-

Posts

1,062 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by grsjax

-

There is a DIY design for a jointer in a back issue of NRJ (Nautical Research Journal) http://www.thenrg.org/the-journal.php . It was in the late '70s I think. NRJ will provide reprints of old articles and I believe there is a complete index online. Just can't find the URL at the moment. Anyway it uses a dremel tool for power and looks like it would be more than adequate for any work you might need on a model.

-

Good website for info on mini-mills and lathes is http://www.mini-lathe.com/Mini_mill/Main/mini-mill.htm

-

The next step... A choice for the next model...

grsjax replied to timo4352's topic in Wood ship model kits

The Pinky is a nice looking kit. No experiance with it but the double backbone construction looks interesting and the boat itself is a great subject. It is a model of H.I. Chappelle's boat that he designed for his own use and I always liked the looks of it. For more info on the history of the Pinky and how it was built you might want to take a look at Chappelle's books "American Sailing Craft" and "The American Fishing Schooners". -

Tung Oil Finish?

grsjax replied to cdogg's topic in Painting, finishing and weathering products and techniques

If the humidity is high it may take awhile for the oil to get hard enough to buff. When I lived in Florida I did some walnut gunstocks with tung oil and it would stay tacky for a couple of days. Trying to buff it before it hardens up enough will only result in a poor finish. -

Mini Drill Press - moved by moderator

grsjax replied to HonuJaye's topic in Modeling tools and Workshop Equipment

I have a small table top Ryobi drill press that works well. Bigger than the micro press but also more capable. A pin vise can be used to hold very small drill bits. Already pretty rigid but can be made better by filling the hollow column with concrete. Cost about $100 from Amazon and that included shipping. Does need to be bolted down. -

Not just reprinted but in a format that is cheap enough that the average modeler can afford them. Steel's Naval Architecture. Currently available in a limited edition for about $1000 Junks and Sampans of the Yangtze River. Only copy I can find is an old reprint for $112. How about some $30 editions for the poor but honest average guy?

-

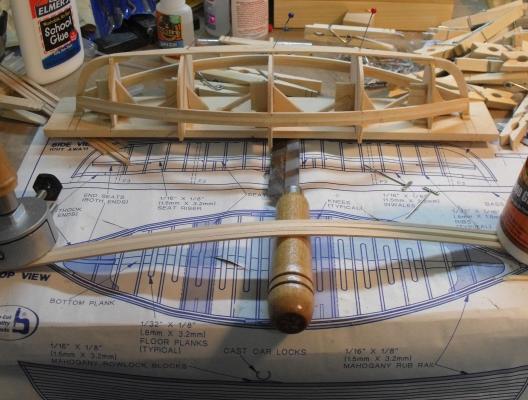

After trying different methods of getting the planks to lay down flat on the forms I decided to use the wet bending method. I soak the planks in warm water for about 10 minutes and pin them to forms to dry. Takes several hours to get completely dry but they are much easier to fit. I will post some more pics later.

-

I like Model Shipways smack Emma C. Berry, or the skipjack Willie Bennett.

