigging, it would “crowd” and be a tripping hazard. Lol are the chosen locations for the 2 accessories correct? I assumed the captain wheel directly over the rudder for “less moving parts” in real life and the capstan just seemed to fit the best there. Or would it look best in the bow deck closer to the anchors?

-

Well I was able to file down the two sides of the grating, the angled side and the side facing the middle. I didn’t think I’d be able to shave enough off to get them to fit and line up adequately but it ended up working out. And once it goes in the display case no one will be able to get close enough to see the different width borders of the grates.

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

Well it looks like I discovered my first mistake. Putting the bow extensions of the bulwarks on, I noticed that the grating was not going to fit. I doublenplanked them to match the rest of the bulwark but I didn’t even look at the directions, it looks like it is only planked with .5mm...so now their is too much material internally and the laser cut grating borders will not fit. Any suggestions? Not exactly sure how to correct this one. Considering just filing the border of the grating so it will move will move forward a little more. This is probably the route I’ll take, short of undercutting the bottom of the bulwark extension (is there a correct terminology?) I don’t see any other solution.

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

Working on the gun ports now...silly me forgot to account for the angle of the bulwark and the inside of the gun ports don’t line up. So for the rest of them I made the side pieces more of a rhombus instead of the square and they lined up perfectly. Probably going to pop that first one off and redo it.

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

Progress has slowed down immensely this month but I’m still trucking away slowly. I had to take my medical board licensing exam, small vacation to dallas, and I just found out I’ll be starting residency in Detroit next year. I’ve also started some small side projects including a live edge table for the new home. Not much thought has gone into any customization of these steps lately, other than not painting everything black I’ve been following the directions pretty close.

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

Nice choice to use the natural wood for the gun ports rather than paint. I have looked at many logs so far and it seems the older AL models were natural wood and they recently moved to painting...I am a fan of the wood myself. I was wondering where you've been, glad to see things are still moving forward

- 139 replies

-

- san francisco

- artesania latina

-

(and 1 more)

Tagged with:

-

I really like the idea of adding the planks where the cannon rigging attaches to the bulwarks, I may be stealing that idea for my own build. Very nice indeed.

- 59 replies

-

- artesania latina

- san francisco ii

-

(and 1 more)

Tagged with:

-

Starting to put the finishing touches on the outer railing. The running rigging gets tied around a few places, so I decided to reinforce the stanchions with small brass pins. Made the alignment easier to measure and plan a well. Increased the time significantly but I think it’ll pay off in the long run.

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

amazon has them, they really do add a nice touch. Although slightly tedious at times. Here is the link for one of the kits, the other one is "model kit A" and a link should be somewhere on the page https://www.amazon.com/dp/B003T37B66?ref_=pe_1196280_123950170

