-

Posts

304 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dr PS - Paul Schulze

-

Thanks for the suggestion. My description is very specific to this model. As far as wider planks, I have some 1/2" basswood stock; however, I want to keep the strakes in this region at 1/4 inch.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

Well, I have completed the third strake. The stem end falls a bit short of what I think it should as seen in the instructions where it seems to end slightly past bulkhead G. In order to extend the third strake farther resulted in a slight concave or reverse edge bend somewhere in the section from the tip at bulkhead G to bulkhead D and this was not acceptable. I was just unable to get it to work. A wider strake would have worked, but I am proceeding as is with the stock planks extended as far as possible while at the same time hoping everything will work out well later.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

The water alcohol mixture allows heating the water to boiling, penetrates the wood well, and more importantly, evaporates quickly with the heat gun. I keep the hot solution in a stainless vacuum thermos type drink container. I also found that small dents can be fairly easily removed by dabbing hot solution on the dents and allowing them to swell out. Klean Kanteen

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

Well I got the next two strakes on. I first sanded a gentler curve on the stem end of the garboards. See the comments by Arthur Wayne in his log on the same boat where he discusses the length of the curve. I concur with his analysis that the cord of the curve on the garboard should be nearer 2 1/4” rather than the suggested 1 1/4” in the instructions. This allows the planks to be edge bent more easily. To edge bend the stem end and twist the stern end of the second strakes, I soaked the stem and stern planks in very hot 50-50 water isopropyl alcohol mixture for several minutes. Then the planks were clamped in place and a heat gun set on low dried them. The planks were then attached using CA applied only on the bulkheads

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks Arthur - No bad weather here -never know in the springtime. I think you’re right about the curve of the garboard. Looking at the top right picture on p 15 it would seem that the curve goes from bulkhead E to bulkhead C rather than a bit past bulkhead D. I have the garboards cut to the suggested 1 3/4” and I am also experiencing some wood collapsing. Before putting on the second strake, I may try filing or sanding the garboard into a gentler curve as removing the garboard may cause some bulkhead and/or keel damage.

- 95 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

Arthur, did you use the taping method when spiking from the second strake on or did you cut the second and third strakes by trial and error and error?

- 95 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

Hello Arthur, I am building this boat for my first plank on bulkhead build. I am very impressed by your good work. I only hope I can live with mine after I get through as I am really struggling along. I have almost taken the position that makers of the original prototypes probably make mistakes and lived with the workarounds and so will I. I will be following your work with anticipation as I move along and I may have some questions for you from time to time if you don't mind. Paul Schulze

- 95 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

Glad to see your on it. Are you doing the armed long boat? It’l be good to have build company.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

I really like the idea of not edge gluing. How well does this work? Do you get any edge separation early or later on?

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hello Vossiewulf, when attaching a long strake with CA, do you attach it little by little or all at once? Since it seems to bond so fast, I have not tried it except on small pieces.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

One problem I have not solved is the “denting” of the planks by clamps. I have tried everything I can think of too avoid this. I may be clamping way too hard but I don’t think so. Some marks can be removed by wetting the affected areas slightly with water after the glue has dried. I hope those with experience can throw out some suggestions.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