-

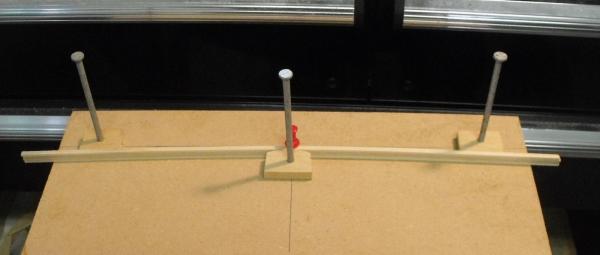

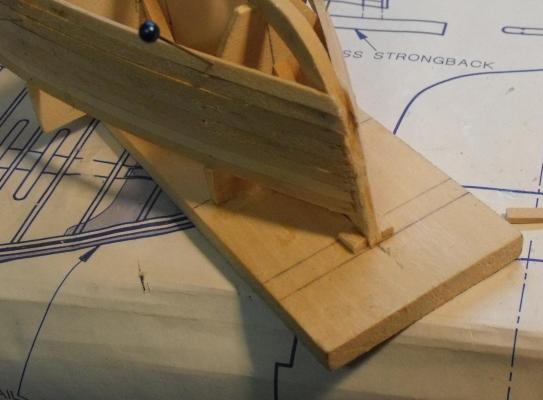

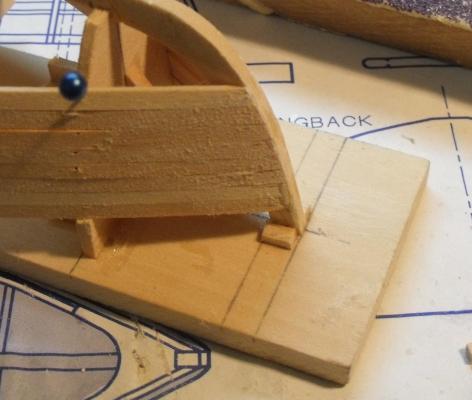

Made a bit more progress. Have learned a few lessons. Last (should have been first but I managed to get the pics in the wrong order) pic is the model with the 3d plank on each side. This was the first one after my adventure with short planks and the subsequent repairs. 2d photo is after the 6th plank on each side was installed. This was the last one that would go on without modification of the planks. The first thing I tried was steam bending the planks to get some edge set. The 3d photo is my jury rigged bending jig. I wrapped the planks in wet paper towels and microwaved them for 3 minutes. Worked ok for the next two planks, see 4th pic, but I think the next ones will require either more bending or tapering. Will post my findings at a later date. A couple of lessons learned so far. 1. Don't try to trim the ends of the planks to fit exactly. Leave a small feather edge to overlap the stem and after everything is glued down come back and trim/sand to shape. The last two pics are the un-trimed ends and the ends after rough sanding to shape. Final shaping will be done when I sand and finish the outside of the hull. 2. pin the planks to the forms very tightly. The have a tendency to lift up as you go down the line gluing the planks together. 3. Use lots of cloths pins to hold the planks in alinement with the one below. If you don't little bumps and hollows develop.

-

Switching between measurement systems can get confusing. When I was a young engineering student one of my professors would give us problems in off the wall units and require us to report the results in other off the wall units like furkins per furlong. I have run across at least 4 different "feet" measurements; standard, english, swedish and french. I am sure there are others as well as units like cubits and chains.

-

Needed some cheap acrylic paint for a project and found some at Walmart. Stuff comes in 2 oz. squeeze bottles and is stocked in the crafts section. Wasn't expecting much from it for $2 a bottle but it has turned out to be pretty good. Maybe not on a par with the high end paints but good. Works very well on wood and isn't bad on metal. Only problem I have had with it is it a bit soft and needs a gentle touch when sanding. However after coating with a clear finish no problems. Brand is "Plaid". Not going to find many "marine" colors lots bright colors and metallics

-

"The Tancook Schooners, An Island and its Boats" by Wayne M. O'Leary Published by McGill-Queen's University Press, Montreal, Canada ISBN 0-7735-1172-5 Excellent book about Tancook Island and the boats built there in the first 30 years of the 20th century. At the end of the 19th century the Tancook builders developed a distinct fishing schooner tailored to their environment. This was an evolution of the Tancook Whalers. About a third of the book is about the boats, the rest is about the people and economy of Tancook Island. The book contains many photos and line drawings of the boats with some explanation of building methods and materials.

-

Just $.02 from someone who has screwed up more than one plank. Take it slow, measure several times before cutting. Use slow setting glue and lots of clamps rather than instant glues. This is so when (not if) you find out at the last moment that your plank isn't fitting right you can remove it without breaking anything.

-

Just ordered the English Pinnace kit from Modelexpo (great deal at $34.99, think the sale is good for a few more days, code is Blues14). The color scheme in the pictures is nice but about the only way you can make a kit like this a bit different from all the others like it is the paint. My question is what colors would be appropriate for an 18th century pinnace? The reccomended colors/decorations look like they would be for a very senior officer with a lot of money to spend on making his pinnace a show piece. What about all the lesser officers with fewer personal resorces? I would like to have a boat representative of the work a day craft likely to be carried by the average man of war.

-

Small lockable tool chest

grsjax replied to mspringer's topic in Modeling tools and Workshop Equipment

I bought a machinist chest on ebay for about what I would have paid for the wood chest from Harborfreight. It is a Kennedy 8 drawer metal chest with felt lined drawers. Much better quality than the HF offering. -

Keep an eye on ebay for a good deal on a compressor. You can get the same thing that Modelexpo sells a lot cheaper. As for air brushes I can only say I got a cheap single action to practice with and it works fine for general use but I would guess I will need a better one when I start experimenting with detail work.

-

Haven't had much time to work on this lately. First a problem with my eye and now we have family visiting. Went back to it after letting it sit for several days and sure enough I discovered I had made a mistake . Comes from poor eyesight and getting in a hurry. The first couple of strips were short. Not by much but enough that it would be obvious when the rest of the planking was applied. To repair the damage I broke the planks free from the stem and managed to break the stem in the process. After sanding everything smooth again I repaired the stem and reinstalled it. I was going to just remove the planks and start over but found the other end fit perfectly and so decided to let it be and see if I could fix the short end by adding a small strip of wood to the end of the planks and sanding it to the right contour. After letting the glue on the added wood dry for a couple of days I set out to carefully sand the ends to fit against the stem. After much sanding and fitting it looks much better. Can still see the added wood at the stem but paint covers many sins and I think this will work fine. Going to have to pay much more attention to fitting the ends of the planks from now on.

-

Had to visit the dentist and saw a real neat set of binocular loupes. Asked the doctor about them and was told that they worked very well and had a depth of field of about 16". Sounds like a great thing for model building. Of course the real good ones cost a lot. Looked on ebay and found some cheap ones with 3.5x power and a 420mm depth of field. Anyone ever use these (especially the cheap ones). Are they something worth getting?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.