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

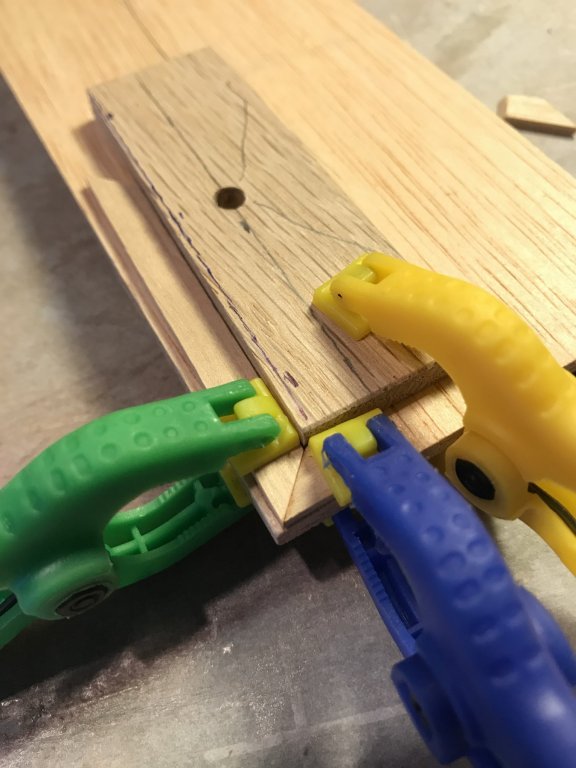

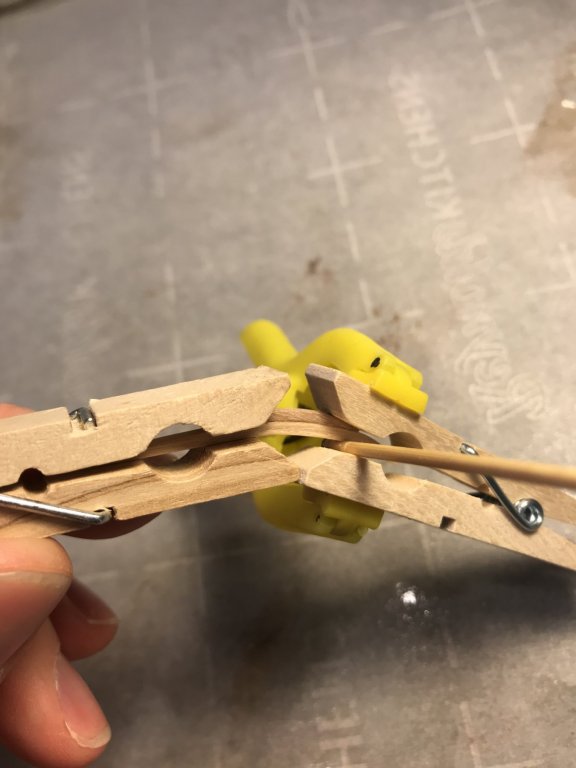

Just a small update. Bending the side bumpers with the taper was a challenge to figure out, I cut a piece of 2x4 with the vertical curve of the hull and then placed the pieces in there. I filed a small leftover plank at an angle to fill the space while bending. Some complicated/creative clamping. im really liking my decision to not paint the wood.

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

This is coming along very nicely. It's making me even more excited to start rigging

- 68 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

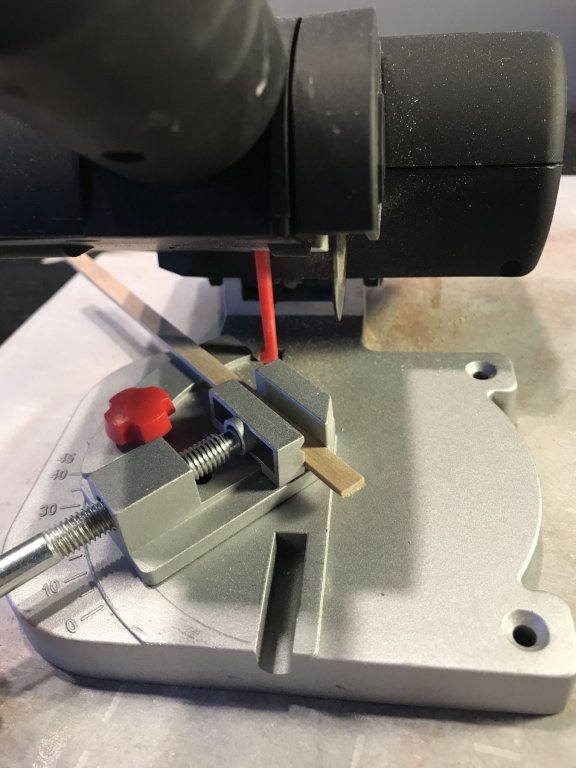

Slow progress these days, but in order to speed things up I purchased a small 2” table saw to start cutting pieces to length. Best 30 bucks I have spent in a long time. The directions in the new and updated kit has the Wales and trim painted black. After reviewing many logs of the previous model where they were not painted I decided to keep to this style. The Wales are stained with a cherry varnish, and the rest of the trim around the boat will be as well.

- 88 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.