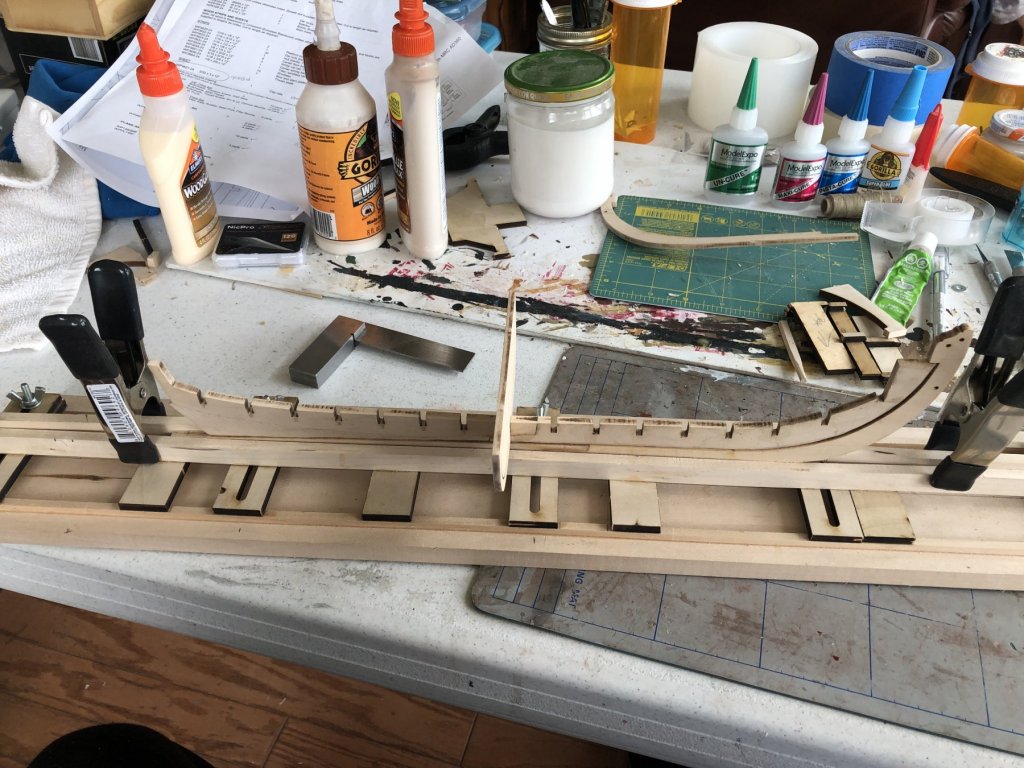

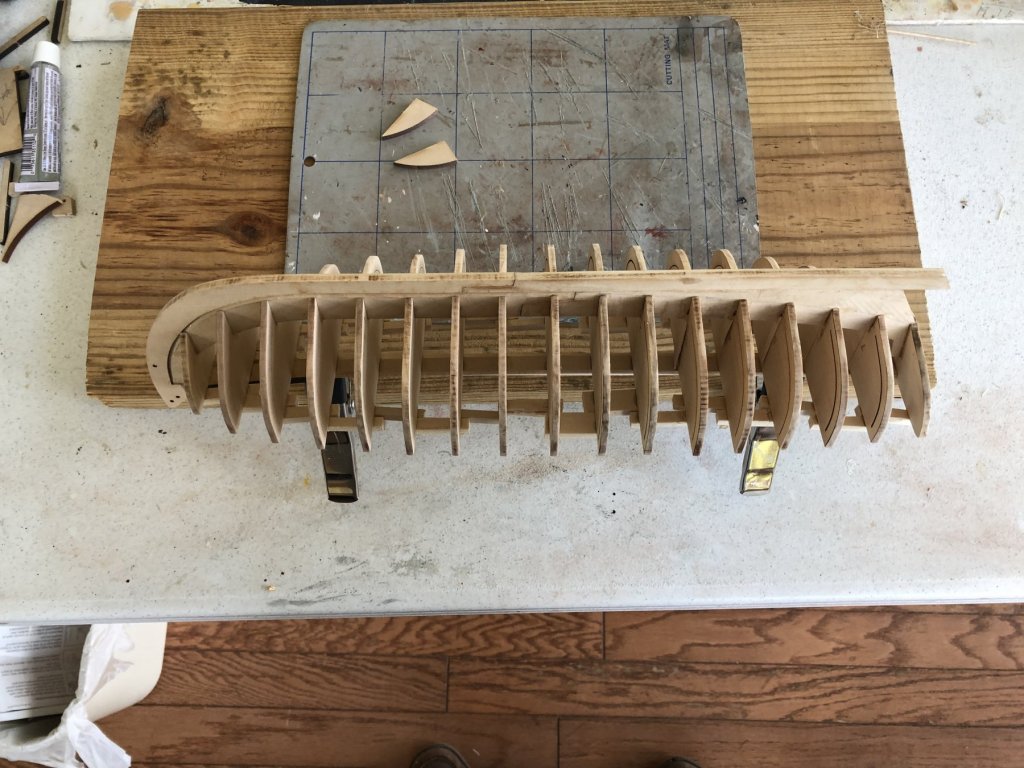

At first I was confused about the garboard. The manual gave instructions which left me somewhat clueless so I asked for help elsewhere on the planking, etc., forum section. After several discussions, all became clear as the lightbulbs came on. My drawing there was essentially correct. Shown below the garboards are being glued into place. The twists were accomplished by soaking in nearly boiling water for a few minutes, clamped in place and then fanned with a heat gun set on low for several minutes. I used yellow glue to attach them to the keel. I did one side at a time.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

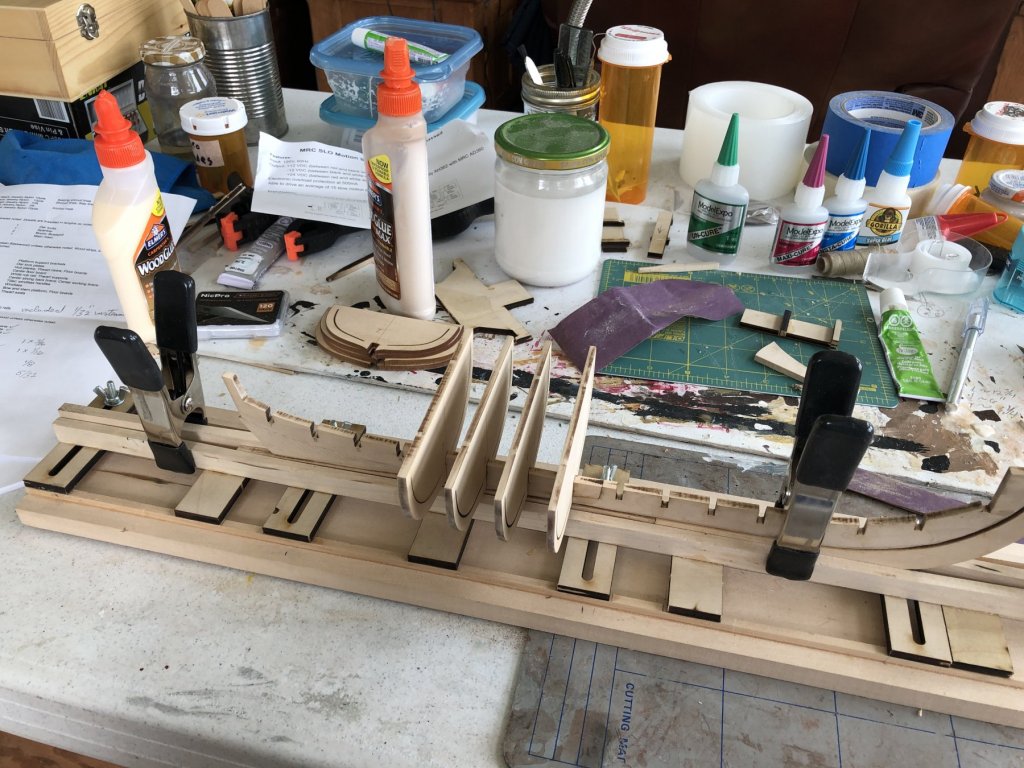

A couple of additional notes to my above post I didn't want to redo the keels when I replaced bulkheads, which I should have measured, 2, 3 and 4, so I made shims to fill the gaps left by replacing the wider bulkheads. This issue could have been avoided if I had been more careful and observant. I feel some work arounds are Ok as real boat builders will surely have had to face them. Secondly, I accidentally found that wood glue on wood from pieces pulled apart will reactivate when a wet piece of wood with no glue is pressed or clamped against it. This can be useful or not depending on the situation. This last fact may be old hat to most but I found it quite interesting.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

The placing of the bulkheads showed up another kit problem which I caught only after gluing. Three bulkheads were slightly thicker than the rest. I measured the laser cut sheets and, yep, the entire sheet was 1/32” thicker than specified in the parts list. I got a replacement and all is well.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

I used a granite countertop as a flat gluing surface. The first attempt was nearly disastrous as the keel and false keel snapped apart when I tried to clamp them. I decided to glue them in steps. I made little wedge “clamps “ using scraps of wood just for this. Next will be to add bulkheads.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

The tools I really like are the Dremmel, an X-acto #17 chisel blade for trimming, a tabletop belt sander for shaping, assorted hemostats, tweezers and sanding sticks, side cutters, and assorted clamps. For glue, my go to is yellow glue. Toothpicks are indispensable. Notice the 2” solid oak board with two clamps attached. This works great for clamping ship/boat by strong back or keel.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

You are most welcome to watch me putter alongside my build. By the way, there is a kit on sale on eBay UK if you are interested.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

You are most welcome to watch me putter alongside my build. By the way, there is a kit on sale on eBay UK if you are interested.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

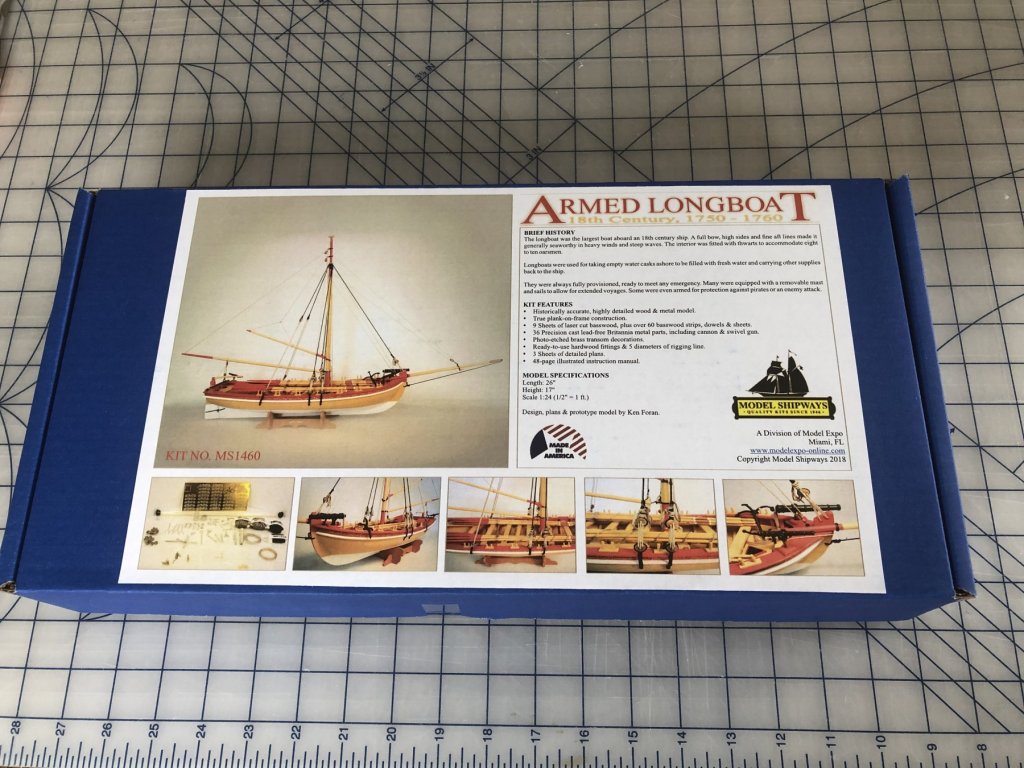

Hello All, this is both my first plank-on-bulkhead build and first build log. I am very slow but hopefully not as slow as my first ship, Scientific Models solid hull Cutty Sark (above) which I started many years ago. My hobby time is divided between astrophotography, model N-Gauge trains and ship modeling. I will start by posting some kit pictures.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

I assume that by the lack of response, what I do is up to me and really is up to me. Except for scale, this boat is very much like the smaller Model Shipways 18th Century Long Boat. If builders of that boat have any comments on this I would appreciate them. My present plan is to start jointing according to the suggested plans. That way only one strake joint will be out of plan.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.